barrier gate operator installation guide

for use with models

1601-080/081

1602-080/081

with circuit board 1601-010 rev.V or higher

supplemental manual available

(P/N 2340-065) for 1601-081, 1601-088

and 1602-081 for optional battery

backup system with additional wiring

information.

DKS DoorKing, Inc.

120 Glasgow, Avenue

Inglewood, Ca. 90301

310.645.0023

310.641.1586 fax

www.doorking.com

copyright © 2006 DoorKing, Inc.

All rights reserved.

notice of rights

The content in this manual is protected

under copyright law and no portion

of this manual may be copied,

reproduced, translated, or converted

to any electronic medium without prior

written consent.

notice of liability

DoorKing,Inc.reservestherighttomake

changes in the products described

in this manual without notice and/or

obligation to notify any persons of any

revisions or changes. DoorKing, Inc.

makes no representations or warranties

with respect to this manual.

publication number

1601-065-M-05-07

general information

safety information.....................................................................................................4

glossary ........................................................................................................................5

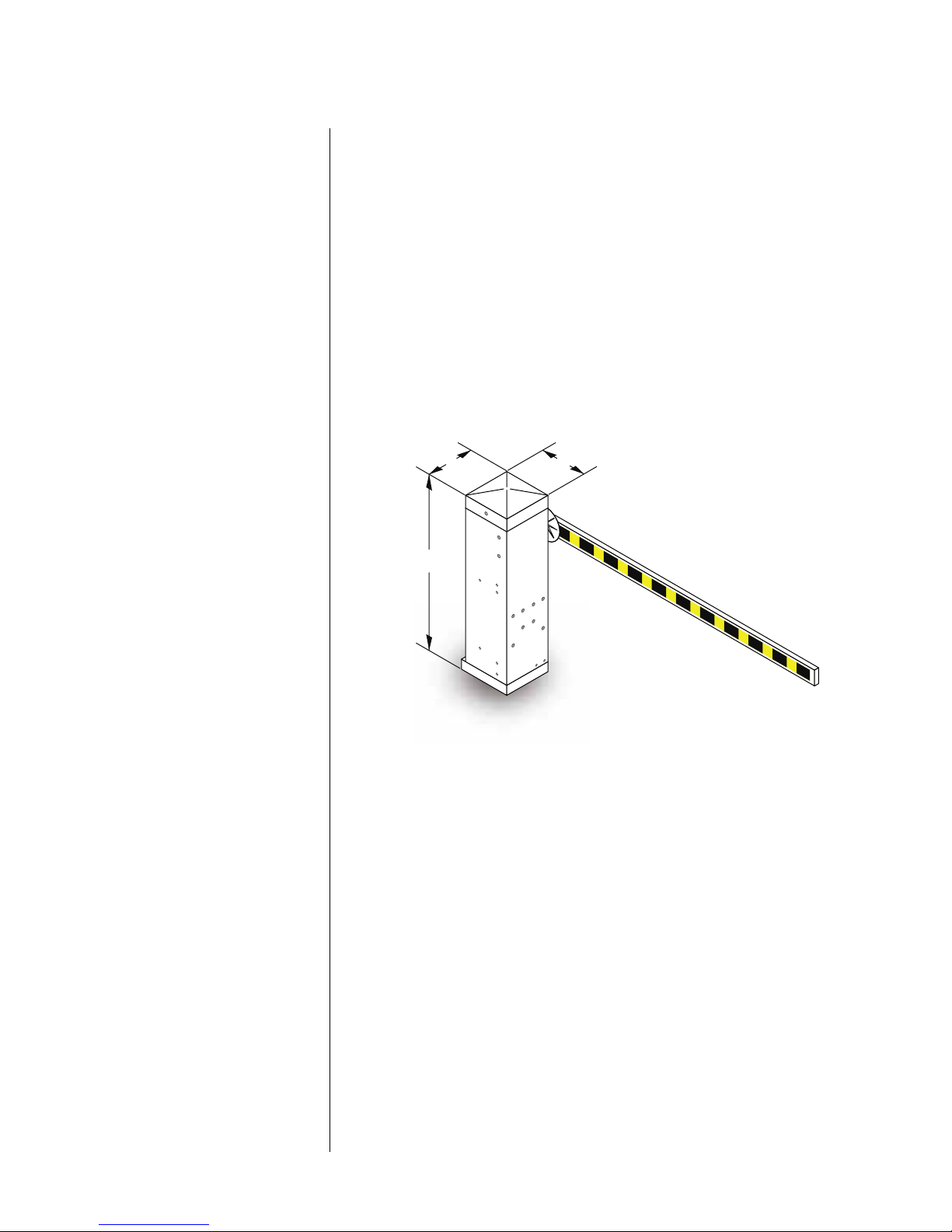

specifications..............................................................................................................6

operator installation

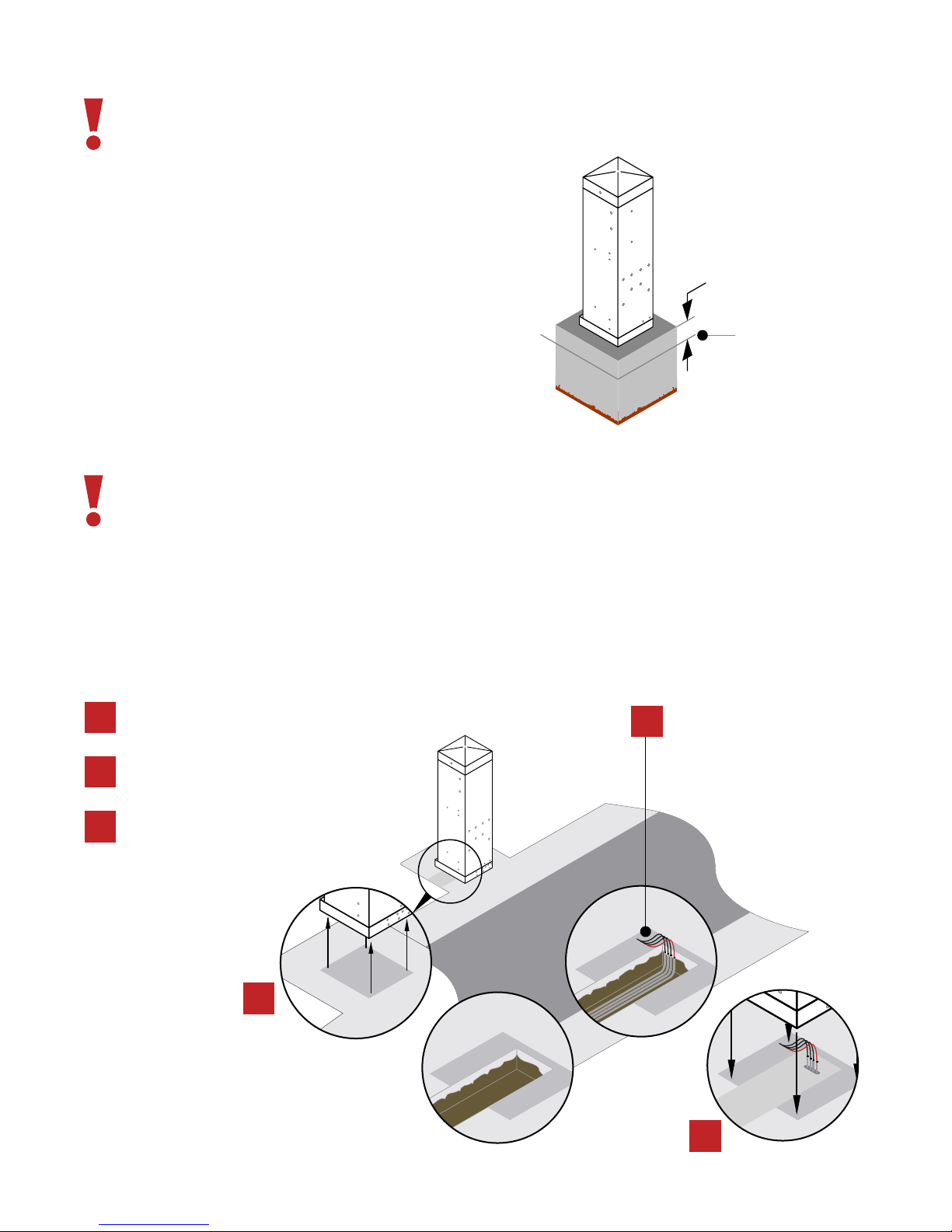

surface operator ........................................................................................................7

electrical installation

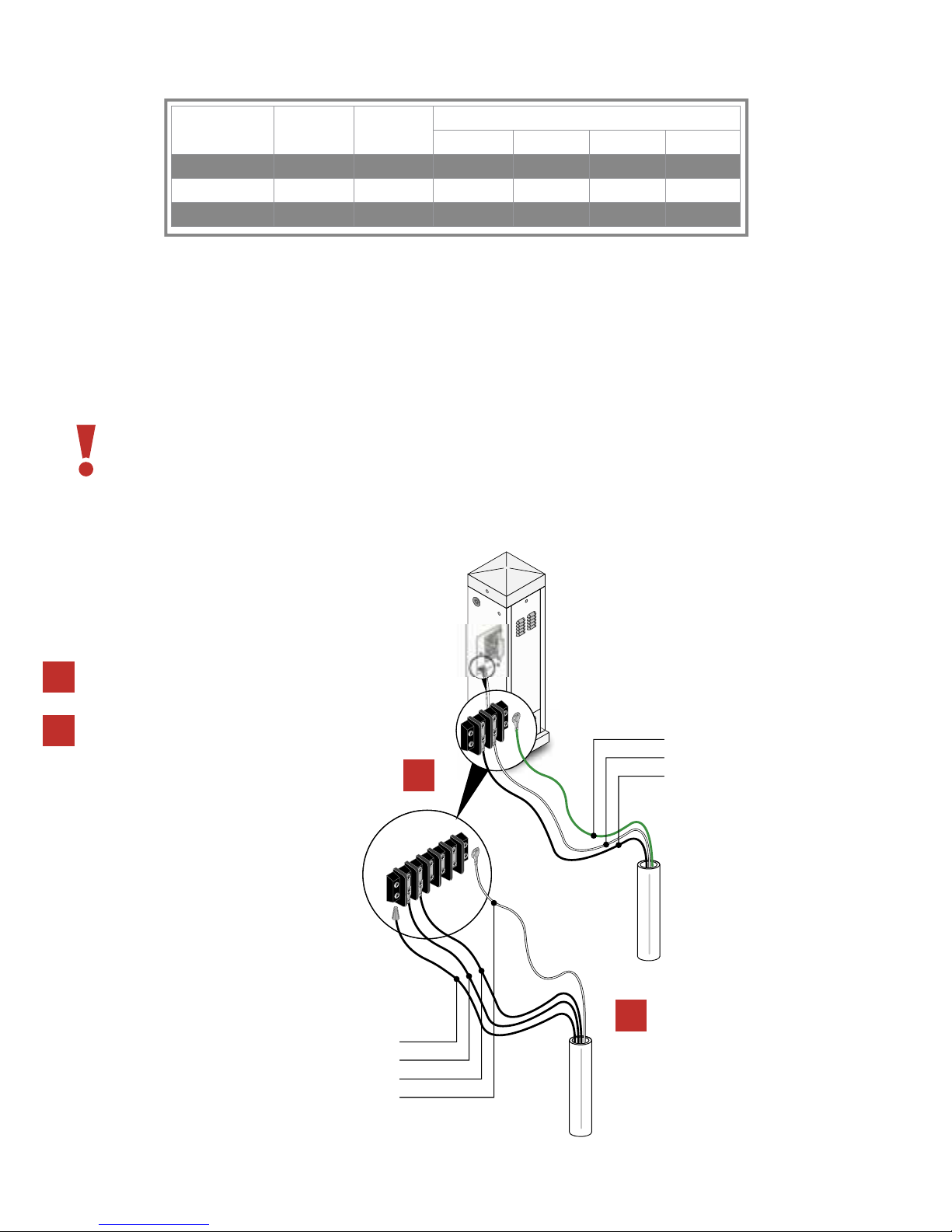

main terminal wiring................................................................................................9

high voltage wiring..................................................................................................10

low voltage wirng ....................................................................................................11

primary/secondary control wiring.......................................................................12

pams wiring ...............................................................................................................13

gate tracker wiring...................................................................................................14

loop detector wiring................................................................................................15

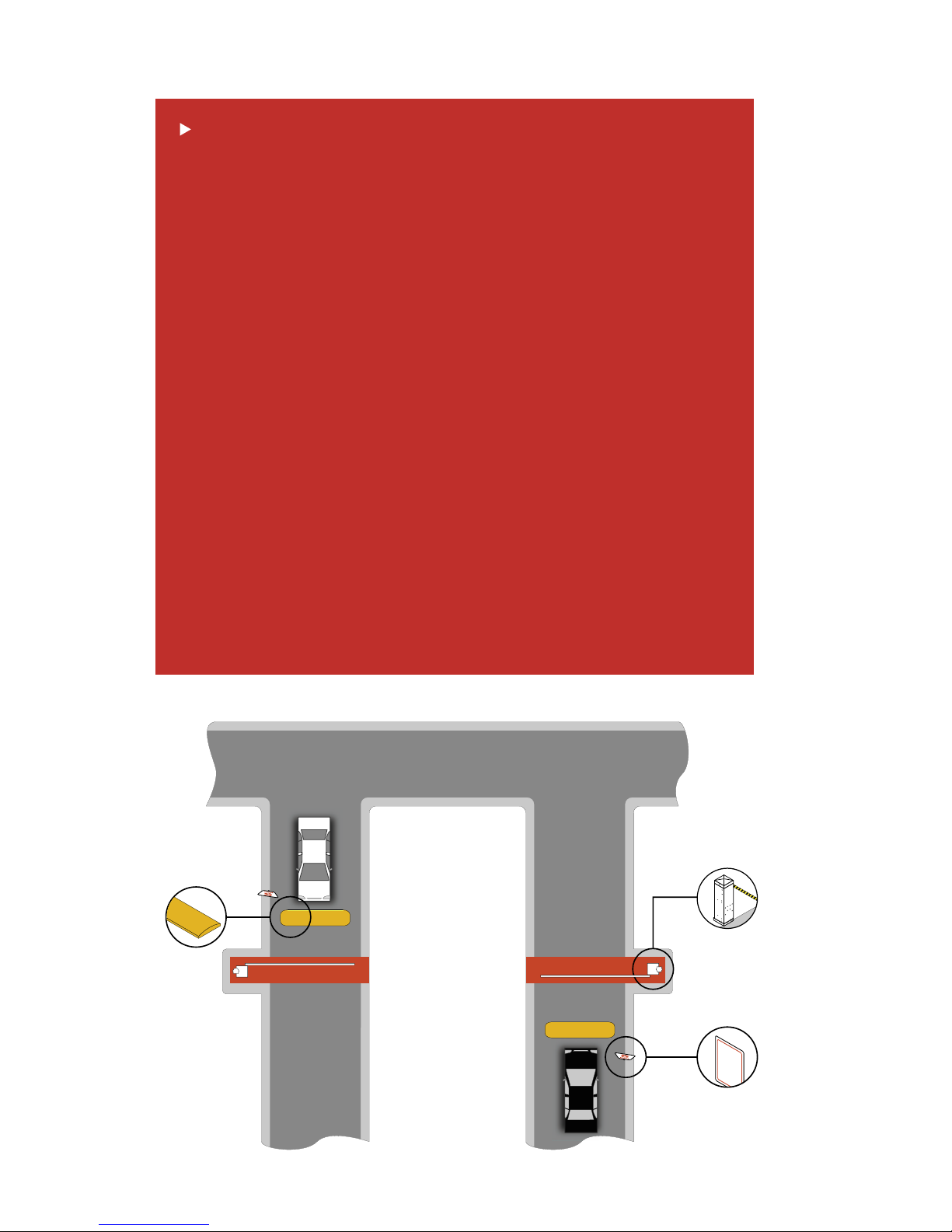

entry lane application.............................................................................................16

exit lane application................................................................................................17

ticket spitter application ........................................................................................18

two-way lane application.......................................................................................19

timer down application..........................................................................................20

arm installation

hub ...............................................................................................................................21

aluminum-plastic-wood .........................................................................................22

wishbone ....................................................................................................................23

settings

control board.............................................................................................................24

magnetic limit ...........................................................................................................25

direction check .........................................................................................................26

reverse sensitivity.....................................................................................................27

switch descriptions & functions ...........................................................................28

accessory installation

reversing edge ..........................................................................................................29

fan kit...........................................................................................................................30

heater kit.....................................................................................................................31

technical information

wiring diagram..........................................................................................................32

wiring diagram-convenience open.....................................................................33

maintenance schedule............................................................................................34

troubleshooting........................................................................................................35

accessories .................................................................................................................36

save this installation guide for reference

1601-065-M-05-07