1 I56-2431-004

7/2/2019

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Photoelectric Smoke Detector

2-Wire: C2WTR-BA (Form C Relay), C2WTA-BA (Sounder)

4-Wire: C4WTR-BA (Form C Relay), C4WTA-BA (Sounder)

C4WTAR-BA (Form C Relay, Sounder), C4WITAR-BA (Isolated Thermal, Form C Relay, Sounder)

Series

Before Installing

Please read thoroughly System Sensor

Application Guide: System Smoke De-

tectors,

which provides detailed information on detector spacing, placement,

zoning, wiring, and special applications. Copies are available on System Sen-

sor’s web site: www.systemsensor.ca.

NOTICE: This manual shall be left with the owner/user of this equipment.

IMPORTANT: This detector must be tested and maintained regularly follow-

ing CAN/ULC S536. At a minimum, cleaning should be performed annually.

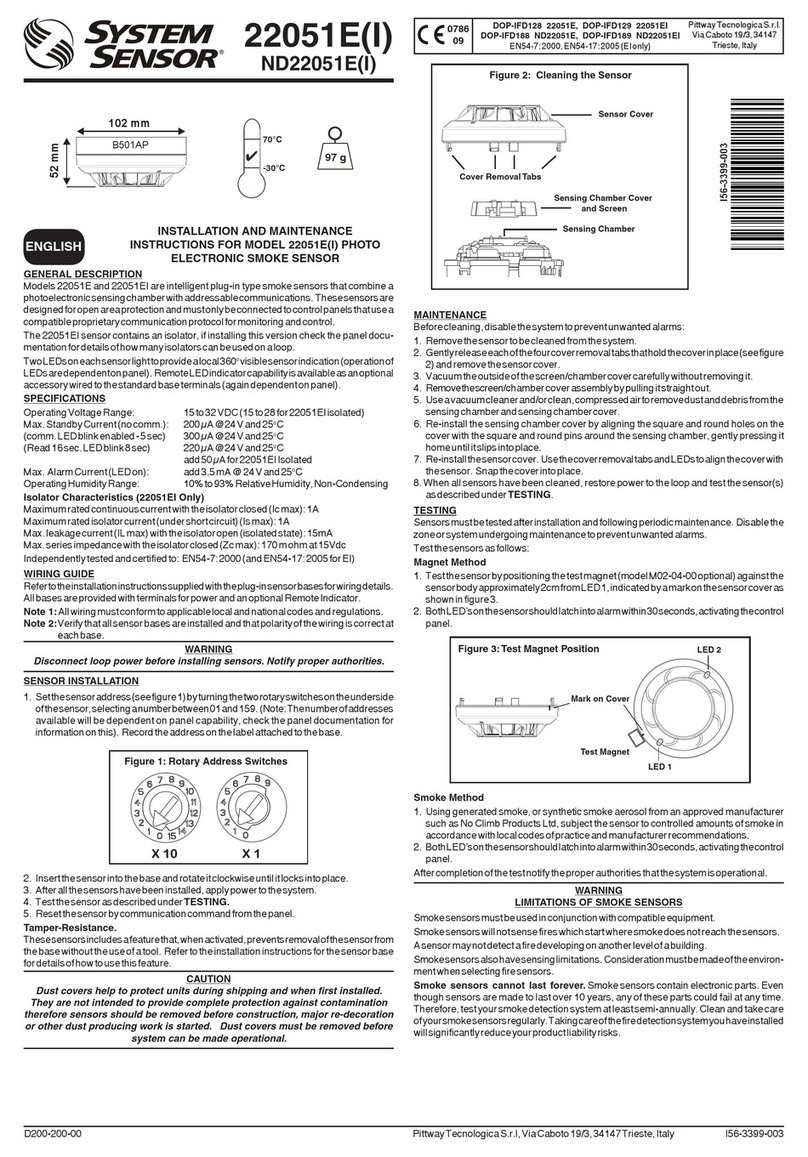

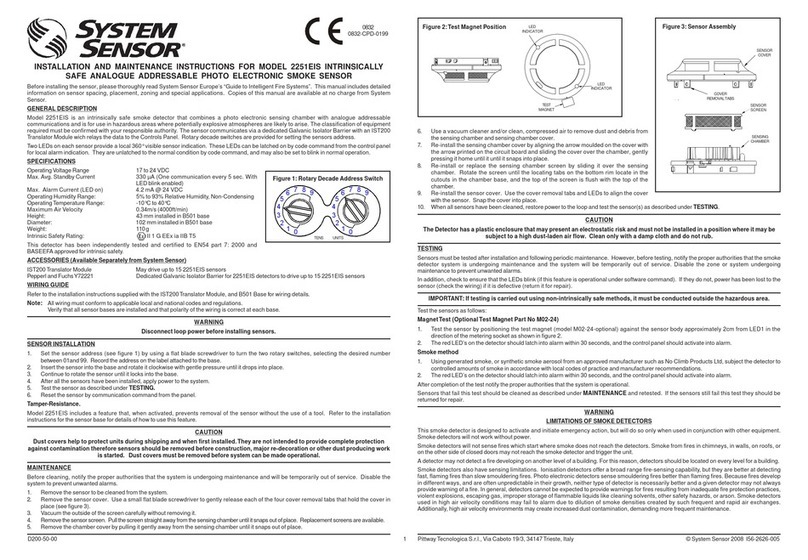

General Description

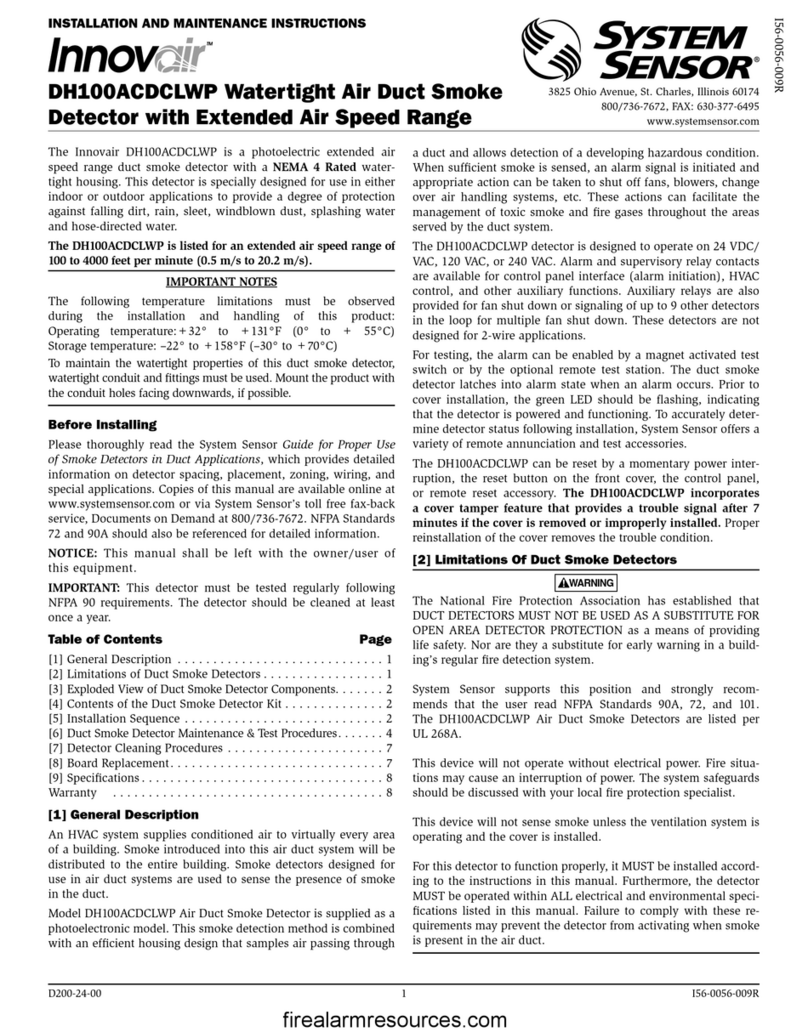

Models C2WTR-BA and C2WTA-BA are 2-wire photoelectric smoke detectors;

models C4WTR-BA, C4WTA-BA, C4WTAR-BA, and C4WITAR-BA are 4-wire

photoelectric smoke detectors. All models incorporate a state-of-the-art optical

sensing chamber and an advanced microprocessor. The microprocessor allows

the detector to automatically adjust its sensitivity back to the factory setting

when it becomes more sensitive due to contaminants settling in its chamber.

In order for this feature to work properly, the chamber must never be opened

while power is applied to the smoke detector. This includes cleaning, main-

tenance or screen replacement. All models also feature a restorable, built-in,

fixed temperature (135°F / 57 °C) thermal detector and are also capable of

sensing a freeze condition if the temperature is below 41°F (5°C)

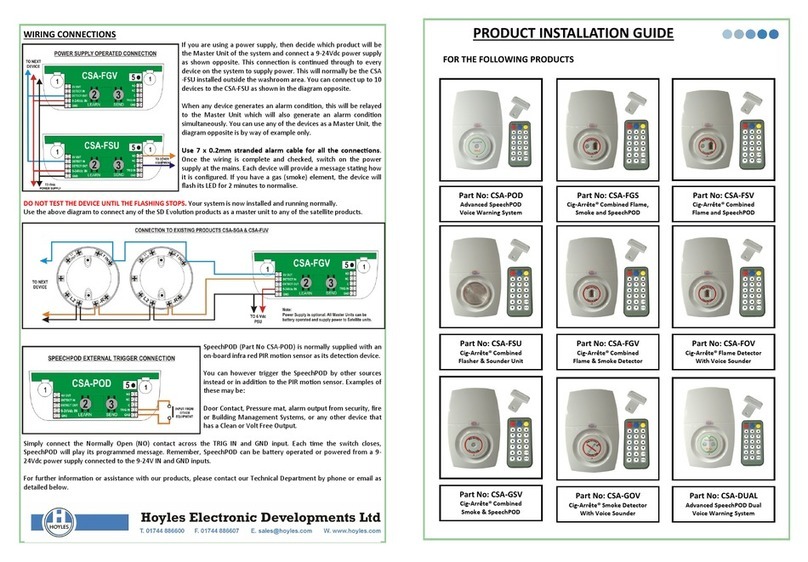

Models C2WTA-BA, C4WTA-BA, C4WTAR-BA, and C4WITAR-BA contain a

piezoelectric horn which generates the ANSI S3.41 temporal pattern in an

alarm condition. All detectors on a zone will sound when the power supply to

them is reversed. The CRRS-MODA can be used for the power supply reversal

function. The CRRS-MODA also enables all the detectors’ sounders on a zone

to be synchronized and allows the zone to be silenced from the panel by en-

tering the alarm silence key at the keypad.

The detector that initiated the alarm condition will have its red LED and

Form C relays (if applicable) latched until reset by panel.

The model C4WITAR-BA photoelectronic smoke sensor is isolated from the

fixed-temperature heat sensor, providing a self-resetting, local audible smoke

alarm that does not alarm at the panel. Only the fixed-temperature heat sensor

will cause the C4WITAR-BA to initiate an alarm at the panel and the relay to

change its state.

NOTE: In order for all i3sounder detectors on a loop to sound when the panel

alarms, the supply voltage polarity must be reversed. A reversing relay, System

Sensor model number CRRS-MODA, must be used. The CRRS-MODA is de-

signed to allow all i3Series detectors in the same loop to sound when one of

the detectors goes into alarm. In addition, the CRRS-MODA will synchronize

all of the i3Series sounder smoke detectors on the loop. Some panels may

require the use of programmable outputs. Refer to System Sensor literature for

further information on the CRRS-MODA.

All i3Series detectors are designed to provide open area protection. Two-wire

models must be used with compatible ULC Listed panels only.

When used with an “i3Ready” control panel or the i3Series C2W-MOD2A

module (refer to installation manual), the C2WTR-BA and C2WTA-BA are ca-

pable of generating a “maintenance needed” signal. The C2W-MOD2A can

indicate a need for cleaning, replacement, or a freeze trouble at the control

panel or module.

The C2W-MOD2A has replaced the previous model number C2W-MODA. To

ensure proper remote maintenance signaling capabilities, do not use the C2W-

MODA with i3model numbers C2WTR-BA and C2WTA-BA.

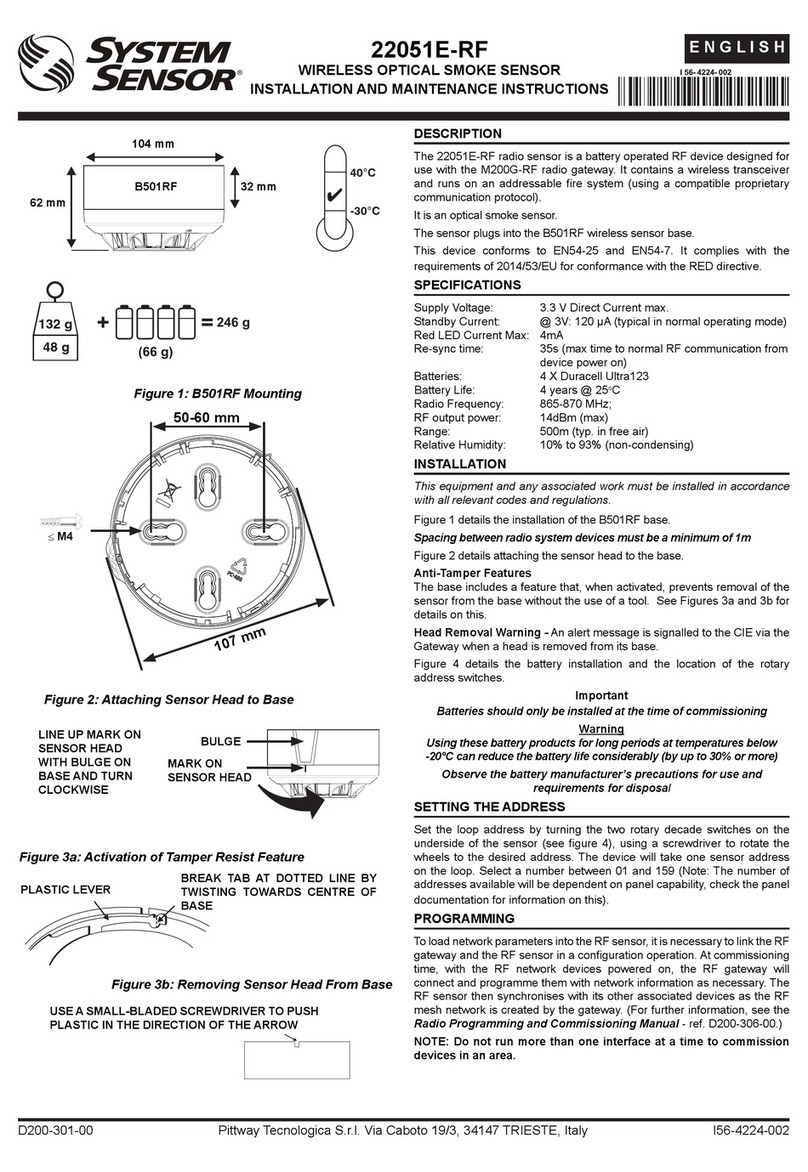

Installation of the C2WTR-BA, C2WTA-BA, C4WTR-BA, C4WTA-BA, C4WTAR-

BA, and C4WITAR-BA detectors is simplified by the use of a mounting base

that may be pre-wired to the system, allowing the detector to be easily in-

stalled or removed. The mounting base installation is further simplified by the

incorporation of features compatible with drywall fasteners.

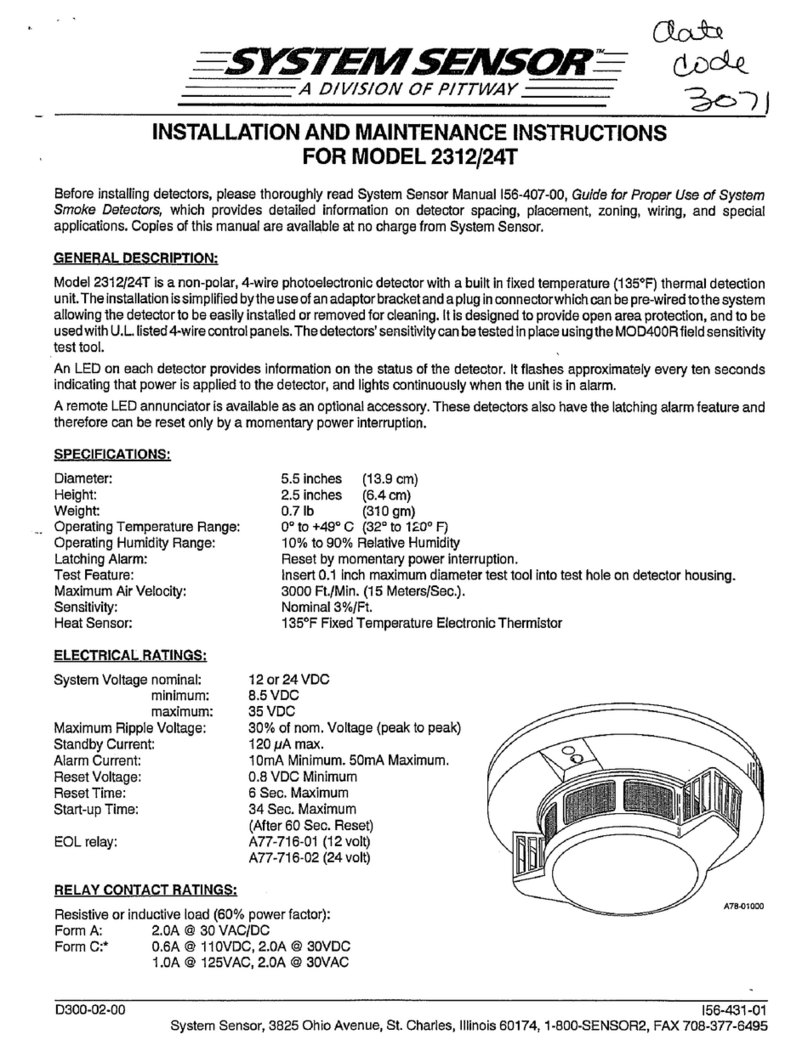

Two LEDs on the detector provide a local visual indication of the detector’s

status:

Table 1: Detector LED Modes

Green LED Red LED

Power-up Blink 10 sec Blink 10 sec

Normal (standby) Blink 5 sec —

Out of sensitivity — Blink 5 sec

Freeqe Trouble — Blink 10 sec

Alarm — Solid

During an initial power-up delay, the red and green LEDs will blink synchronously once

every ten seconds. It will take approximately 80 seconds for the detector to finish the

power-up cycle (see Table 2).

Table 2: Power-up Sequence for LED Status Indication*

Condition Duration

Initial LED Status Indication 80 seconds

Initial LED Status Indication

(if excessive electrical noise is present) 4 minutes

*Refer to Electrical Specifications for start-up time in conjuction with panel alarm veri-

fication.

NOTE: If, during power-up, the detector determines there is excessive electri-

cal noise in the system such as those caused by improper grounding of the

system or the conduit, both LEDs will blink for up to 4 minutes before display-

ing detector status (see Table 2).

After power-up has completed and the detector is functioning normally within

its listed sensitivity range, the green LED blinks once every five seconds. If the

detector is in need of maintenance because its sensitivity has shifted outside

the listed limits, the red LED blinks once every five seconds. When the detec-

tor is in the alarm mode, the red LED latches on. The LED indication must not

be used in lieu of the tests specified under Testing.In a freeze trouble condi-

tion, the red LED will blink once every 10 seconds (refer to Table 1).

To measure the detector’s sensitivity, the i3Series Model CSENS-RDRA Infra-

red Sensitivity Reader tool (see Figure 4) should be used. Refer to instructions

manual I56-2219 for the proper use of the CSENS-RDRA.

Models C2WTR-BA and C2WTA-BA also include an output that allows an op-

tional Model RA400ZA Remote Annunciator to be connected.

Mounting

General spacing guidelines are 30' × 30', with each detector covering 900 ft2

under maximum conditions.

Consult CAN/ULC S524, the local Authority Having Jurisdiction (AHJ), and/

or applicable codes for specific information regarding the spacing and place-

ment of smoke detectors.

Each i3Series detector is supplied with a mounting base that can be ceiling- or

wall-mounted:

1. To a single gang box, or

2. To a 31⁄2-inch or 4-inch octagonal box, or

3. To a 4-inch square box with a plaster ring, or

4. Direct mount or to ceiling using drywall fasteners.

I56-2431-004

3333 Unity Drive, Mississauga, Ontario L5L 3S6

800/736-7672, FAX: 905-812-0771

www.systemsensor.ca