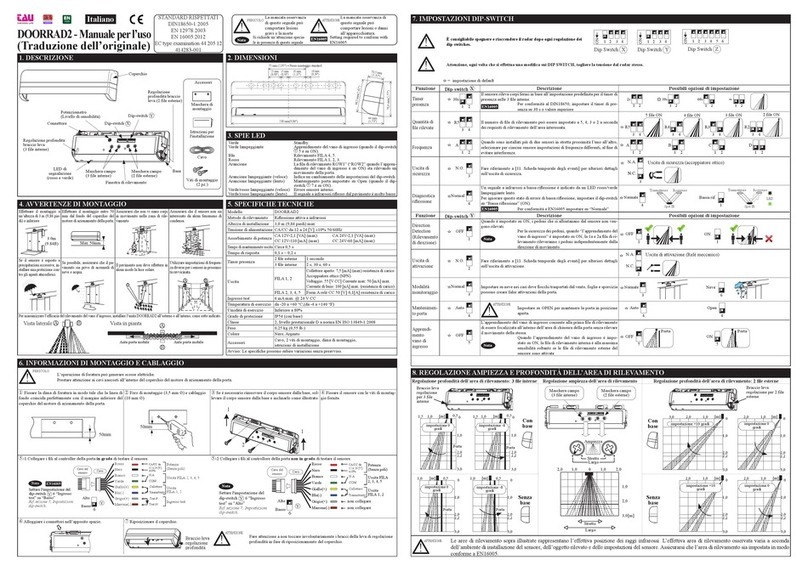

tau DOORSS User manual

1. General Description / Features

2. Components

3. Mounting and Wiring Information

3.1. Notice CAUTION

WARNING

!

1 2 3

Do not mount the

sensor higher than

2.6 [m]( 8' 6" ).

Do not mount the

sensor where rain or

snow will fall directly

on the unit.

Ensure the minimum

of reflected sunlight

from the floor.

Ensure no condensation

gets onto the sensor.

4

The Aluminum

Case(s) should be

located close to the

Leading edge of the

door to maximise

safety detection.

5

3.2 Mounting Hole

3.3 Mounting the Aluminum Case

1) 2)

12

34

3.5 Wiring to the door controller

Install the Jamb Hole Cover and Wire Sheath when wiring to the door controller.

Connect the wires to the

door controller using the

Terminal Block

Drill following holes. Clamp the Wire Sheath between the Jamb Hole Cover A/B

Unit : [mm]

30

10 15

Screw Holes

Wiring Hole

CAUTION

!

Length

[mm]

Filter

Cover

Installation

Instruction

Wire Sheath

600 [mm]

(1) (3)

(2)

Mounting

Screws

4×16 [mm]

(5)

Mounting

Screws

3x10 [mm]

Jamb Hole

Cover A/B

Accessories

Before mounting this sensor please note the following remarks.

!

2,6 [m]

Joint

3 - φ2,6

φ10

English

Note

WARNING

!CAUTION

!

EN16005

Model name

3.4 Replacing the PCB unit(s)

CAUTION

!

1

Side Cover-L

Side Cover-R

Filter Cover

Aluminum Case

Screw

Screw

PCB unit

Hinge

Hinge

Leading edge Leading edge

<Top view>

torque

0.5 Nm

Infrared

Beam

Infrared

Beam

Hinge

2

Power supply ( AC/DC 12〜24[V] )

Relay Output ( Common )

Relay Output1

Relay Output 2(Another PCB Unit Output)

TEST Input ( - )

TEST Input ( + )

2

3

4

1

5

6

7

1

7

PCB unit

Note

Wires to

the controller

Jamb Hole

Cover A

Wire Sheath

Wire size

0.15 to 3.5 [mm2]

Screw (3×10 [mm])

Jamb Hole

Cover B

Push SW

Angle Stabilizer

PCB Holder

PCB unit

PCB unit Assembly

LEADING

EDGE

MARK

LEADING EDGE MARK

LEADING EDGE MARK

Unit : [mm]

390 390

DOORSS1023T

3-φ3,5

Screws

Joint

6Be careful not to drop the sensor, during transportation and installation. It may cause the sensor to break.

Fix the Aluminum Case to the door with

Screws.

Front view of PCB unit

Dip SW

Terminal Block

Operation LED

Communication Cable

(4)

4. Dip Switch Settings

PCB unit

=

4.1 TEST Input

21 3 4 5 6 7 8

To avoid dangerous door movements,

configure the DIP-SW settings of the sensor

before powering up the sensor.

When connected to a door controller without a

TEST input, set to “A”. When connected to a

door controller with a TEST input, set to “B”

Refer to [6.Timing Chart of events].

When two DOORSS's are installed in close proximity ,

optical cross interference between DOORSS's might

cause mis-operation. To avoid this , different frequency

settings should be selected using DIP Switch #2.

1

A

Senza TEST

Con TEST

0v

B

Senza TEST

0v

B

A

Set to “B” to comply with EN16005

4.2 Optical Interference DOORSS DOORSS

A

2

B

2

21 3 4 5 6 7 8

4.5 Detection Range

4.3 Relay Output Mode

Refer to [6. Timing chart of events]

for full details on Relay Output Mode.

3

NO NC

21 3 4 5 6 7 8

3

Set Non-Detection

distance A

21 3 4 5 6 7 8

5. Detection Angle Adjustment

Angle Stabilizer

PCB unit

5゜

The detection angle can be adjusted between 5〜25 [deg] in 5 [deg] increments using the Angle Stabilizer.

Example) Changing angle from 5°to 25°

Side View

5゜25゜

20゜

15゜

10゜

1.

(1)Lift (3)Rotate PCB unit (4)Slide Back

(2)Slide

2. 3.

25゜

21 3 4 5 6 7 8

67

50 mm

100 mm

150 mm

200 mm

250 mm

300 mm

400 mm

500 mm

Check that the detection area position conforms to EN16005

5

EN16005

Check that the detection

range conforms to EN16005

EN16005

EN16005

8

6 7 8

678

678

678

67 8

6 7 8

6 7 8

Door Leaf

Detection

Non-Detection A

4.4 Masking detecting

spots 45

1

2

3

4

5

6

spots

spots

spots

spots

4 5

1

2

3

4

5

-

45

1

2

3

4

-

-

4 5

1

2

3

-

-

-

3.6.1 Option 1: Plan View of SSS-5 Installation

(PCB units on both sides of the door wired back to the Door Controller independently)

PLAN VIEW and Wiring

Wire Sheath

Door Controller

Door Controller

Hinge

Hinge

Jamb Hole Cover

Jamb Hole Cover

Leading

Edge

Leading

Edge

Extra Wire Hole through the door

Connector 6P

Unità PCB 1

Unità PCB 2

7P Terminal stand

(Unused)

7P Terminal stand

PCB units are connected to each other

using the Communication Cable

(supplied)

Slide SW

「OFF」

Hole( 」 φ10) drilled through the

door.

3.6.2

Option 2: Plan View of SSS-5 Installation

(PCB units connected using Communication Cable and only 1 PCB units is wired back to the Door Controller)

「ON」

「OFF」

「OFF」

Note: Remember to set the Slide SW as indicated

Default Setting

BORDO DI

CHIUSURA

Slide SW

User Manual (Original)

DOORSS

Safety Sensor for

Swing Doors

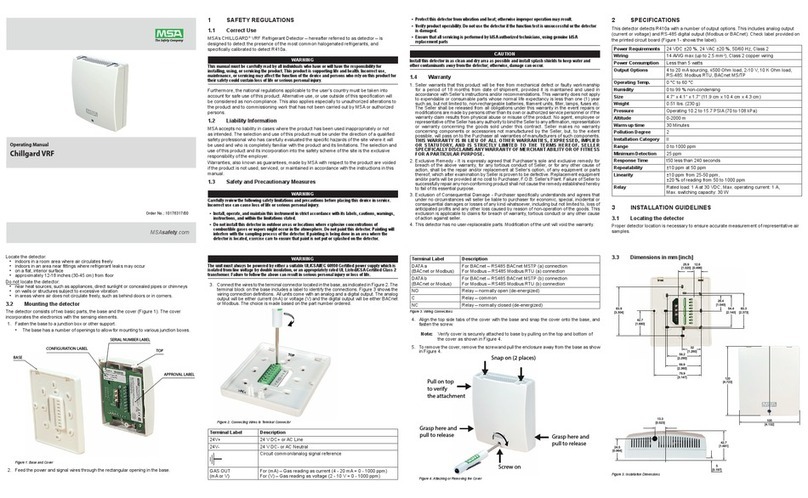

The DOORSS is a microprocessor controlled active infrared presence detector for swing doors.

- 6 detection spots per PCB unit provide a wide detection area.

- The detection distance to the floor is set automatically by pressing a Push Switch.

- The detection range can be adjusted manually, using dip switches in increments of 50mm

- The relay output can be changed from NO to NC using a dip switch.

- Self diagnostic and monitoring functions are implemented.

The illustration below shows the standard configuration of DOORSS with one PCB units.

Table.1 Information of DOORSS

!

COMPLIED STANDARDS

DIN18650-1:2010

EN 12978:2003 +A1:2009

EN16005:2012

EC type examination

44 205 13738001

Disregarding this symbol may result

in serious injury or death

Special attention is required when

this symbol is shown

Disregarding this symbol may result

in injury or damage to equipment

Setting required to conform with EN16005

Drill fixing holes as illustrated

below. When installing the

DOORSS on both sides of the

door it may be necessary to drill

a wiring hole through the door.

(Ref. 3.6 Plan View of DOORSS

Installation)

Drilling may cause Electric shock! When drilling, pay attention to

hidden wires.

Unscrew the Side Covers and remove the Filter

Cover.

Remove the PCB Unit. Loosen the Screw on the PCB Holder and slide it

aside to remove the PCB Unit.

When replacing the PCB unit it is very important that the side with "LEADING EDGE" marked on it is inserted

so that it is closest to the leading edge of the door. This will ensure maximum pedestrian safety at the door

edge.

Remove the Terminal Block from the PCB unit.

Insert the PCB unit into the Aluminum Case, making sure that the

side marked “LEADING EDGE” is closest to the leading edge of the

door.

Attach the Angle Stabilizer and tighten the screws on the PCB

Holders.

Remove Angle Stabilizer.

1)Lift and slide the Angle Stabilizer to the side as indicated.

2)Push the Angle Stabilizer with your thumb to remove it from

the Aluminum Case.

Leading Edge

Leading Edge

PCB unit

Hinge

PCB Unit 2

7P Terminal

stand

PCB Unit1

7P Terminal

stand

S-10DOORSS340 / DOORSS1023T

S-10DOORSS340 0 2340 1

S-10DOORSS1023T 2 31023 3

DOORSS340

2-φ3.5 Screw holes

200

State Red LED

Red LED

Red LED

Green LED

Green LED

Green LED

Non-Detect ON

ON

OFF

7. LED information

2

34

Cut out the Side Cover wiring point and insert the

Wire Sheath into it.

Attach the Side Cover with

Screws provided.

14. Dimensions

Screw

6. Timing chart of events

Relay Output / Test Input

DETECTION as

response to TEST

POWER OFF NO DETECTION NO DETECTIONDETECTION

TEST RESPONSE

T

Test Input

NON-TEST NON-TEST

TEST

B

Dip Switch #3

Dip Switch #1

T : 8 to 18 [mSec]

Test Input

Relay Output Mode

Interromperelacorrente

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

T

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

COM

NC

NO

NC

A

6

7

6

7

6

7

Supplying DC12 to 24V,

make current flow from

7th terminal to 6th.

Sensor

Sensor

Sensor Sensor

SensorSensor

6

7

6

7

6

7

12. Final Detection Range Check

After the Filter Cover is fitted, confirm that the detection range is as expected

and conforms with local regulations.

13. Technical Data

MODEL

TECHNOLOGY

POWER SUPPLY

CURRENT

CONSUMPTION

RELAY OUTPUT

TEST INPUT OPERATING

TEMPERATURE

MOUNTING HEIGHT

DETECTION RANGE WEIGHT

95 [mA] a DC12[V]

55 [mA] a DC24[V]

1.7 [VA] a AC12 [V]

2.3 [VA] a AC24[V]

OPTO RELAY 1A (NON POLE)

DC 50[V] 0.1[A] (RESISTANCE LOAD)

RESPONSE SPEED

DIP SW FUNCTIONS

TEST INPUT : 1 [BIT]

OPTICAL INTERFERENCE : 1 [BIT]

RELAY OUTPUT MODE :1 [BIT]

MASKING DETECTING SPOTS:2[BIT]

DETECTION RANGE:3[BIT]

LESS THAN 100 [mSec]

AC/DC 12〜24[V] ±10% BEAM ANGLE

ADJUSTMENT 5 , 10 , 15 , 20 , 25 [degrees]

COMPLETE STATIONARY DETECTION with PSD DISTANCE MEASUREMENT

2,6 [m] max

0 - 2,55 [m] Max

-20 〜+60 [゜C]

6 [mA] max. a 24 [V CC]

OFF

7-1 Normal state

Detect PCB unit

7-2 Error state

Cause

“N”

times

N

1

3 over

Error category

Environmental error

Environmental noise or the

reflection level from the floor is

too low.

Execute the “TEACH” from

Section 8 whilst laying a sheet

of white paper on the floor.

Other Error Internal component failure Change the units.

7-3 Teaching state See Section 8

8. Teaching

Conduct the following steps with the Filter Cover off.

1) Check the wiring connection and supply power.

2) Execute “TEACHING”

“TEACHING” is necessary to make the sensor work properly, that is to learn the distance from

the sensor to the floor.

STEP 1.

Press the “Push SW" switch

for more than 2 seconds.

STEP 2.

LED blinks slowly for 10 sec’s in a non-detection

state. Ensure that there are no people or objects

(ladder etc) in the detection area during this time.

STEP 3.

After STEP2, LED blinks faster and starts " TEACHING". If during

this time, a person or object is in the detection area, try again from

STEP 1.

STEP 4.

After STEP3, the green LED blinks once and then this process is

completed.

9. Detection Area

9.1 FRONT VIEW 9.2 SIDE VIEW

2000

2600 400 200 0

600

1000 1000

2000

2600 400 200

6008001000 0

5

25

10. Detection Range Check without Filter Cover

Check the detection range without the Filter Cover attached.

Put a test object in the detection area to check the detection patterns and other Dip Switch

settings. Tests according to local standards should be carried out.

After this check, Turn power off.

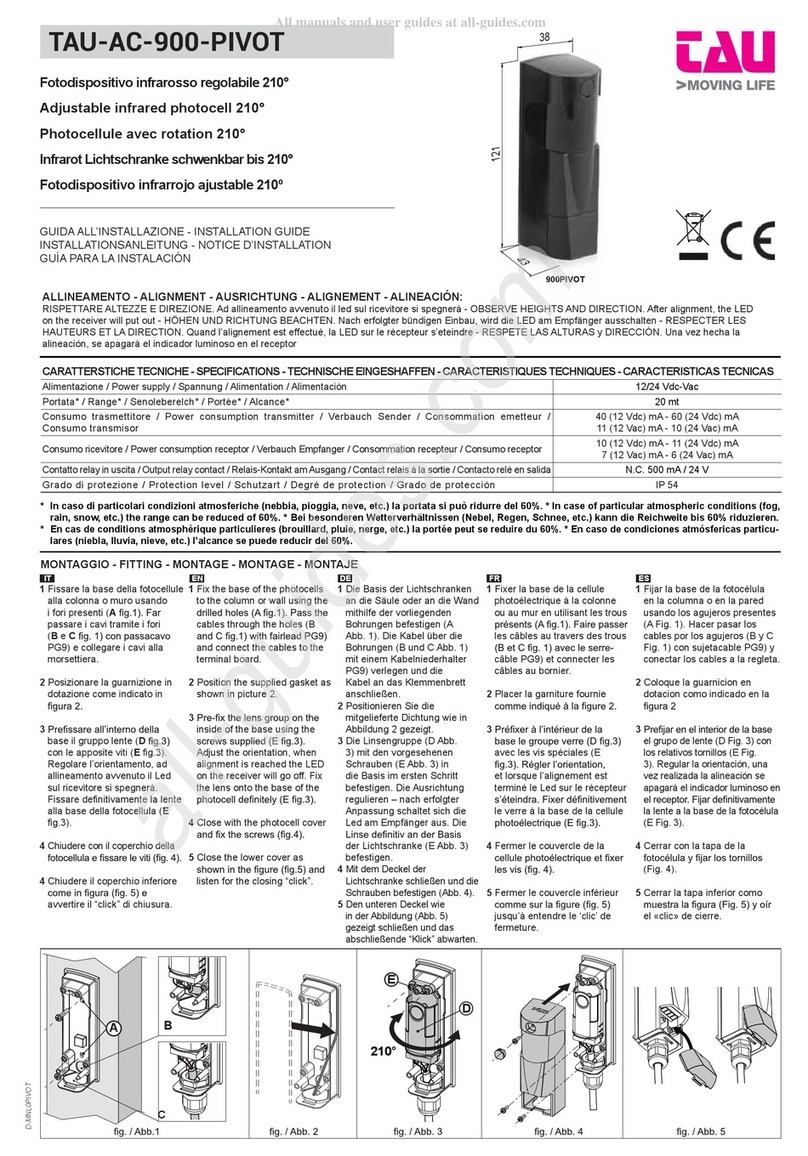

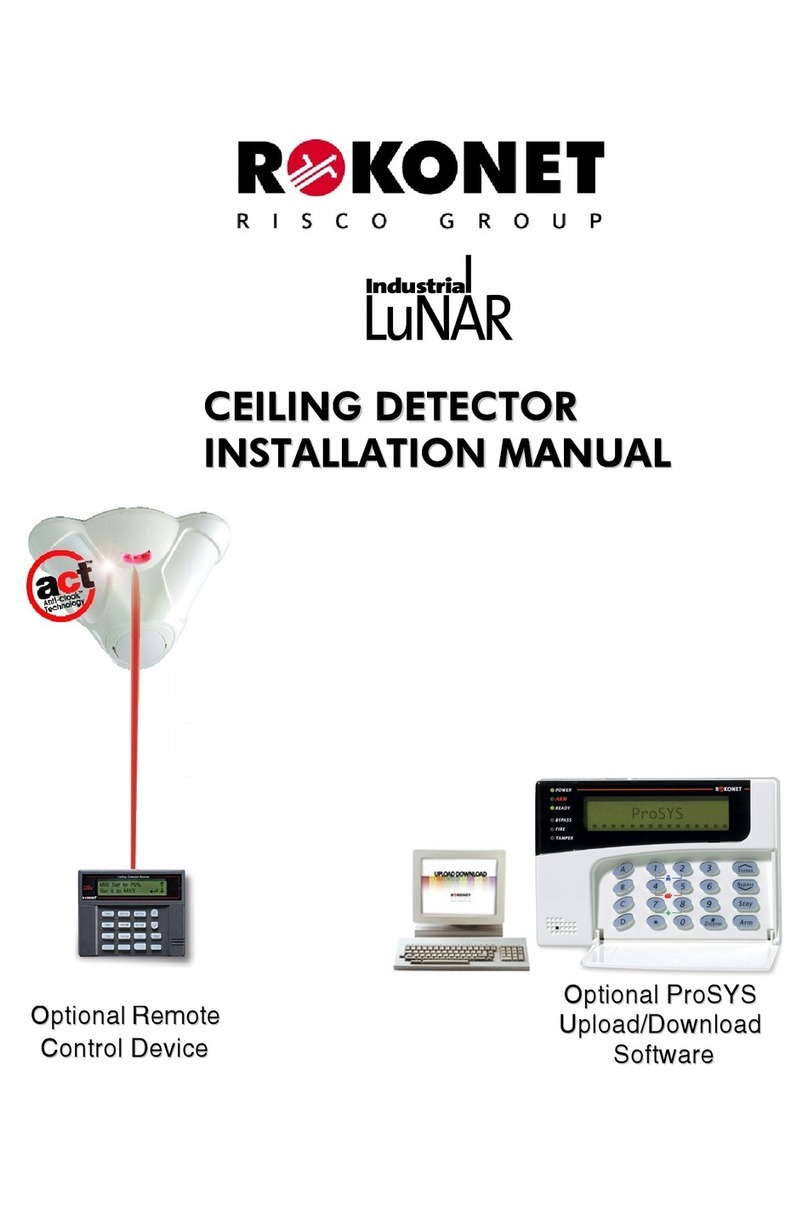

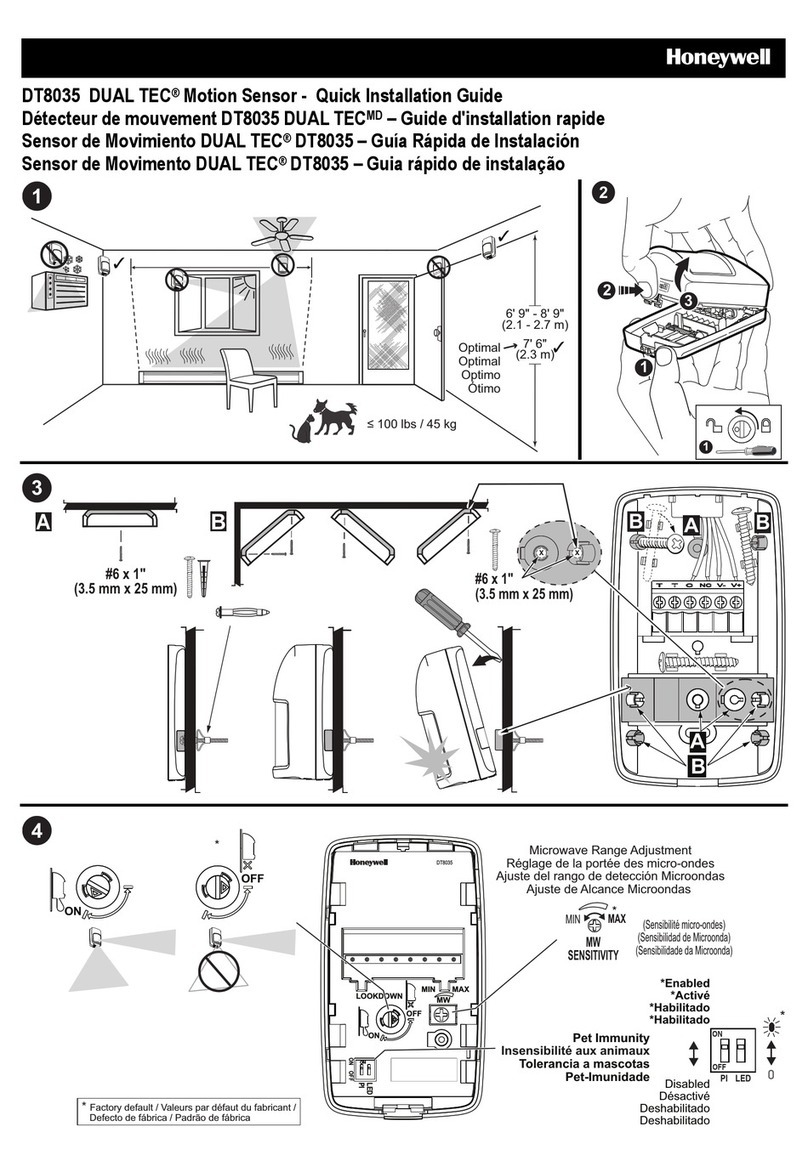

Description of Product:

DOORSS Safety Sensor for Swing Doors .

Complete stationary detection with PSD distance measurement.

15. EC DECLARATION OF CONFORMITY

Check that the detection area conforms to EN16005

When the test is completed, go to Section 11 to install the Filter Cover and Side Cover.

If an error occurs, re-check the settings referring to Section 3.

EN16005

Check that the detection area conforms to EN16005EN16005

1200

Check the adjustments , range and other setting.

3

Date

Unit: [mm]

11. Replacing the Filter Cover and Side Cover

1CAUTION

!

Be careful not to obstruct

the optical components

with wires.

800

1000

1) First fit the upper side of the Filter Cover into the full

length of the Aluminum Case.

2) Slightly bend the Filter Cover at one end to latch

it onto the bottom lip of the Aluminum Case.

3) Slide your hand along the bottom lip to lock the Filter Cover

onto the Aluminum Case all along the length of the Aluminum

Case.

1) Snap the Joint into the Aluminum Case.

2) Slide the Joint so that it fits snugly into the Filter Cover. Make sure there are no gaps left.

3) Attach remaining Filter Covers as illustrated

123

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

5

3

4

Safety Sensor for Swing Doors DOORSS

Compiler of Technical File (EC Community)

Loris Virgilio Danieli

TAU S.r.l. - Via E. Fermi, 43 - 36066 Sandrigo (VI) - IT

Tel: +39 0444 750190 - Fax: +39 0444 750376

Declaration made by

Loris Virgilio Danieli

Location of Declaration

(Manufacture)

TAU S.r.l..

Via Enrico Fermi, 43

Sandrigo (VI), Italia

05-02-2018

D-MNL 0DOORS S

TAU S. r.l.

Via Enrico Fermi, 43

36066 Sandrigo (VI) - Italy

e-mail: [email protected]

Tel.: +39 0444 750190

Fax: +39 0444 750376

www.tauitalia.com

Solution

Red LED

Green LED

Red LED

Green LED

Red LED

Green LED

Attaching the Joint

Directives Fulfilled:

DIRECTIVE 2006/42/EC Machinery Directive

DIN 18650-1:2010 Powered pedestrian doors Part 1: Product requirements. Chapter 5.7.4

EN12978:2003 +A1:2009 Industrial, commercial and garage doors and gates - safety devices for power operated doors

and gates - Requirements and test methods.

EN62061:2005 Functional safety of electrical/electronic/programmable electronic safety-related systems.

EN ISO 13849-1:2008 /AC:2009 Safety of machinery - Safety-related parts of control systems.

EN 16005:2012 Power operated pedestrian doorsets - Safety in use - Requirements and test methods. Chapter 4.6.8

EC type examination No. 44 205 13738001

Above EC Type Directives Certified by:

TUV NORD CERT GmbH

Langemarckstr.20 45141 Essen Germany

Harmonized Standards

Used:

EN ISO 13849-1:2008/AC:2009

Other Technical Standards

Used:

DIN 18650-1:2005

EN16005:2012

<Disclaimer> The manufacturer cannot be held responsible for the below.

1. Misinterpretation of the installation instructions, miss connection, negligence, sensor modification and inappro-

priate installation.

2. Damage caused by inappropriate transportation.

3. Accidents or damages caused by fire, pollution, abnormal voltage, earthquake, thunderstorm, wind, floods and

other acts of providence.

4. Losses of business profits, business interruptions, business information losses and other financial losses caused by

using the sensor or malfunction of the sensor.

5. Amount of compensation beyond selling price in all cases.

Rev. 02 31/08/2023

Unità: [mm]

DOORSS340: CIRCA 350 [g]

DOORSS1023T: CIRCA 760 [g]

48

50,5

1023

DOORSS1023T

DOORSS340 47,5

49

360

This manual suits for next models

2

Other tau Security Sensor manuals