2/48 | User Manual S-BM2 | 202010

Table of Contents

Good to know

Current information on all products is

available at www.design.systemair.com

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Conditions . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

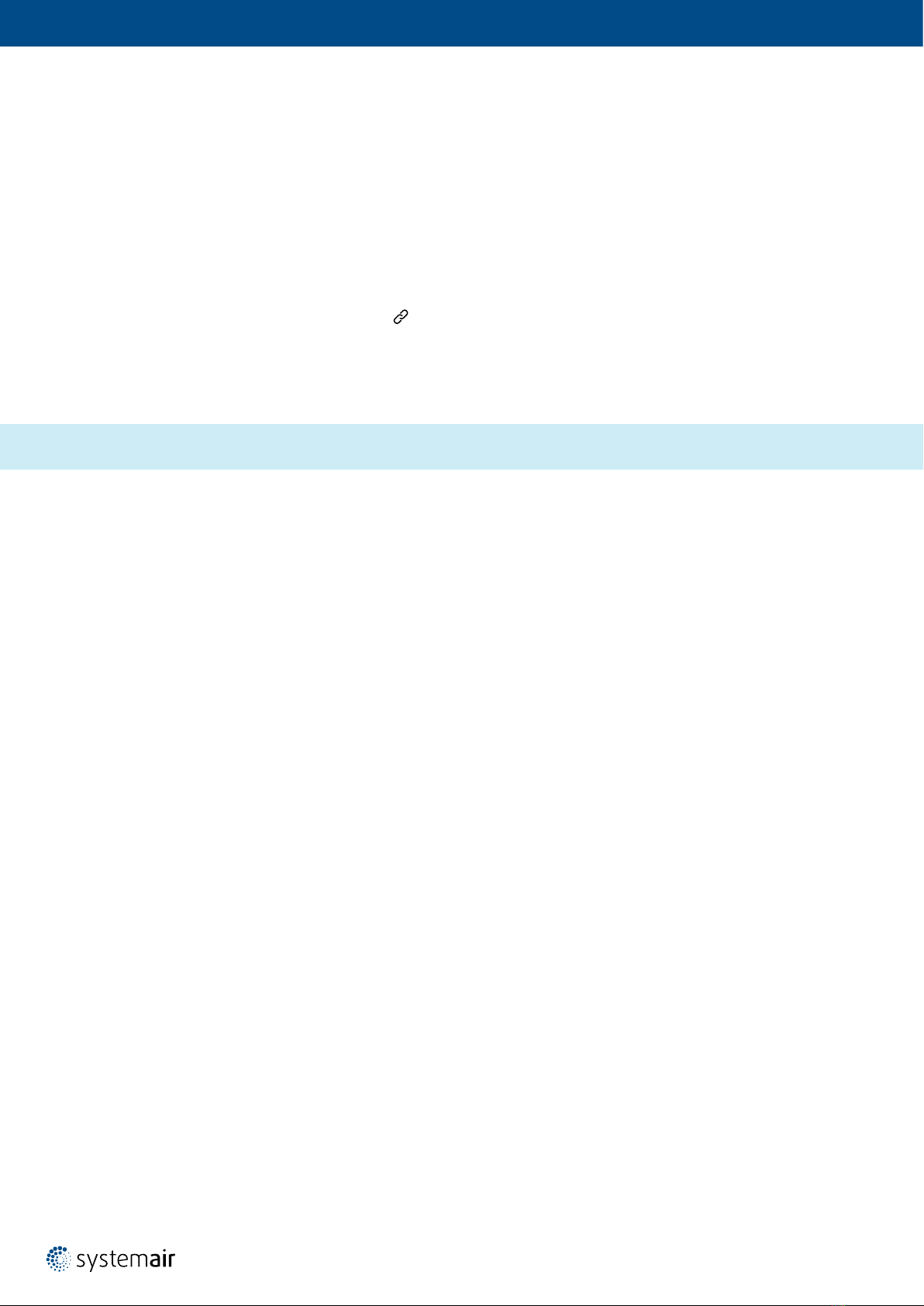

Installation Methods . . . . . . . . . . . . . . . . . . . . 6

Opening Preparation for S-BM2 Installation. . . . . . . . 8

Installation Distances . . . . . . . . . . . . . . . . . . . 10

Manipulation of S-BM2 . . . . . . . . . . . . . . . . . . 11

Wet Installation . . . . . . . . . . . . . . . . . . . . 14

Dry Installation . . . . . . . . . . . . . . . . . . . . . 18

Fit Installation . . . . . . . . . . . . . . . . . . . . . 22

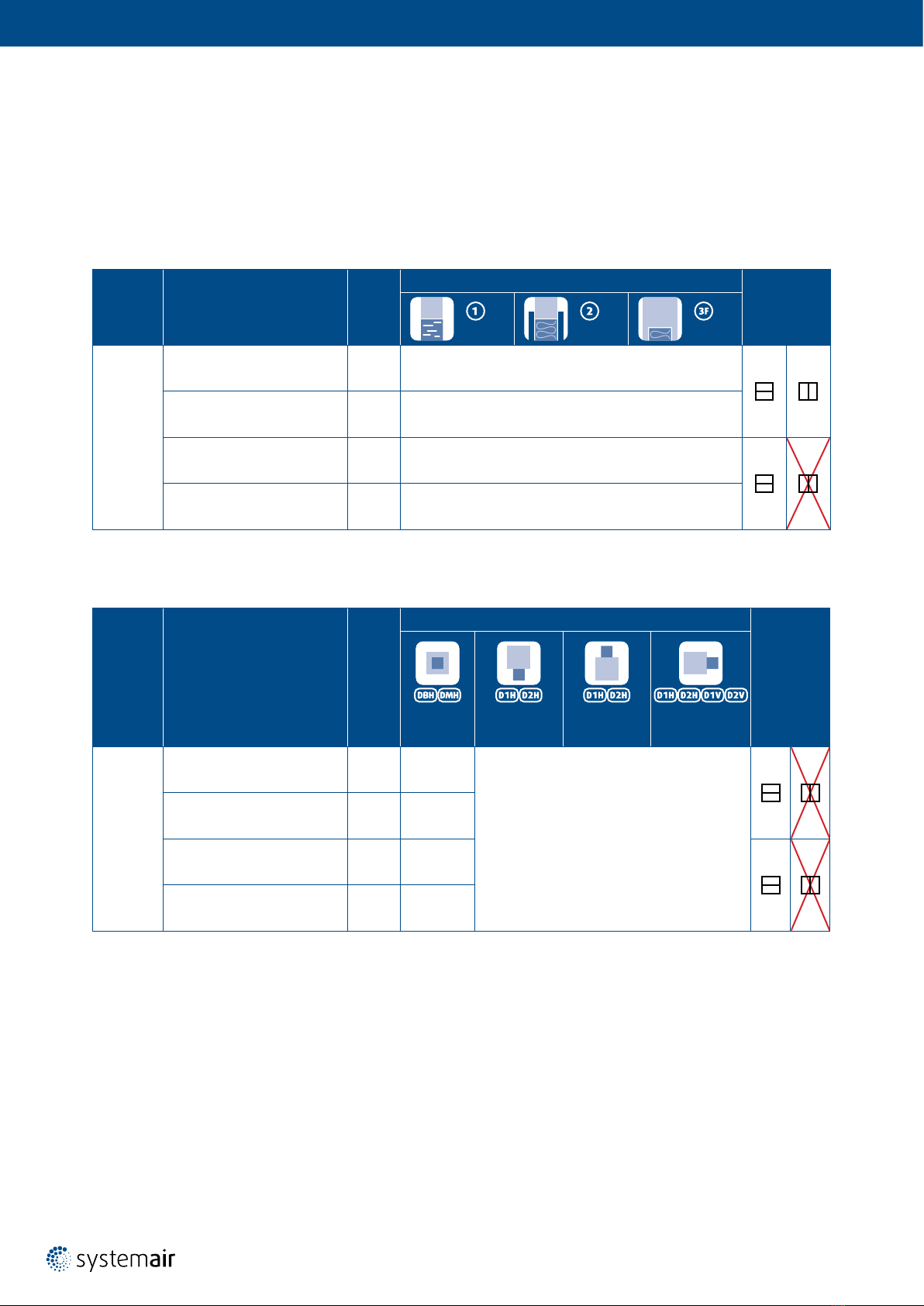

Installation in the Duct Made of Promatect Boards . 26

Installation in the Duct Made of Sheet Metal. . . . . 30

Installation on the Horizontal Duct . . . . . . . . 34

Installation on the Vertical Duct . . . . . . . . . 38

Electrical Connections . . . . . . . . . . . . . . . . . . . . . 42

Operation Manual . . . . . . . . . . . . . . . . . . . . . . . 44

Smoke Control Damper Functionality Check . . . . . . . . . 44

Smoke Control Damper Inspection . . . . . . . . . . . . . . 44

Warranty Conditions . . . . . . . . . . . . . . . . . . . . . . 45

Operating Journal . . . . . . . . . . . . . . . . . . . . . . . 46

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . 48