P.O. Box 7069 • Greenwood, IN 46142 • Ph. 888-908-4826 • Fx. 317-215-2770 • www.titanlifts.com

LIMITED WARRANTY

The Titan 2 Post lifts and 4 Post lifts are backed by a standard 1 year replacement parts warranty and a 5 year structural

warranty from the date of purchase, to the original purchaser only. The 1 year replacement parts warranty covers power

units, hydraulic cylinders, and all other assembly components such as, but not limited to: turn plates, slip plates, cables,

chains, valves, switches etc. This does not cover normal wear items such as but not limited to rubber lifting pads and nylon

slide blocks. Titan HD2P-9000ACE-D and HD2P-9000AFE 2 Post lifts are backed by a 2 year replacement parts warranty

and a 5 year structural warranty from the date of purchase, to the original purchaser only. The 2 year replacement parts

warranty covers power units, hydraulic cylinders, and all other assembly components such as, but not limited to: turn

plates, slip plates, cables, chains, valves, switches etc. This does not cover normal wear items such as but not limited to

rubber lifting pads and nylon slide blocks.

Titan Mid Rise Scissor lifts are backed by a standard 1 year replacement parts warranty and a 5 year structural warranty

from the date of purchase, to the original purchaser only. The 1 year replacement parts warranty covers power units,

hydraulic cylinders, and all other assembly components such as, but not limited to: turn plates, slip plates, cables, chains,

valves, switches etc. This does not cover normal wear items such as but not limited to rubber lifting pads and nylon slide

blocks.

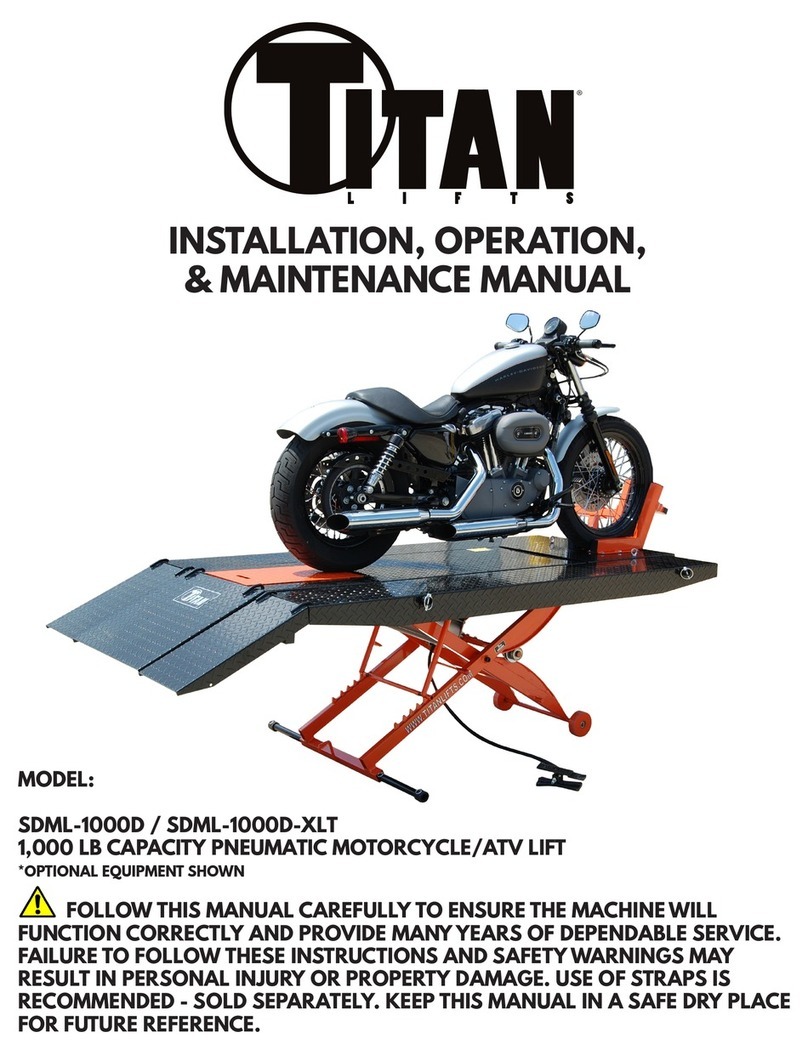

Titan Standard Duty and Heavy Duty motorcycle lifts are backed by a standard 1 year replacement parts warranty from

the date of purchase, to the original purchaser only. The 1 year replacement parts warranty covers power units, hydraulic

cylinders, pneumatic cylinders, and all other assembly components such as, but not limited to: cables, caster wheels,

valves, switches, wheel vises etc. This does not cover normal wear items such as but not limited to rubber wheel vise pads.

Titan Bulldog Moto Cradle Wheel Chock is warrantied for replacement parts, only to the original purchaser, for a period of 2

years from the date of purchase.

XL Tool by Titan Wheel Service Machines and Helper Arm Assemblies are backed by a standard 1 year replacement parts

warranty from the date of purchase, to the original purchaser only. The 1 year replacement parts warranty covers internal

boards, motors, pneumatic cylinders, and all other assembly components such as, but not limited to: cabinet, switches,

valves, ttings etc. This does not cover normal wear items such as but not limited to: rubber pads, jaw protectors, air hoses,

quick nut assemblies.

Titan shop equipment products and accessories are warrantied for replacement parts only to the original purchaser for

a period of 90 days from the date of purchase. This 90 day replacement parts warranty covers products such as but not

limited to: EZ -Mover Jacks, Mini Jacks, tie down products, wheel service accessories, Bulldog Moto Cradle Wheel Chock

accessories, dollies, stands, Light Duty Motorcycle Lifts, etc.

For all warranty considerations, Titan Marketing, LLC will supply replacement parts only during the warranty period. The

original purchaser is responsible for all shipping, handling, and any labor charges incurred. All defective parts must be

returned to Titan for inspection and examination. Any parts that are found to be defective will be replaced or repaired

to proper working order. Other items not listed above may be considered general wear parts and therefore, will not be

covered under warranty. These warranties do not extend to defects caused by ordinary wear, abuse, misuse, shipping

damage, improper installation, voltage or lack of required maintenance. Titan Marketing, LLC is not to be held responsible

for any failure that results from an accident, purchaser/operator abuse, neglect, or failure to operate products in

accordance with instructions provided in the owner’s manual(s) supplied. Damage caused by rain, excessive humidity,

corrosive environments or other contaminants are not covered under warranty. THESE WARRANTIES DO NOT EXTEND

TO ANY COSMETIC DEFECT NOT INTERFERING WITH EQUIPMENT FUNCTIONALITY OR ANY INCIDENTAL, INDIRECT, OR

CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF

A TITAN MARKETING LLC PRODUCT OR THE BREACH OR DELAY IN PERFORMANCE OF THE WARRANTY.