SS-450-000 1 I56-3469-000

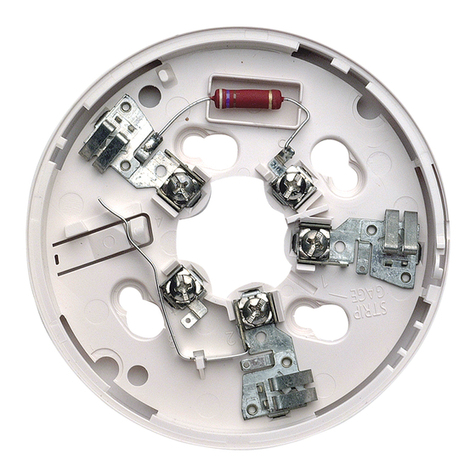

B200SA

Intelligent Sounder Base

INSTALLATION AND MAINTENANCE INSTRUCTIONS

6581 Kitimat Road, Unit 6, Mississauga, Ontario L5N-3T5

1-800-SENSOR2, FAX: 905-812-0771

www.systemsensor.ca

BEFORE INSTALLING

Please read the System Sensor Smoke Detector Application Guide, which

provides detailed information on sensor spacing, placement, zoning, wiring,

and special applications. Copies of this manual are available from System

Sensor. CAN/ULC S524 and NEMA guidelines should be observed.

NOTICE: This manual should be left with the owner/user of this equipment.

IMPORTANT: The detector used with this base must be tested and main-

tained regularly following CAN/ULC S536 requirements. The detector should

be cleaned at least once a year.

GENERAL DESCRIPTION

The B200SA sounder base is used with System Sensor 200-Series sensor

heads or equivalent. For a list of compatible sensors, refer to the System Sen-

sor website at www.systemsensor.com. Refer to the appropriate manual for

more information on sensors.

The B200SA sounder base was designed specifically to meet the needs of

dwelling unit applications. It offers maximum flexibility in configuration and

operation to meet or exceed the requirements of CAN/ULC S525 and CAN/

ULC S529.

The sounder base is capable of producing a variety of tone patterns, includ-

ing the distinctive three-pulse temporal pattern (ANSI Temporal 3) fire alarm

signal now required by ULC for commercial and residential applications.

The B200SA can be commanded by the Fire Alarm Control Panel to adopt

the address of the attached sensor head, but as a unique device type on the

loop. By using the address, the fire alarm control panel can command an

individual sounder base to activate, or a group of sounders in a suite or other

multi-room configuration. The command set from the panel can be tailored to

the specific event, allowing selection of volume, tone, and group. The device

offers two volume levels. The available tones are Continuous, ANSI Temporal

3, and March Time. In addition, some fire alarm panels will offer the ability to

command a custom tone pattern. Refer to the appropriate fire alarm control

panel manual for more information.

The B200SA can be silenced remotely by using a ULC listed remote silence

switch model RSM-1SWA. When operated, the base will be silenced for not

more than 10 minutes after which time the base will resound if the system is

still in alarm. The Fire Alarm Control Panel can also resound the base. The

B200SA also has a silence test feature. If when the base is sounding the si-

lence switch is pressed and held for more than 5 seconds and then released,

the base will silence but resound after 10 seconds.

Specifications

Base Diameter: 6.875” (17.46 cm)

Base Height (less sensor): 2.0” (5.08 cm)

Weight: 0.50 lb. (227 gm)

Operating Temperature Range: 32° to 150°F (0° to 66°C)

Operating Humidity Range: 10% to 93% relative humidity (non-condensing)

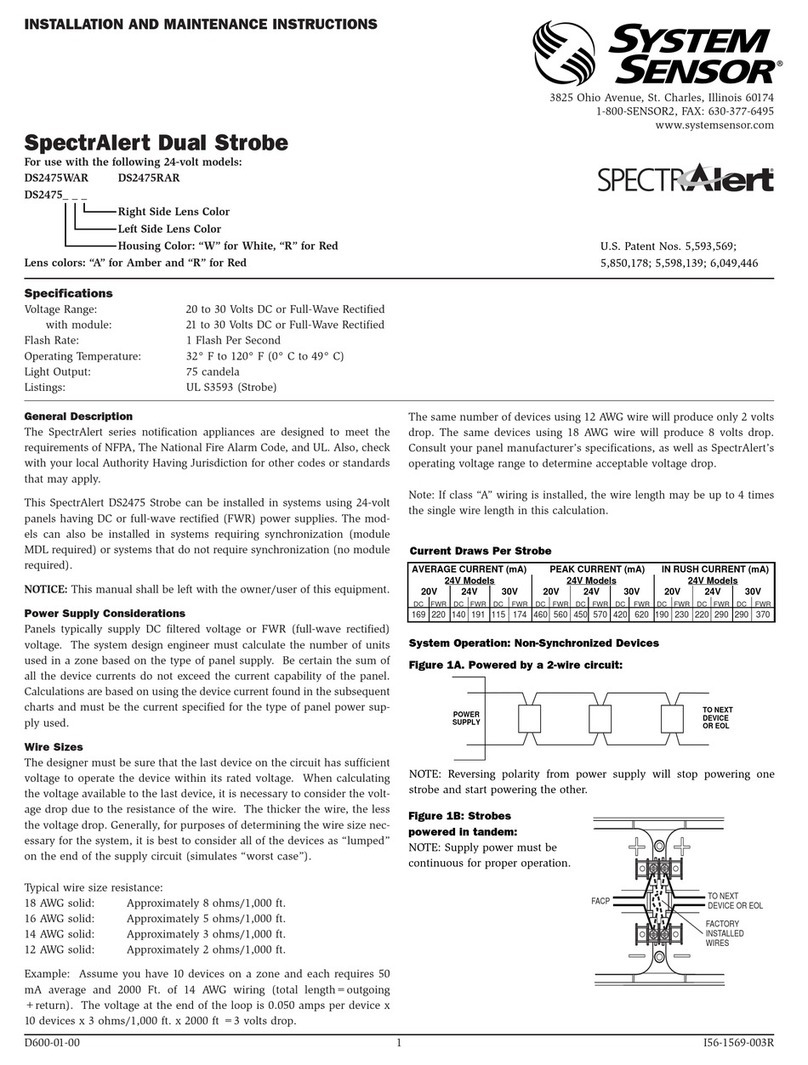

External Supply Electrical Ratings

External Supply Voltage: 16 to 33 VDC (VFWR)

Standby Current: 500 μA maximum

Alarm Current: 40mA Max. (DC)

70mA Max. (FWR)

SLC Electrical Ratings

SLC Operating Voltage: 15 to 32 VDC

SLC Standby Current: 300 μA maximum

Sound Output

High Volume: Greater than 87 dBA minimum measured in a ULC anechoic room at 10 feet, 24 Volts (in continuous tone)

Low Volume: Greater than 85 dBA minimum measured in a ULC anechoic room at 10 feet, 24 Volts (in continuous tone)

In addition, the B200SA is equipped with the circuitry to recognize the System

Sensor synchronization protocol, enabling the sounder base to be used as

a component of the general evacuation signal – producing a ULC compliant

Temporal 3 pattern in synchronization with other System Sensor notification

devices. This requires connection to a power supply capable of generating

the System Sensor synchronization pulses. In this scenario, the sounder

bases will have the ability to synchronize with other System Sensor horns,

horn/strobes, and chimes using the same power source.

The sounder base is intended for use with intelligent systems. The sounder

base requires an external 24 VDC power supply. The connections for the

external power supply and the communication loop are isolated to prevent

electrical interaction between them. Refer to the panel manual for maximum

allowable number of units per loop.

NOTE: For ULC Installations, the Temporal 3 tone at high volume should be

used for evacuation. The use of other tone styles and low volume level will be

at the discretion of the local Authority Having Jurisdiction (AHJ).

NOTE: When not used as a supplementary evacuation system, the external

24 VDC supply shall be treated as a component of the main power supply

system and shall fall under the requirements of the main power supply sys-

tem per ULC.

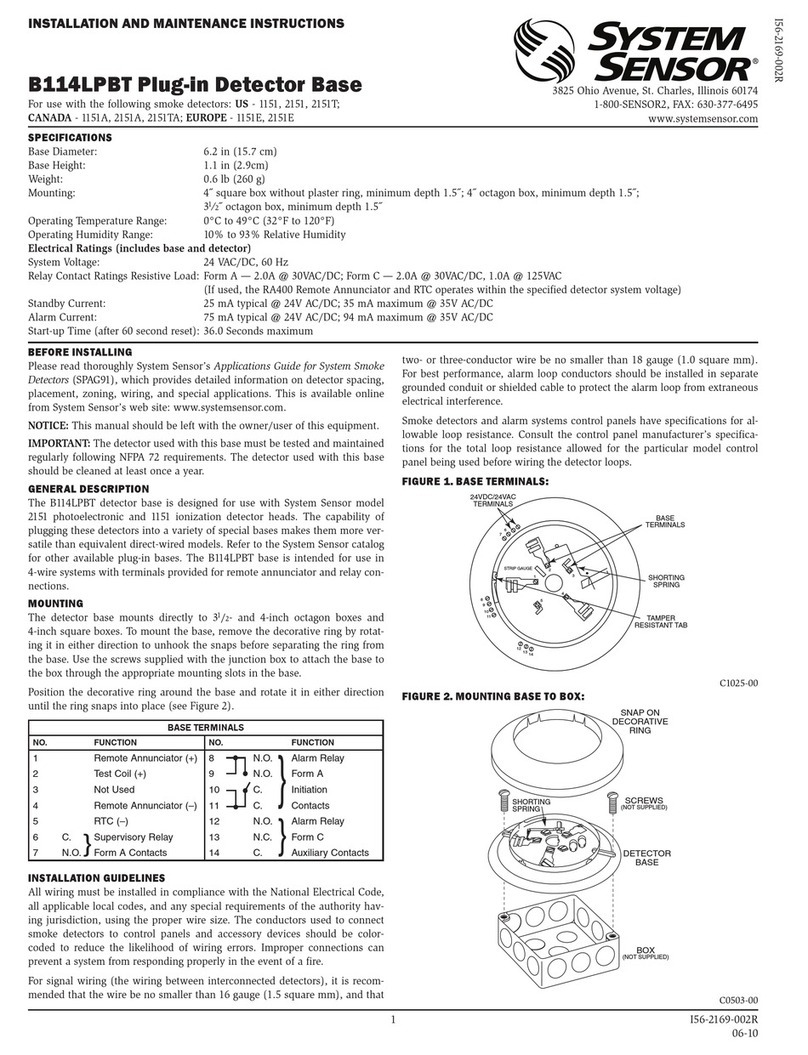

WIRING GUIDELINES

All wiring must be installed in compliance with the Canadian Electrical Code

and the local codes having jurisdiction and must not be of such length or wire

size which would cause the base to operate outside of its published specifica-

tions. The conductors used to connect smoke sensors to control panels and

accessory devices should be color coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from responding properly

in the event of a fire.

This model is compatible with Sytem Sensor Models MDLA, MDL3RA, MDLWA, MDL3WA and SYNC-1A