Transportation and storage | 3

• Keep this manual at the location of the product.

• Do not install or operate the product if it is defective.

• Do not remove or disconnect safety devices.

• Make sure that you can read all warning signs and labels on the product when it is installed. Replace labels that have

damage.

• Only permit approved personnel to work on the product and to be in the adjacent area during all work on the

product.

• Make sure that you know how to stop the product quickly in an emergency.

• Use applicable safety devices and personal protective equipment during all work on the product.

• Before you do work on the product, stop the product and wait until the heating element to cool. Make sure that there

is no voltage on the control board terminals.

• Do not operate the product near flammable materials, fluids, and gases.

• If the maintenance is not correctly and regularly done, there is risk of injury and damage to the product.

• Only do the maintenance as given in this manual. Speak to Systemair technical support if other servicing is

necessary.

• Always use spare parts from Systemair.

• The product is not to be used by persons, including children, with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

• Do not allow children to play with the device.

2.3 Personal protective equipment

Use personal protective equipment during all work on the product.

• Approved eye protection

• Approved protective helmet

• Approved hearing protection

• Approved protective gloves

• Approved protective shoes

• Approved work clothing

3 Transportation and storage

Warning

Make sure that the product does not become damaged or wet during transportation. A damaged or wet

product can cause fire or electric shock.

Always transport the product the in the original packaging.

Prevent impact stress to the product and its packaging at all times.

Inspect the device for any transport damage after delivery. The product must be stored in the original packaging, dry,

weather-protected, at a temperature between -10 °C to 40 °C.

The packaging material must be disposed in accordance with local rules and regulations.

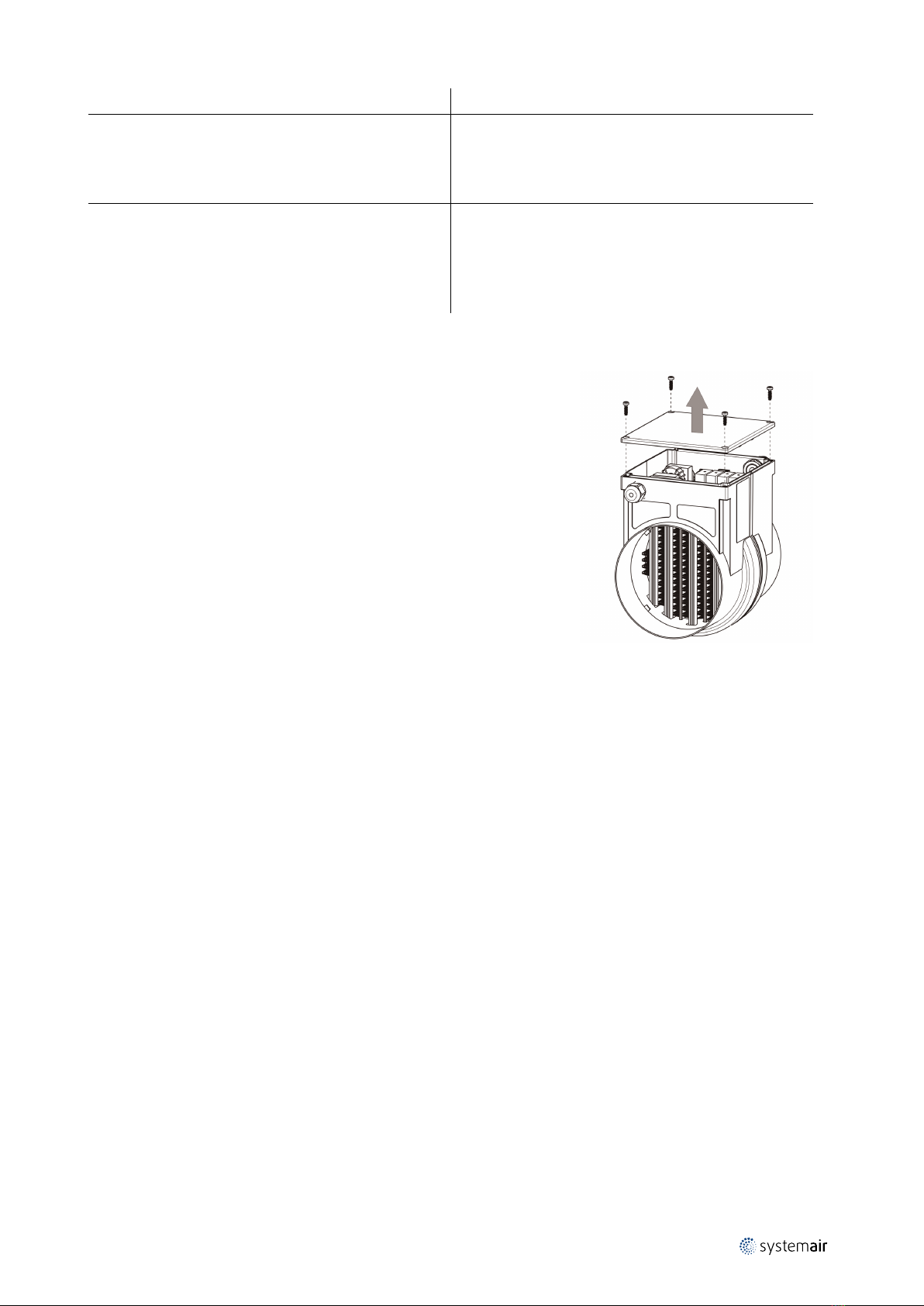

4 Installation

4.1 To do before the installation of the product

• Make sure that you have the necessary installation accessories.

• Use installation material with fire resistance rating for the installation location.

• Examine the packaging for transportation damage and remove the packaging from the product carefully.

• Examine the product and all components for damage.

• Install the product in a location where there is space for commissioning, troubleshooting and maintenance.

• Make sure that the installation location is clean and dry, for full safety during electrical work.

398046 | v1.1