The performance specifications are nominal andconform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc. www.johnsoncontrols.com

1

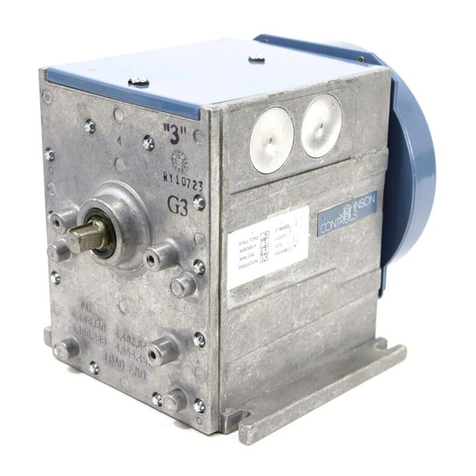

M9102-AGA-2S, -3S and M9104-xGA-2S, -3S Series Electric Non-Spring Return

Actuators

Description

The M9102 and M9104 Series Actuators are

direct-mount, non-spring return electric

actuators that operate on AC 24 V power.

These synchronous motor-driven actuators

provide floating control (AGA), floating control

with automatic shutoff (IGA), and proportional

control with selectable 0-10 or 2-10 VDC

(GGA). The -2S models are equipped with

plenum cables, and the -3S models are

equipped with terminal blocks.

All models are compact in size and are easily

installed on Variable Air Volume (VAV) boxes,

Variable Volume and Temperature (VVT)

two-position zone applications, or small- to

medium-sized dampers with a round shaft up

to 1/2 in. (13 mm) in diameter or a 3/8 in.

(10 mm) square shaft.

The M9102 Series Electric Non-spring Return

Actuators provide a running torque of

18 lb·in (2 N·m), and the nominal travel time is

30-seconds at 60 Hz (36 seconds at 50 Hz) for

90° of rotation. The M9104 Series Electric

Non-spring Return Actuators provide a

running torque of 35 lb·in (4 N·m), and the

nominal travel time is 60-seconds at 60 Hz

(72 seconds at 50 Hz) for 90° of rotation.

Refer to the M9102-AGA-2S, -3S and

M9104-xGA-2S, -3S Series Electric

Non-Spring Return Actuators Product Bulletin

(LIT-1201742) for important product

application information.

Features

• two torques available: 18 and 35 lb·in

(2 and 4 N·m) — offer the most suitable

choice for the specific application

• short 30-second travel time available —

provides a quick response for two-position

zone applications

• 35 dBA nominal audible noise rating —

meets the audible noise requirements for

open ceiling environments

• synchronous drive — provides a constant

rotation time that is independent of the load

• 100,000 cycle rating — provides years of

trouble-free service

• direct shaft mounting with single-screw

coupler — reduces installation time and

provides three-point shaft gripping

• magnetic clutch — protects the actuator

gear train and the damper from damage

due to excessive torque during a stall

condition

• manual gear release — simplifies actuator

setup and adjustments in the field

• plenum cable or screw terminal electric

connections — make wiring quick and easy

• floating, floating with timeout, and

proportional 0(2) to 10 VDC control inputs

available — offer a full range of control

input options

• small,compactdesign—allowsinstallation

in tight-fitting locations

Applications

The M9102 and M9104 Series Electric

Non-spring Return Actuators are designed to

position balancing, control, round, and zone

dampers in Heating, Ventilating, and Air

Conditioning (HVAC) systems. These electric

actuators are also designed to position blades

in a VAV box, or they can be used in VVT

two-position zone applications.

Eachactuatormountsdirectlytothesurfacein

any convenient orientation using a single

No.10self-drillingsheetmetalscrew(included

with the actuator). No additional linkages or

couplers are required. Electrical connections

on the actuator are clearly labeled to simplify

installation.

Repair Information

If the M9102 or M9104 Series Electric

Non-spring Return Actuator fails to operate

within its specifications, replace the unit. For a

replacement electric actuator, contact the

nearest Johnson Controls® representative.

Code No. LIT-1900247

Issued July 15, 2013

M9102/M9104 Series Electric

Non-Spring Return Actuator

FIG:act_dim

3/16

9/16

(14)

1-3/32

(28)

2-13/16

(71)

4-3/32

(104)

5-5/32

(131)

2-1/4

(57)

2-1/16

(52)

1-1/4

(32)

25/32

(20)

Set Screw

Radius

Clearance

M9102/M9104 Series Electric Non-Spring Return Actuator

Dimensions, in. (mm)