SysTEMM

SENSOR

INSTALLATIoN

AND

MAINTENANCE

INSTRUCTIONS

rech

Intral

Deeiogmrnt

Zan

WFD

Vane-type

Waterflow

Detectors

Prinee

f Sh

aam.

71

0075,

Chi

Teiephone

(29

347800

Fas

(037)

382959

SPECIFICATnONS

Contact Ratings:

higgering Threshold Bandwidth

(Flow

Rate):

Static

Pressure

Rating

Dimensions, Installed:

l0

A

@

125/250

VAC

N

25

A@

24

VDC ---

4 to

10

gpin

See

models listed below

3.5

in

Hx

30

in

W x6.7 in D

Operating

Temperature

Range:

Compatible

Pipe:

Shipping

Weight:

Enclosure Rating:

U.

S.

Patent

Numbers

32°F

to

120°F (0°C

to

49°C)

Steel

water

pipe,

schedule

10

through

40

4 to 7 Ib

(according

to

size)

NEMA Type 4,

as

tested

by

Underwriters

Laboratories,

Inc. (1PS6)

5,213,

3,205

IMPORTANT

INSTALLATmON

GUIDELUNES

Please Read Carefully

And

Save

Before

instaling any waterflow alarm device,

be

thoroughly

farmiliar

with:

This

instructionmanual

contains

important

information

about

the

installation

NFPA

72:

National

Fire

Alarm

Code

and

operation

of

waterlow

detectors.

Purchasers

who install waterflow

detec

tors

for

use by others must leave this manual or a copy of

it

with the user.

NFPA

13:

Installation

of

Sprinkler Systems, Sect.

3.17

NFPA

25:

Inspection.

Testing

and

Maintenance

of

Sprinkler

Systesms,

Sect

5332

Read all instructions carefully before beginning. Follow only those instnuc-

tions that apply to the model you are installing.

Other

appiicable

NFPA

standards,

local

codes,

and

the

requiremenits

of

the

authority having jurisdiction

ACAUTION

NOTE:

Installation

methods

other

than

those listed in this instaliation

manual

Use vane-type

waterlow

detectors in wel-pipe systems only.

Do

NOT

use

Imay

preven!

tihe

device

irom

reporiing

the

Llow

oí

water

in

the

event

the

asso-

them in dry pipe, deluge.

or

preaction systems. The

sudden

inrush

of

water in ciated sprinkier system

is

activated by a ire.

XTan

Sysem Sensor is not responsible

such systems may break the vane or damage the mechanism. for

devices

that

have

been

improperiy

installed, tested,

or

maintained

Do

not use in potentially explosive atmospheres.

Do

not

allow

unused wires

lo

remain

exposed.

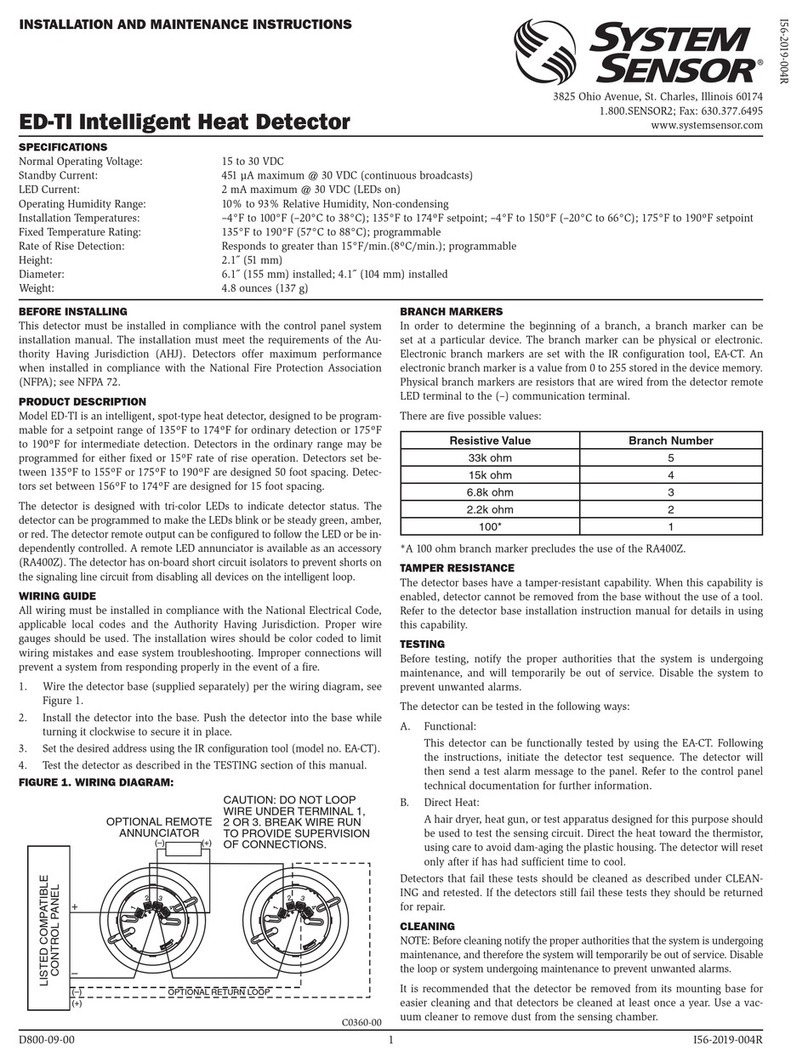

1.

Mount the detector where there

is

adequate clearance tor installation and

removaB

and

a clear view

of

it

for inspections. See Figure I for

maunting

dimensions.

2.Locate

the

detector 6

to

7

feet

above

the

floor

to

protect

from

acca

dental damage.

PRINCIPLES OF OPERATION

Vane-type waterflow detectors imount to water-filled pipes in sprinkler systems.

Waterflow in the pipe deflects a vane, which produces a switched

outpul

3.

On

horizontal runs, position the detector

on

the top or side

of

the

pipe.

usually

after

a specilied delay.

All

waterflow detectors have a

pneumatically

controlled mechanical delay mechanism. Delays do

NOT

accuinulate; they

re

set

if the

flow

of water stops before the entire delay has elapsed.

All

switches

actuate

when

the water flow rate is

10

gallons per minute or greater, but will

not actuate

if

the

low

rate is less than 4 gallons per minute. This System

Sen-

sor

installation manual

covers

the

following

watertlow detectors

for

sprinkler

ire

alarm

applications.

Do

not

mount

it

upside

down

because

condensation

may

collect in the

housing

and

impair

thse

operaüon

of

he

detector. For vertical flow appli-

Ccations,

mount

the

detector on

pipe

through which water fiows upward.

Otherwise, the unit

mnay

not operaie properiy.

4.

Mount

the

detector

at

least

6

inches

fron

a

f+itüng

that

changes

the

direc-

tion

of

water tlow

and

no less than 24 inches irom a valve

or

drain.

5.

Be

sure

the

direction-of-low

aToW

matches

the

directOn

of

llow in the pipe.

Pipe

Size

Pipe Max.

Pressure

MOUNTING

INSTRUCTiONS

Model

(inches)

Schedule

Rating

(psig)

1.

Drain

the

pipe.

WFD20

10

thru

40

450

Cut a hole

at

the desired location. Center the hole

in

tbe pipe, às

shown

in

Figure

2,

and

be

sure the hole

is

perpendicular

to

the

center

of

the

pipe. Before drilling. use a punch or scribe

to

mark the

dill

site

to

pre

vent

the

bit

trom

slipping.

If

the

hole

is

off

center,

the

vane

will

bind

gainst

the inside wall of the pipe.

Use

a

dril

or hole saw

to

cut a hole of

the

proper

diameter.

See Table I tor hole size.

WFD25 2.5 10 thru

40

450

WFD30-2

10

thru

40

450

WFD35

3.5

10 thru

400

450

WFD40

10

thru

40

450

WFD50

10 thru

40

450

ACAUTION

When

drilling

the

hole

with

a

hole

saw,

make

certain

that

the

center

ot

the

cut

does nol

remain

in

the

pipe.

WFD60 10 thru 40

450

WFD80

10

thru

40

450

Kemove

burrs and sharp edges

from

the hole. Clean and remove

all

scale

and

toreign

matter

trom

the

inside

ot

the

pipe

lor

one

diameter

on

each

Side

of

the

hole to

ensure

free

movement

of the

vane.

Clean

the

outside

of

the

pipe

to

remove

dirt,

metal

chips,

and

cutting

lubricant.

Maximum Ptressure

Rating

400

psig

as

approved

by

Factory

Mutual

Research.

ACAUTION

Do

NOT

use any

of

the

WFD

models on copper pipe. The clamping 1orces . Seat the gasket against the saddle and mount the delector directly

to

the

the

mounting

bolts may

collapse

the

pipe

sufficiently

to

prevent

the

detector

from

functioning properly.

pipe.

Carefully

roll

the

vane

opposite

the

direction

of

tlow

and

insert

through the hole. Seat the saddle firmly against the pipe

so

that the local-

ng

boss

goes

into

the

hole.

Do

NOT

install

steel

or

iron

pipe

sections

in

copper

piping

for

mounting

waterflow detector. Incompatibility

between

the

dissimilar metals causes b

ustnal

Development

Zone

Province

o1

Shaanxi,

710075,

China

Telephone: (029) 8S387800 Fax: (029) 88332959

metallic corrosion.

D770-01-00C

I56-0459-017C