TDK-Lambda Genesys Series User manual

Other TDK-Lambda Power Supply manuals

TDK-Lambda

TDK-Lambda Genesys Series User manual

TDK-Lambda

TDK-Lambda PAH-S48 series User manual

TDK-Lambda

TDK-Lambda LS Series User manual

TDK-Lambda

TDK-Lambda RWS 1000B Series User manual

TDK-Lambda

TDK-Lambda ZBM-AC Series User manual

TDK-Lambda

TDK-Lambda HWS 15A-150A/A Series User manual

TDK-Lambda

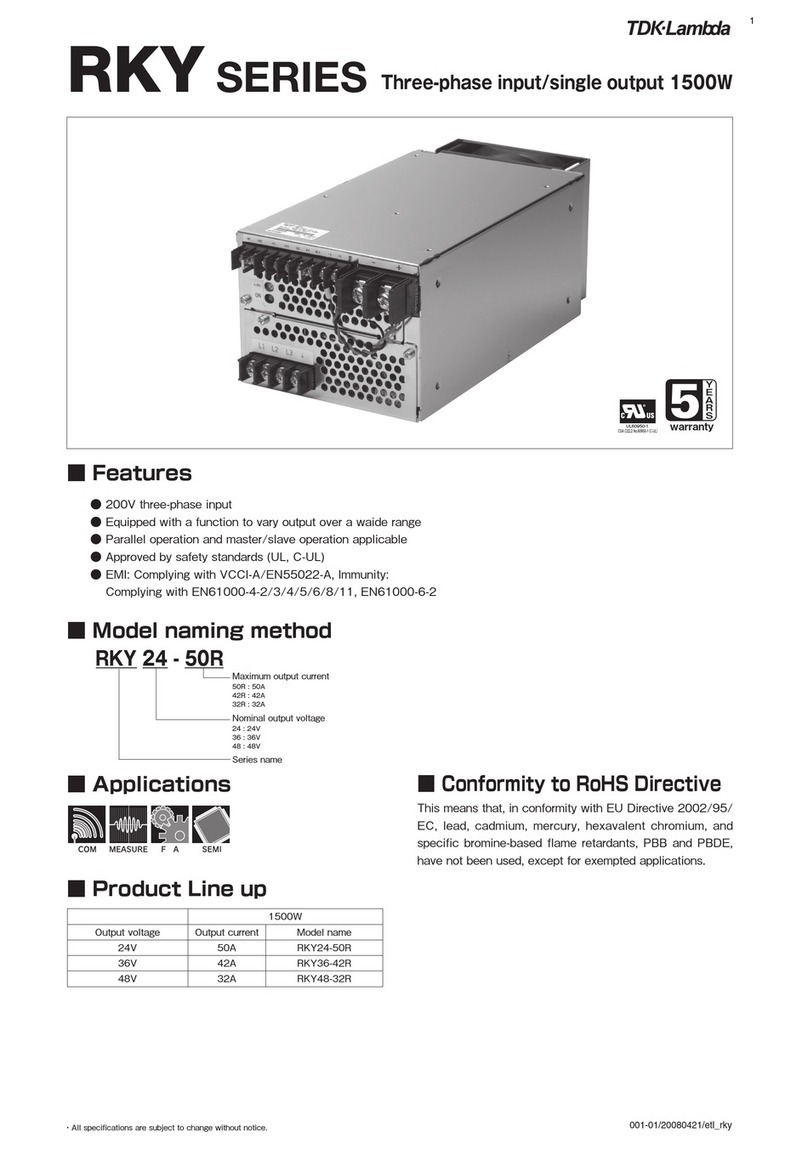

TDK-Lambda RKY Series User manual

TDK-Lambda

TDK-Lambda Z+ series User manual

TDK-Lambda

TDK-Lambda Genesys GEN6-100 User manual

TDK-Lambda

TDK-Lambda VS-E Series User manual

TDK-Lambda

TDK-Lambda Genesys User manual

TDK-Lambda

TDK-Lambda HWS 1500 Series User manual

TDK-Lambda

TDK-Lambda HWS 1500/ME Series User manual

TDK-Lambda

TDK-Lambda GXE600 Series Use and care manual

TDK-Lambda

TDK-Lambda GWS 500 User manual

TDK-Lambda

TDK-Lambda CUT35 Series User manual

TDK-Lambda

TDK-Lambda Z+ series User manual

TDK-Lambda

TDK-Lambda ZWQ Series User manual

TDK-Lambda

TDK-Lambda HFE1600/S series User manual

TDK-Lambda

TDK-Lambda Genesys Series User manual