TALEX Spółka z ograniczoną odpowiedzialnością

Spółka komandytowa

ul. Dworcowa 9c

77-141 Borzytuchom

tel. (59) 821 13 40

www.talex-sj.pl

Page 2of 76

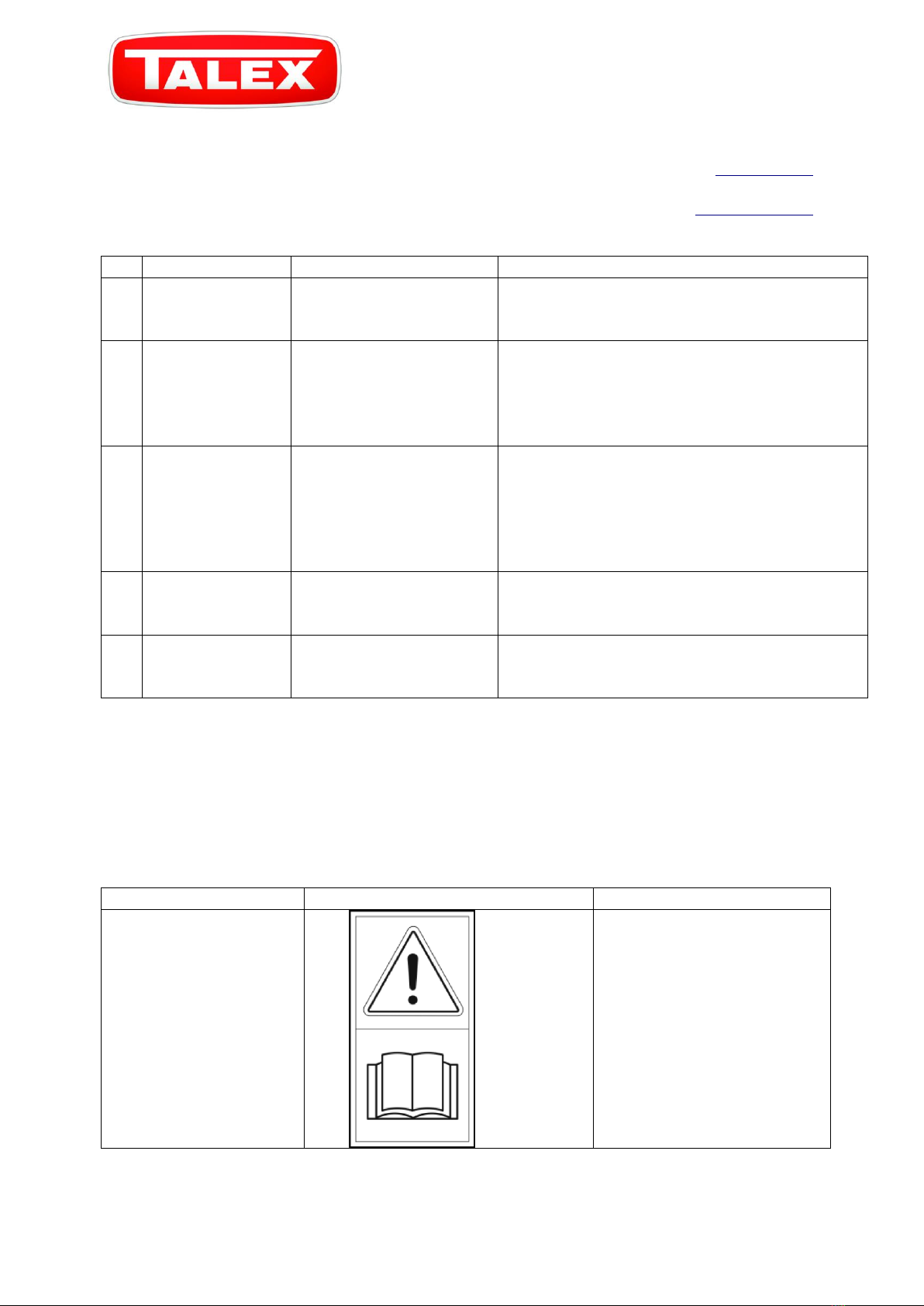

2. Sweeper identification ........................................................................................................................................ 4

3. Intended use ....................................................................................................................................................... 5

4. Safety rules at work............................................................................................................................................. 5

4.1 Usage of Sweeper.......................................................................................................................................... 5

4.2 Connection and disconnection of sweeper................................................................................................... 6

4.3 Hydraulic installation..................................................................................................................................... 7

4.4 The sweeper’s transport ............................................................................................................................... 7

4.5 Maintenance ................................................................................................................................................. 8

4.6 Working with the machine............................................................................................................................ 8

4.7 The description of residual risk ..................................................................................................................... 9

4.8 Information and warning labels .................................................................................................................. 10

5. Design and Operation ....................................................................................................................................... 12

5.1 Basic technical data..................................................................................................................................... 12

5.2 General design of sweeper.......................................................................................................................... 15

5.3 Construction and operation of the hydraulic system.................................................................................. 16

5.3.1 Version with side brush and hydraulic dustbin.................................................................................... 16

5.3.2 Version with two side brushes and hydraulic dustbin ......................................................................... 17

5.3.3 Version with side brush and maual dustbin......................................................................................... 18

5.3.4 Version with hydraulic dustbin ............................................................................................................ 20

5.3.5 Standard version .................................................................................................................................. 21

5.4 Desing and operations of sprinkler system ................................................................................................. 22

6.Preparing for work ............................................................................................................................................. 24

7. Proper installation of the sweeper.................................................................................................................... 24

7.1 Roller brush ................................................................................................................................................. 24

During the installation of the roller brush pay attention to the same setting of push on the whole length of

the roller. Uneven installation causes faster wear of the roller brush. ........................................................ 25

7.2 Dustbin ........................................................................................................................................................ 26

7.2.1 Manual emptying of dustbin................................................................................................................ 27

7.2.3 Sweeper’s work without the dustbin ....................................................................................................... 27

When using the dustbin with hydraulic emptying ........................................................................................ 29

7.3 Side brush.................................................................................................................................................... 29

7.5 Third supporting wheel ............................................................................................................................... 30

8. Maintenance and replacement of parts ........................................................................................................... 31

8.1 Assembly and disassembly of roller brush .................................................................................................. 31

8.1.1 Hydraulic engine: ................................................................................................................................. 31

8.1.2 Bearing unit:............................................................................................................................................. 31

8.2 Installation and replacement of side brush................................................................................................. 33

Table 8..................................................................................................................Błąd! Nie zdefiniowano zakładki.

9. Defects and methods of repair ......................................................................................................................... 33

10. Lubrication points ........................................................................................................................................... 35

11. After season maintance .................................................................................................................................. 36

12. Disassembly, scrapping and environment protection..................................................................................... 36

12.Warranty .......................................................................................................................................................... 74