tayco The Shield Series User manual

Table of contents

Other tayco Indoor Furnishing manuals

tayco

tayco Halifax User manual

tayco

tayco One-Touch User manual

tayco

tayco Height Adjustable Tables User manual

tayco

tayco Up User manual

tayco

tayco Switch User manual

tayco

tayco Hanna Series User manual

tayco

tayco Norris Series User manual

tayco

tayco Scene User manual

tayco

tayco Kip User manual

tayco

tayco Halifax User manual

Popular Indoor Furnishing manuals by other brands

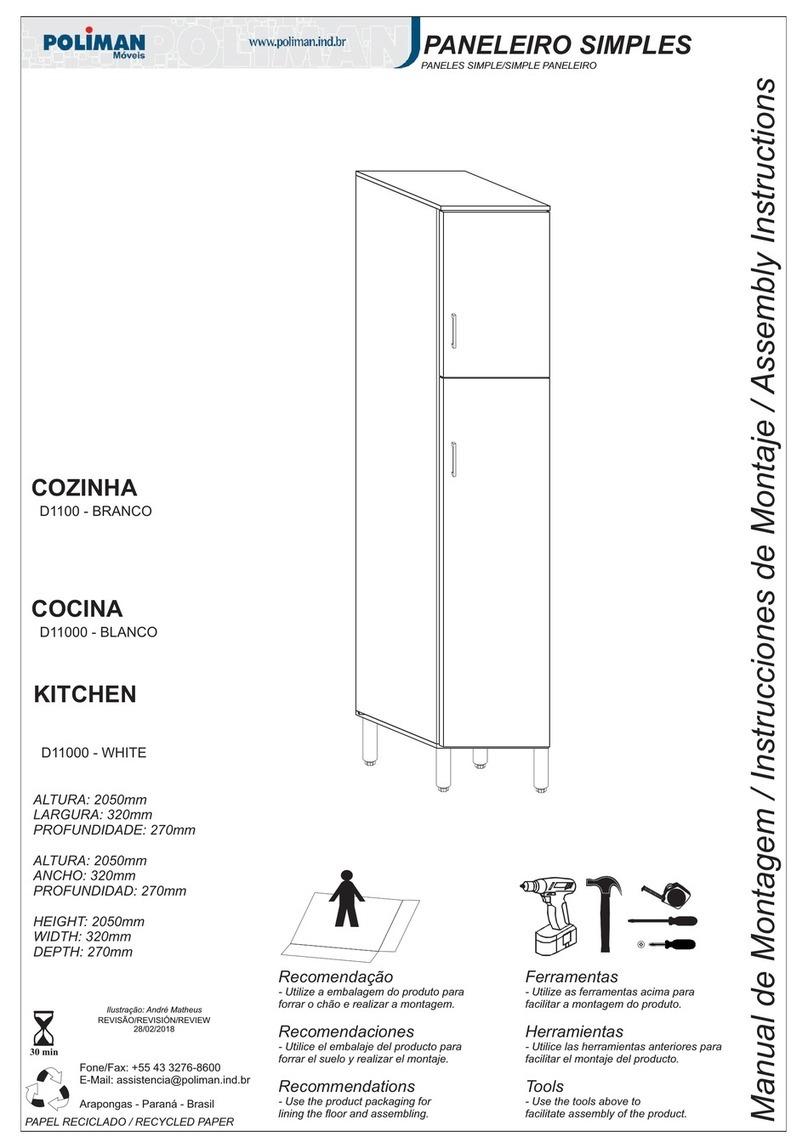

Poliman

Poliman D1100 Assembly instructions

Mocka

Mocka Taylor Assembly instructions

Furniture of America

Furniture of America Diocles CM3020BN Assembly instructions

Flokk

Flokk HAG Creed Communication Assembly guide and User Guide

GFW

GFW POLAR HIGH GLOSS LED TV UNIT Assembly instructions

Habitat

Habitat Marble 820983 manual

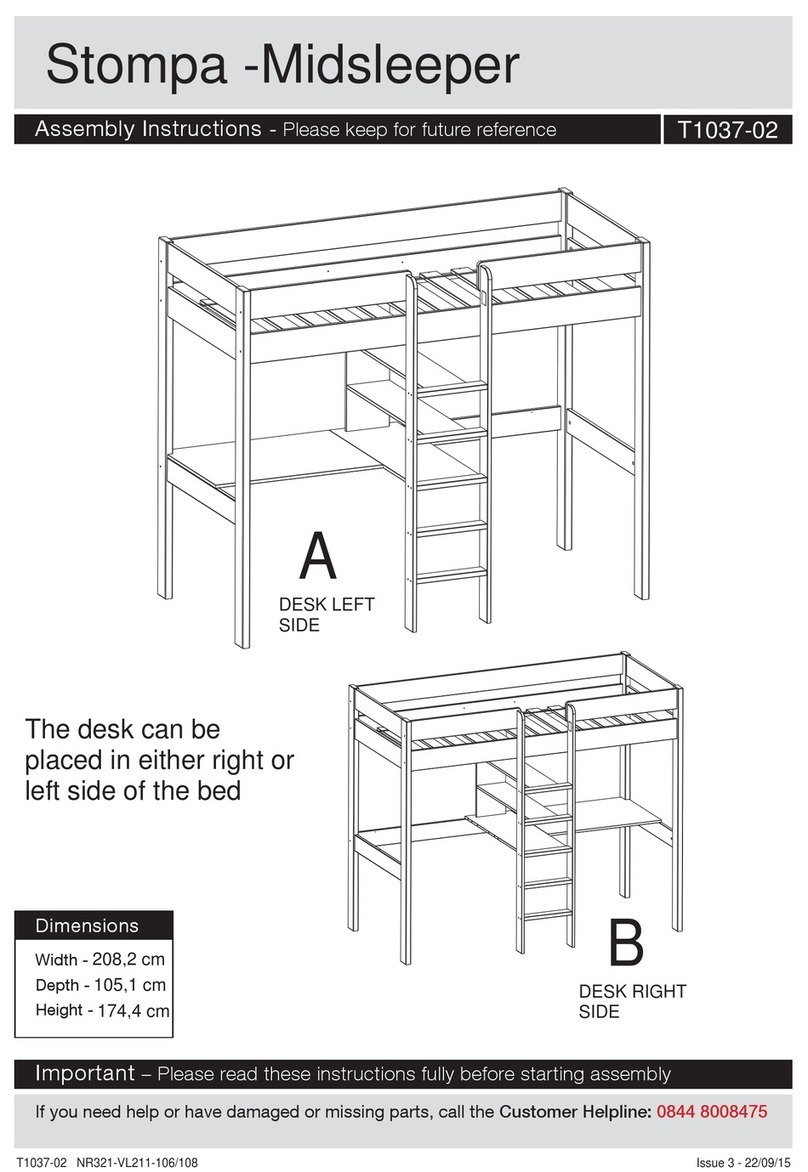

Stompa

Stompa T1037-02 Assembly instructions

Maintal

Maintal Louisville EB SH55 OHNE Assembly instructions

Ironwood

Ironwood MH60 quick start guide

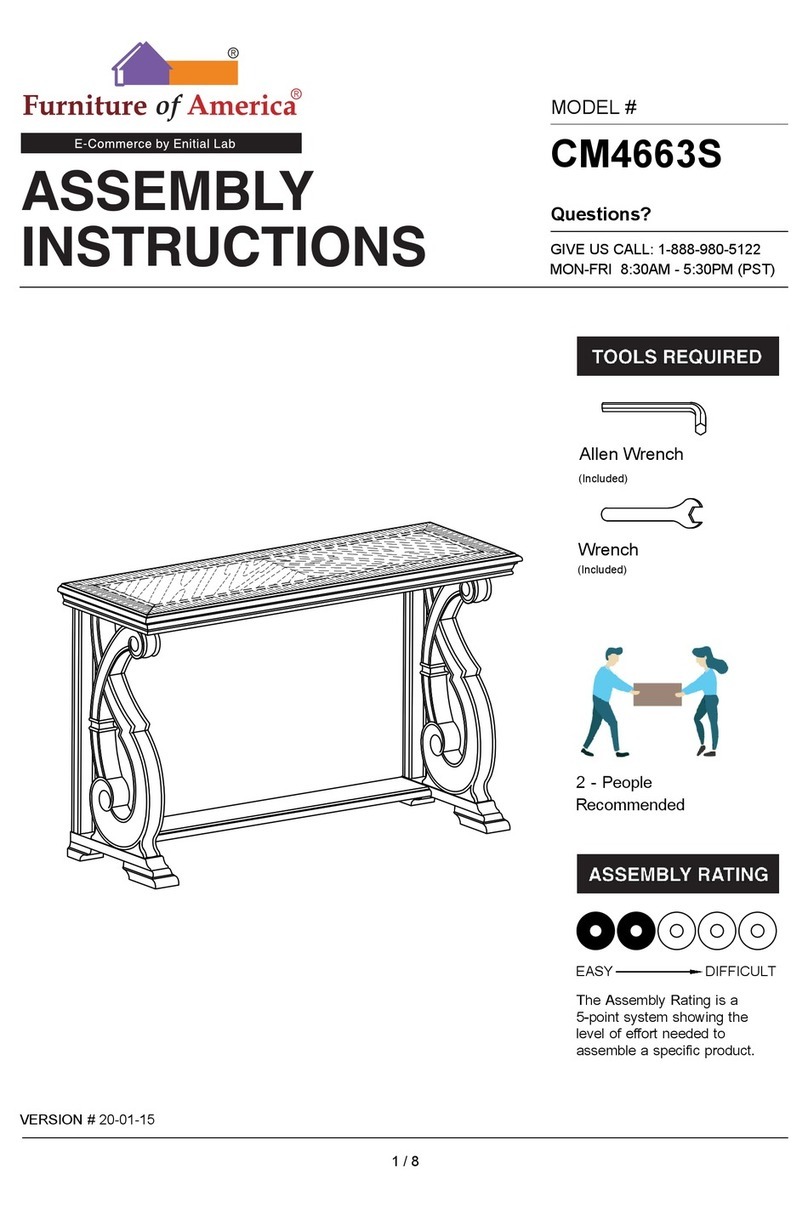

Furniture of America

Furniture of America CM4663S Assembly instructions

GUIDO MARIA KRETSCHMER HOME&LIVING

GUIDO MARIA KRETSCHMER HOME&LIVING Toona 57787137 manual

Coaster

Coaster 930133 Assembly instructions

hygena

hygena 462/5670 Assembly instructions

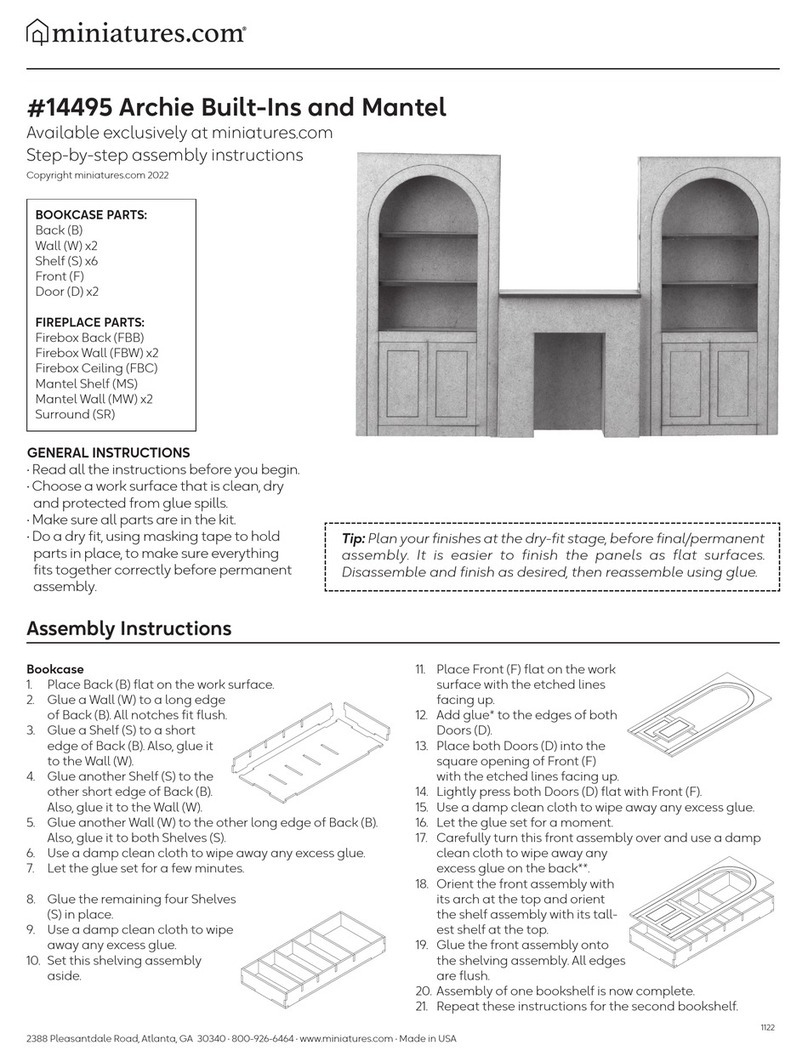

Miniatures

Miniatures Archie 14495 Step by step assembly instructions

VIPACK

VIPACK KIDDY BOOKCASE WHITE Assembly instructions

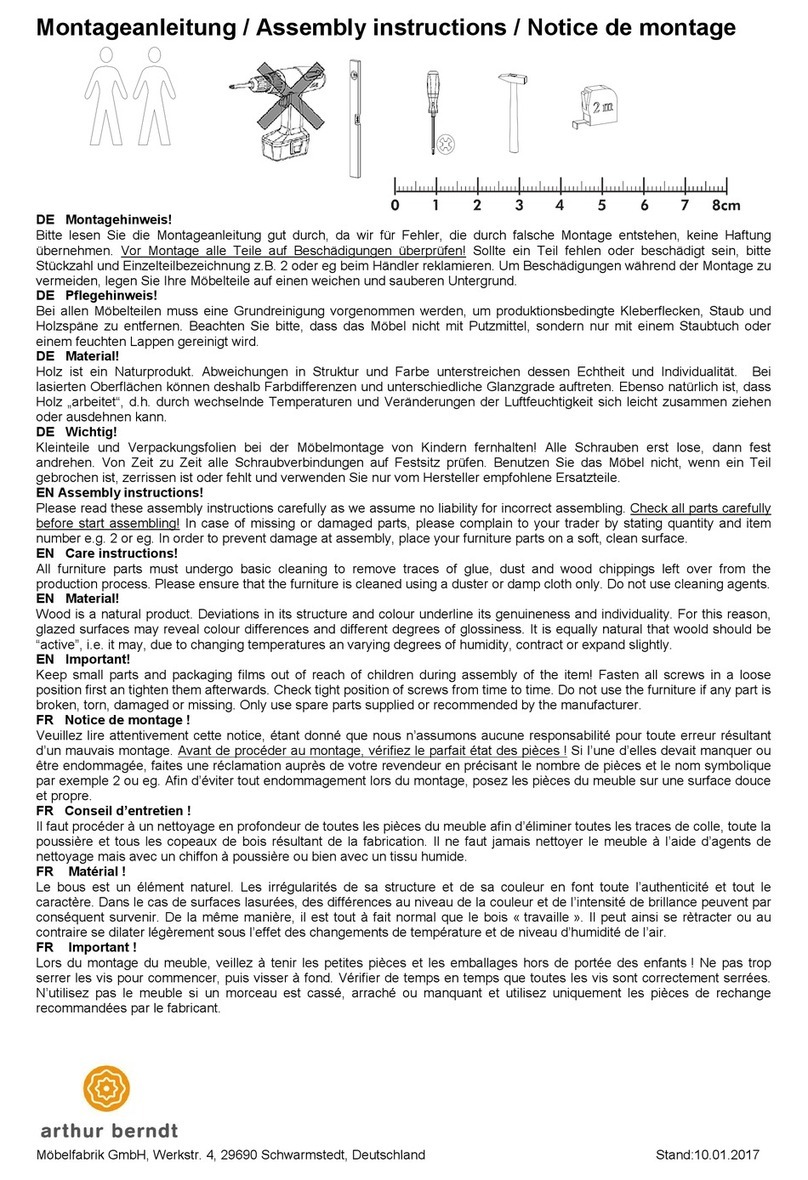

Arthur Berndt

Arthur Berndt Johan 33 Assembly instructions

Furniture of America

Furniture of America Bridgewater FOA7490PL Assembly instructions

Forte

Forte PDVV721 Assembling Instruction