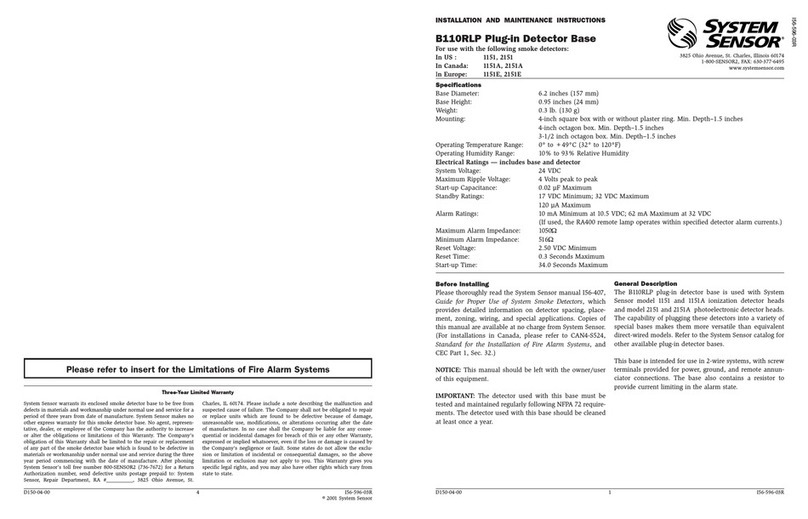

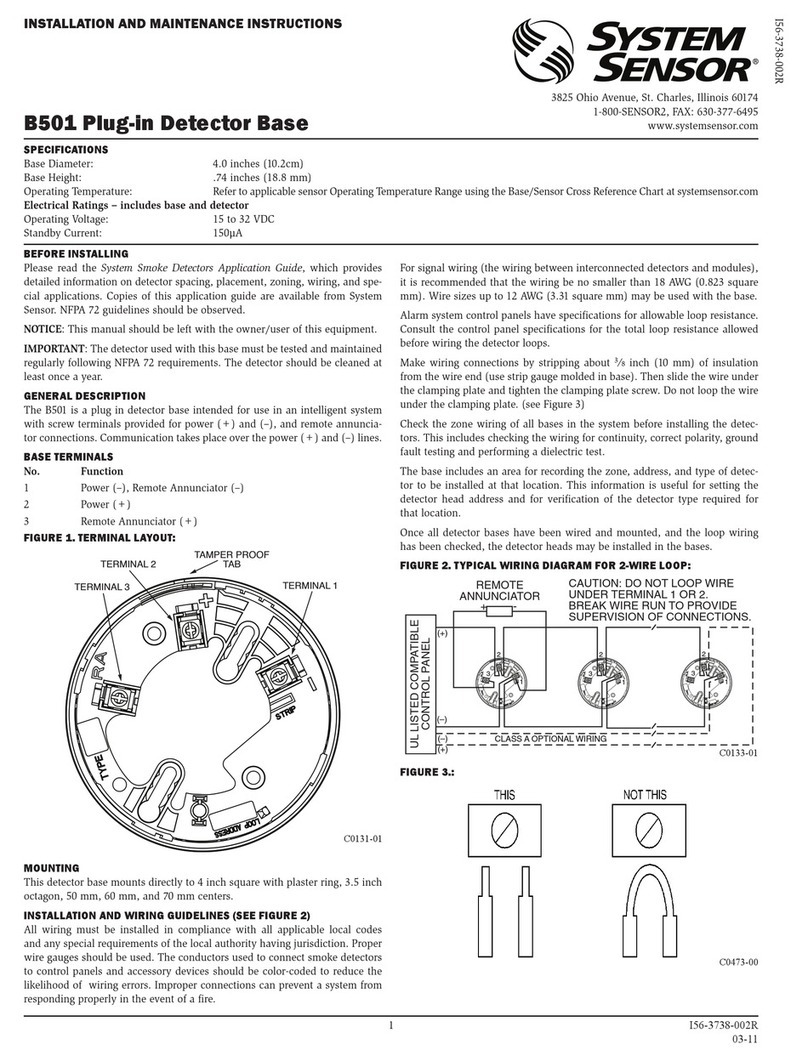

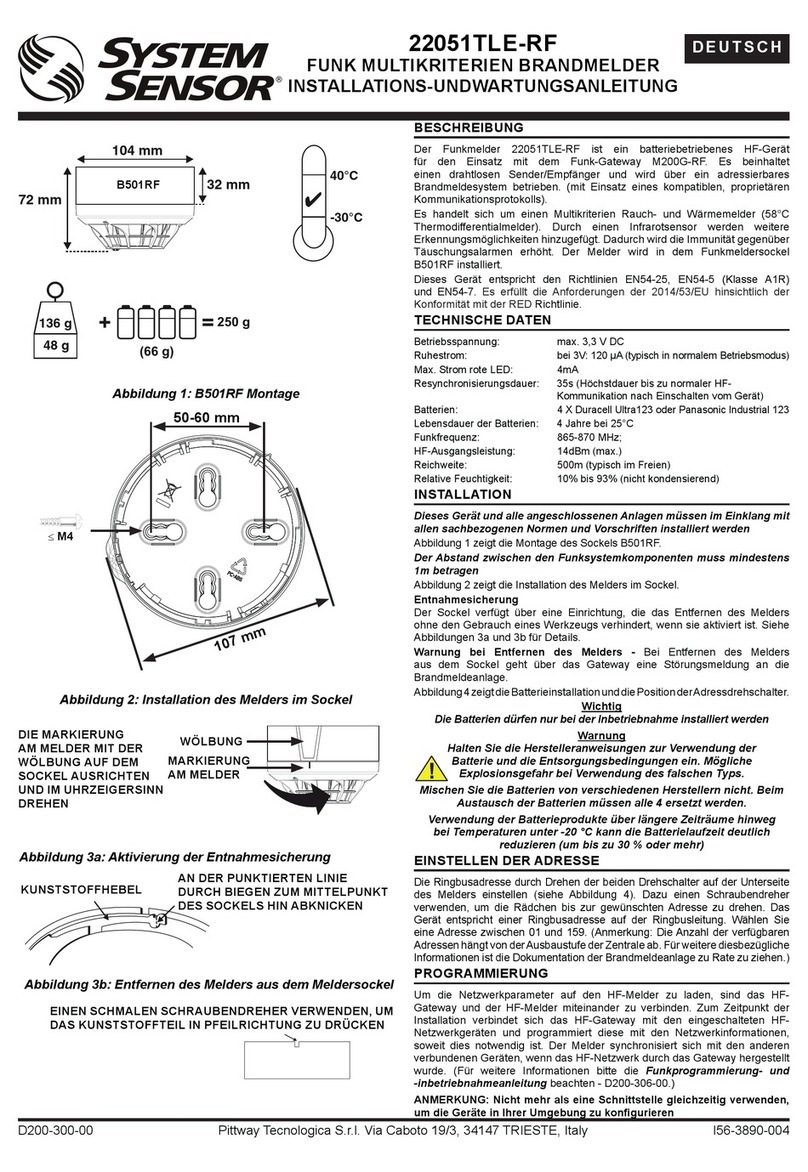

TAMPER-RESIST FEATURE

NOTE: Do not use the tamper-resist feature if the removal tool is to be used.

The detector base includes a tamper-resist feature that prevents removal of

the detector without using a small screwdriver or similar tool.

To activate this feature, use needle-nose pliers to break the tab on the detec-

tor base as shown in Figure 4A. Then, install the detector.

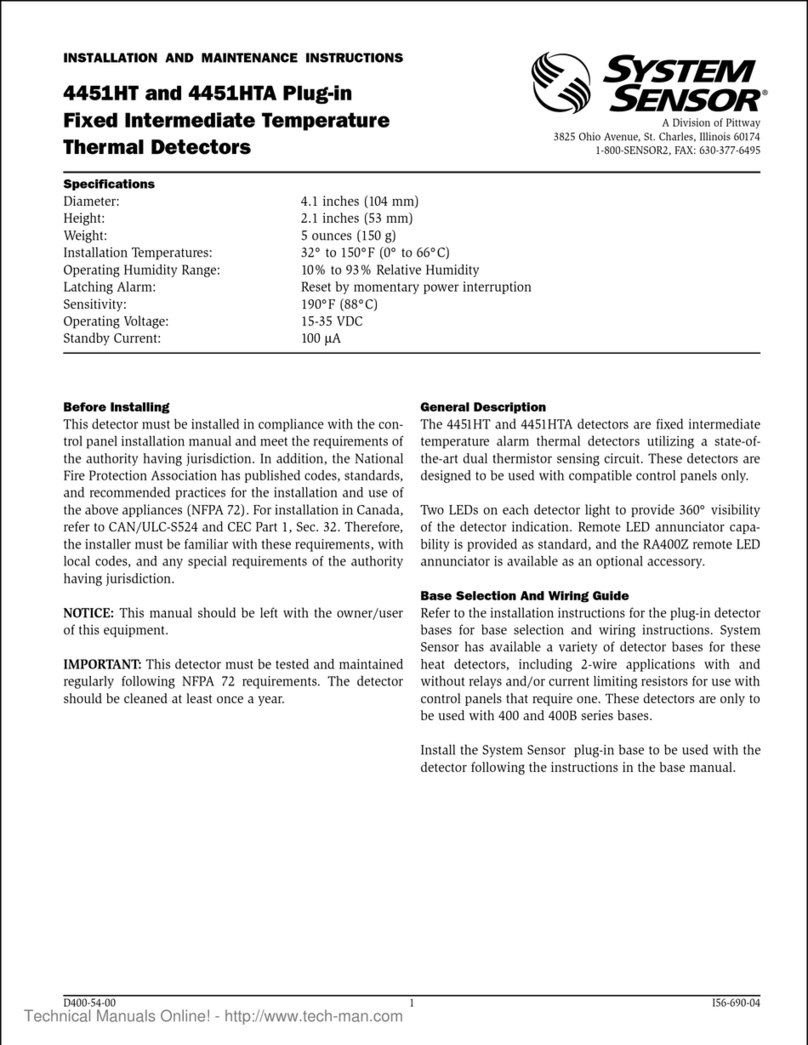

To remove the detector from the base once the tamper-resist feature has

been activated, insert a small-bladed screwdriver into the small hole on the

side of the base and push the plastic lever away from the detector head (see

Figure 4B). This allows the detector to be rotated counterclockwise for re-

moval.

The tamper-resist feature can be defeated by breaking and removing the

plastic lever from the base. However, this prevents the feature from being

used again.

FIGURE 4A. ACTIVATING TAMPER-RESIST FEATURE:

PLASTIC LEVER BREAK TAB AT DOTTED LINE BY

TWISTING TOWARD CENTER OF BASE

SCREWDRIVER TO PRESS PLASTIC LEVER

IN DIRECTION OF ARROW

SS-450-004 2 I56-1042-004

©2011 System Sensor

System Sensor warrants its enclosed smoke detector base to be free from defects in

materials and workmanship under normal use and service for a period of three years

from date of manufacture. System Sensor makes no other express warranty for this

smoke detector base. No agent, representative, dealer, or employee of the Company

has the authority to increase or alter the obligations or limitations of this Warranty. The

Company’s obligation of this Warranty shall be limited to the repair or replacement of any

part of the smoke detector base which is found to be defective in materials or workman-

ship under normal use and service during the three year period commencing with the

date of manufacture. After phoning System Sensor’s toll free number 800-SENSOR2

(736-7672) for a Return Authorization number, send defective units postage prepaid

THREE-YEAR LIMITED WARRANTY

to: System Sensor, Repair Department, RA #__________, 6581 Kitimat Road, Unit 6,

Mississauga, Ontario L5N-3T5. Please include a note describing the malfunction and

suspected cause of failure. The Company shall not be obligated to repair or replace units

which are found to be defective because of damage, unreasonable use, modifications,

or alterations occurring after the date of manufacture. In no case shall the Company

be liable for any consequential or incidental damages for breach of this or any other

Warranty, expressed or implied whatsoever, even if the loss or damage is caused by the

Company’s negligence or fault. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Please refer to Insert for the Limitations of Fire Alarm Systems

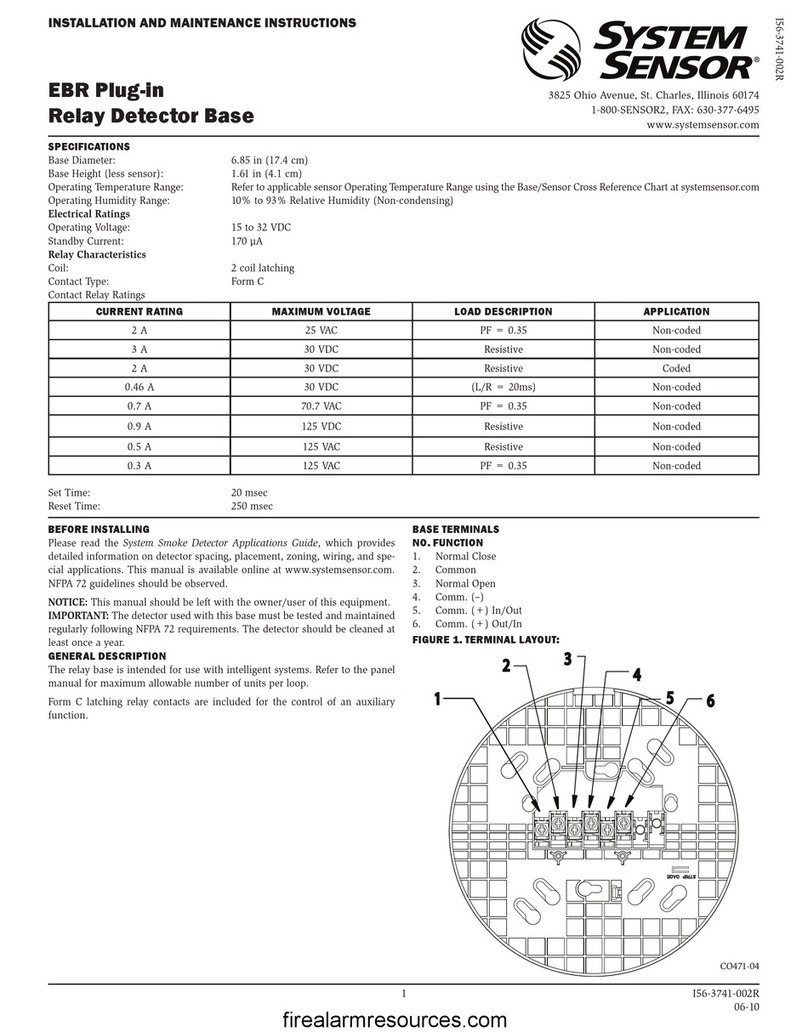

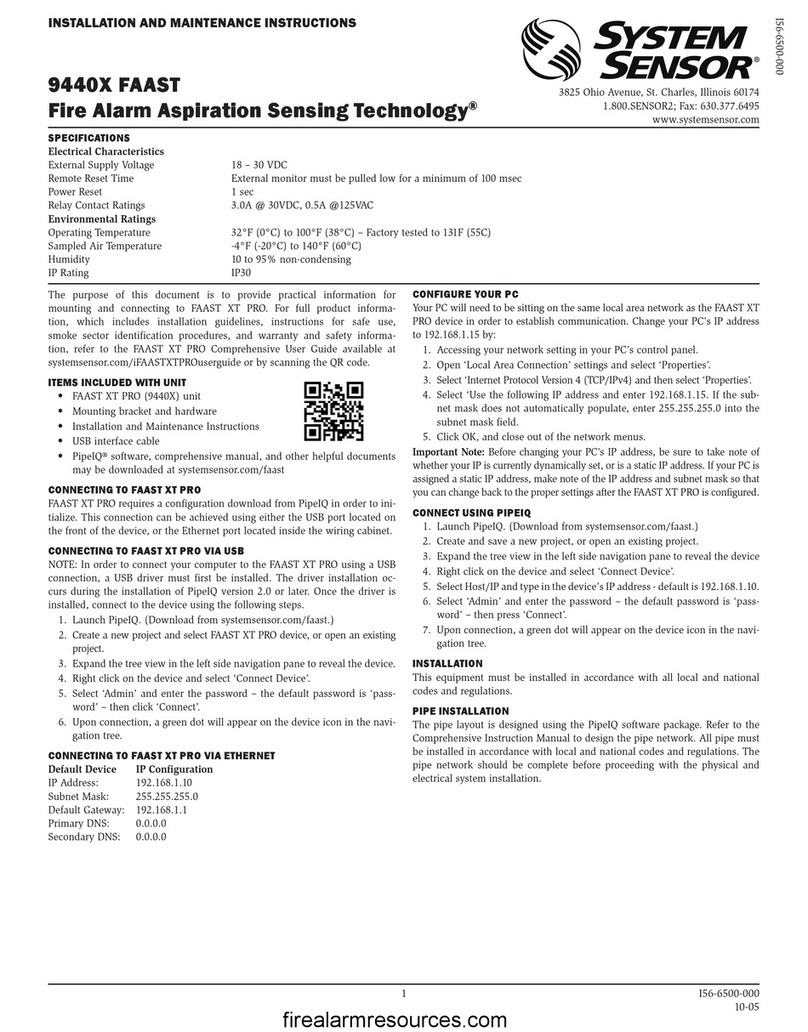

REMOTE ANNUNCIATOR (RA400ZA/RA100ZA)

The remote annunciator is connected between terminals 1 and 3 using the

spade lug terminal packed with the remote annunciator. The spade lug termi-

nal is connected to the base terminal as shown in Figure 5.

It is not acceptable to have three stripped wires under the same wiring termi-

nal unless they are separated by a washer or equivalent means. The spade

lug supplied with the model RA400ZA/RA100ZA is considered an equivalent

means. See Figure 2 for proper installation.

PLASTIC LEVER BREAK TAB AT DOTTED LINE BY

TWISTING TOWARD CENTER OF BASE

USE SMALL-BLADED SCREWDRIVER TO PRESS

PLASTIC LEVER IN DIRECTION OF ARROW

FIGURE 4B. REMOVING DETECTOR HEAD FROM BASE:

C0132-01

C0132-00

FIGURE 5. CONNECTION TO REMOTE ANNUNCIATOR TERMINAL:

STRIPPED WIRE

WIRE WITH SPADE LUG

C0116-00