3 I56-5151-007C

Specifications

Diameter : 104 mm (Installed in DZ-B401 Base)

Height : 51mm( Installed in DZ-B401 Base)

Weight : 80g(Without Base)

Operating Temperature Range : -10°C to 50°C

Operating Humidity Range : 10% to 95% Relative Humidity noncondensing

Operating voltage : 8.5 to 28VDC

Standby Current : ≤120uA

Alarm Current : 10mA Min. 93mA Max. (Must be limited by control panel)

Latching Alarm : Reset by momentary power interruption

Sensitivity : 63°C Fixed or 10°C /min rate-of-rise

Standard : GB4716-2005 / GB3836.1-2000 / GB3836.4-2000

Intrinsic Safety Rating : Exia ⅡC T5

Certification : Software Version:A

BEFORE INSTALLING

Before In stalling please thor oughly r ead the X i’an Syst em Sensor manu al, Copies o f this manu al ar e available from Xi’an System

Sensor.

GENERAL DESCRIPTION

JTWB-BCD-5151EIS/HT is a conventional 2-wire intrinsically safe thermal detector. This detector is designed to provide open area

protection and to be used with compatible panels (or interface module) only. This sensor utilizes a state-of-the-art thermistor sensing

circuit for fast response. It can be used in every environmental condition and also has the simple maintenance and lower fault rate

advantages. Two red LEDs blink in standby each 5S and latch on in alarm, and do not blink in trouble. A remote output option is also

available. A built in test switch is used in the detector for test alarm. The detector is commpliance with the GB3836.1-2000

&GB3836.4-2000 standards requiremets.

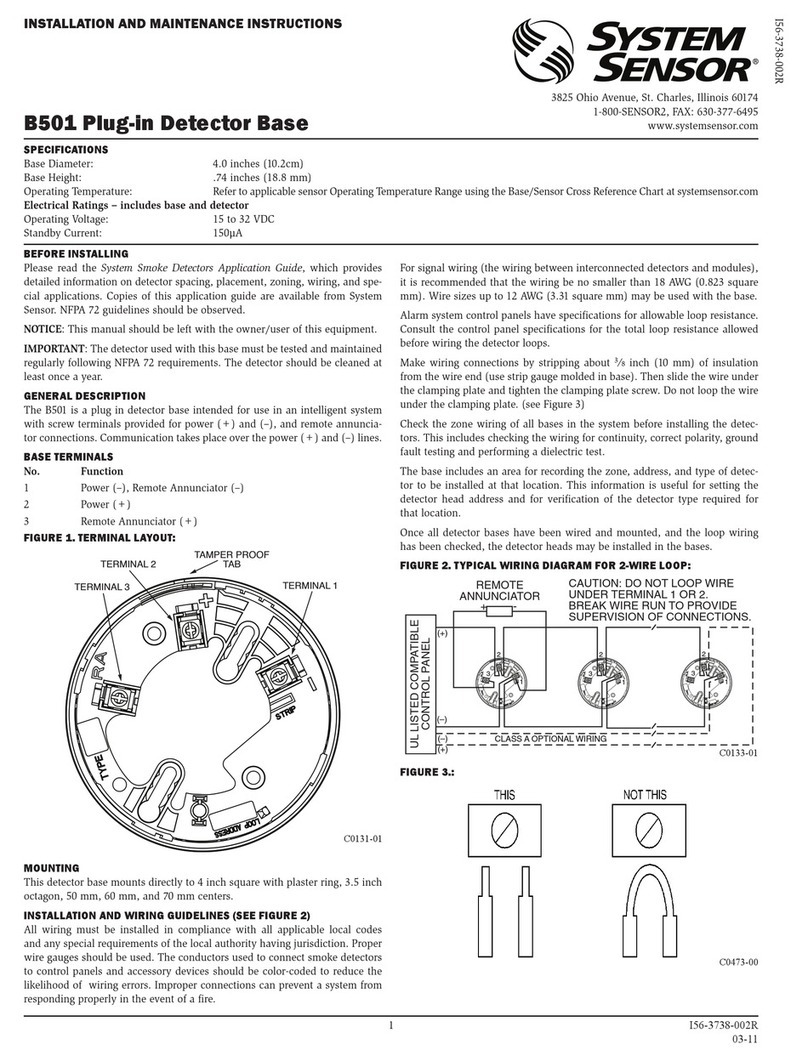

INSTALLATION

NOTE: All wiring must comply with all applicable national codes of practice and regulations.

WARNING: Disconnect the power to the initiating device before installing the detectors.

1. Install detectors:

a. Place the detector into the detector base.

b. Turn the detector clockwise until the detector drops into

place.

c. Continue turning detector clockwise to lock it in place.

Tamper Resistance: T he d etector b ases can be made tamper

resistant. Whe n capabilit y is enabled, de tectors cannot be removed

from the base without t he u se o f a tool. See the detector base

installation ma nual of the de tector base for details in us ing this

capability

2. After all detectors have been installed, apply power to the control

unit.

3. Test the detector using the magnet as described under TESTING.

4. Reset the detector at the system control panel.

5. Notify the proper authorities that the system is back on line

.

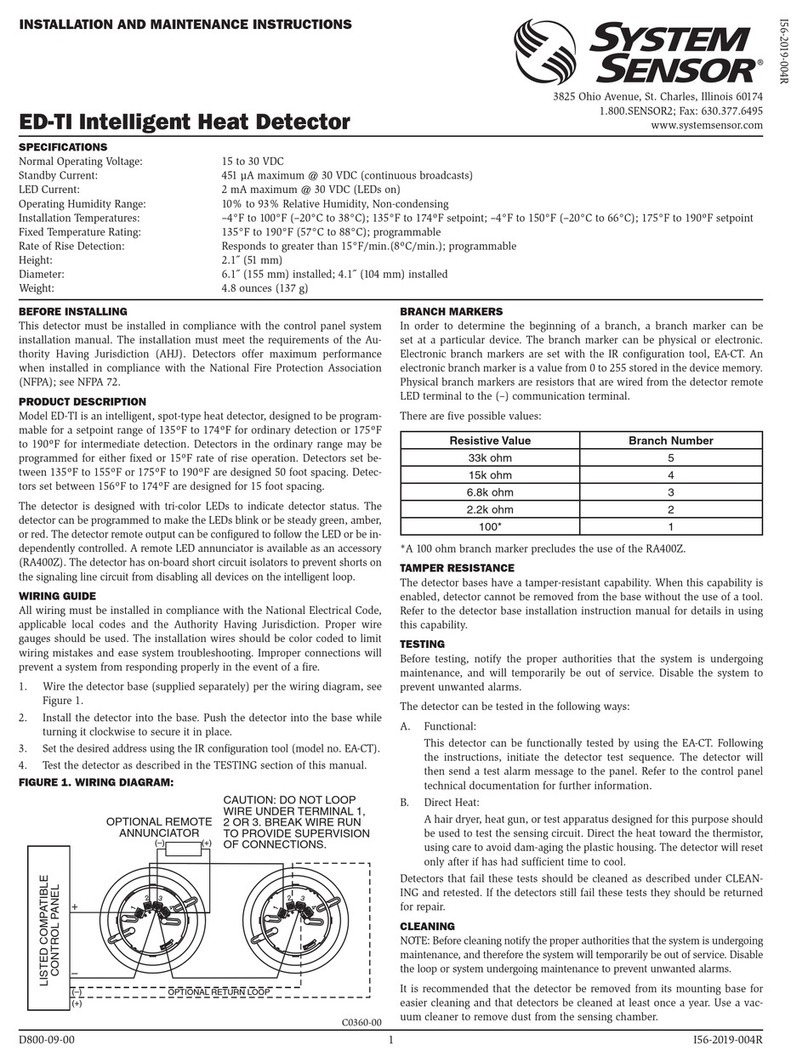

TESTING

A. Test Magnet

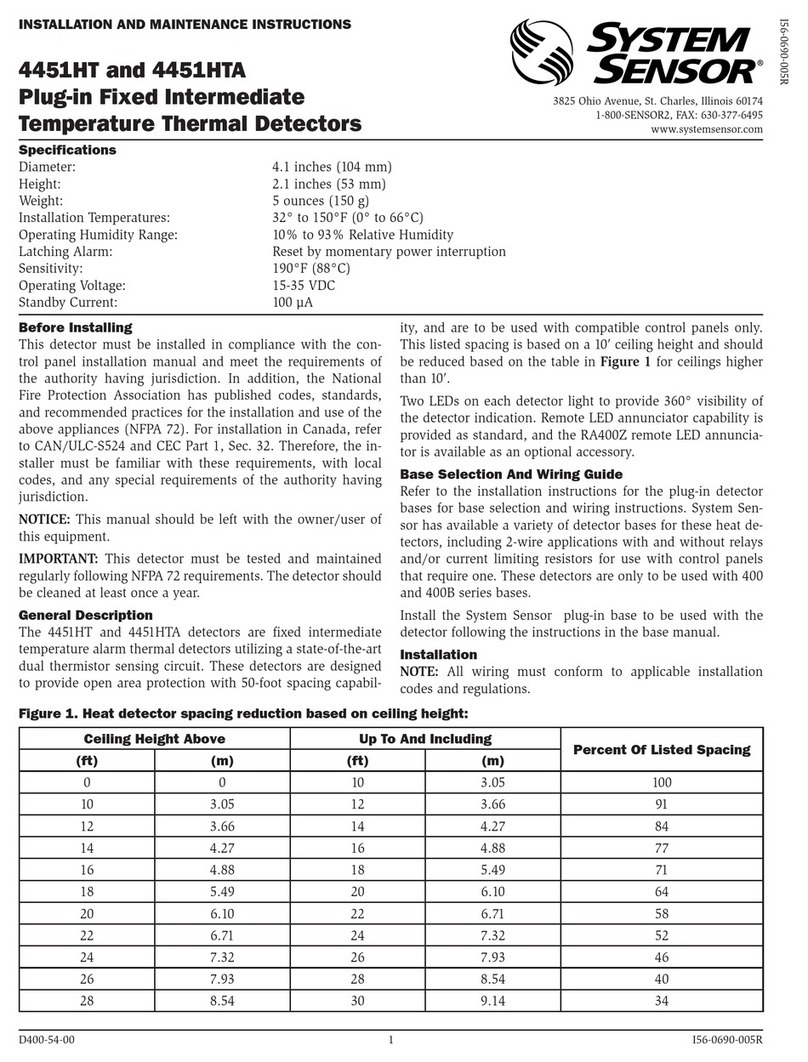

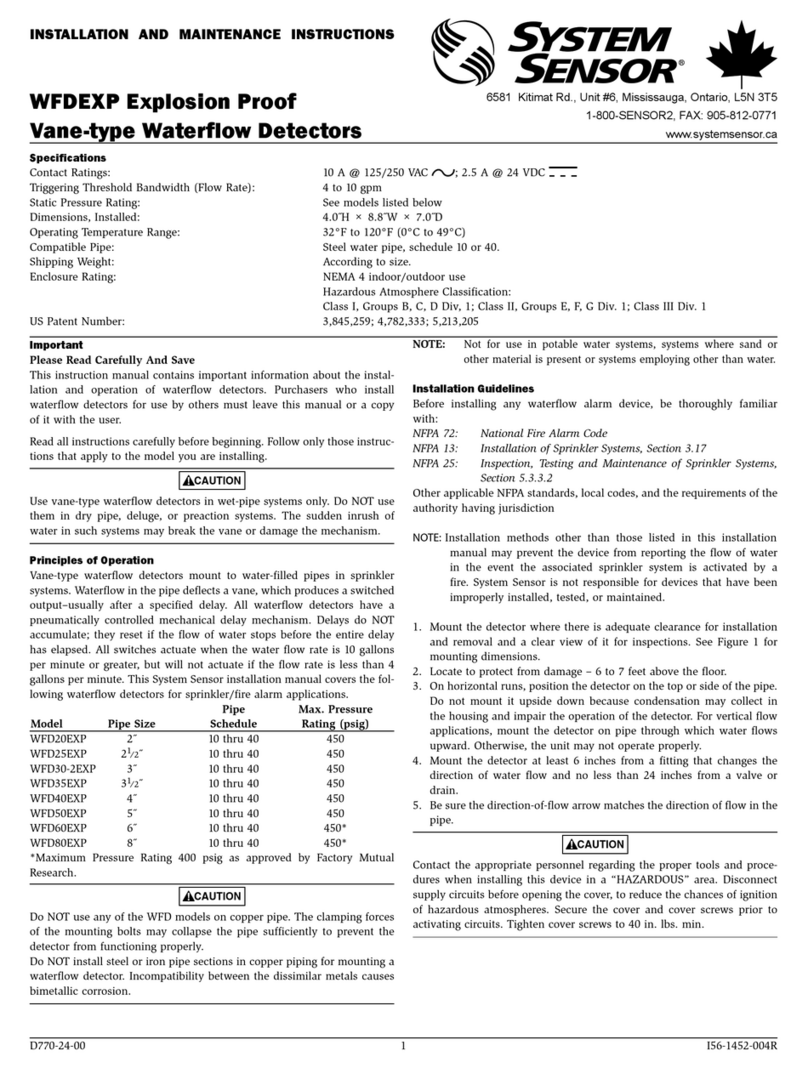

1. Place the magnet against the cover in the location designated by

the raised mark to activate the test feature (see Figure 1).

2. The LEDs should latch ON within 5 seconds indicating alarm and

an-nunciating the panel.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Model JTWB-BCD-5151EIS

Plug-in

Intrinsically Safe Thermal Detector

with Fixed Temperature Alarm

28 Tuan Jie South Road, Xi’an Nationa

Hi-tech Industrial Develo

ment Zone

Province of Shaanxi, 710075, China

Telephone: (029) 85387800 Fax: (029) 88332959

Figure 1.

4 I56-5151-007C

3. Reset the detector at the system control panel.

B. Direct Heat Method (Hair dryer of 1000 - 1500 watts)

From the side of the d etector, direct the heat t oward the sensor. Hold the h eat source ab out 15 cm away to prevent da mage to th e

cover during testing

NOTE: If a detector goes into alarm, it will reset only if the detector has cooled and if its power is momentarily interrupted. Check the

control panel being used to determine whether the RESET switch (or some other auxiliary device or control) momentarily cuts off power

to the detector loop.

Detectors that fail these tests should be cleaned as desc ribed under M AINTENANCE and retested. If the detectors still fail thes e test s

they should be returned for repair.

MAINTENANCE

The JTWB-BCD-1151EIS/HT det ector has been designed to b e as m aintenance free as possible . Normal ai r-borne d ust, however, can

accumulate on the detector’s sensing elements and cause them to become less sensitive. All detectors should be tested and cleaned at least

once a year, and those in dustier areas should be tested and cleaned more often. Detectors must also be cleaned and tested immediately

after a f ire. Before c leaning, notif y the proper authorities that the system is und ergoing maintenance, and therefore the system w ill

temporarily be out of service. Disable the loop or system undergoing maintenance to prevent unwanted alarms.

1. Remove detector from mounting base.

2. Use a vacuum cleaner to remove dust from the sensing chamber.

3. Reinstall the detector.

4. Test detector as described under TESTING.

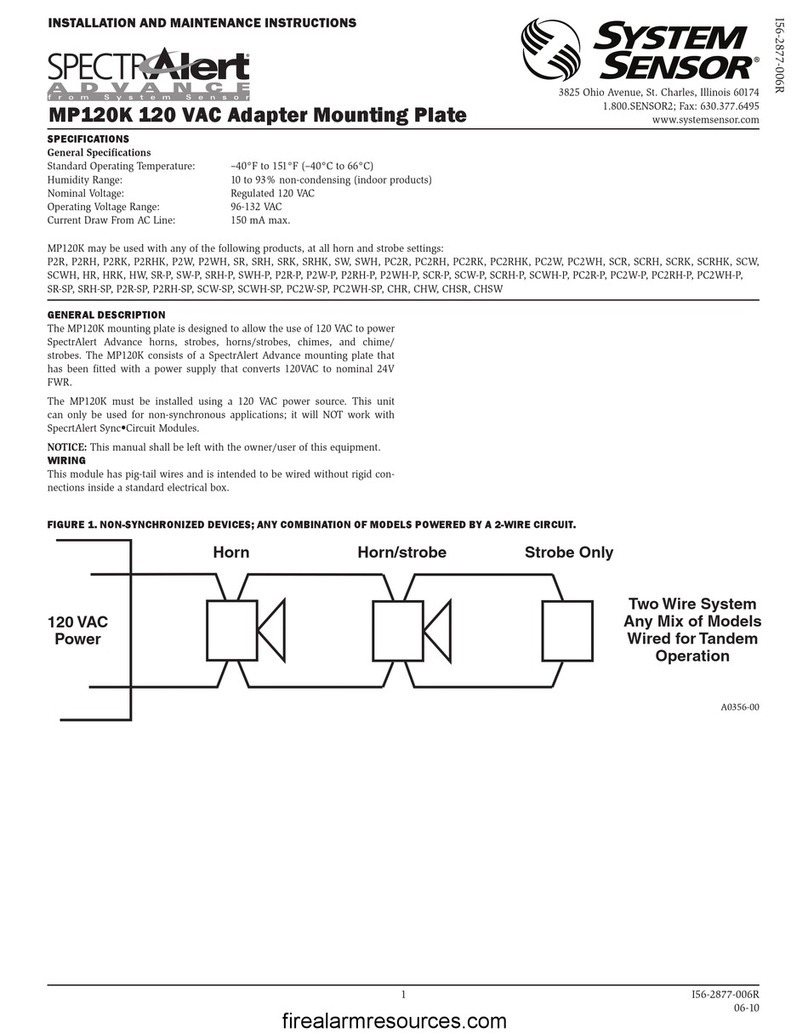

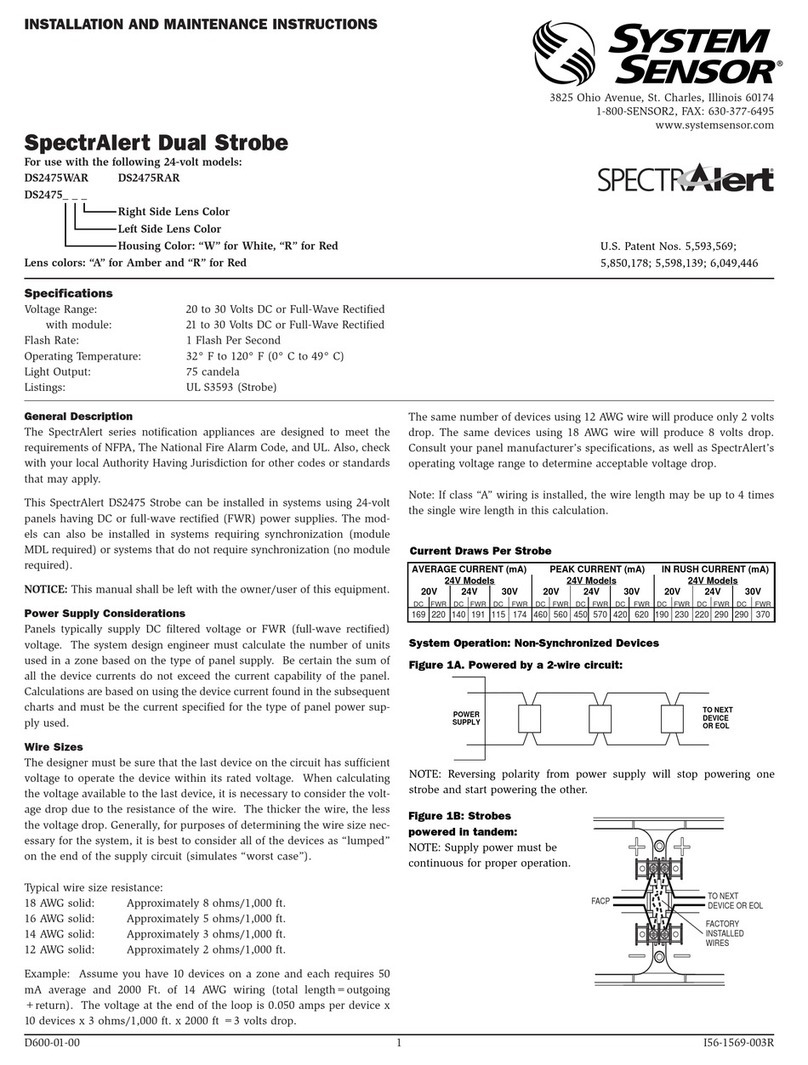

SYSTEM WIRING DIAGRAM

The system includes the control panel, the zener diode safety barrier or the isolated barrier, the intrinsically detector, the DZ-B401 base

and the wires.

Intrinsic

Safety Barrier

[Exia]ⅡC

3 2 4

(B401 Base)

Detector

Exia

ⅡC T5

To next

detector

HAZARDOUS AREA

Note 2 Note 3

SAFE AREA

Safe area apparatus

,

which is

unspecified except that it must

not be suppliedo from or contain

under normal or abnormal condi-

ions a source of potential with

respect to earth in excess of

250Vrms or 250VDC

Notes:

1. The detector has the following Intrinsically-safe parameters: Ui: 28VDC, Li: 93mA, Pi: 0.65W, Ci: 0, Li: 0 When to compatible with

the S afety b arrier, th e parameters mu st b e c omplied w ith t he fo llowing formula: Uo ≤Ui, I o≤Ii, Po ≤Pi, Co ≥Ci+Cc, L o≥Li+Lc,

Among them, about the definitions of Uo、Ui、Io、Ii、Po、Pi、Co、Ci、Lo、Li refer to the GB3836.4-2000. Cc and Lc separately stand

for the capacitance and inductance between the detector and the safety barrier, the remote indicator or the general cable.

2. The transformer in the hazardous area must be accordance with the Item 8.1 of the GB3836.4-2000 standard.

3. The installation must comply with the Item 15 of the GB3836.15-2000 standard.

4. Don’t clean the detector housing with a dry cloth.

5. The electrical circuit in the hazardous area must be capable of withstanding an A.C. test voltage of 500VRMS to earth or frame of the

apparatus for one minute.

6. Zone wiring of the detector bases refer to the DZ-B401 base installation manual.

PRODUCT NAMEPLATE DATE CODE NOTE

X X X X

Stands for: The end number of the producing year t he producing month the week of the month

LIMITATIONS OF FIRE ALARM SYSTEMS

This smoke sensor is designed to activate and initiate emergency action. It will not work without power and it has its limitations. It also

can not last forever.

THREE-YEAR LIMITED WARRANTY

Xi’an System Sensor warrants its enclosed thermal detector to be free from defects in materials and workmanship under normal use and

service for a period of three years from date of manufacture. The Company’s obligation of this Warranty shall be limited to the repair or

replacement o f any p art o f the thermal dete ctor which is found to be d efective in materials or workmanship und er n ormal u se and

service during the three year period commencing with the date of manufacture.

LED Status

Indicators

Magnet Test

Marker

Test Magnet

Position

Test Magnet

Position

Magnet Test

Marker

HEAT