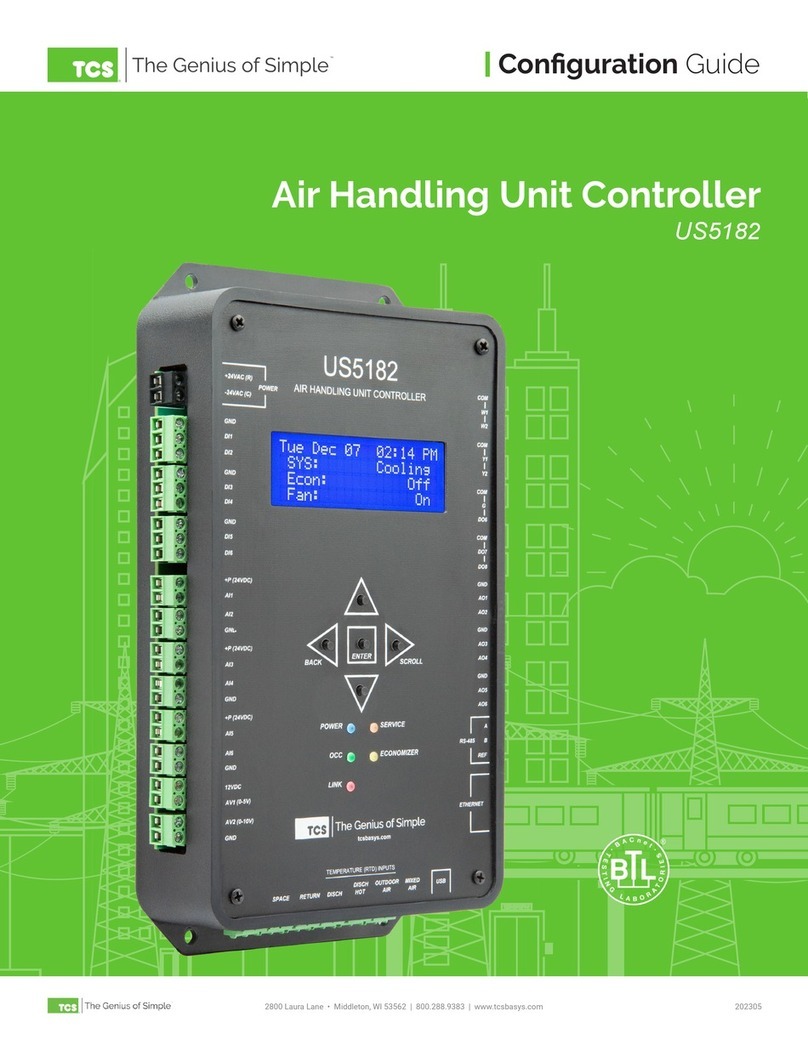

2800 Laura Lane Madison, WI 53562 | 800.288.9383 Fax: 608.836.9044 | www.tcsbasys.com 10

Zone Temperature

Zone Temperature

HEAT COOL FAN OCC

In the occupied mode, the

relay is closed.

In the unoccupied mode, the

relay is open.

In the occupied mode, the fan

is on.

The unoccupied fan sequence

is shown below.

DO5 AND DO6 MODES

Differential

Offset

Deadband

Setpoint

On Point

Off Point

OFF

ON

Deadband

Offset

Differential

Setpoint

Off Point

On Point

OFF

ON

Setpoint

Deadband

Deadband

ON

ON

OFF

Digital Outputs NO15 and NO2

Zone Temperature

Digital Outputs NO1 and NO2

SEQUENCE LEGEND

SP=Setpoint

DB=Deadband

P(temp)=Temperature Proportional Band

P(CFM)=CFM Proportional Band

MODULATING OUTPUT AO1

For pressure independent systems, a CFM setpoint is

generated based on: temperature proportional band,

sensed temperature and the temperature setpoint. The

control output is dependent on the CFM proportional

band, CFM measured and the CFM setpoint that has

been generated. For pressure dependent systems, the

control output is based on the temperature proportional

band, sensed temperature and the temperature setpoint.

TRIACS DO1, DO2, DO3, DO4

The SZ1025b can be configured for floating damper and/

or valve motors when used with the QE25 interface. The

CW1 provides clockwise rotation to open the damper

motor.

The CCW1 provides a counter-clockwise rotation to close

the damper motor. The power that CW1 and CCW1 pro-

vide to the damper motor must not exceed 200 mA.

The CCW2 provides clockwise rotation to open the valve

motor. The CCW2 provides a counter-clockwise rota-

tion to close the valve motor. The power that CW2 and

CCW2 provide to the valve motor must not exceed 200

mA.

1. Be sure to check and verify all wiring before powering

the SZ1025b.

2. Turn power on. The SZ1025b display LED should

light up.

3. If the SZ1025b has not been pre-programmed, it

should be programmed at this time.

4. Increase the setpoint on the analog (TS2032a) or digi-

tal (PX1060) zone sensor. Observe the damper opera-

tion and heating stage(s) if used.

5. Decrease the setpoint on the analog (TS2032a) or

digital (PX1060) zone sensor. Observe the damper

operation and cooling stage(s) if used.

6. Note that the operation of the SZ1025b will depend on

how it is programmed.

The SZ1025b is now ready for operation.

TROUBLESHOOTING

No Display

Check for 24 VAC on terminals “R” and “C”.

No communication

Make sure baud rate selection jumper for the QD1010 is

the same as programmed in the SZ1025b.

No communication while connected to TS2023a

When a QD1010 is connected to a PX1060 or TS2023a,

the QD1010 must be powered with the external power

supply supplied with the QD1010. The TS2023a or

PX1060 does not provide power on the phone connector.

Inputs do not read correctly

If not using a setpoint input, SP must be shorted to

GND. For the room temperature and supply air temper-

ature readings, slight adjustments can be made in via

software. For different pressure readings, make slight

adjustments to the zero port which is the middle pressure

pot located closest to the high pressure port fitting.

Output operation is not correct

Check programmed parameters. In particular check

“Reverse” and “Direct” acting selections for the damper

and valve and offset and differential selections for the

relay outputs. Check wiring.

Sequence of Operations

Checkout & Troubleshooting