3

1 Safety guidelines

Danger: This device is electrically

operated. Incorrect installation or in-

correct repair attempts can cause dan-

ger to life by electrical shock.

Warning: Make sure that, before

wiring work, all lines are at zero poten-

tial! Never touch the wires and connec-

tion terminals of the device. Any

electrically live wiring work or terminal

coupling can lead to destruction of the

device and dangerous electric shock!

Installation and commissioning may

only be carried out by authorized skilled

personnel. Please pay particular attention

to the applicable accident prevention regu-

lations, the relevant standards and regula-

tions, as well as the installation and

operating instructions of additional plant

components. The controller is not repla-

cing any safety related equipment which

might be necessary on site!

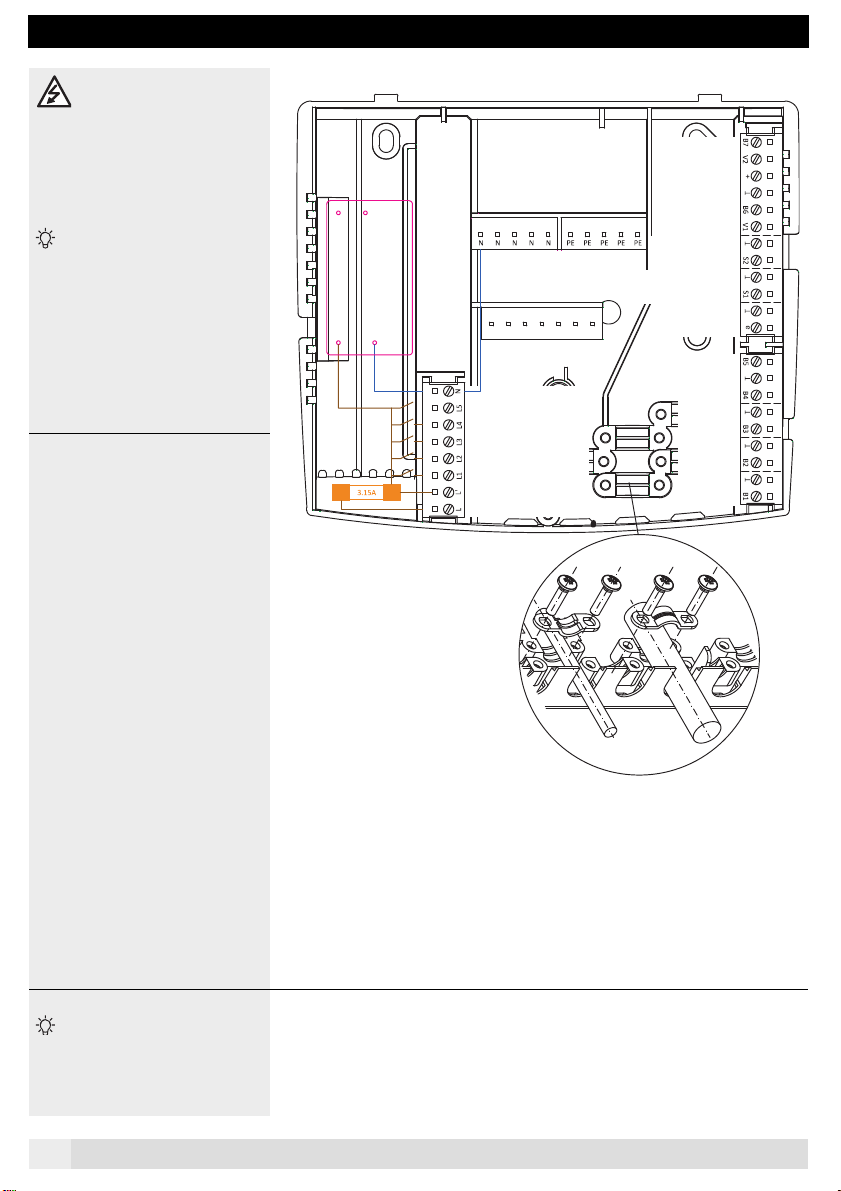

Mains connection regulations:

Electric installation and fusing must com-

ply with local regulations

According to EN 60335, for stationary

devices a separator for switching off

from mains, must be installed in com-

pliance with installation regulations

(a switch for example)

The distance or the insulation from

any potential heat source must be

chosen such that the allowed ambient

temperature during operation is never

exceeded. (See technical data)

Device wiring from sensors, room de-

vices, operating devices, communica-

tion bus etc. should be separated

spatially from high voltage lines

It may be necessary to electrically

suppress strong inductive loads in

the vicinity of the controller (contac-

tors, solenoid-operated valves, etc.).

This can be done by connecting RC

circuit directly to the coil terminals of

the disturbing components.

Recommended RC circuit:: 0.047 mF,

275 VAC.

Operating requirements:

Under normal conditions the device must

be powered continuously, to ensure ope-

ration at all times. Preceding switches

should therefore be limited to emergency

or main switches that are permanently

"on".

Danger: Never connect or reconnect

an electrically live device or operate

device when open. Never run device in

a potentially explosive environment.

Never mount device on a flammable

underground. Never run device above

or below limit values as listed under the

technical data. When it’s expected that

a safe operation isn’t possible anymore

then immediately shut down device.

(For example when damage or mal-

function is obvious)

Operating instructions:

The mounting and operating instruction

provides fundamental advice and im-

portant information concerning safety,

mounting, commissioning, maintenance

and optimal use of the device. These de-

vice instructions should be completely

readand followed by installer, specialist

and plant operator before mounting, com-

missioning and operating.

All hydraulic schemes illustrated in

this manual only indicate the principle

diagrams; they do not replace a pro-

fessional installation design, which is

why in case of direct reproduction

functionality can not be guaranteed!

Technical descriptions can change wi-

thout prior notice. Possible misprints

or intermediate changes of any kind do

not entitle to any claims.

For the operator:

Let yourself be instructed by the specialist

extensively about functionality and opera-

tion of the controller. Always keep this ma-

nual near to the controller.

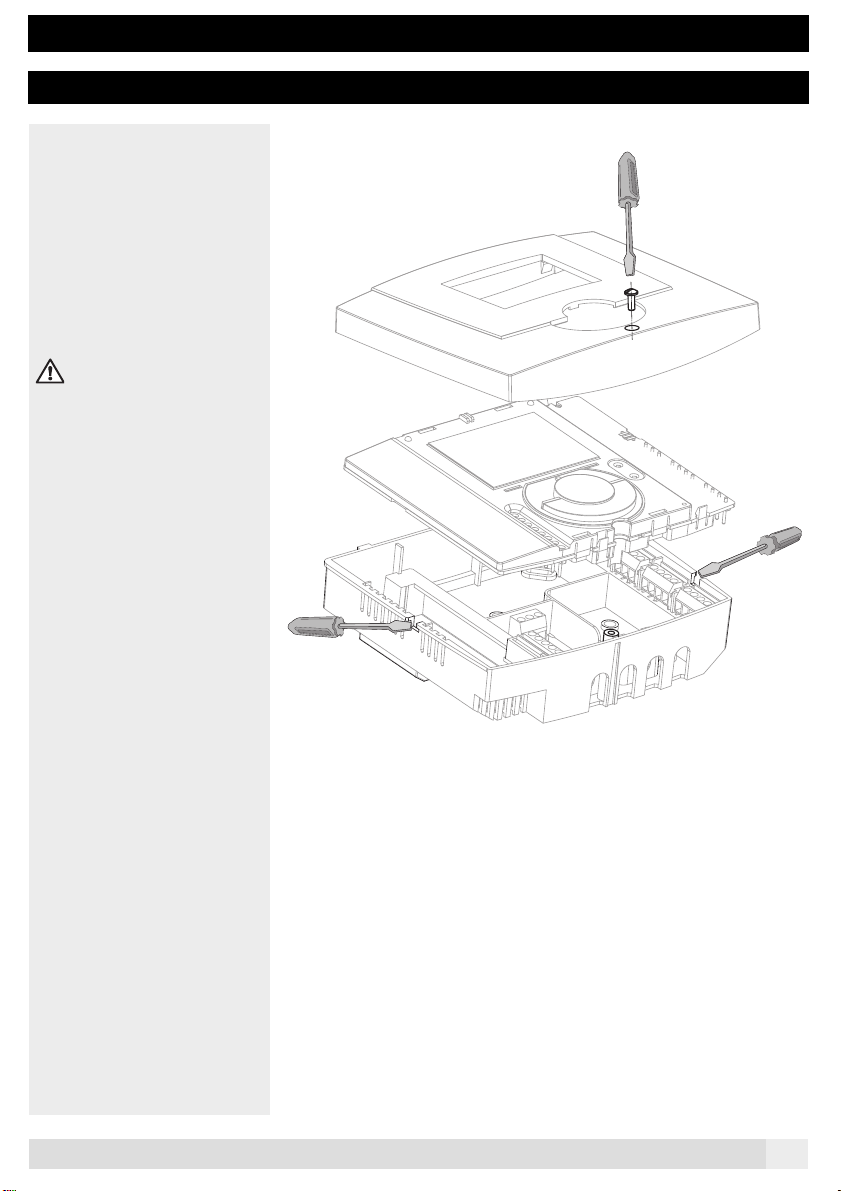

Warranty and liability:

Refrain from opening device or accesso-

ries. Repairs may only be carried out by

manufacturer. Only genuine parts and ac-

cessories may be used. Warranty claims

expires in case of improper installation,

commissioning, maintenance and repair of

the device, disregard of these mounting

and operating instructions or unintended

or misuse of the device.

Device settings:

By means of the integrated long-term

memory, individually entered installation

parameters as switching times remain

stored after RESET or longer power down

periods, guaranteeing reliable operation

over many years.

Declaration of conformity:

If all applicable installation and manu-

facturer instructions are taken into consi-

deration then this device complies to the

requirements of the relevant guidelines

and standards.

Waste disposal:

The device complies with the Euro-

pean ROHS directive 2002/95/EG for the

restriction on the use of certain hazardous

substances in electrical and electronic

equipment.

Under no circumstances should this

device be disposed with household waste.

The device should only be disposed at

specific waste collection points or at the

distributor.