TdA ZK300DC User manual

Swing Gate Operator

ZK300DC

Installation and Users Manual

Total Door Automation (Australia) Pty Ltd

www.totaldoorautomation.com.au

sales@totaldoorautomation.com.au

Technical Support 1800 AUSTDA (1800 287 832)

WARNING

ONLY QUALIFIED AND EXPERIENCED

TECHNICIANS SHOULD ATTEMPT INSTALLATION

OR SERVICE TO THIS UNIT, OTHERWISE, SERIOUS

PERSONAL INJURY, DEATH, OR PROPERTY

DAMAGE MAY OCCUR.

SAVE THESE INSTRUCTIONS.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

2

TABLE OF CONTENTS

Important Safety Information 3

Additional Features 3

Packing List 4

Specifications 5

Necessary Tools 5

Site Preparation 5

Mechanical / Installation 6

Electrical / Control Box Mounting 12

Electrical / Main Terminal Wiring 13

Electric Lock 14

Flashing Light 14

External Button Switch 14

Infrared Photocell 14

Battery 14

Electrical / Setting 15

Learn Remote Controls 15

To Erase All Remote Controls 15

Setting Open and Close Limit 15

Setting Auto Close Time 15

Setting Interval Time 15

Setting obstruction force 15

Maintenance 16

Troubleshooting 16

ZK300DC SWING GATE OPERATOR USER’S MANUAL

3

1. Important Safety Information

Please read these important safety instructions and follow all instructions as

incorrect installation can lead to severe injury/death or property damage:

DISCONNECT the power from the MAINS before making any repairs or removing its

covers. ONLY experienced service gate installer can install the gate and control unit.

Drive through the gate system only after complete opening.

DO NOT operate the gate operator unless the gates are in full view and free from

objects such as cars and children/people. SERIOUS PERSONAL INJURY and/or

property damage can result from failure to follow this warning.

The gate must be WELL BALANCED. Sticking or binding gate must be repaired by an

experienced service gate installer prior to Opener installation.

DO NOT allow control devices to be placed so that a person can access them by

reaching through the gate.

NEVER active your gate operator until you ensure that the area is clear of people,

pets or other obstructions.

When using the auto close mode, a PHOTOELECTRIC BEAM must be correctly fitted

and correctly tested for operation at regular intervals. EXTREME CAUTION is

recommended when using the Auto close mode. All the safety rules must be followed.

NEVER mount any device that operates the gate operator where the user can reach

over, under, around or through the gate to operate the controls.

We strongly recommend the use of PHOTOELECTRIC BEAM to provide ADDITIONAL

SAFETY PROTECTION.

Failure to comply with the instructions above may result in personal injury/death or

property damage. Our company does not accept responsibility for damage or injury

resulting from installing this operator.

2. Additional Features

One drive operator for single gate installation, and two drive operators for dual gate

installation.

Supports up to 40 remote control transmitters, (2 transmitters included in the

packing)

User programmable and user erasable remote codes.

Remote control hopping code technology prevents your remote code being accessible

to others.

For safety protection, ZK300DC will stop if it encounters an obstruction during closing

or opening.

Manual key release design for emergency purposes.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

4

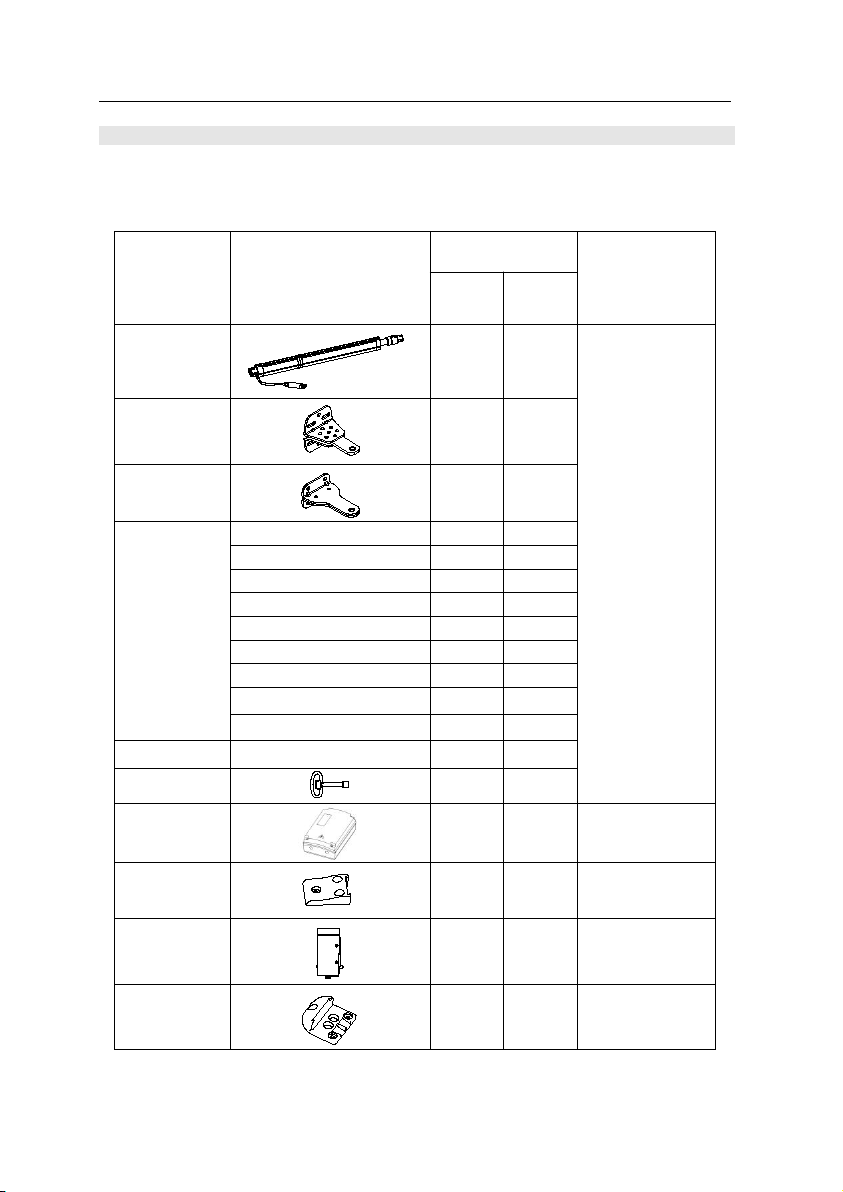

3. Packing List

After receiving the product, you should make an unpack-inspection, in which you should

check whether the product was damaged. If you have any problem please contact dealer.

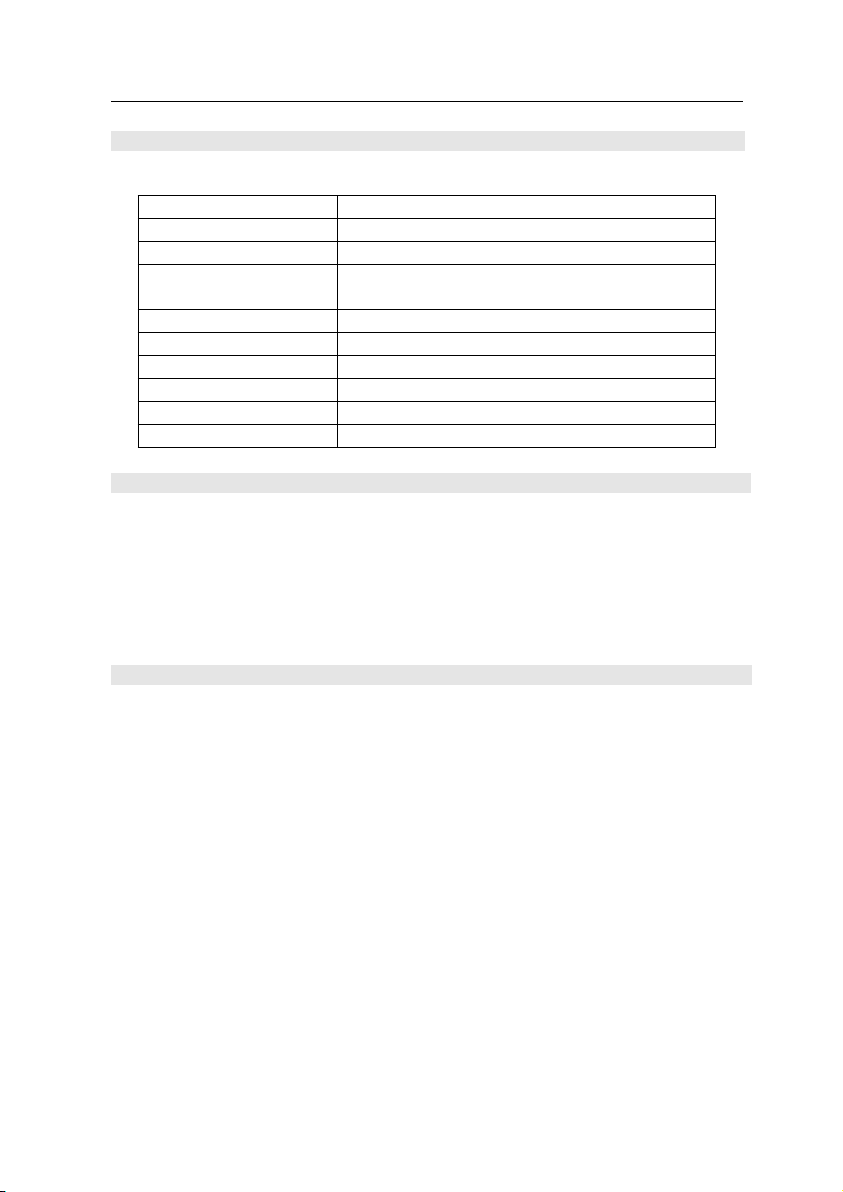

Table 1 Packing List of ZK300DC Swing Gate Operator

Item

Diagram

Quantity

Remark

For one

drive

operator

For two

drive

operators

Gate Operator

1

2

In the same box.

Post bracket

1

2

Gate bracket

1

2

Accessories

Pin

2

4

Nut

2

4

Screw M6X16

2

4

Nut M6

2

4

Spring washer

2

4

Screw M8X25

2

4

Nut M8

2

4

Spring washer8

2

4

Level gauge

1

1

User’s manual

1

1

Release Key

1

2

Control box

+2 remotes

1

1

Stop block

1

2

Optional

Electric lock

1

1

Optional

Base plate

1

1

Optional

ZK300DC SWING GATE OPERATOR USER’S MANUAL

5

4. Specification

Table 2 Technical data

5. Necessary Tools

The following tools may be necessary to install the ZK300DC operator. You will need an

electric drill, hacksaw, screwdrivers, tape measure, multimeter, level, wire cutters and wire

stripper, a socket set, and possibly access to a welder if your installation cannot use the

supplied brackets. If the brackets included do not fit your gate because of the dimensions

of your gate, you may have to fabricate brackets for your application or notch a column in

order to obtain the necessary set back.

6. Site Preparation

Before commencing installation, check the following:

The gate moves freely by hand for the full length of open and close travel.

Check that the structure is sufficiently strong and rigid, the operator must operate on

a reinforced point on the gate and that its dimensions and weights conform to those

listed in the specifications of this document.

The gate should be mounted to the fence post and swinging freely, there should be

little resistance in the swing of the gate.

Make sure that the gate is plumb and level.

The fence posts must be mounted in concrete.

If you want to use electric lock, make sure the bottom of the gate is 45-50mm from

the ground. If the electric lock is not required, make sure the distance from the

bottom of the gate to the ground more than 20mm.

In order to protect the wires, between the gate operator and the control box,

armored cable, galvanized cable or PVC conduit must be set into the concrete when

it is poured. The diameter of the cable must be more than 20mm.

Wires within the cable shall be located or protected so that no damage can result

from contact with any rough or sharp part.

Power supply

AC240V, 50Hz

Motor

DC24V 50W

Rated force

1000N

90 opening or closing

time (one gate)

20 seconds

Max. gate weight

300kg

Max. gate width

9.8 feet (3 meters)

Working angle of gate

90or 105

Limit switch

Encoder

Ambient temperature

-15ºC~+50ºC

Battery

3.5Ah, 24V

ZK300DC SWING GATE OPERATOR USER’S MANUAL

6

Use another cable for safety devices (such as electric lock, infrared photocell, flashing

light, external button switch etc.), electrical lock wire should be more than 1.5mm2,

and the other wires should be more than 0.5 mm2.

To prevent rainwater from entering into the cable, arrange the cable as show in Fig.1.

Fig.1

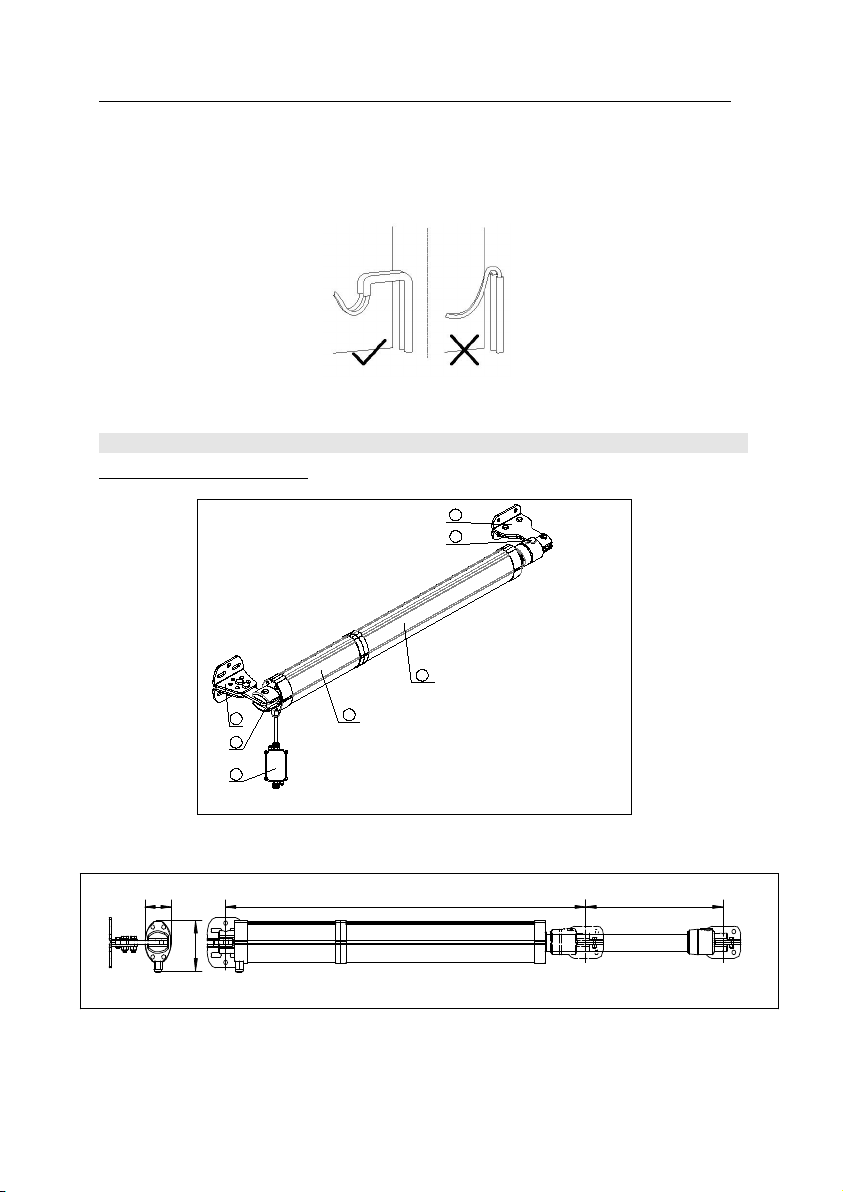

7. Mechanical / Installation

Main structure and dimension

1

2

34

5

6

7

7、Gate bracket

6、Release nut

5、Lead screw

4、DC Motor

3、Post bracket

2、End joint

1、Connector

Fig.2

Fig.3

315840

1 0 0

60.5

ZK300DC SWING GATE OPERATOR USER’S MANUAL

7

To release the operator by turning the release nut anticlockwise.

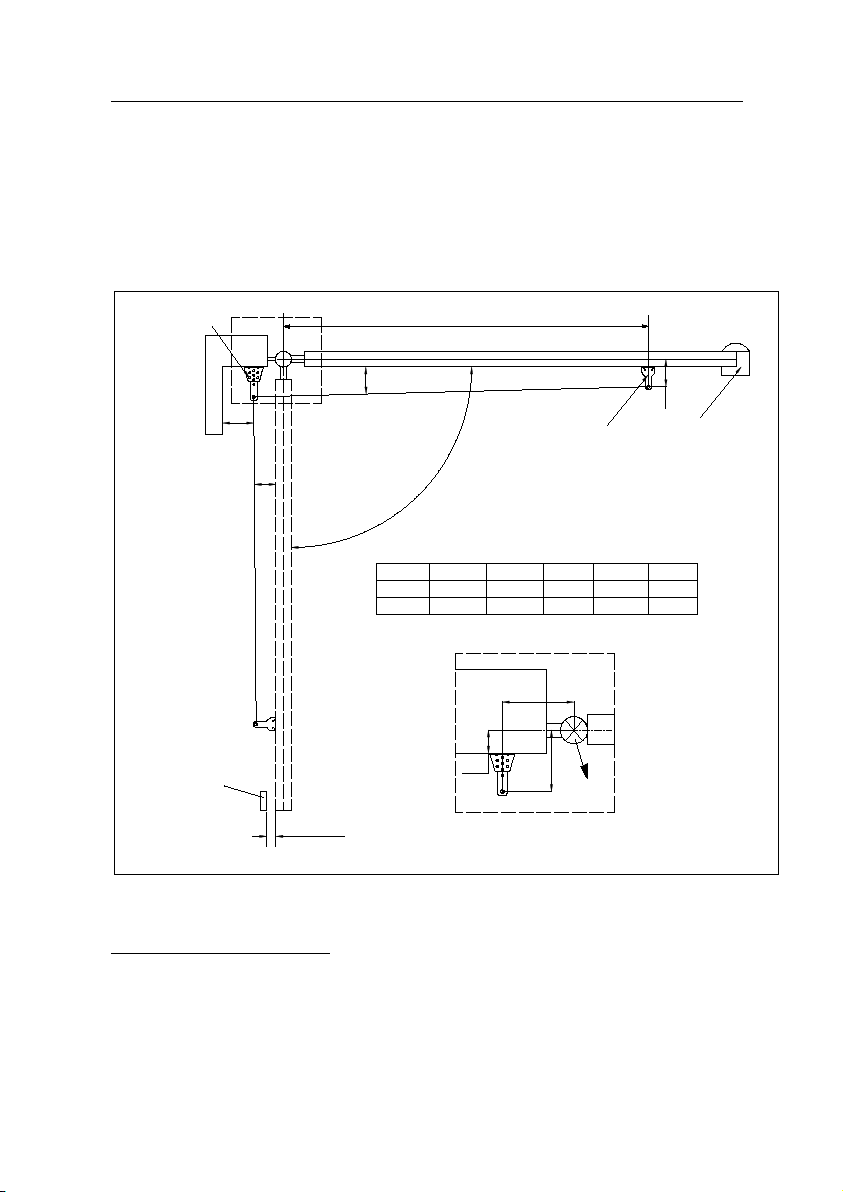

The gate is mounted on one face of the mounting post, and the operator is mounted on the

face 90 degrees from it. Below is schematic of push to open configurations.

As shown in the diagram below, correctly mounting geometry assures that the desired

degrees of swing are achieved, that the gate speed is correct, and that the operator and

gate will operate properly and have a long life.

A

B

α

Hinge

Post

Post bracket

Gate bracket

105°

90°

50

50130

115150

135

αCmaxBA

Cmax

>0°

>0°

D

E

D E

110

110

975

974

5-10mm

Stop block

(Open position)

Base plate

(close position)

>100

Fig.4 Pull to open mounting geometry

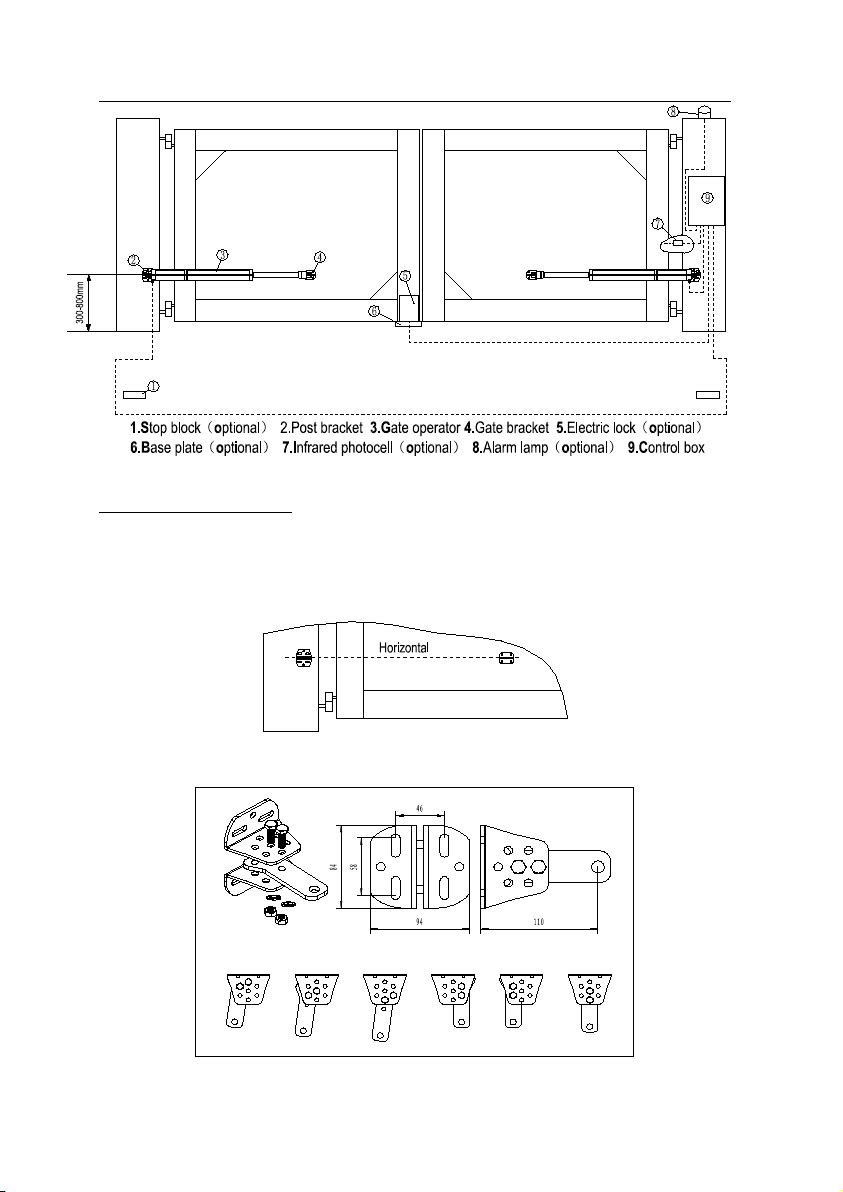

Install automatic gate operator (see Fig.5)

Locate the gate operator between the two hinges, the installation height range is 300 –

800mm. this will prevent the gate from twisting and flexing. Add a cross bar on the gate if

necessary.

Note: If the operator is mounted at a height above the specified range, and the gate is not

sturdy enough, then it may result in bending or damage to the gate and gate operator.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

8

Fig.5

Rear parts of gate operator

Fix the post bracket on the cement pillar with screws and spacers (or welding for

metal pillar). Make sure that the bracket is plumb and lever.

Mount the rear part of the gate operator on the post bracket using the pin supplied,

secure the pin using the nut. See Fig. 7.

The bracket installation should meet the specifications as shown in figure 4.

Fig.6

Screw

Washer

and nut

1 2 3 4 5 6

ZK300DC SWING GATE OPERATOR USER’S MANUAL

9

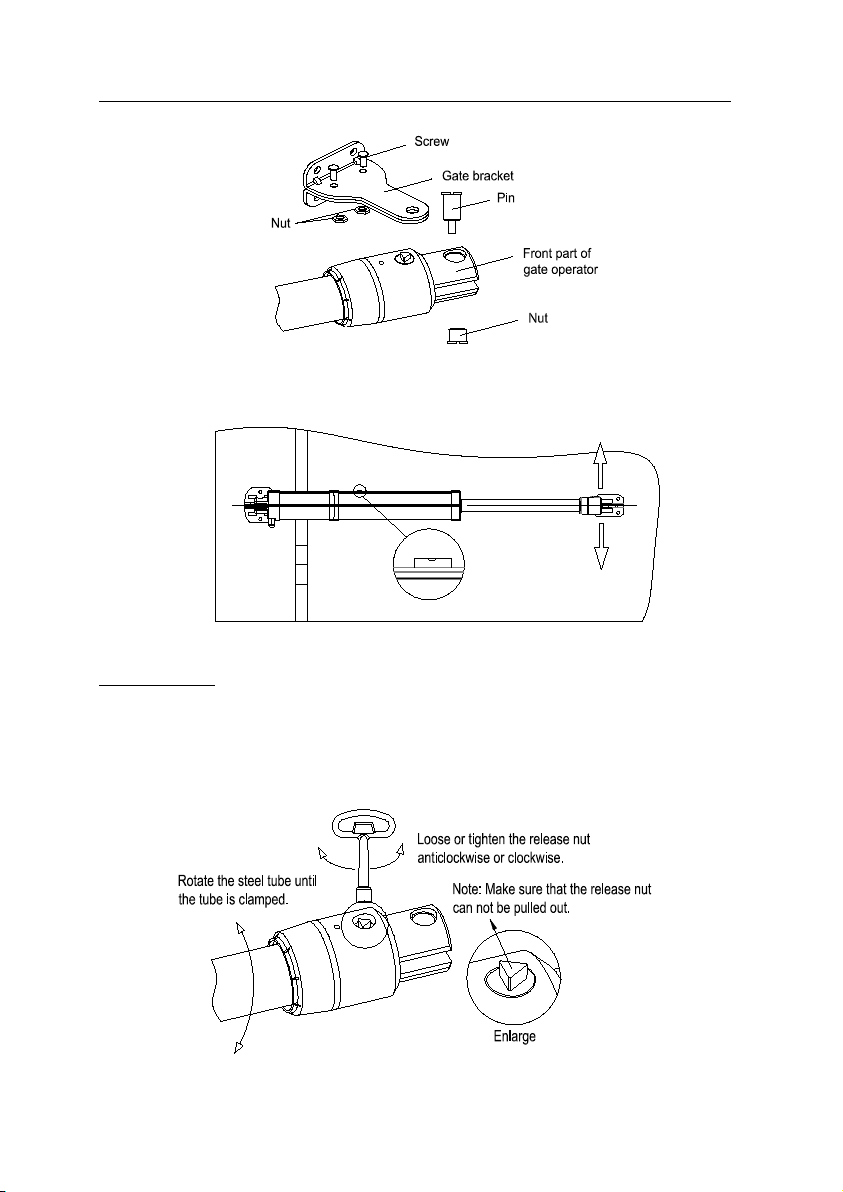

Fig.7

Front parts of gate operator

Move the front part of gate operator up and down slowly, check the installation height

of the gate bracket, fit the gate bracket to the gate, and use a level meter to check

the flatness of the operator (See Fig.9). Tack weld the gate bracket on the gate,the

bracket installation should meet the specifications as shown in Fig.4.

Release the gate operator, open and close the gate manually, performing complete

opening and closing travel. Movement must be smooth.

If this is not the case, review bracket positioning and that its dimensions conform to

those listed in the specifications of this document.

After you have identified the desired position of the bracket, remove the gate

operator, fix or weld the gate bracket on the gate permanently. See Fig.9.

Mount the front part of gate operator on the bracket using the pin and nut supplied.

See Fig.8.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

10

Fig.8

Fig.9

Release function

After installing the brackets, loose the release nut by turning the key about 5 circles

anticlockwise, make sure that the release nut can not be pulled out. Manually open or close

the gate, review bracket positioning and that its dimensions conform to those listed in the

specifications of this document. After adjusting, tighten the release nut clockwise, then

rotate the steel tube by hand until the tube is clamped (meanwhile, the tube is click), finally

tighten the release nut firmly.

Fig.10

Level

ZK300DC SWING GATE OPERATOR USER’S MANUAL

11

Stop block –open position

After the gate reaches the desired angle (90°or 105°), ensure 5-10mm space exists

between the gate and stop block See Fig.4. This margin is required to prevent the

gate from bumping on the stop block.

Fix the stop block to the ground with expansion bolts, add pad if necessary.

After mounting the operator, with the key unlocked, move the gate, verify that it

stops at the proper position.

Electric lock

An electric lock is provided for installation for gate lengths greater than 1.5 meters.

To install the base plate of the lock, place the base plate between the two gates,

determine the location, mark and drill the holes.

Fix the base plate to the ground with 3 screws, make sure the gate is higher than

base plate and that the lock pin can fit tightly in the hole in the plate.

Weld the steel plate of the lock to the primary gate, and then fix the lock to the steel

plate. See Fig.11 to determine the height of the electric lock.

Stop plate (see Fig.11)

The pair of gate sections will not start simultaneously. The gate section with the lock

will start to open earlier than the other gate section, so that both sections can be

locked properly.

With the gate in the desired closed position.

Weld a stop plate on the gate section without the lock.

A plate or tab can be welded on the gate section with the lock so that when it closes,

it will trap the gate section without the lock between itself and the base plate, thus

locking both gate sections.

Stop plate

A

B

Secondary gate

Primary gate

Plate or tab

Electric lock

Lock pin

ZK300DC SWING GATE OPERATOR USER’S MANUAL

12

Fig.11

8. Electrical / Control Box Mounting

Install the control box

Make sure that power is OFF before making any electrical connections.

Place the control box in the desired mounting position, open the cover of the control box,

mark the mounting holes, and install the control box. See Fig.12

Perform the wiring.

Note: we regard the gate with the electrical lock as the A gate (open first, close later), the

other gate as the B gate.

A- Top view

15

Primary Secondary

B- Side view

Base plate

Electric lock

Release here

45-50

3-6

8-10

Gate

Steel plate

ZK300DC SWING GATE OPERATOR USER’S MANUAL

13

Fig.12

9. Electrical / Main Terminal Wiring

Connect the operator to the control box as shown in Fig.14.

Connect primary motor that on the primary gate (with electric lock) to MOTOR A, connect

the secondary gate to MOTOR B. (See Fig.14)

Fig.13

ZK300DC SWING GATE OPERATOR USER’S MANUAL

14

Learn button

Indicator light

C lo s e

K1

K2

A C 2 4V

Jumper

O p en

Sto p

O p en /C lo se /S to p

Alarm lam p

Electric lo c k

Motor A Hall

Motor A Hall

Motor B Hall

Motor B Hall

Motor B positive(red)

Motor B negative(black)

Motor A positive(red)

Motor A negative(black)

Pow er +

Infra red inp u t (N .C .)

Po w er -

BA T+

BA T -

C o m

C o m

C o m

K3

K4

Fig.14 Control board diagram

Electric lock (DC24V)

Connect two wires of electric lock to port ‘Electric lock’.

Flashing light (DC24V)

Attach two wires of flashing light to port ‘Alarm lamp’.

Install the external button switch (Normally open)

The ZK300DC is equipped with an interface for an external button switch or keypad.

To install the keypad attach two wires of your keypad to the port ‘Open/ Close/ Stop’.

The keypad will function in single channel mode.

For three-button switch installation, use the terminals for multi-channel mode. The

port ‘Com’ is the common port, the port ‘Open’ is used to open the gate, ‘Close ’ is

used to close the gate, and ‘Stop’ is used to stop the gate.

Infrared photocell (Normally close)

If the infrared beam is interrupted during closing, the gates will stop immediately.

Connect signal wire of infrared device to ‘Infrared input’ (see Fig.14).

Connect common wire (i.e. ‘power supply –‘) of infrared device to ‘Power -’, connect

‘power supply +’ of infrared device to ‘Power +.

Battery

Connect battery to ‘BAT+’ (red) and ‘BAT-’ (black). A fully charged standard battery still can

provide enough power for operating 10 cycles after power disruption.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

15

10. Electrical / Setting

Learn remote controls

Adding extra remote controls (Learn):

Press the Learn Button on the control board for 1 second, release the button, the

indicator ‘LED’ will be on.

Press the same button you want to use twice, the ‘LED’ will flash 6 times, the learning

process is completed.

Up to 40 remote controls may be used.

To erase all remote controls

Press and hold the Learn Button on the control board for 8 seconds until ‘LED’ turns

off. This indicates that all the remote controls have been erased completely.

The remote control mode (single or three channel mode) is adjustable by Jumper cap,

put the jumper cap on left two pins, with single channel mode, put the jumper cap on

right two pins, the remote control is three channel mode.

Warning: DO NOT operate the gate operator unless the gates are in full view and free

from objects such as cars and children/people.

For safety and security, we recommend that the factory setting be replaced with a

personal code.

Setting open and close limit position

Press and hold K1 button for 3 seconds, ‘11’ will be displayed on the LED.

While ‘11’ is displaying on LED, Press K2 and K4 button to set open limit for gate B,

press K1 button to confirm the setting. The gate B will then close automatically to its

closed position.

Then ‘22’ will be displayed on LED. press K2 and K4 button to set open limit for gate

A, press K1 button to confirm the setting, the gate A will then close automatically to

its closed position.

Setting Auto close time

Press and hold K2 button for more than 4 seconds, release the button until ‘-‘ is

displayed on LED

Press K2 button to increase auto-close time, press K4 button to decrease auto-close

time. The auto-close delay time: 0–90 seconds.

Setting Interval time between two gates (Default: 2 seconds)

Press and hold K4 button for more than 4 seconds, release the button until ‘H’ is

displayed on LED.

Press K2 button, ‘H’ is indicated on the LED display, without interval time, press K4

button, ‘Ⅱ’ is indicated on the LED display, the interval time between two gates is 2

seconds.

Setting obstruction force (level1- level20 adjustable)

ZK300DC will stop if it encounters an obstruction during closing or opening.

Press and hold K3 button for more than 4 seconds, until the number ’-’ is displayed

on LED.

Press K2 to increase the obstruction force, the maximum force is level 20. Press K4

to decrease force, the minimum force is level 1.

Press K1 to confirm the setting. ‘II’ is indicated on the LED display.

ZK300DC SWING GATE OPERATOR USER’S MANUAL

16

11. Maintenance

Regularly verify that the gate swings freely.

Make sure the hinges function perfectly.

Verify correct operation of the safety devices.

Keep operator clean at all times.

12. Troubleshooting

Table 3

Symptoms

Possible cause

Remedy

Motor runs, but gate

does not open or

close.

1.The gate is obstructed.

2.The operator is released.

3.The gate is obstructed.

1. Remove obstructions.

2. Engage the operator.

3. remote the obstructions.

Gate does not open

far enough or does

not have the proper

opening angle.

The gate operator is not

installed properly according to

Fig.4 in the gate geometry

section of this manual.

Either modify the

installation to meet Fig.4 or

adjust the size or replace

the installation brackets in

accordance with the gate

geometry section of this

manual.

The motor does not

run.

1.Power supply.

2.The fuse in the control box is

broken.

1. Check the power.

2. Change the fuse.

Remote control does

not work.

1. The indicator light of

remote control does not light.

2. Remote control is broken.

3. The operating distance is

too far away.

1. Check the batteries in

your remote control.

2. Change the remote

control.

3. Make sure the operating

range is less than 30m.

S0019

Table of contents

Other TdA Gate Opener manuals

Popular Gate Opener manuals by other brands

Omker

Omker OMK-K373 instruction manual

TMT

TMT PAPILLON 250 user manual

Georg Fischer Piping Systems

Georg Fischer Piping Systems EA 11 instruction manual

SOMFY

SOMFY FX24 installation manual

Chamberlain

Chamberlain Elite SL3000 installation manual

Nice

Nice HySecurity CBOX936 Installation and programming manual