11. Do not use this television set near water ... for example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a

wet basement, or near a swimming pool, etc.

Never expose the set to rain or water. If the set has been exposed to rain or water, unplug the set from the wall

outlet and refer servicing to qualified service personnel.

12. Choose a place where light (artificial or sunlight) does not shine directly on the screen.

13. Avoid dusty places, since piling up of dust inside TV chassis may cause failure of the set when high humidity persists.

14. The set has slots, or openings in the cabinet for ventilation purposes, to provide reliable operation of the receiver, to

protect it from overheating. These openings must not be blocked or covered.

Never cover the slots or openings with cloth or other material.

Never block the bottom ventilation slots of the set by placing it on a bed, sofa, rug, etc.

Never place the set near or over a radiator or heat register.

Never place the set in enclosure, unless proper ventilation is provided.

15.1. If an outside antenna is connected to the television set, be sure the antenna system is grounded so as to provide some

protection against voltage surges and built up static charges, Section 810 of the National Electrical Code, NFPA No.

70-1975, provides information with respect to proper grounding of the mast and supportingstructure, grounding of the

lead-in wire to an antenna discharge unit, size of grounding conductors, location of antenna discharge unit, connection

to grounding electrode, and requirements for the grounding electrode.

15.2. Note to CATV system installer : (Only for the television set with CATV reception)

This reminder is provided to call the CATV system attention to Article 820-40 of the NEC that provides

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding

system of the building, as close to the point of cable entry as practical.

16. An outside antenna system should not be located in the vicinity of overhead power lines or other electric lights or power

circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system, extreme care

should be taken to keep from touching such power lines or circuits as contact with them might be fatal.

17. For added protection for this television set during a lightning storm, or when it is left unattended and unused for long

periods of time, unplug it from the wall outlet and disconnect the antenna. This will prevent damage due to lightning

and power-line surges.

ANTENNA

LEAD- IN WIRE

ANTENNA DISCHARGE

UNIT (NEC SECTION

810-20)

GROUNDING

CONDUCTORS

(NEC SECTION810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250. PART H)

ELECTRIC SERVICE

EQUIPMENT

GROUND CLAMP

NEC-NATIONAL ELECTRICAL CODE

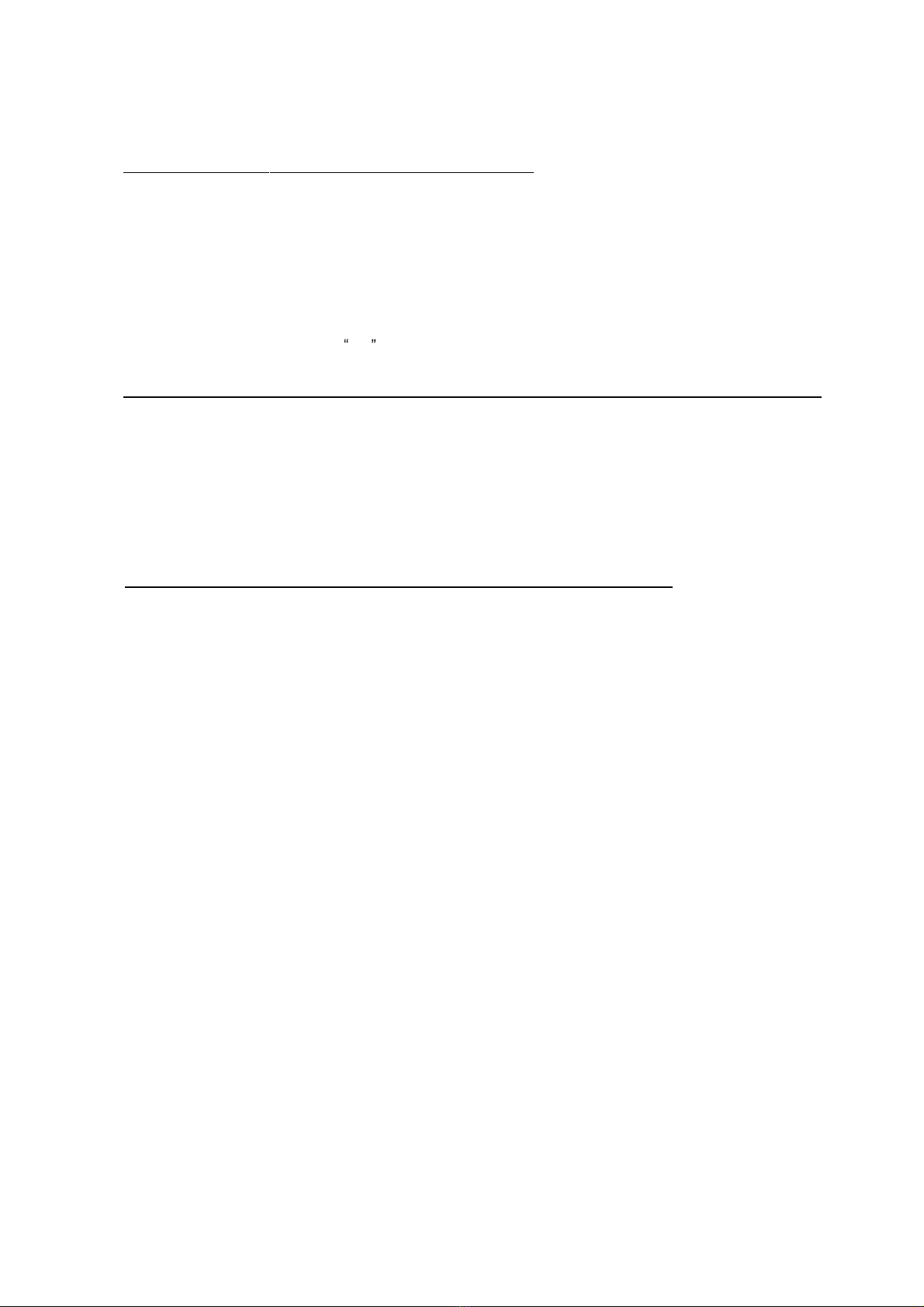

EXAMPLE OF ANTENNA GROUNDING AS PER

NATIONAL ELECTRICAL CODE

EXAMPLE OF ANTENNA GROUNDING AS PER NATIONAL ELECTRICAL CODE INSTRUCTIONS

a built-in

installer s

4

SCHNEIDER ELECTRONICS GMBH-GERMANY

PROTECTION AND LOCATION OF YOUR SET

PROTECTION AND LOCATION OF YOUR SET

4