PYH200 Manual

DC-DC Converter Isolated, 200W, ½ Brick, PCB Mount

1. PRODUCT DESCRIPTION

The PYH200 series are board mount 200W DC-DC converters in a rugged half-brick housing with silicone

potting. They provide a regulated and galvanically isolated output voltage.

The most outstanding features of this series are the exceptionally wide input voltage range from 14V to 160V

(12:1) and the high input/output isolation strength of 3000Vac.

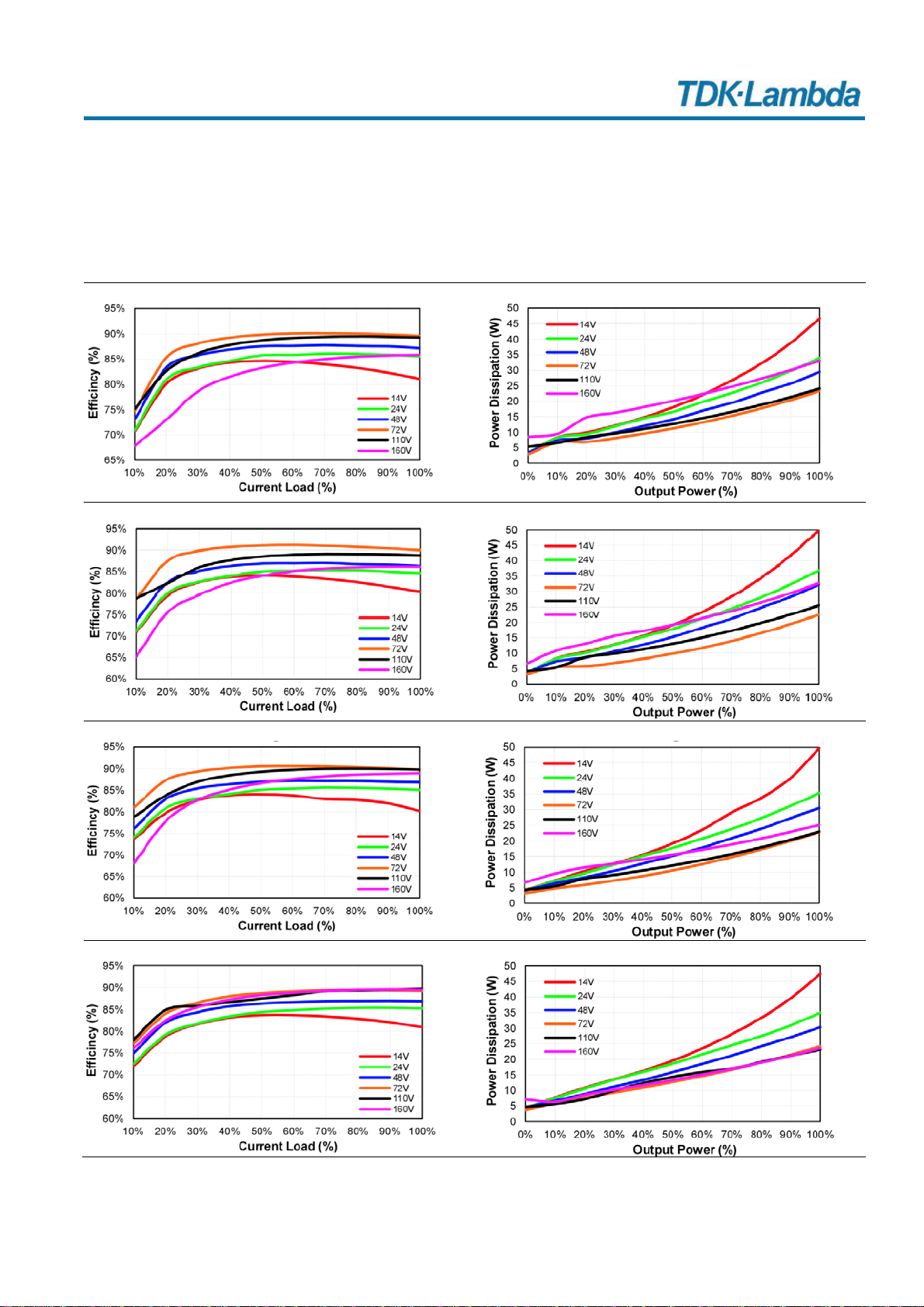

The wide allowed case temperature range from -40°C to +100°C, the low heat generation, due to the high

efficiencies up to 90% and the high shock and vibration resistance thanks to the potted design make this

device suitable for nearly every situation.

Another unique feature is the compliance with the standard EN 50155, which is an international standard

covering electronic equipment used on rolling stock for railway applications. In combination with the wide

input voltage range, there are many application opportunities in this segment. Further applications for this

DC-DC converter can be found in Distributed Power Architecture (DPA), telecommunications, battery-

powered devices, measurement and laboratory equipment, devices in industrial environments, and many

other areas.

2. PRODUCT FEATURES

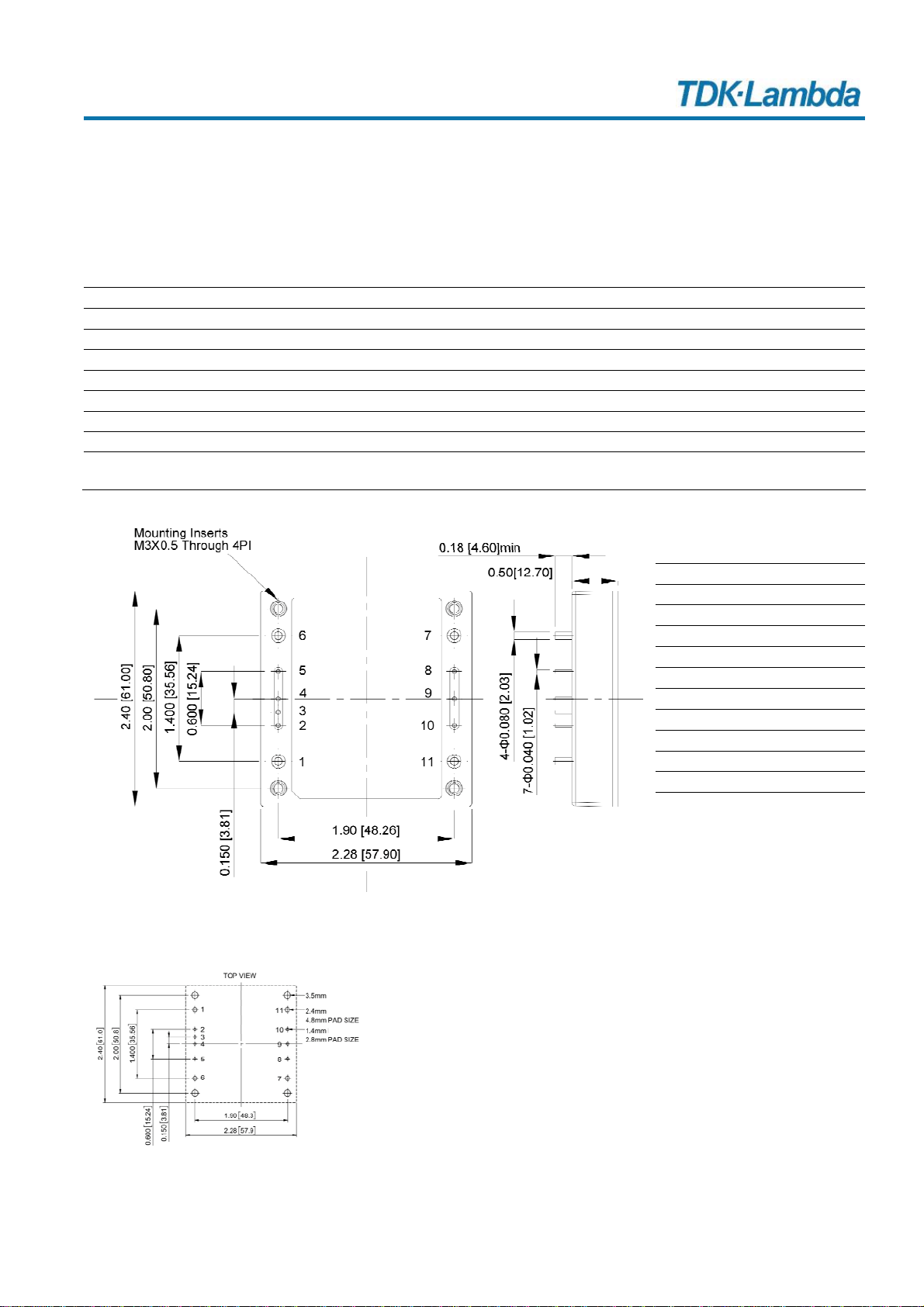

- Half-brick (2.28x2.4”) Industry Standard Footprint

- 3000Vac Input to Output Isolation

- 14-160V (12:1) Wide-range Input

- EN 50155 Railway Compliant

- IEC 62368-1 (ICT) Approved

- High Shock and Vibration Resistance Due to Potted Design

- Efficiency up to 90%

- -40 to +100°C Operating Case Temperature Range

- Remote ON/OFF Input

- Output Voltage Sense Lines

- Frequency Synchronization With External Clock

3. INTENDED USE

This device is designed and manufactured as a component part to be mounted on a pc-board and to be

installed in electronic devices.

This device is intended for commercial use, such as in industrial control, process control, monitoring and

measurement equipment or the like.

Additionally, this device is also designed for equipment that is intended for use in railway rolling stock

applications according to EN 50155.

Do not use this device in equipment, where malfunctioning may cause severe personal injury or threaten

human life without additional appropriate safety devices, that are suited for the end-application.

If this device is used in a manner outside of its specification, the protection provided by the device may be

impaired.

All parameters are typical values specified at nominal input voltage, nominal output load, 25°C ambient and after a 5 minutes run-in time unless

otherwise noted. The information presented in this document is believed to be accurate and reliable and may change without notice.

For additional information, please visit https://product.tdk.com/info/en/products/power/index.html 2/21

DOC-ID: IM-PYH200-2022-05-04