Table of Contents

General Instructions 3|09

Table of Contents ..................................................................................................................... 3

Installation Checklist ................................................................................................................ 5

Care and Maintenance ............................................................................................................. 6

Application Guidelines ............................................................................................................. 7

Panel Connections, Components, Fillers and Hardware 10|92

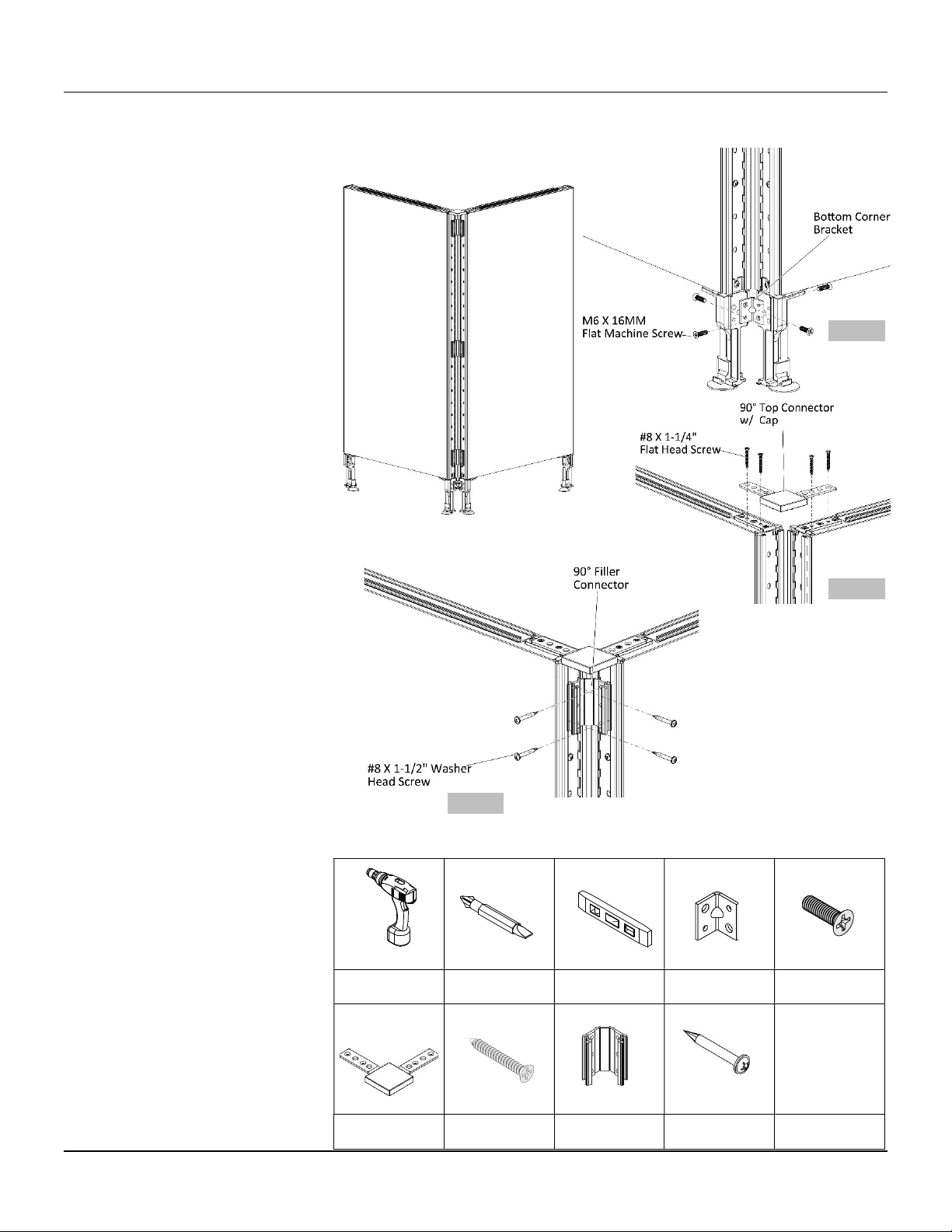

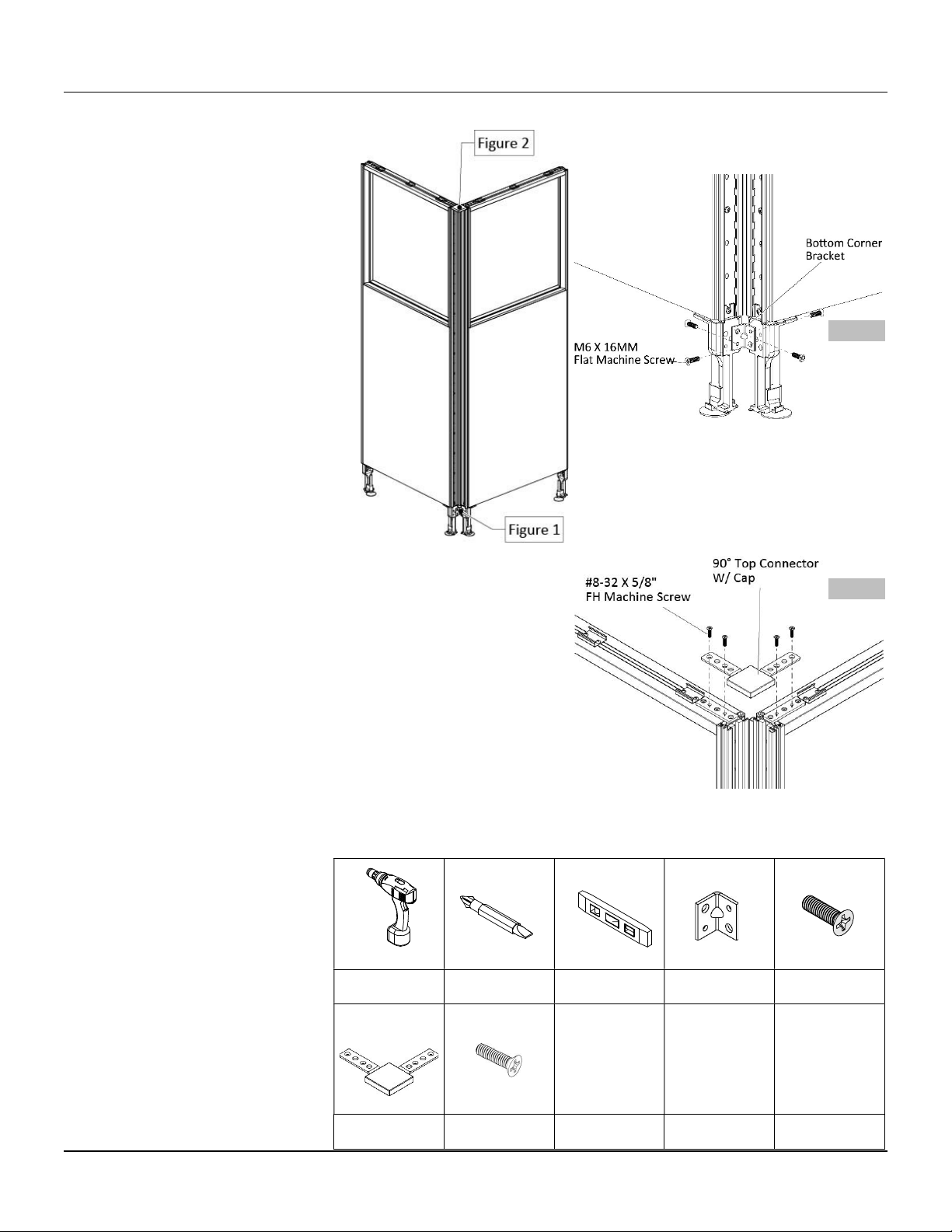

2-Way 90° Panel Connection - Type A..................................................................................... 10

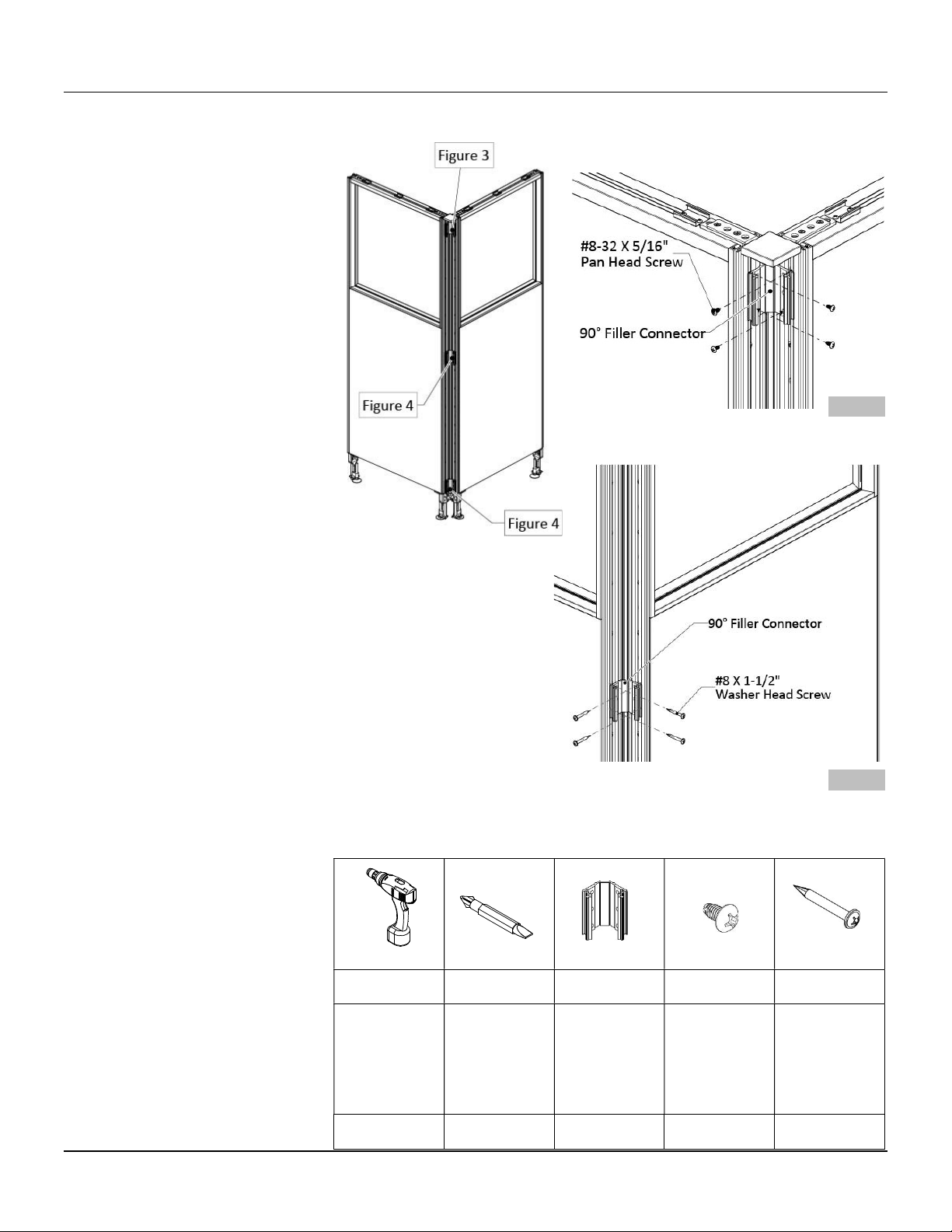

2-Way 90° Panel Connection - Type A (2 glazed panels) ........................................................ 11

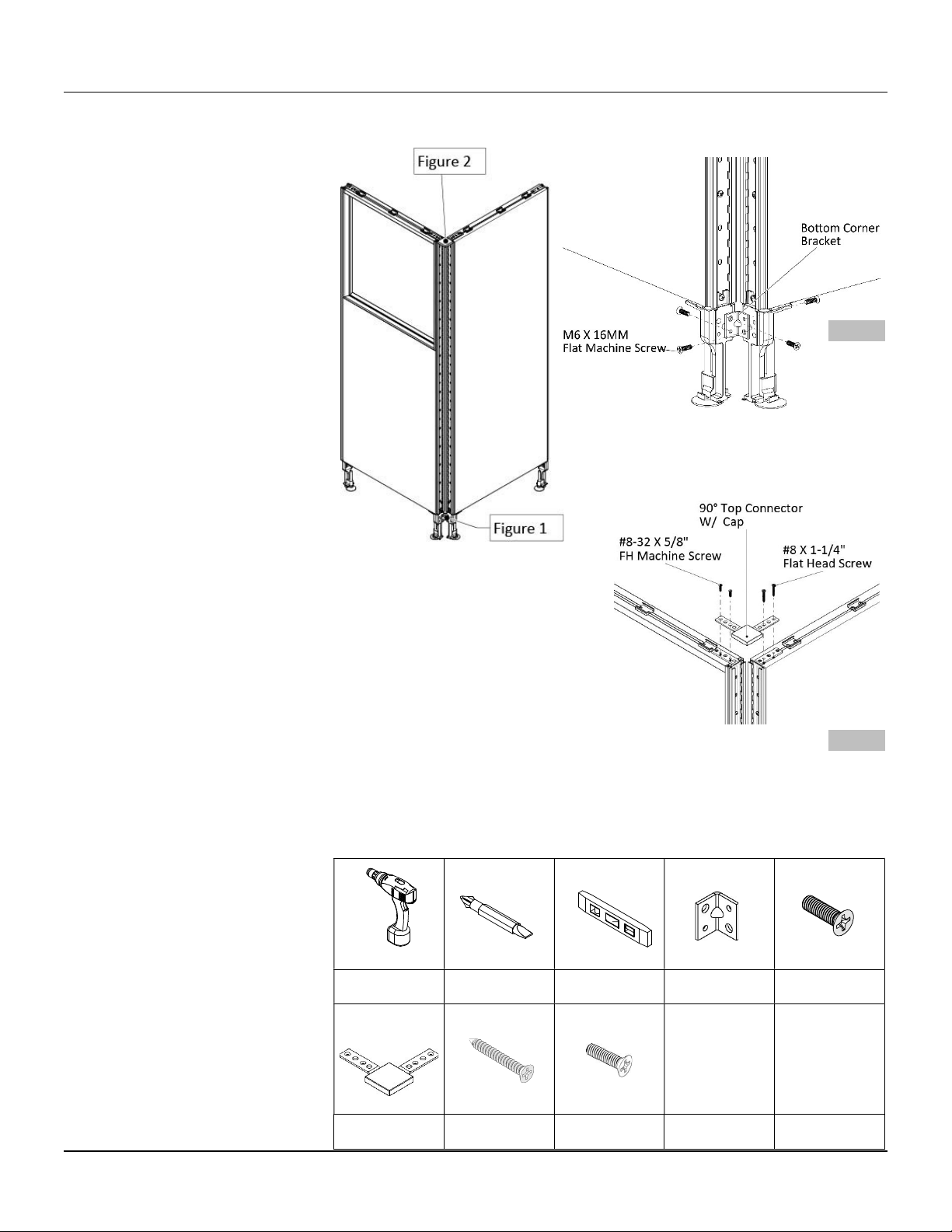

2-Way 90° Panel Connection - Type A (standard & glazed panels) ........................................ 13

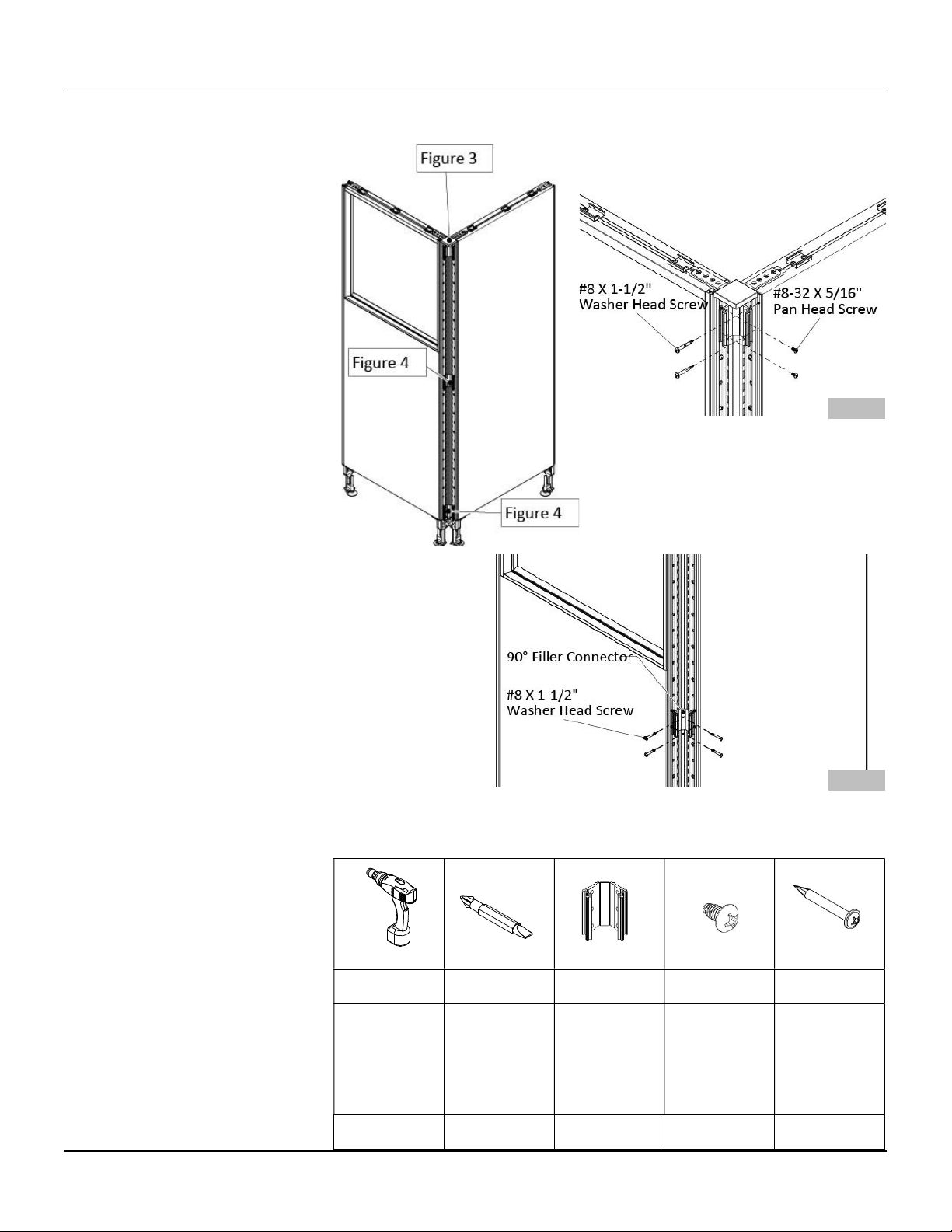

2-Way 90° Panel Connection - Type B ..................................................................................... 15

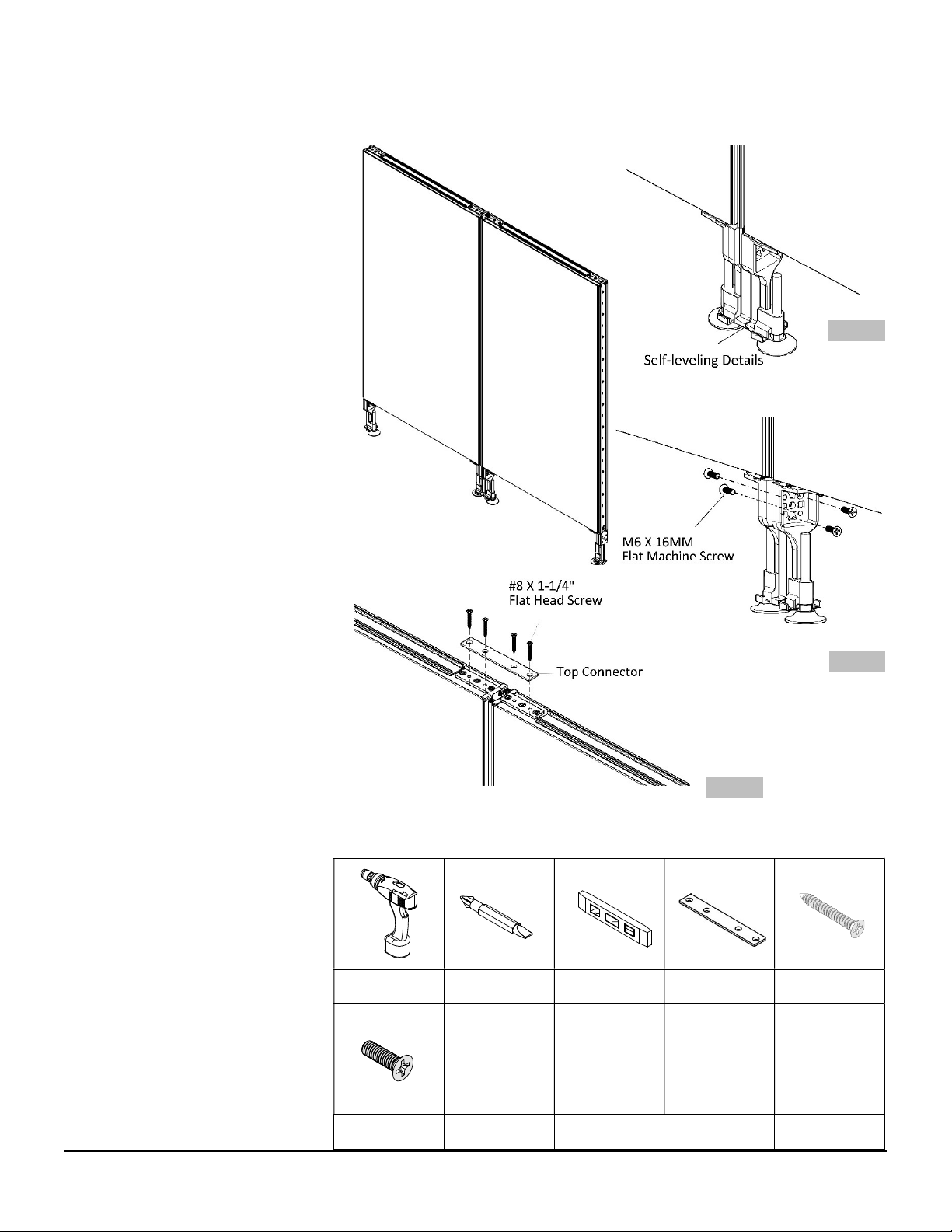

2-Way 180° Panel Connection - Type A .................................................................................. 17

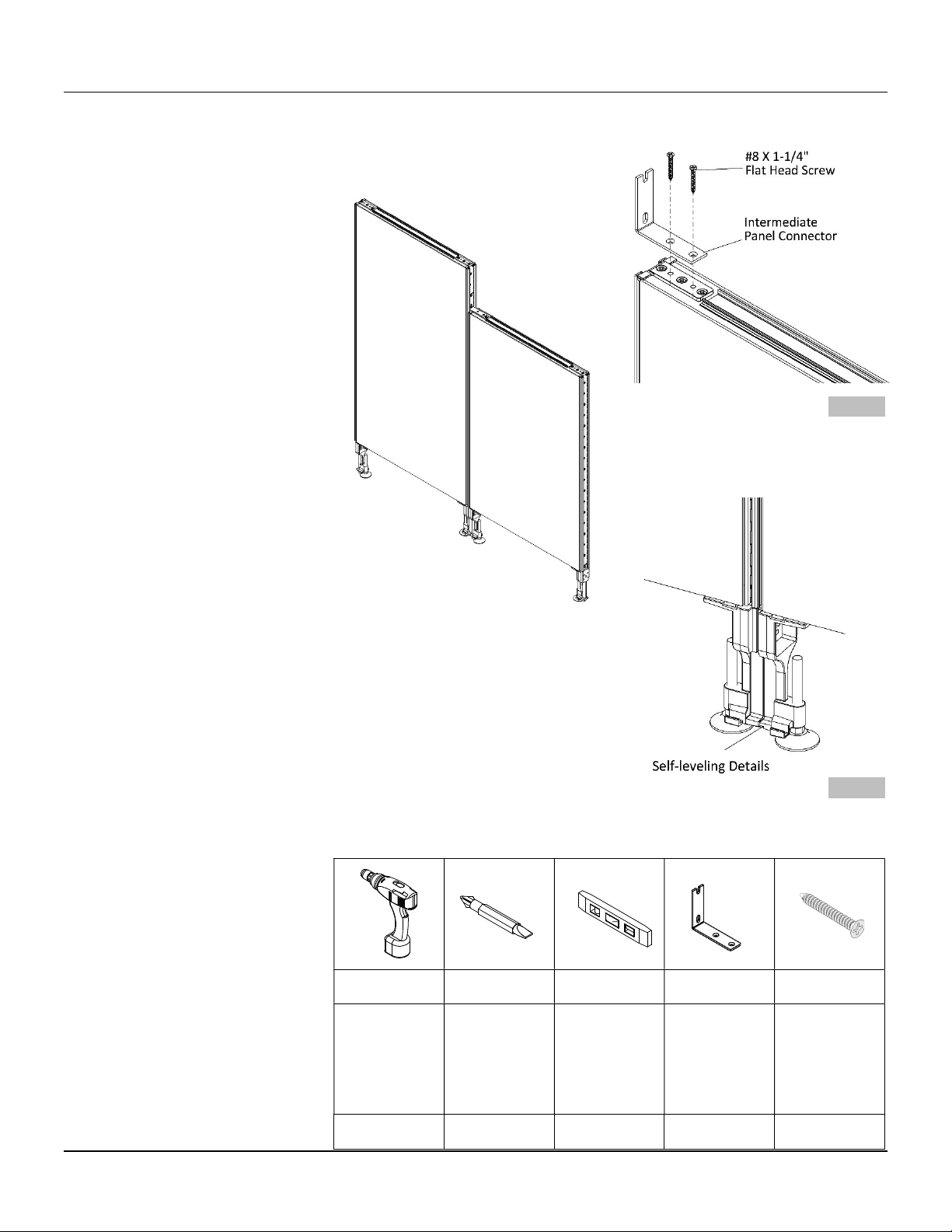

2-Way 180° Panel Connection - Type B ................................................................................... 18

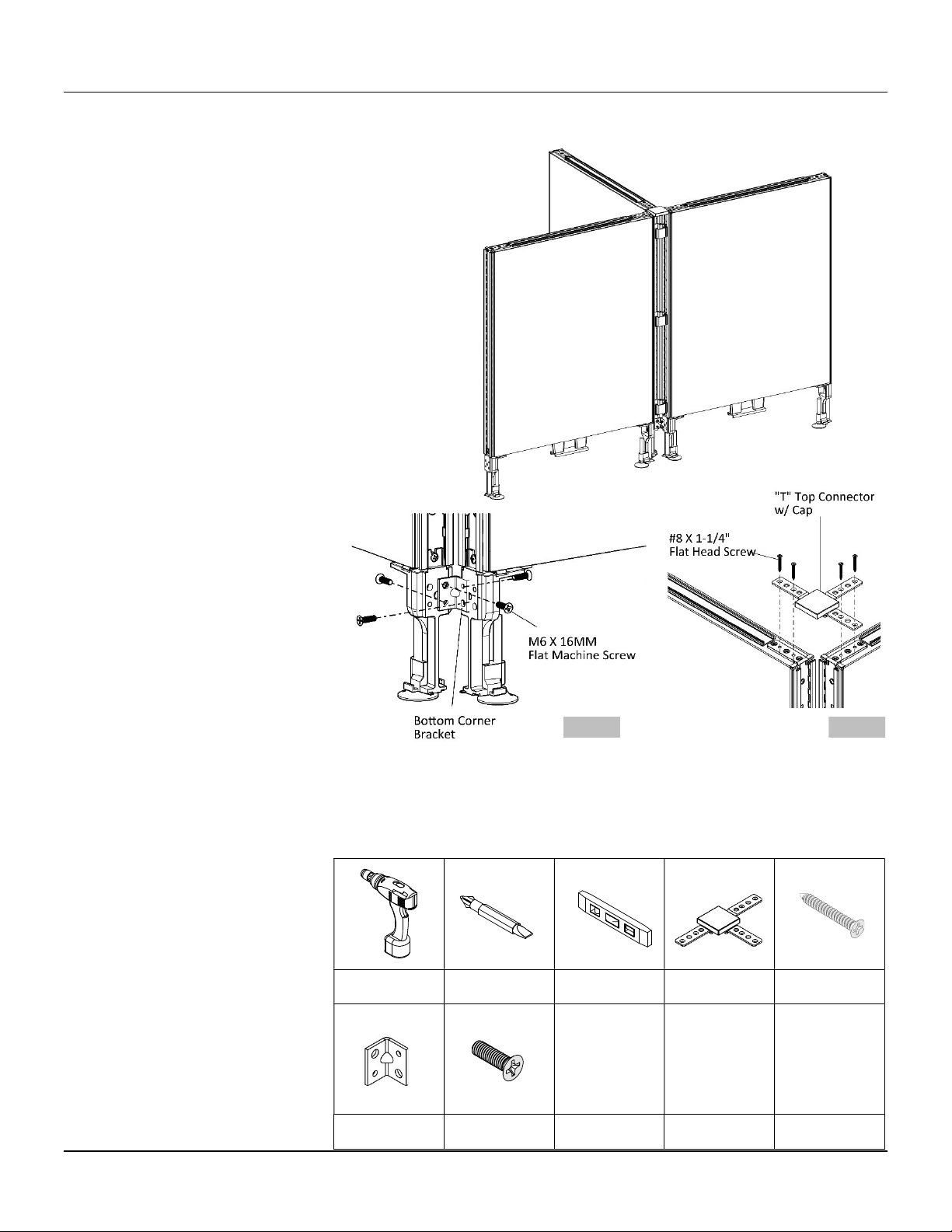

3-Way Panel Connection - Type A ........................................................................................... 20

3-Way Panel Connection - Type B ........................................................................................... 22

3-Way Panel Connection - Type C ........................................................................................... 25

3-Way Panel Connection - Type D ........................................................................................... 28

4-Way Panel Connection - Type A ........................................................................................... 31

4-Way Panel Connection - Type B ........................................................................................... 34

4-Way Panel Connection - Type C ........................................................................................... 38

4-Way Panel Connection - Type D ........................................................................................... 41

Elevated Panel Foot Cap Installation....................................................................................... 45

Machine Screws Removal from Glass or Acrylic Panel ........................................................... 46

Top Trim Installation ............................................................................................................... 47

End Trim Installation ............................................................................................................... 48

90° Filler Installation ............................................................................................................... 49

“T” Filler Installation................................................................................................................ 50

Partial End Trim Filler Installation ........................................................................................... 51

Partial 90° Filler Installation .................................................................................................... 52

Partial “T” Filler Installation .................................................................................................... 53

Top Trim Mid Cap .................................................................................................................... 54

Top Trim Mid Cap with Panel Mounted Glass/Acrylic Screen ................................................ 55

Corner Connector Installation ................................................................................................. 56

Corner Connector Installation with Flipper Cabinet ............................................................... 57

Spline Connector Installation .................................................................................................. 58

Raceway Cover Installation ..................................................................................................... 59

Gallery Panel, Single Span, End, .............................................................................................. 60

Gallery Panel, Double Span, End, 1 Piece................................................................................ 61

Gallery Panel, Double Span, End, 2 Pieces .............................................................................. 63

Gallery Panel, Single Span, Mid ............................................................................................... 65

Gallery Panel, Double Span, Mid, 1 Piece ............................................................................... 67

Gallery Panel, Double Span, Mid, 2 Pieces .............................................................................. 69

Gallery Panel, Single Span Step-down End ............................................................................. 71

Gallery Panel, Double Span Step-down End, 1 Piece .............................................................. 73

Gallery Panel, Double Span Step-down End, 2 Pieces ............................................................ 75

Gallery Panel, Single Span Step-down Mid ............................................................................. 77

Gallery Panel, Double Span Step-down Mid, 1 Piece .............................................................. 80

Gallery Panel, Double Span Step-down Mid, 2 Pieces ............................................................ 83