D450-16-01 1 I56-659-09R

B224RB Plug-in

Relay Detector Base

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3825 Ohio Avenue, St. Charles, Illinois 60174

1-800-SENSOR2, FAX: 630-377-6495

www.systemsensor.com

Before Installing

Please thoroughly read the system wiring and installation

manuals and the System Smoke Detectors Applications

Guide, which provide detailed information on detector

spacing, placement, zoning, and special applications.

NOTICE: This manual should be left with the owner/user

of this equipment.

IMPORTANT: The detector used with these bases must be

tested and maintained regularly following NFPA 72 require-

ments. The detectors should be cleaned at least once a year.

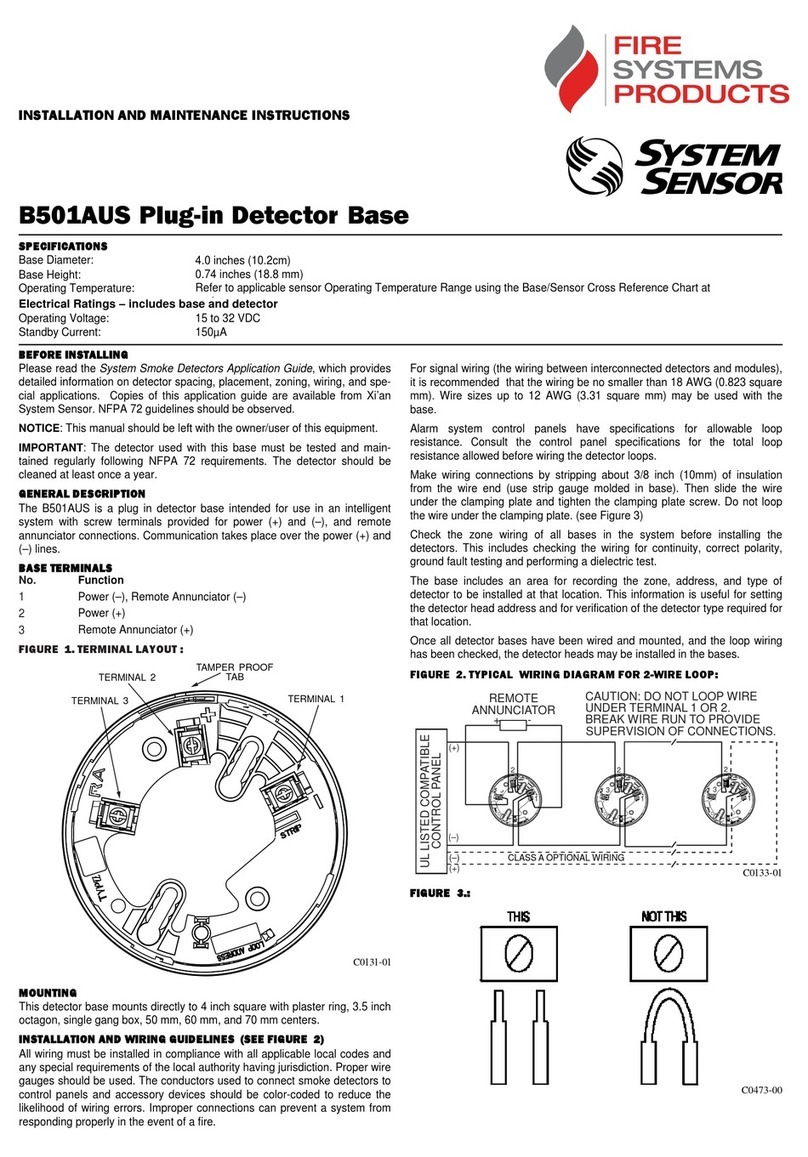

General Information

Form C latching relay contacts are included for the control

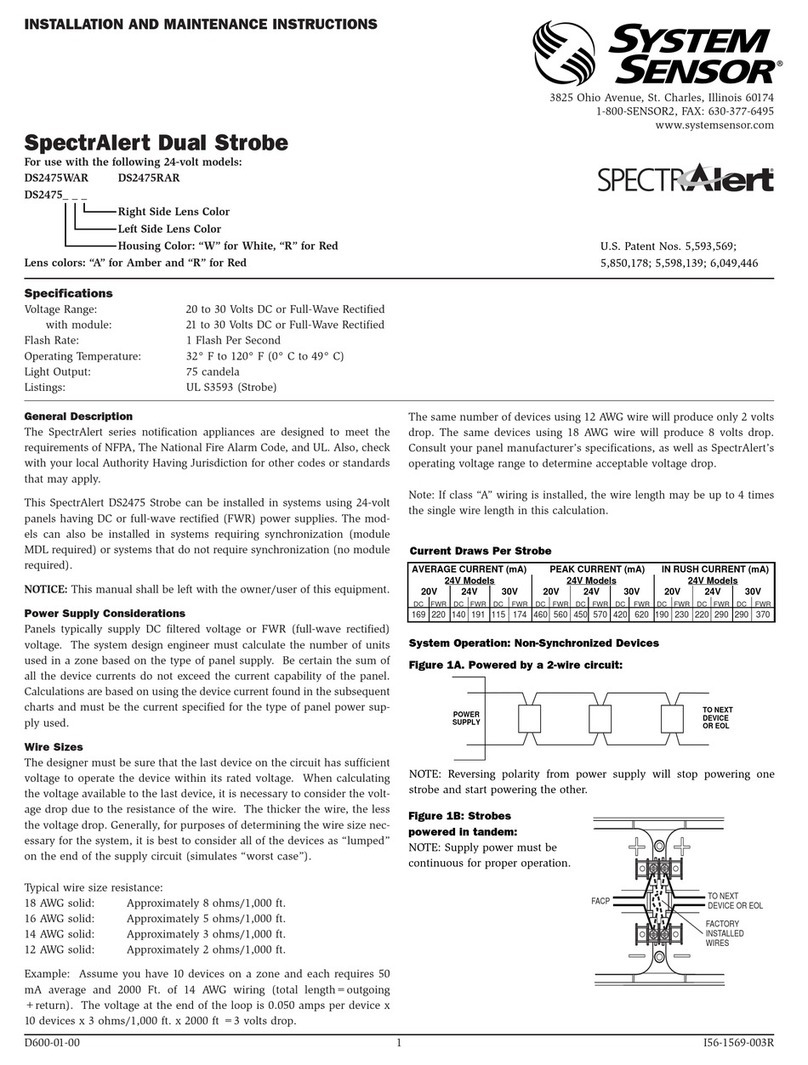

Specifications

Base Diameter: 6.1 inches (155 mm)

Base Height: 1.2 inches (31 mm)

Mounting: 4-inch square box with or without plaster ring, Min Depth - 1.5 inches (38 mm)

4-inch octagon box, Min. depth - 1.5 inches (38 mm)

31⁄2-inch octagon box, Min. depth - 1.5 inches (38 mm)

Operating Temperature Range: 0° to 49°C (32° to 120°F)

Operating Humidity Range: 10% to 93% Relative Humidity (Non-condensing)

Electrical Ratings

Operating Voltage: 15 to 32 VDC

Time Averaged Standby Ratings: <500 µA @ 24 VDC

Relay Characteristics

Coil: 2 coil latching

Contact Type: 1 Form C

Contact Relay

Resistive: 2 A @ 30 VDC

Inductive: 0.3 A @ 110 VDC (with .35 PF or greater)

0.3 A @ 120 VAC (with .35 PF or greater)

1.0 A @ 30 VDC (with .6 PF or greater)

Set Time: 4 seconds minimum, 20 seconds maximum

Reset Time: 1 second minimum, 8 seconds maximum

of an auxiliary function. The relay operates 12 seconds

(nominally) after activation of the sensor head remote

annunciator output.

Mounting

The detector base mounts directly to 31⁄2- and 4-inch octa-

gon and 4-inch square boxes, with or without a plaster ring.

To mount, remove the decorative ring by rotating it in either

direction to unhook the snaps. Then, separate the ring from

the base. Install the base on the box, using the screws sup-

plied with the junction box and the appropriate slots in the

base. Replace the decorative ring on the base and rotate it in

either direction until the ring snaps in place (see Figure 1).