SYX661-CSC Commissioning Guide V1.1 10/2020

Page 2 of 17

Table of Contents

1. INTRODUCTION.......................................................................................................................................................3

1.1 Important Information Regarding Product Safety..........................................................................................4

1.2 Notes on Disposal...........................................................................................................................................4

1.3 INPUTS ............................................................................................................................................................5

1.5 OUTPUTS.........................................................................................................................................................6

1.6 WEB BROWSER CONNECTION..............................................................................................................................7

2 CONFIGURATION OVERVIEW..................................................................................................................................8

3 Equipment Selection and location..........................................................................................................................9

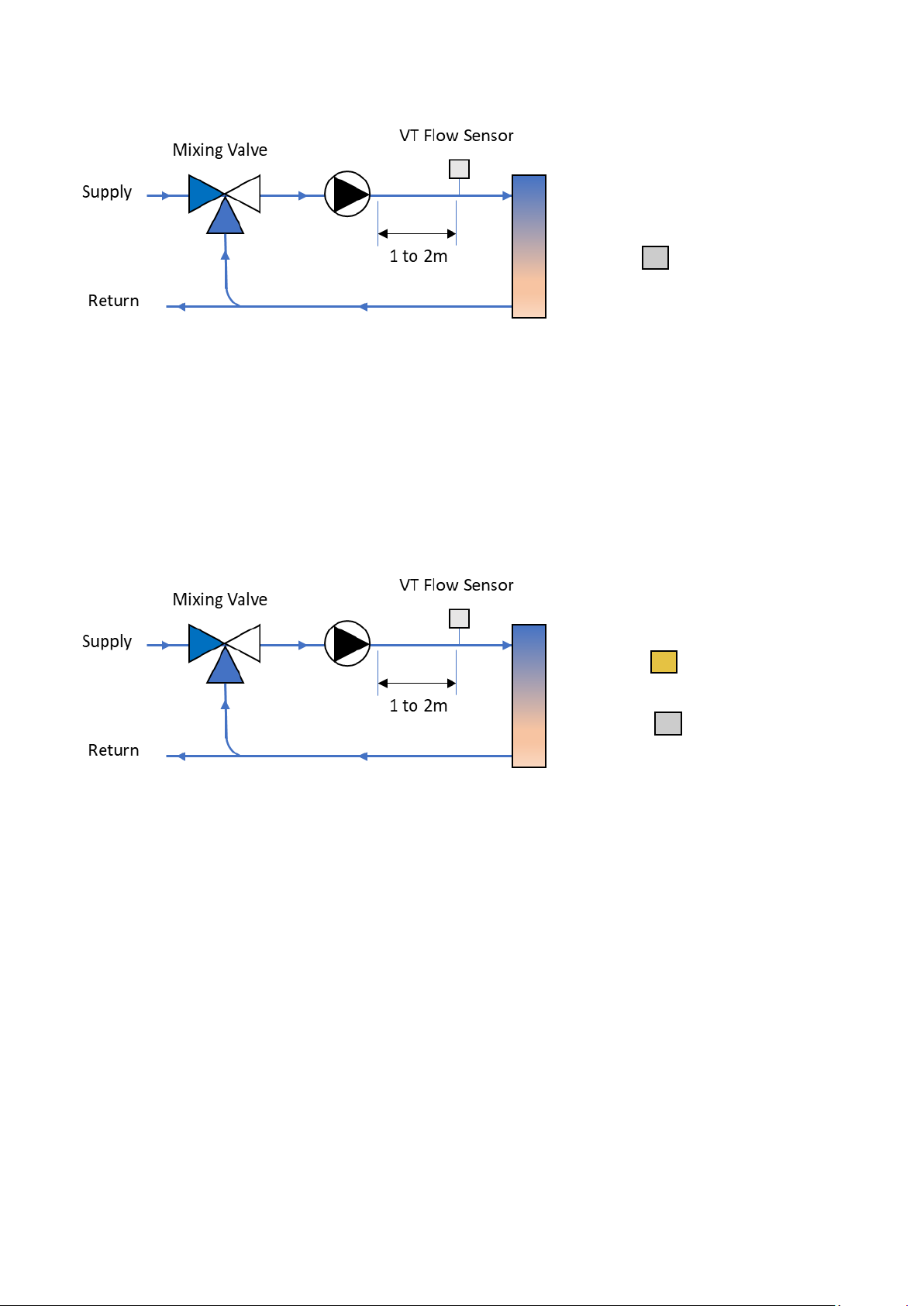

3.1 Heating Application Example (CSC-V) - Valve Control Only .................................................................................9

3.2 Heating Application Example (CSC-V-T)- Pump and Valve Control ......................................................................9

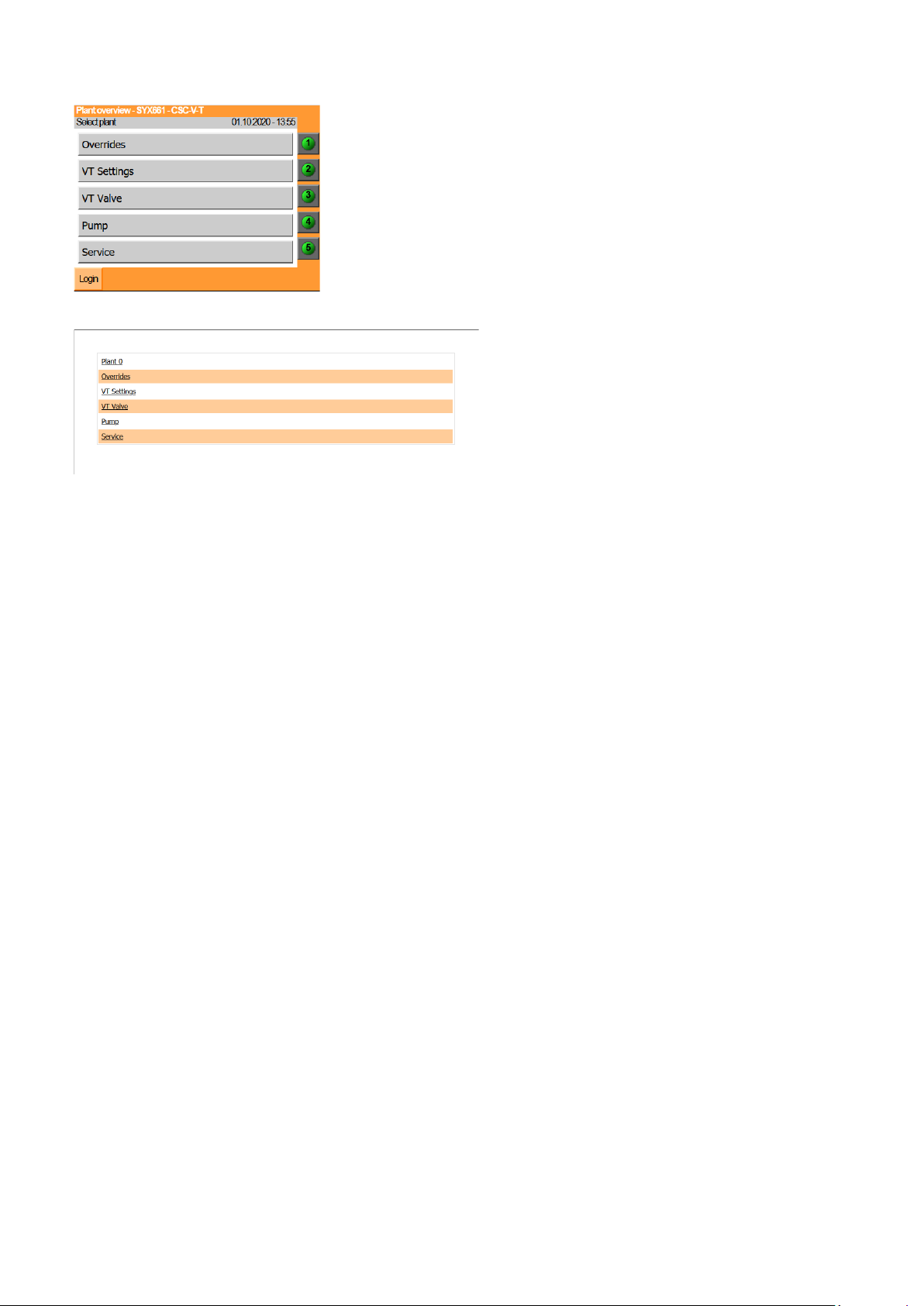

3.2 Access and Controller Configuration....................................................................................................................9

6.1 SYX661-CSC-V-T ............................................................................................................................................11

7. Controller Settings in detail..................................................................................................................................11

7.1 Outside High Limit ........................................................................................................................................11

7.2 Frost Protection (SYX661-CSC-V-T Only) ......................................................................................................11

7.3 Pump Overrun ..............................................................................................................................................11

7.4 Valve Exercise ...............................................................................................................................................12

7.5 Pump Exercise...............................................................................................................................................12

7.6 Heating Time Extension (CSC-V-T)................................................................................................................12

7.7 Summer Winter Time Change and Leap Years .............................................................................................12

7.8 Flow Temperature High Limit.......................................................................................................................12

8. Parameter Summary –CSC-V and CSC-V-T Controllers........................................................................................13

8.1 Connecting with a laptop..............................................................................................................................15

8.2 Passcodes......................................................................................................................................................15

8.3 Factory Defaults............................................................................................................................................15

8.4 Service Level - Sensor Calibration.................................................................................................................15

9. Overrides ..............................................................................................................................................................16

10. Alarms and Management .................................................................................................................................16

10.1 Flow High Limit .............................................................................................................................................16

10.2 Sensor Alarms...............................................................................................................................................16

11. Maintenance and Warranty .............................................................................................................................16

12. FAQ ...................................................................................................................................................................16