TALEX Sp. z o.o.

ul. Dworcowa 9c

77-141 Borzytuchom

tel.: +48 59 821 13 40

www.talex-sj.pl

3

TABLE OF CONTENTS

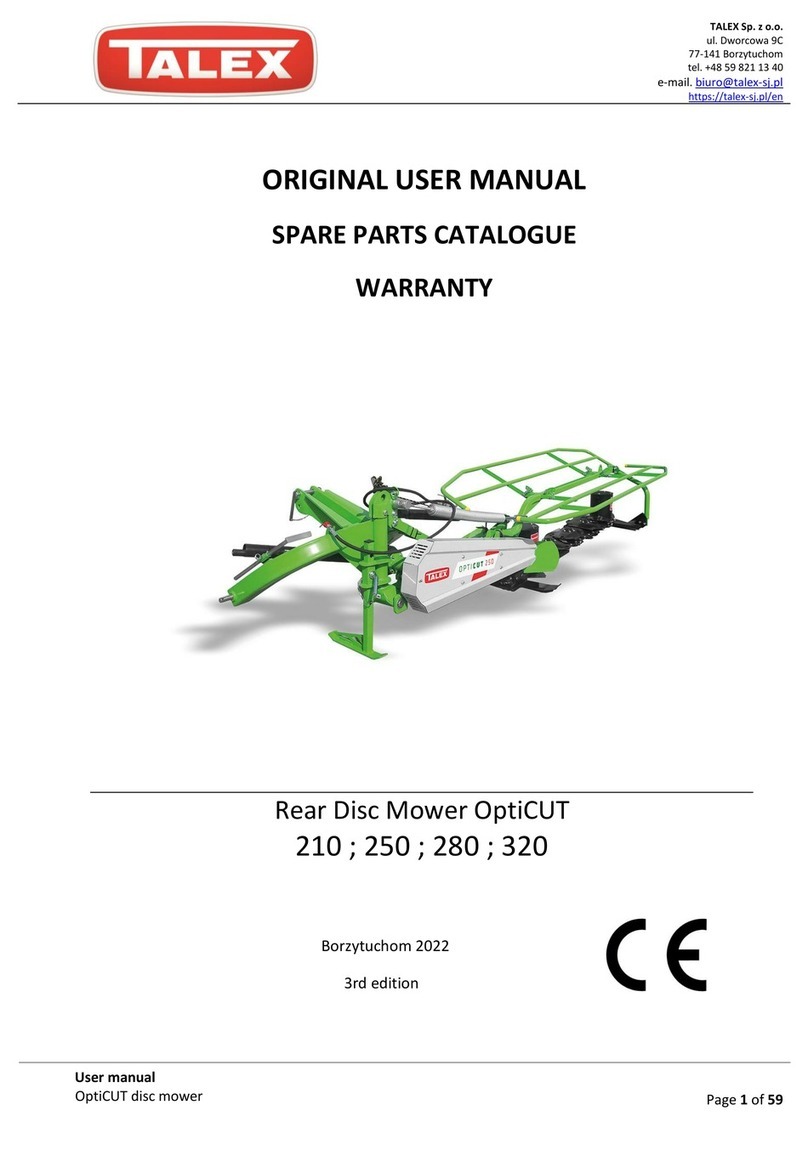

1. Machine identification ..................................................................................................................... 5

2. Introduction ................................................................................................................................... 6

Read the manual ...................................................................................................................... 6

2.1.

Intended use ........................................................................................................................... 6

2.2.

Warranty ................................................................................................................................. 7

2.3.

3. Health and safety rules .................................................................................................................... 7

General safety rules .................................................................................................................. 7

3.1.

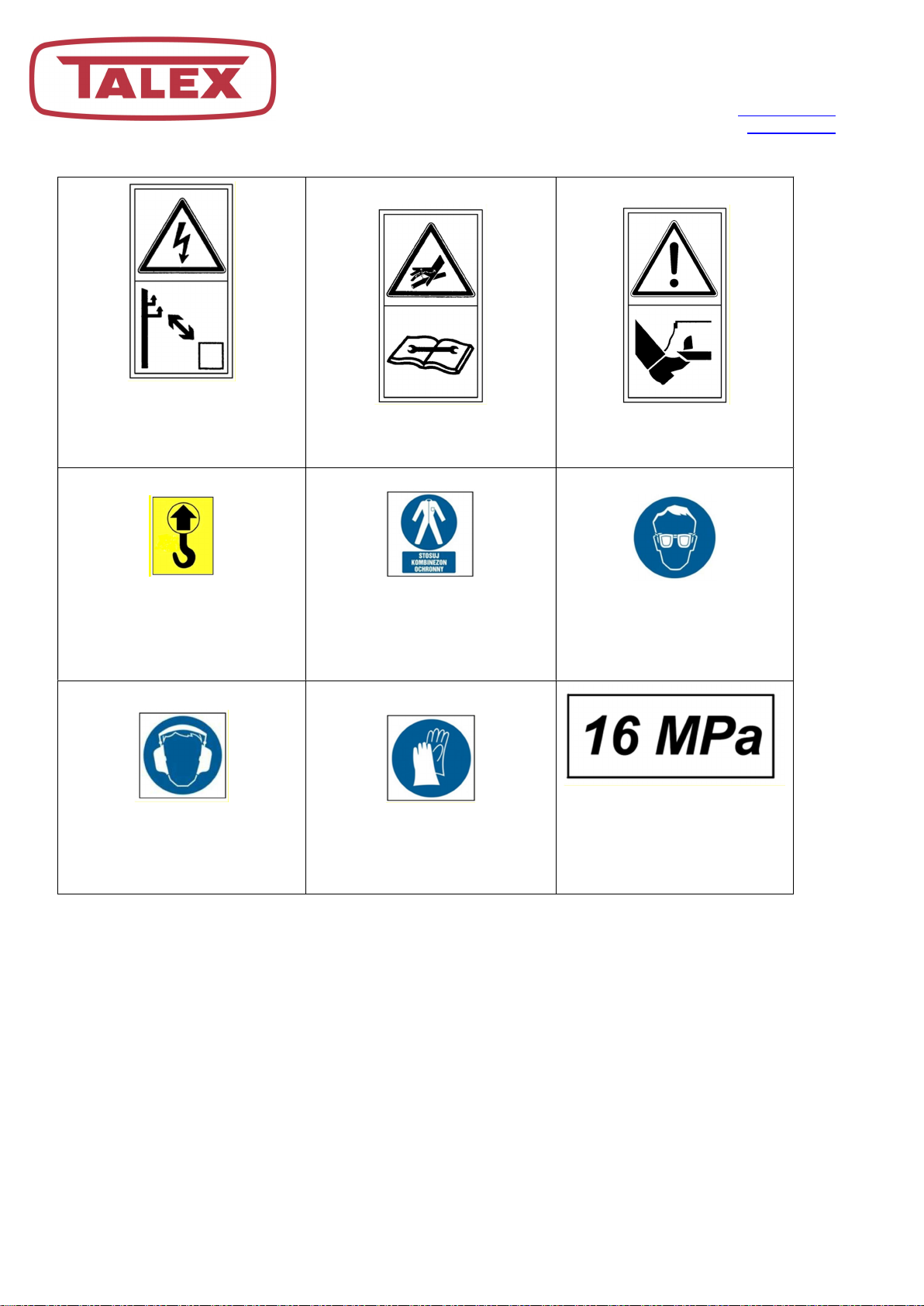

Safety signs on the machine .................................................................................................. 9

3.2.

Threats occurring during the use of the mower .................................................................... 11

3.3.

Working parts of the machine .................................................................................................. 12

3.4.

Machines linked with three point hitch ..................................................................................... 12

3.5.

Machine unlinked from the tractor ........................................................................................... 12

3.6.

Work with the PTO shaft ......................................................................................................... 12

3.7.

Service .................................................................................................................................. 13

3.8.

Technical specification ............................................................................................................ 14

3.9.

Construction and operation ................................................................................................. 15

3.10.

4. Usage ........................................................................................................................................... 16

Linking the machine with the tractor, setting and adjusting the height. ........................................ 16

4.1.

Work .................................................................................................................................... 17

4.2.

5. Recommended machine maintenance ............................................................................................. 18

Greasing ................................................................................................................................ 18

5.1.

V-belts tensioning .................................................................................................................. 19

5.2.

Replacing the flail hammers ................................................................................................. 20

5.3.

6. Technical inspections, storage and utilization ................................................................................... 21

Storage ................................................................................................................................. 22

6.1.

Disassembly and utilization ..................................................................................................... 22

6.2.

7. Spare parts catalogue ................................................................................................................. 23

General machine construction ............................................................................................. 24

7.1.

Working shaft ....................................................................................................................... 26

7.2.

Contour following roller ECO 100, 135, 150 ......................................................................... 27

7.3.

Contour following roller ECO 180, 200, 220 ......................................................................... 28

7.4.

Rear curtain ......................................................................................................................... 29

7.5.

Skids .................................................................................................................................... 31

7.6.

V-belt gearbox cover ECO 100/135/150 .............................................................................. 32

7.7.