TdA DC535Y User manual

AUTOMATIC BOOM GATE

USER’S MANUAL

MODEL

DC535Y/DCZ535Y

DC655Y/DCZ655Y

WARNING!

ONLY QUALIFIED AND EXPERIENCED TECHNICIANS

SHOULD ATTEMPT INSTALLATION OR SERVICE TO THIS

UNIT, OTHERWISE, SERIOUS PERSONAL INJURY,

DEATH, OR PROPERTY DAMAGE MAY OCCUR.

PLEASE KEEP THESE INSTRUCTIONS FOR FURTHER

REFERENCE.

Total Door Automation (Australia) Pty Ltd

www.totaldoorautomation.com.au

sales@totaldoorautomation.com.au

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

2

OUTLINE

1. Important safety information……………………3

2. Introduction………………………………………3

3. Main technical parameters ……………………3

4. Installation ………………………………………4

5. Electrical…………………………………………9

6. Maintenance ……………………………………13

7. Troubleshooting…………………………………13

8. Packing list………………………………………14

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

3

1. Important safety information

Carefully read and follow all safety precaution and warnings before attempting to install and use

DC660-3(L, M, R) boom gate. Incorrect installation can lead to severe injury.

⚫The automatic boom gate should be installed by a qualified technician; otherwise, serious personal

injury or property damage may occur.

⚫Children should not be allowed to play near or operate automatic boom gate.

⚫Before any job on the boom gate, cut out electrical power.

⚫Do not in any way modify the components of the automatic boom gate, otherwise serious personal

injury or property damage may occur. We do not accept responsibility for damage or injury

resulting from installing this boom gate.

⚫Notify the users that the boom gate is never to be operated unless it is in full view.

⚫Always keep people and objects away from the boom gate when it is operated.

⚫Keep remote controls away from children, to prevent the boom gate from being activated

involuntarily.

⚫The distance between the end of the bar and the nearest objects should exceed 0.5m.

⚫Any changing of the bar by customer is not allowed. If you have any special requirements about

the bar, please kindly contact a dealer.

⚫Under no condition should boom gate be used with bar or spring not attached.

⚫For your safety, withdraw the crank before switching the power back on.

⚫For service, call an experienced technician.

⚫Our company reserves the right to change the design and specification without prior notification.

2. Introduction

Please read the instructions carefully before proceeding. The automatic boom gate intended for use in

parking area, commercial premises or apartment block access.

⚫Compact design, attractive appearance, safe and reliable performance.

⚫Self-locking at any position.

⚫A unique internal spring counterbalance mechanism aids the action of the boom gate.

⚫To ensure safety, the boom gate will reverse if it comes in contact with people or vehicle when

closing, and will stop if jammed when opening.

⚫Manual operation in case of power failure.

⚫Terminals available to photocell, loop detector and alarm lamp.

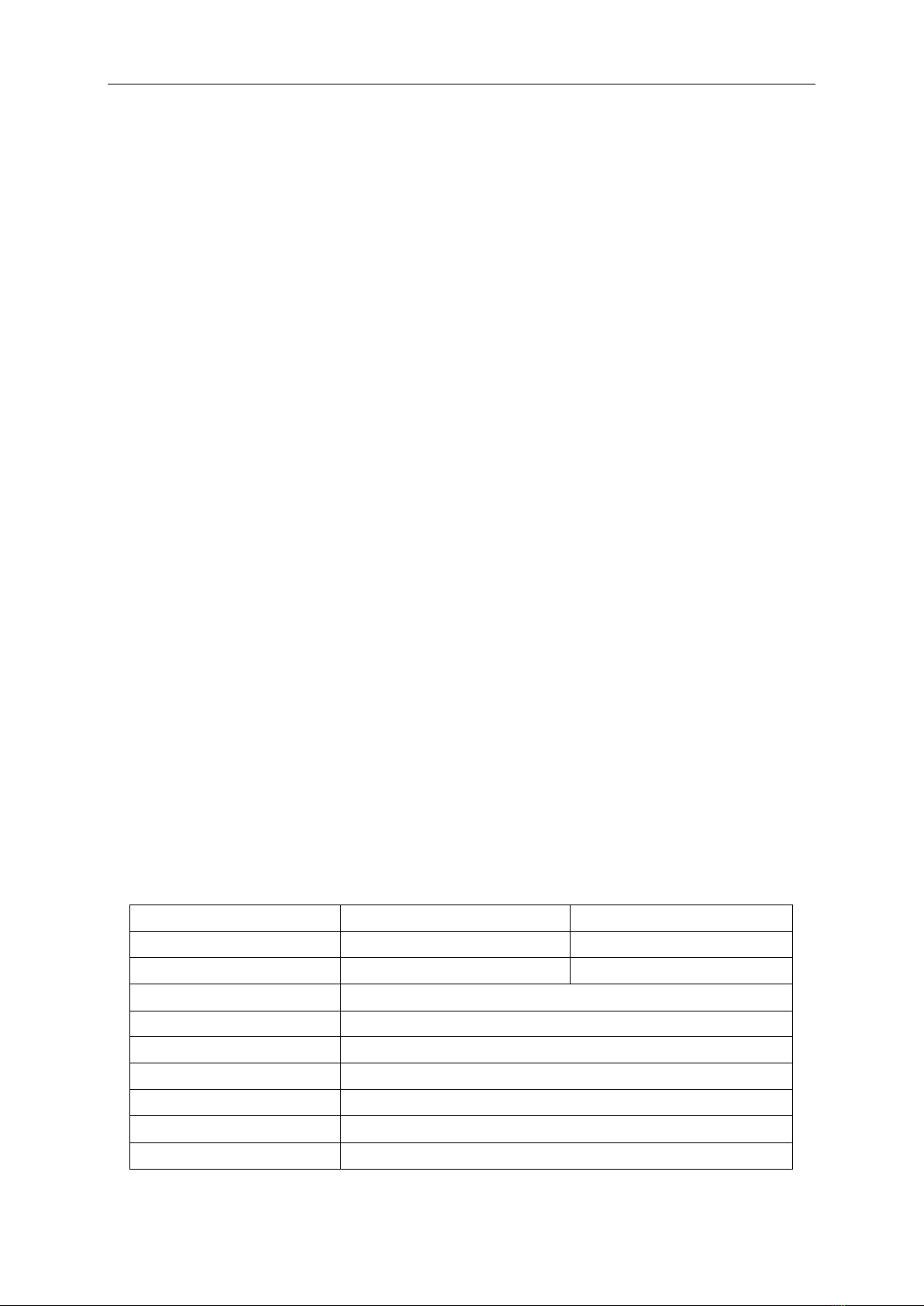

3. Main technical parameters

Type

DC535Y/DCZ535Y

DC655Y/DCZ655Y

Opening time

3.5 seconds

5.5 seconds

Bar length

3m~5m (standard)

5m~6m (standard)

Power supply

Single-phase AC240V 50Hz

Motor speed

1400r/min

Motor output power

180W

Duty cycle

40%

Noise

≤62dB

Measurement

360mm (L) x 230mm (W) x 1050mm (H)

Environmental temperature

-20ºC~+50ºC

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

4

4. Installation

Necessary Tools

The following tools may be necessary to install the automatic boom gate. You will need standard

screwdrivers, an electric drill and spanners.

The entire configuration and dimension are shown in the diagram below.

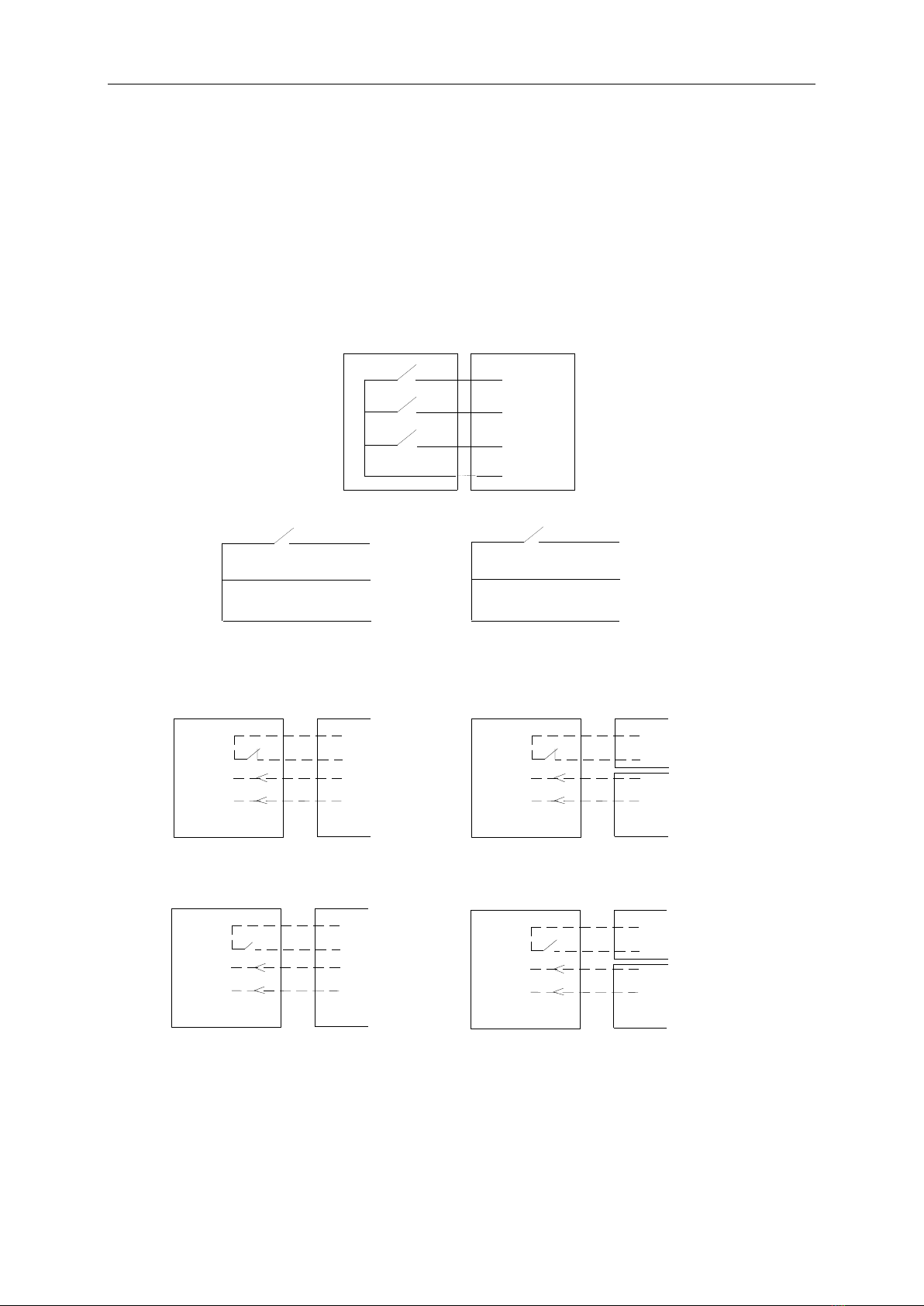

Fig.1

Top view

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

5

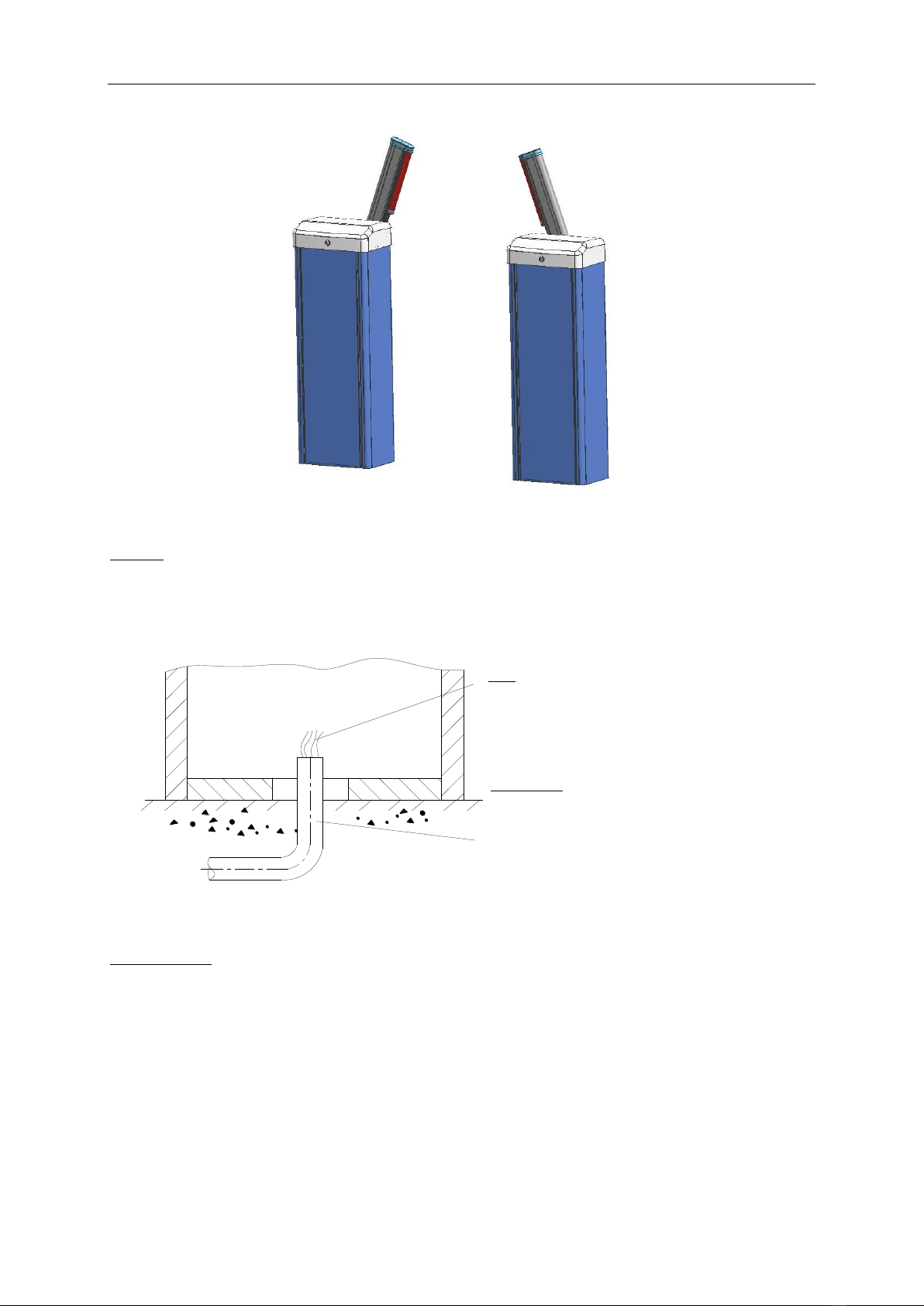

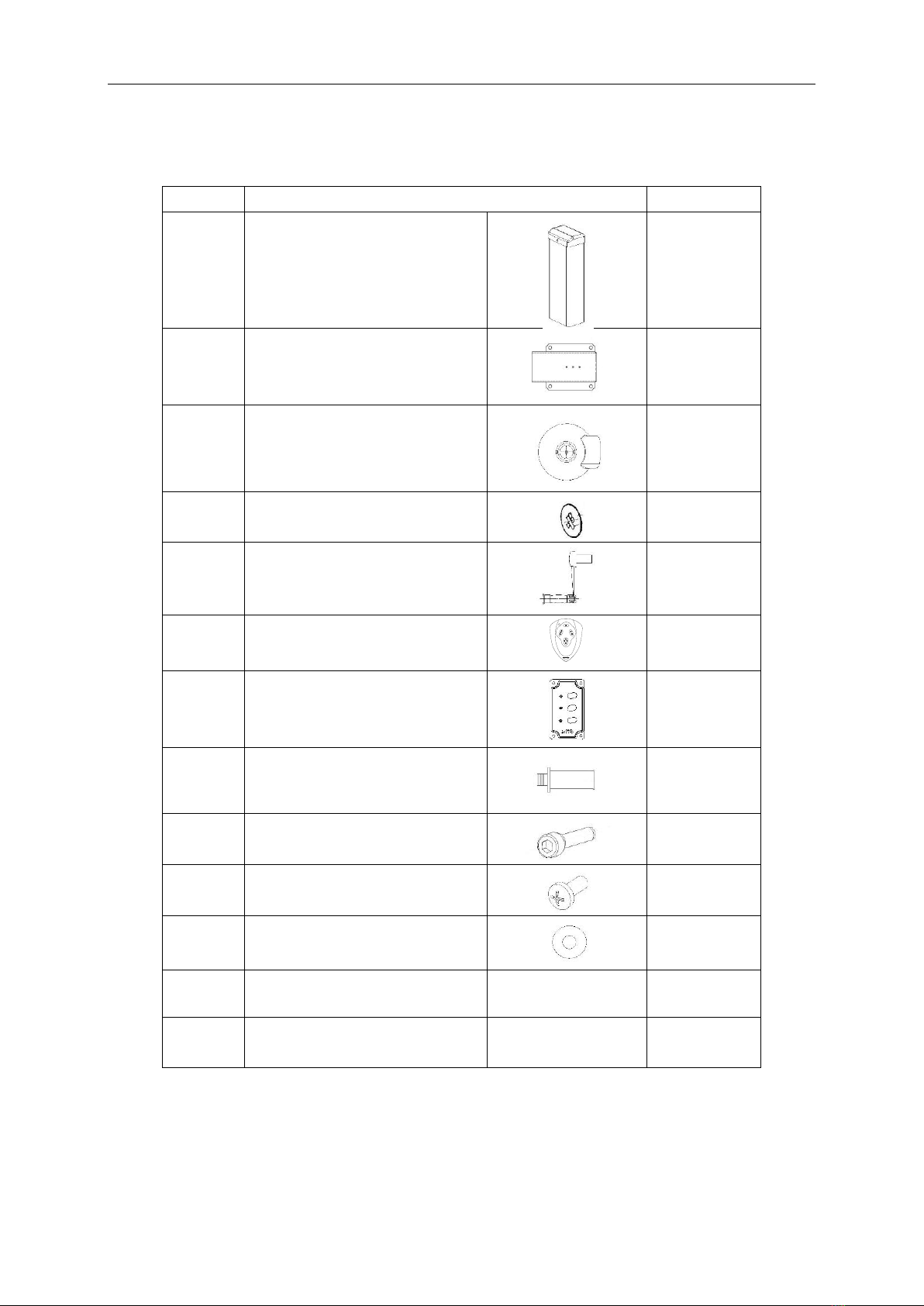

Right-hand boom gate (DC535Y, DC655Y) and left-hand boom gate (DCZ535Y, DCZ655Y)

DC535Y, DC655Y DCZ535Y, DCZ655Y

Fig.2

Conduit

Make one input hole for electric wires. In order to protect the wires, conduits must be set into the

concrete when it is poured. Wires within the conduit shall be located or protected so that no damage

can result from contact with any rough or sharp part.

2

PVC conduit (the conduit size should be more than

12mm in diameter)

We advise you to use two conduits: one for main

power wires, another one for control wires.

Always separate power wires from control wires.

Wire

The power wire size should be

more than 1.5mm .

The control wire size should be

more than 0.5mm .

2

Fig.3

Expansion bolt (see Fig.4)

⚫The boom gate requires a concrete pad in order to maintain proper stability. Place the boom gate

on its concrete pad and check the boom gate orientation with regard to the roadway.

⚫Mark the base hole locations onto the cement with a pencil or similar.

⚫Then move the operator to the side and drill the 4 holes on the marks that you have just drawn on

the concrete pad.

⚫Insert the (4) M12 wedge expansion bolts that are provided with the boom gate into the holes or

you can use the (4) M12 bolts, these bolts must be set into the concrete when it is poured.

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

6

Fig.4

Boom gate (see Fig.5)

Place the boom gate back into position, mount the boom gate to the concrete pad with washers and

nuts.

Fig.5

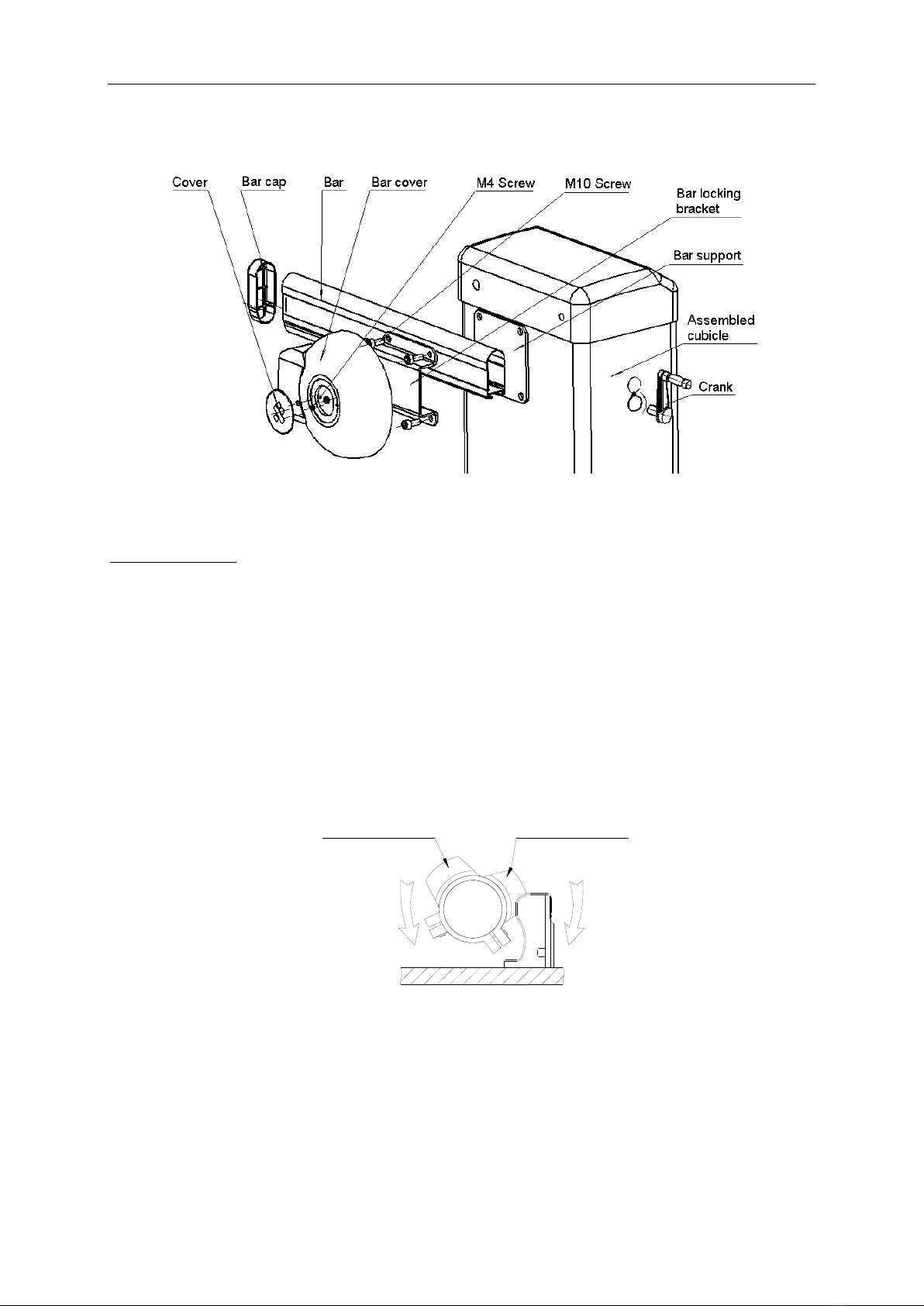

Bar (see Fig.6)

Mount the bar to the assembled cubicle and lock it with the four M10×16 socket head screws.

Mount the bar cover using the three M4×5 screws.

Manual operation (see Fig.6)

In case of power failure use crank to open or close boom gate manually, use the crank as follow:

⚫Shut off the main power of the boom gate. This safety measure is mandatory to avoid any risk of

injury in case of accidental running of the motor.

⚫Insert the crank in the opening of the housing (protected by a cover).

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

7

⚫Turn the crank clockwise or counterclockwise.

⚫Withdraw the crank before switching the power back on.

Fig.6

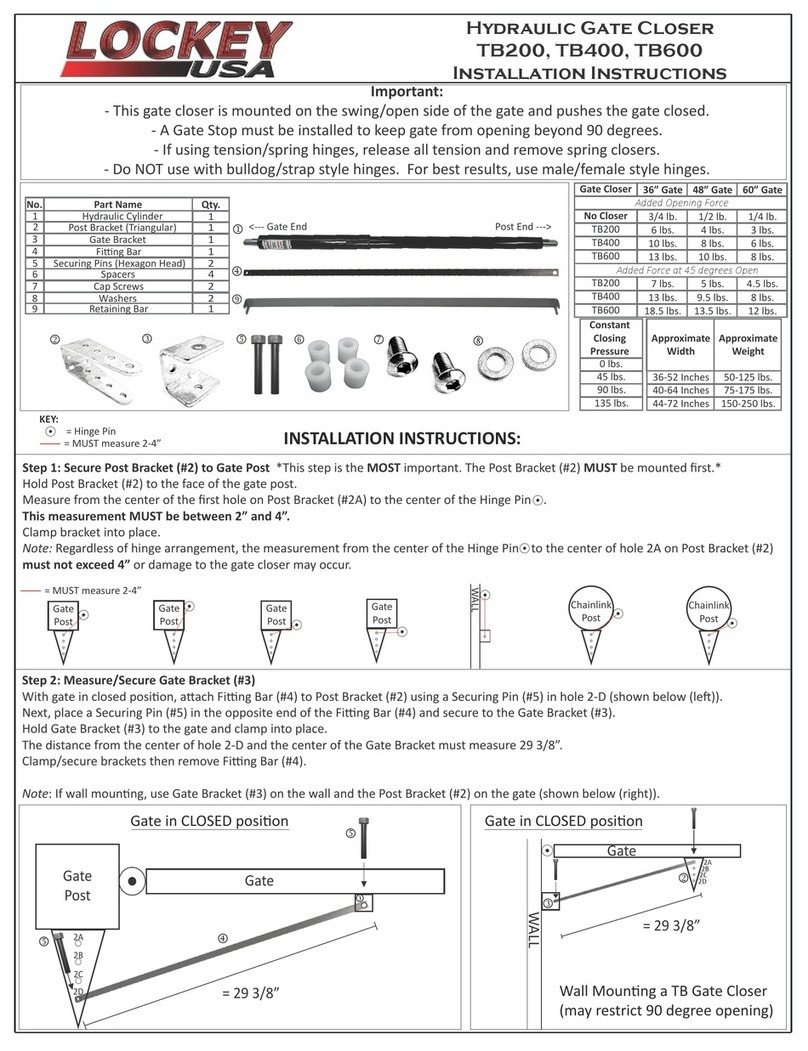

Limit switch (N.O.) see Fig.7

⚫The adjustable limit switches are used to stop the bar in the opened and closed positions.

⚫Loose the M4 screw of open limit cam, turn the open limit cam until the open limit switch light

illuminated, then tighten the screws.

⚫Loose the M4 screw of close limit cam, turn the close limit cam until the close limit switch

illuminated, then tighten the screws.

⚫After adjusting, you can open the bar then close the bar and observe whether the bar has

successfully reached the opened (vertical) position and closed (horizontal) position. If the bar does

not reach the opened position and closed position, you can repeat the adjusting process.

Close limit cam

Open limit cam

Fig.7

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

8

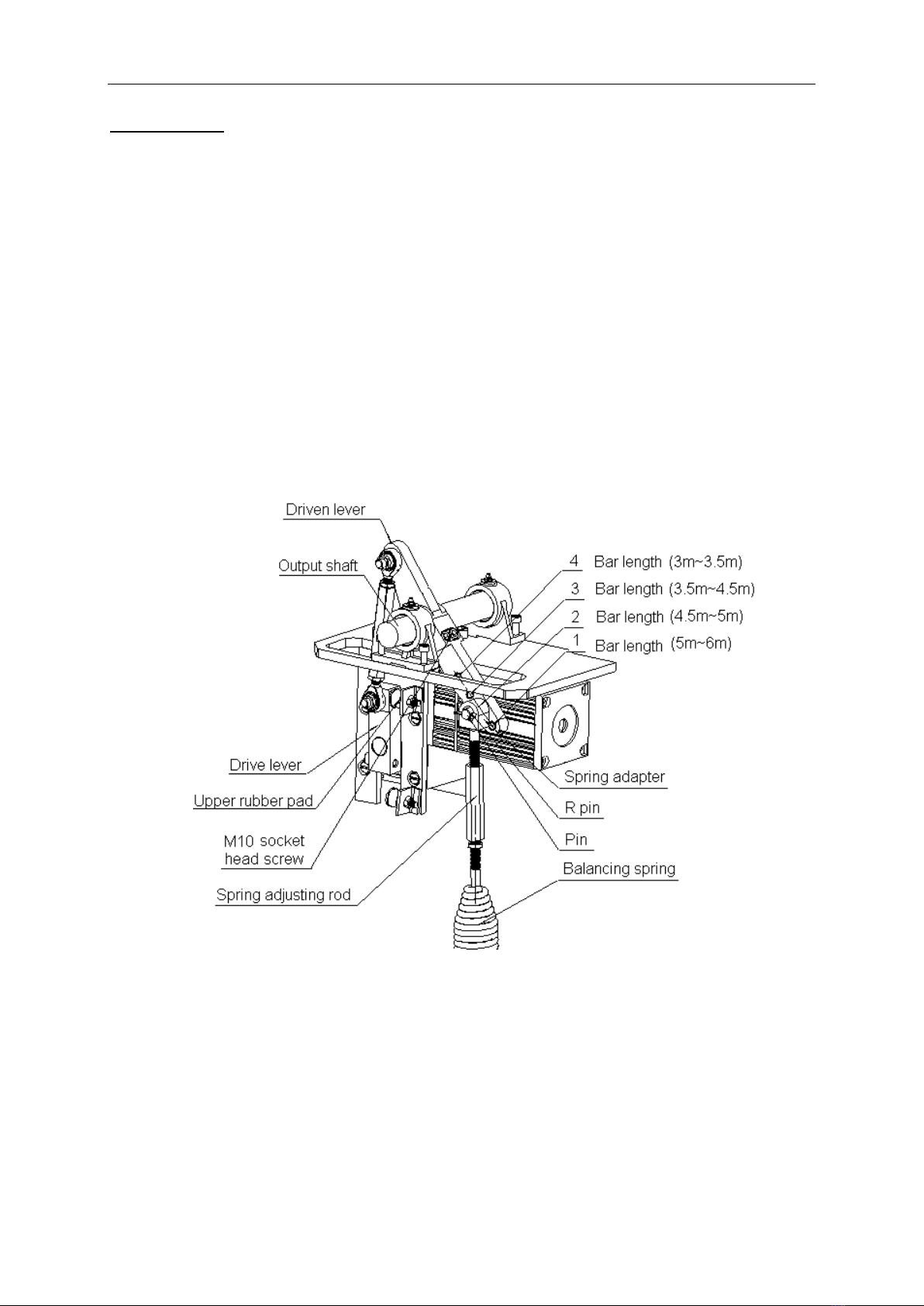

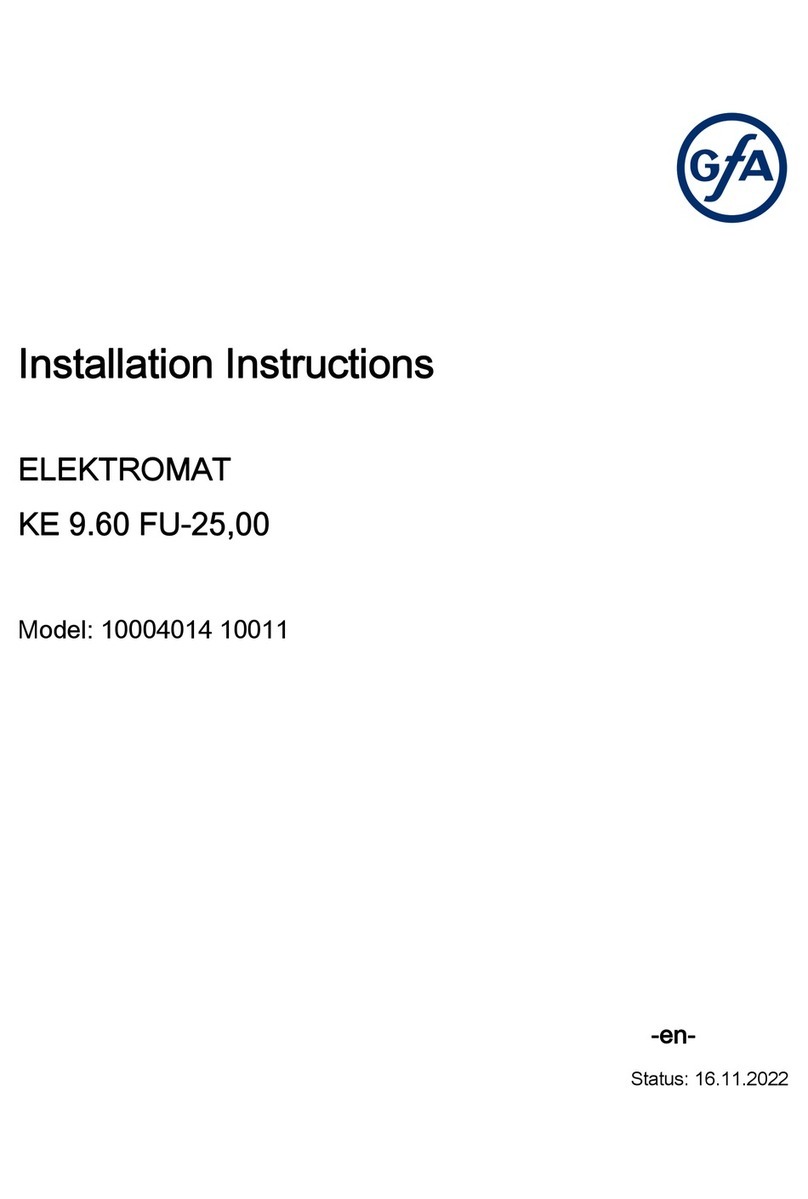

Balancing spring (see Fig.8)

Correct balancing is essential if boom gate is going to work properly. Rectify balancing spring only

when the bar is in open position (i.e. the balancing spring is loose).

Four holes (ø15) on the driven lever. The boom gate is normally delivered in the first hole

(DC655Y/DCZ655Y: suitable for bar length from 5m~6m) or the second hole (DC535Y/DCZ535Y:

suitable for bar length from 4.5m~5m). If you need to change it to the third (3.5m~4.5m) or the fourth

(3m~3.5m) hole proceed as follows:

⚫When the balancing spring is loose (the bar is in open position), undo the nuts, release the

balancing spring by turning the spring adjusting rod clockwise.

⚫Connect the spring adapter to the third or the fourth hole of driven lever, tighten with pin and R pin.

⚫Connect the spring adjusting rod to the balancing spring and spring adapter by turning spring

adjusting rod anti-clockwise. Tighten the spring adjusting rod to make the balancing spring for

ideal condition of use.

⚫Fasten the two nuts.

Fig.8

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

9

5. Electrical

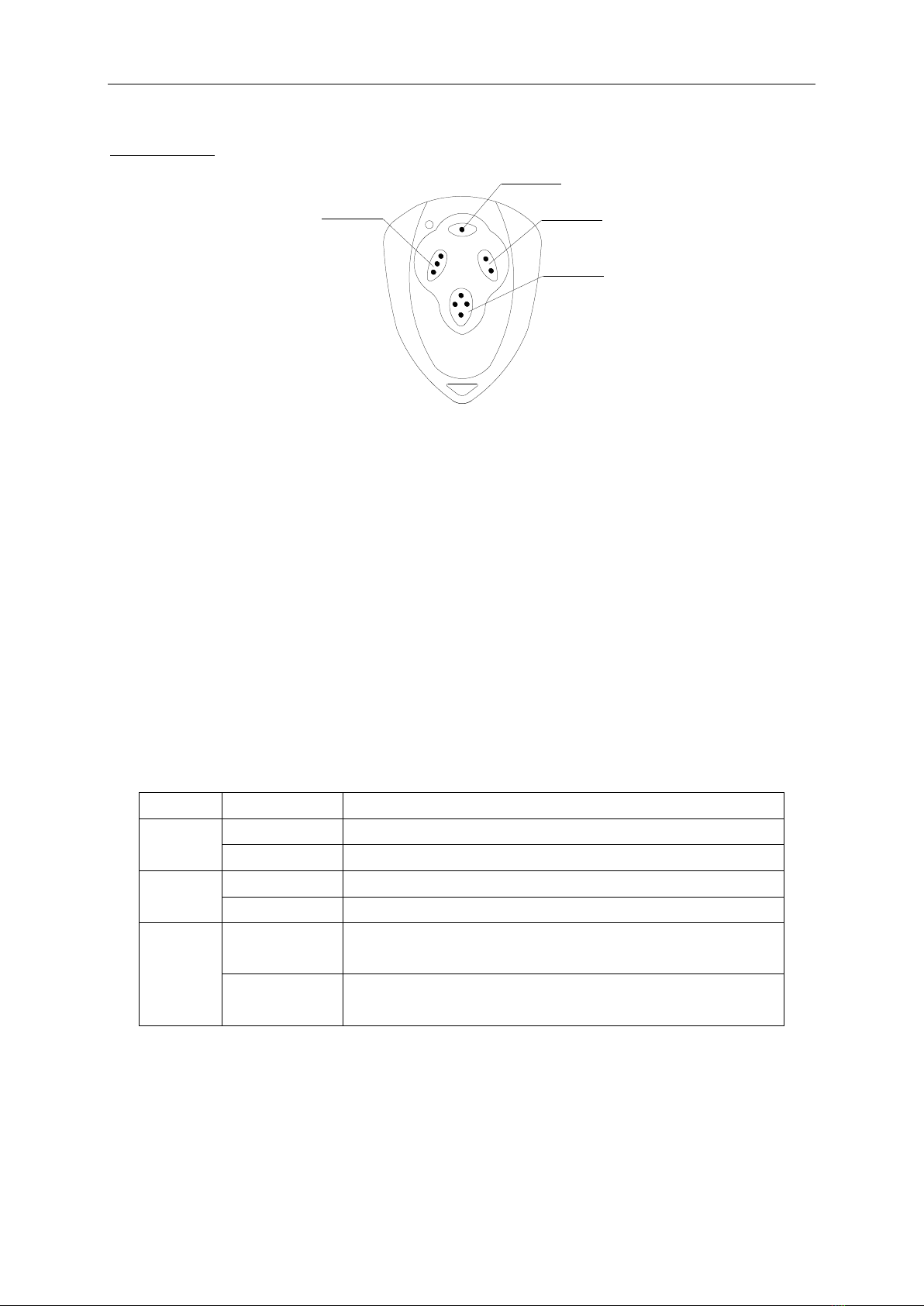

Remote control

Button 1

Button 2

Button 4

Button 3

Fig.9

⚫To add extra remote controls (Learning): Press the button ‘AN’(see Fig.10 control board

scheme No.13) on the control board, a beeper will be heard, then press the remote control button

which you want to use, the beeper will ring again, press the same remote control button again, the

beeper will ring at 1/2Hz frequency and then stop, the last ring is continuous. Then the learning

process is finished.

Up to 25 remote controls may be used.

⚫Erase remote controls: To erase all existing remote controls, press and hold ‘AN’ button, the

beeper will ring, release the button once the beeper stops ringing. This indicates that all the

remote controls have been erased completely.

⚫The remote control works in a single channel mode. With each press of the remote control button

the bar will open, stop, close or stop cycle.

DIP-switch (SW)

Position

DIP-switch

Function

1

ON

Limit switch mode is NC.

OFF

Limit switch mode is NO.

2

ON

Auto-close function is available.

OFF

Auto-close function is shut off.

3

ON

Programming / In this position the control board is in

programming condition, NOT USE condition.

OFF

Normal / In this position the control board can be normally

used.

⚫Set the bar auto-close function: (This feature can be selected to keep the bar stay open for

some seconds before it automatically closes. The auto-close time can be adjusted to between 0

and 44 seconds.) Please turn on the second and the third DIP-switch (see Fig.10 control board

scheme No.5 ‘SW’) to ON position. Press the remote control button which has been programmed

to open the bar, with the bar in vertical position, wait a few seconds according to your requirement

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

10

(the range is 0~44 sec.), this period of time is regarded as ‘auto-close time’. close the bar by

pressing the same button, after the bar stops at the horizontal position, return DIP-switch 3 to OFF

position. Thus the auto-close function has been set.

⚫Cancel auto-close function: Please turn on the second and the third DIP-switch (see Fig.10

control board scheme No.5) to ON position. Press the remote control button to open the bar. When

the bar stops at the vertical position, wait until the bar close automatically (45 sec.). After the bar

stops at the horizontal position, return DIP-switch 3 to OFF position immediately. Thus the

auto-close function has been canceled.

Note:

(1) If any button 1, 2, 3 has been set with auto-close function, then the other two buttons also have

this function. Button 4 needs to be set independently.

(2) There are two different ways to cancel the auto-close function:(a) see Cancel the auto-close

function section. (b) You also can turn off the second and the third DIP-switch to OFF position, the

auto-close function will be shut off. The auto-close feature will not function.

Activities covered in this section

Tuning the auto-reverse safety function

⚫Rotate the ‘Force Adj. VR1’knob (see Fig.10 control board scheme No.14) with a screwdriver. The

resistance may be increased or decreased by rotating clockwise or counterclockwise.

⚫If the boom gate operates freely and can auto-reverse in the event of an obstruction during closing

and stop in the event of an obstruction during opening, then the adjustment is completed.

Loop detector

⚫If loop detector detects vehicles during the bar closing, the bar will reopen immediately and stay

open until the vehicles move out of the loop, after vehicles move out of the loop, the bar will

continue to close.

⚫If loop detector detects vehicles when the bar stops at vertical or middle position, the bar will

remain stop until vehicles move out of the loop. After vehicles move out of the loop, the bar will

close.

If loop detector detects vehicles when the bar stops at horizontal position, the bar will not move.

⚫The bar will keep opening if loop detector detects vehicles during opening. After vehicles pass

through the loop, the bar will close.

Infrared photocell

⚫If infrared beam is interrupted during closing, the bar will reopen immediately.

Limit switch

⚫The switch is used to accurately stop the bar in the vertical and horizontal positions.

⚫If the bar stops at opened position (vertical) when the switch is reached, the bar will not move if

you press ‘▲’(Open) button of button switch.

⚫If the bar stops at closed position (horizontal) when the switch is reached, the bar will not move if

you press ‘▼’(Close) button of button switch.

Open priority

⚫The bar will return to open if press ‘▲’(Open) button of external button switch during closing.

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

11

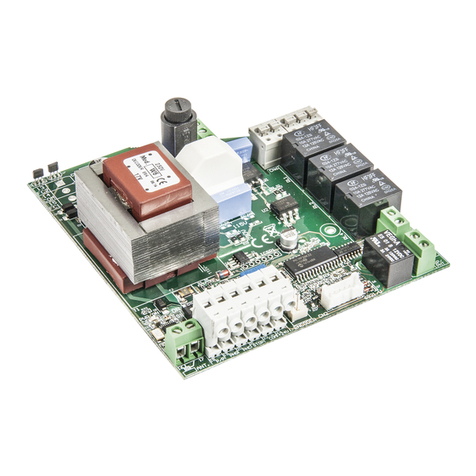

Fig.10 control board scheme

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

12

Wiring Notes of Control Board (See Fig.10)

1. Power Switch: ON/OFF

2. Fuse: 5A, Ø5x20

3. Antenna: ANT

4. Beeper: DC12V

5. DIP-switch

6. Memory Card: 93C66

7. MCU: PIC16C57C

8. External button Switch: T (Stop), G (Close), K (Open), COM (CO)

N.O.

COM

K

G

TControl box

Button switch

Common

Open

Close

Stop

9. Limit switch: CL(Close), COM (Com), OP (Open), +5V(DC +5V)

N.O.

COM

CL

OP

COM N.O.

+5V

+5V

Limit switch (close)

Limit switch (open)

10. Output power supply: +12V (DC +12V), COM (GND, CO),DET (Loop detector, normally open

contact), I.R. (Infrared, normally close contact)

COM

GND

+12V

Out COM

I.R

COM

+12V

Terminal

X8, No.10

Terminal

X8, No.10

I.R

COM

Out

COM

AC24V AC24V Terminal

X5,No.11

Infrared Control board Infrared Control board

Infrared with DC input Infrared with AC input

Loop detector with DC input

Control board

Loop detector

Terminal

X8, No.10

+12V

COM

DET

COM

Out

+12V

GND

COM

Loop detector with AC input

Control board

Loop detector

Terminal

X5,No.11

AC24VAC24V

COM Out COM

DET

Terminal

X8, No.10

11. Output Power Supply: AC24V

12. Power Indicator: LED

13. Learn Button (AN): LEARN

14. Force Adjustor: Clockwise +, Anticlockwise –

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

13

15. Transformer: 220V/12Vx2

16. Sampling Transformer: 110V/ 8.8V 4W

17. Alarm Lamp: AC220V

18. Motor Capacitor: 10μF 450V AC

19. Motor: U (Com), V (Positive direction), W (Opposite Direction), E (Earth)

20. Power Input: E (Earth), L (Live), N (Neutral) AC240V

6. Maintenance

⚫Every 3 months check and add grease (2#) regularly in two grease cups. There should be no

water and impurity in grease cup.

⚫Every 6 months check and add oil. Use WA220 oil only. To avoid high pressure in the reducer

casing, please loose the oil screw a little (one or two turns) before using.

Grease cup (2# grease)

Top view

Oil screw (WA220 oil inside)

Note: Loose the oil screw before

using to avoid oil leakage.

Fig.11

⚫Check and tighten the two M10 socket head screws in the driven lever.

⚫Check if all screws and nuts have been tightened firmly except oil screw as shown in Fig.11.

⚫Check if all wires are firmly connected to their respective terminal blocks.

⚫Make sure the bar is correctly fixed.

⚫Check the general state of the balancing spring.

⚫Keep boom gate clean at all times.

7. Troubleshooting

No.

Trouble

Possible causes

Solutions

1

The bar fails to close or

open fully.

Limit switch

Re-adjust the limit switch.

2

The bar opens too slowly.

Balancing spring

Adjust the balancing spring rod or

replace the balancing spring.

3

The indicator light on the

control box does not light.

Fuse blown

Replace fuse

4

The remote control

operating distance is too

short or not far enough.

Battery level may be

low.

Replace the battery inside of the

transmitter or try another transmitter.

5

Red indicator light of the

transmitter does not light.

Poor contacted.

Replace the transmitter.

DC535Y/DCZ535Y, DC655Y/DCZ655Y BOOM GATE USER’S MANUAL

14

8. Packing list

Make sure that all parts are included before using. Refer to packing list. If any parts appear to be

missing, contact a dealer.

No.

Item

Quantity

1

Assembled cubicle

1

2

Bar locking bracket

1

3

Bar cover

1

4

Cover

1

5

Crank

1

6

Transmitter

2

7

Button switch(optional accessory)

1

8

Expansion bolt M12

4

9

M10×16 Screw for mounting bar

4

10

M4×5 Screw for mounting bar cover

3

11

Bigger washer

4

12

Key

2

13

User’manual

1

This manual suits for next models

3

Table of contents

Other TdA Gate Opener manuals

Popular Gate Opener manuals by other brands

DoorKing

DoorKing 9000 Series quick start guide

LOCKEY USA

LOCKEY USA TB200 installation instructions

Topens

Topens CASAR HJ4021 user manual

cedamatic

cedamatic RAM 50V Series Operating instructions and spare parts catalogue

DoorKing

DoorKing 6004 reference guide

GFA

GFA ELEKTROMAT KE 9.60 FU-25,00 installation instructions

Richmond

Richmond GTR062 user manual

Vimar

Vimar ELVOX RS20 Installation and operation manual

GFA

GFA ELEKTROMAT FT 80.5 FU-45,00 installation instructions

Maximum Controls

Maximum Controls MAX SUPER ARM 2300 manual

Cardin Elettronica

Cardin Elettronica 200/BL3924ESB instruction manual

Supeero

Supeero 606S Assembly instructions and directions for use