PAQ

B-232

・All specifications are subject to change without notice.

Example :

PAQ65D48-3325/PV; Represent positive logic, OVP/OCP Auto-restart

MODEL

ITEMS/UNITS CH

PAQ65D48-2518 PAQ65D48-3318 PAQ65D48-3325 PAQ65D48-5033

12121212

Input Voltage Range V 36 - 76 VDC

Efficiency (Typ) (*2) %86.0 87.0 90.0

Current (Typ) (*2) A 0.82 0.97 1.10 1.36

Output

Nominal Voltage VDC 2.5 1.8 3.3 1.8 3.3 2.5 5 3.3

Minimum Current A 0

Maximum Current A 15 17 15 17 15 17 13 16

Maximum Current Combination A Io1+Io2 = 18A

Total Allowable Power (*1) W Po1+Po2 = 37.5 Po1+Po2 = 49.5 Po1+Po2 = 65

Voltage Setting Accuracy (*2) % ± 2

Maximum Line Regulation (*5) mV ±6.6 ±10 ±6.6

Maximum Load Regulation (*6) mV ±16.5 ±25 ±16.5

Temperature Coefficient 0.02%/℃

Maximum Ripple & Noise (*4)

mVp-p

75 100 75 100 75 100

Voltage Adjustable Range (*3) ±10%

Function

Over Current Protection

(Io1+Io2) (*7)(*8)(*10) 105 ~160%

Current limiting with inverter shutdown (Option available : Refer to option table)

Over Voltage Protection (*7)(*8) 120 ~140%

Inverter shutdown (Option available : Refer to option table)

Remote ON/OFF Control (*8) Negative logic (Option available : Refer to option table)

Parallel Operation ------------

Series Operation ------------

Environment

Operating Temperature ℃-40 to +85

Storage Temperature ℃-40 to +100

Operating Humidity %RH 5 ~ 95 (No dewdrop)

Storage Humidity %RH 5 ~ 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1 min.)

Amplitude 0.825mm constant (maximum 49.0 m/s²) X,Y,Z 1 hour each

Shock 196.1 m/s² (In package)

Cooling (*8)(*9) Convection cooling / forced air cooling with derating

Isolation Withstand Voltage Input - Output : 1.5kVDC for 1 min.

Isolation Resistance More than 100Mohm at 25℃and 70 %RH, Input - Output : 500 VDC

Standards

Safety Standards Approved by UL60950-1, CSA 22.2 No.60950-1, EN60950

Mechanical

Weight (Typ) g 40

Size (W x H x D) mm 36.8 x 8.9 x 57.9 ( Refer to outline drawing)

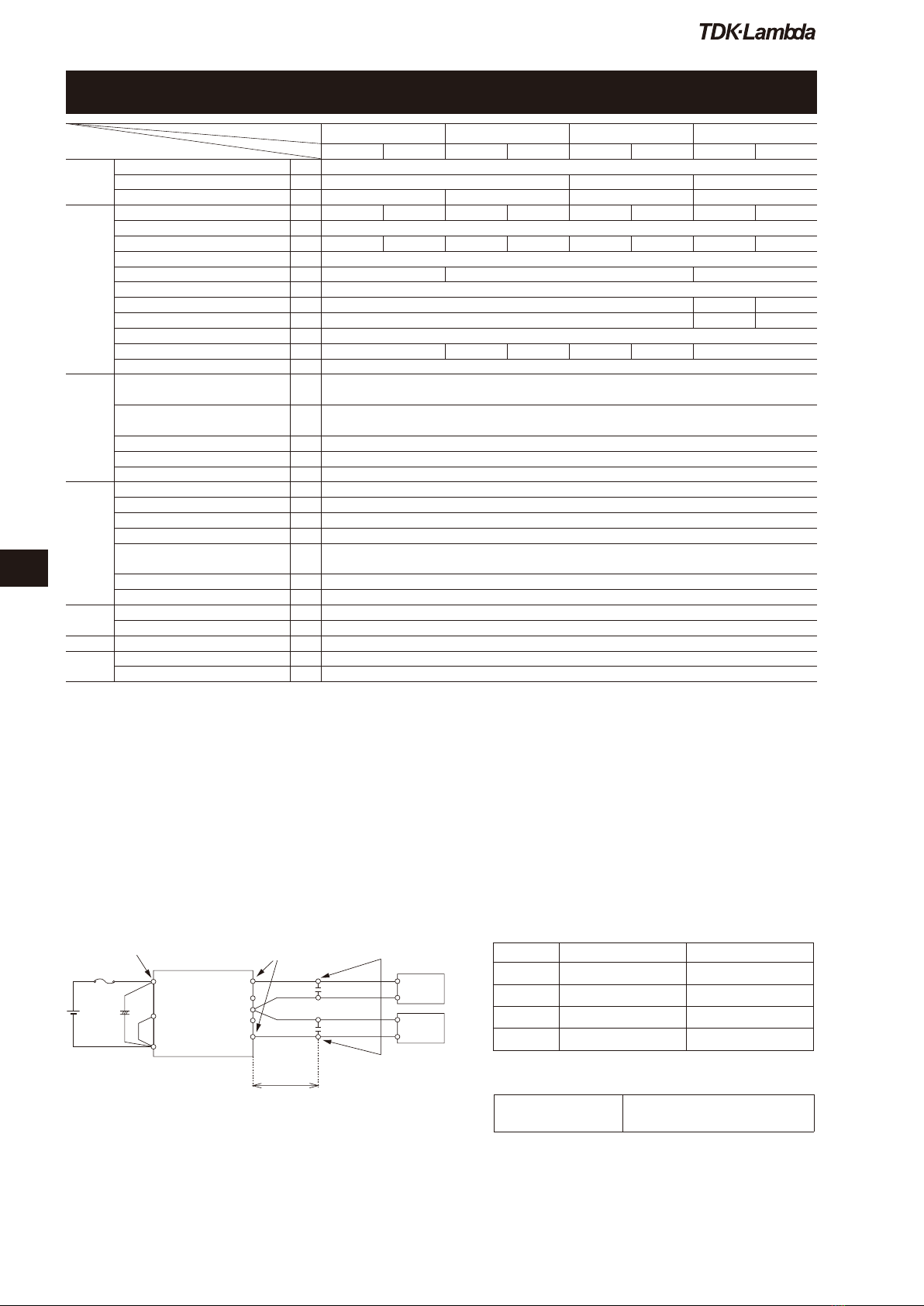

PAQ65D48 PAQ65D48 Specifications

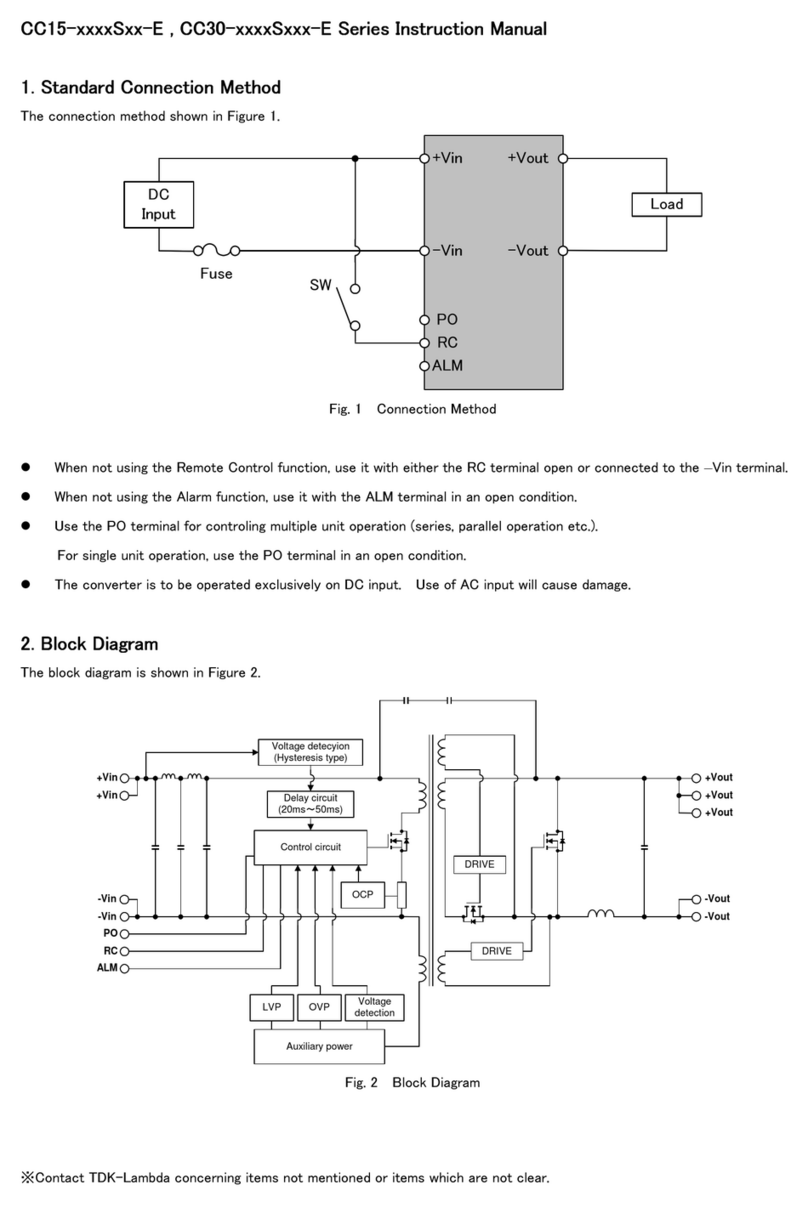

■ Basic Connection ■ Option Table

PAQ65D

(*1) Use external fuse (fast blow type) for each unit.

(*2) Recommended input capacitor C1

-20℃to +85℃: 33µF electrolytic type capacitor.

-40℃to +85℃: 33µF ceramic capacitor or equivalent such

as 5 parallel 6.8µF ceramic type capacitor.

(*3) 22µF ceramic capacitor

Option : ON/OFF Logic OVP/OCP

Standard Negative Shut-down

/P Positive Shut-down

/V Negative

Auto-restart

/PV Positive

Auto-restart

(*1) Maximum allowable combination output power for both channel; also maximum output current for each channel and combination output current for

both channel should not exceeded.

(*2) At 48 VDC, ambient temperature = +25℃and air velocity = 2m/S; 5033: Io1 = Io2 = 7.5A; 3325, 3318, 2518: Io1 = Io2 = 8.5A.

(*3) Additional external components have to be connected; Both outputs are trim independantly; Refer to application notes.

(*4) Measured at Ta = 25℃, Vin = 48VDC and with external components connected;

refer to basical connection drawing. For all temperature range, please refer to the application notes.

(*5) 36 ~ 76 VDC with respect to nominal input line 48V; constant load; ambient temperature = +25℃.

(*6) No load ~ full load with respect to 50% of maximun load; other output: no load; constant input voltage; ambient temperature =+25℃.

(*7) CNT reset or manual reset. Auto-restart option available.

(*8) Refer to application notes.

(*9) Refer to output derating curve.

(*10) Percentage is with respect to maximum combination current which is 18A.

Option for “/C”

(/C, /CP, /CV, /CPV)

Each output voltage can be varied

simultaneously and by the same

proportion by one trimmer.

MeasurementpointforVin

+Vin

Fuse 5A (*1)

C1

(*2)

+

Vin

36〜76VDC

CNT

-Vin

Vo2

Trim2

Gnd

Trim1

Vo1

L=50mm

C3 22uF(*3)

C222uF(*3) +

-

-

+Load

Load

MeasurementpointforVo,

line&loadregulation

Measurementpointforoutputripple&noise

Bandwidthforscope:20MHz