TDSi EXcel4 User manual

EXcel4Controller

User Manual

UM0012, Issue 8

Foreword

Copyright © 2003 TDSi. All rights reserved.

Time and Data Systems International Ltd operate a policy of continuous improvement

and reserves the right to change specifications, colours or prices of any of its products

without prior notice.

Guarantee

For terms of guarantee, please contact your supplier.

Copyright © 2003 Time and Data Systems International Ltd (TDSi). This document or any

software supplied with it may not be used for any purpose other than that for which it is

supplied nor shall any part of it be reproduced without the prior written consent of TDSi.

Trademarks

Microsoft and Windows are registered trademarks of Microsoft Corporation.

All other brands and product names are trademarks or registered trademarks of their

respective owners.

Cautions and Notes

The following symbols are used in this guide:

CAUTION! This indicates an important operating instruction that should be followed to

avoid any potential damage to hardware or property, loss of data, or personal injury.

NOTE. This indicates important information to help you make the best use of this

product.

Document Control

Issue

Date Issued

Change Summary

Issued by

5

15/08/2015

Updated content from 6656-0396

GFH

6

08/03/2017

Content and style update

GFH

7

21/05/2019

Case change and style update

RM

8

28/06/2019

Branding Update

FM

EXcel4 Controller Page i

Contents

1Introduction

1.1 Layout of EX-Series Access Control Units................................................. 2

1.2 System capabilities –EXcel4.............................................................................. 3

1.3 Technical specification EXcel4.......................................................................... 4

1.4 Cable specifications................................................................................................ 5

2Installation

2.1 Mains Installation..................................................................................................... 7

2.1.1 Power Supply........................................................................................................ 7

2.2 Installation do’s and don’ts................................................................................ 8

2.3 Terminating screened cable at the ACU................................................... 9

2.3.1 When to terminate ........................................................................................... 9

2.3.2 How to terminate.............................................................................................10

2.3.3 Readers...................................................................................................................11

2.4 Power supply for locks........................................................................................13

2.5 Locks ..............................................................................................................................13

2.6 Suppression of Electrical Noise.....................................................................13

2.7 Fail-locked ..................................................................................................................15

2.7.1 Fail-locked Drawing (Less than 2A lock) ...........................................15

2.7.2 Fail-open................................................................................................................15

2.7.3 Fail-open drawing (Less than 2A lock)................................................16

2.7.4 Connecting a DC Lock Rated at MORE than 2A...........................16

2.8 Door sensors..............................................................................................................17

2.9 Egress buttons (push to exit)..........................................................................17

2.10 Inputs.............................................................................................................................17

2.11 Supervision options..............................................................................................18

2.12 Relays.............................................................................................................................18

2.13 Memory Battery......................................................................................................18

2.14 Dip Switches .............................................................................................................18

2.15 Communications....................................................................................................19

2.15.1 Single ACU over RS232 to a PC................................................................19

2.15.2 Protocol Converter USB to RS232/RS485 Converter..................20

2.16 Ethernet Communications..............................................................................22

2.17 Built In TCP/IP Xport as Converter..............................................................23

2.18 PC Communications set-up...............................................................................25

2.18.1 Viewing a unit on Rs485 or Rs232 with xsearch...........................25

2.18.2 How to assign an I/P address ...................................................................27

2.18.3 Troubleshooting TC/IP ..................................................................................29

2.18.4 Other ways to assign I/P address...........................................................29

2.18.5 For documentation on How to use the EXgarde Toolkit........30

3Testing the installation

3.1 Installer mode ..........................................................................................................31

3.2 Reset (simply link jumper 1 and remove)................................................33

3.3 Firmware .....................................................................................................................33

3.4 How to upgrade EX series ACU with new Firmware.......................33

3.4.1 Firmware Update.............................................................................................35

EXcel4 Controller Page ii

4Trouble-shooting

4.1 Fault-finding communications problems..............................................36

4.1.1 Controller Identification...............................................................................36

4.1.2 Controller Losing Memory..........................................................................36

4.1.3 Controller is Alarming - buzzing.............................................................37

4.1.4 Reader Problems..............................................................................................38

4.1.5 Reader not working........................................................................................38

4.1.6 Interpretation of XKDX Messages..........................................................40

4.1.7 For more details on the XKDX refer to the EXgarde Toolkit Manual.

40

4.1.8 Intermittently card works...........................................................................41

4.1.9 Monitored Locks...............................................................................................41

4.1.10 Identifying Versions of Hardware. .........................................................42

4.2 Final configuration................................................................................................42

5Connection tables

5.1.1 Power and communications ....................................................................43

5.1.2 MA-45 RS232/RS485 converter................................................................43

5.1.3 Connecting one EXcel4to another (the same pin connections apply

for all EX series)...................................................................................................................43

5.1.4 RS232 to EXcel4..................................................................................................43

5.1.5 Readers and doors...........................................................................................44

6Compliance Notices

6.1 Compliance with CE regulations .................................................................46

6.2 Limitations on the intended operating environment. ...................46

6.3 FCC Regulations Notice.....................................................................................47

6.4 ...........................................................................................................47

7.1 ....................................................................................................48

7.2 ..............................................................................................................................48

7.3 ..............................................................................................................................48

7.4 ...................................................................48

7.5 ......................................49

7.6 .....................................................................................................49

7.7 ............................................................................................................49

EXcel4 Controller Page iii

Table of Figures

Figure 1 - EXcel 4 controller .............................................................................................2

Figure 2 - Peripheral mounted in Non-Metal surface...................................................9

Figure 3 - Peripheral mounted on Metal surface .........................................................9

Figure 4 - Incorrect Screening Method (Tails Left Long)............................................10

Figure 5 - Correct Screening Method (Tails Kept Short) ............................................10

Figure 6 - Suppressor.......................................................................................................14

Figure 7 - Fail locked drawing .......................................................................................15

Figure 8 - Fail open drawing..........................................................................................16

Figure 9 - DC lock release diagram..............................................................................16

Figure 10 - 9way D-Type connector .............................................................................19

Figure 11 - RS485 communication diagram................................................................21

Figure 12 - Lantronix Xport .............................................................................................23

Figure 13 - TCP/IP Connection setup ...........................................................................24

Figure 14 - XSearch home screen.................................................................................25

Figure 15 - COM port select ..........................................................................................26

Figure 16 - XSearch options ...........................................................................................26

Figure 17 - XSearch main screen ..................................................................................27

Figure 18 - Communication channels..........................................................................28

Figure 19 - Selected channel ........................................................................................29

Figure 20 - Xinstall window...............................................Error! Bookmark not defined.

Figure 21 - Firmware loading ...........................................Error! Bookmark not defined.

Figure 22 - ACU UID.........................................................................................................42

EXcel4 Controller Page 1

1Introduction

EX Series Variations and nomenclature

During the History of the EX Series (Now Version 3), it has also been spelt as EX series

(version 2 models), and the earliest version 1 models were known as X series. This Manual

describes the Latest Product.

All versions are compatible and able to be on the same communications line.

Software also referred to is EXgarde, which used to be called EXgarde (version 1and 2).

Both software versions are compatible with all EX series products but as more features

are added then EX series firmware is required to be kept up to date for full compatibility

with later software versions

Table shows the range of EX series Access Control Units available.

EXcel

EXpert & EXpert IP

PC-controlled only

Stand-alone (requires additional

EXkeypad programmer) or PC-controlled

EXcel2- 2-door, 2-reader with 4 spare

inputs & 2 spare relays

EXcel4-4-door, 4-reader, on-board TCP/IP

EXpert2, EXpert2slave &EXpander2

providing 2-16 door master/slave sub-

system.

Each product is 2-door, 2-reader with 4

spare inputs & 2 spare relays

EXpert2IP on-board TCP/IP

EXpert4 & EXpert4 IP –eXpert2 (IP)

+expander2for 4-doors, 4-readers

4 Fused Outputs supply for controller &

locks

4 Fused Outputs supply for controller &

locks

EXcel2 -24000 cards

EXcel4- 18000 cards

16000-48000 cards, depending on

number of slaves

16 counters

16 counters

No support for additional input/output

boards

EXin/out32/16 board for additional inputs &

relays (I/O)

Readers:

TDSi Infra-red MICROcard (EXcel 4 requires

digital output reader), mag-stripe track 2

ABA, Wiegand 26-bit, Wiegand 34 bit,

Wiegand 37 bit, Octopus 44 bit, Me Lucky

34 bit, EXprox Proximity, EXsmart Mifare.

Supports Universal Decode for EXgarde

Software.

Readers:

TDSi Infra-red MICROcard, mag-stripe

track 2 ABA, Wiegand 26-bit, Wiegand 34

bit, Wiegand 37 bit, Octopus 44 bit, Me

Lucky 34 bit, EXprox Proximity, EXsmart

Mifare. Supports Universal Decode for

EXgarde Software.

EXcel4 Controller Page 2

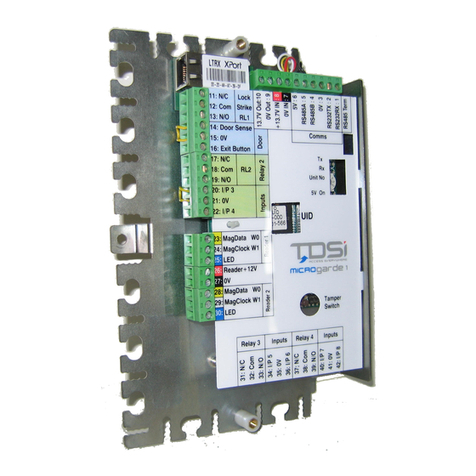

1.1 Layout of EX-Series Access Control Units

The following diagram shows the layout of the EX series controller.

Please familiarise yourself with the layout of the product before attempting installation.

Figure 1 –EXcel4controller

1

Output Distribution Board and Fuses

2

Controller UID Numbers For EXcel4Number begins with 4 e.g. 4-xxx-xxx-xxx

3

Earth connection

4

Power Supply Unit

5

Fused Mains Terminal Block

6

Space For Standby Battery (not supplied)

7

Standby battery connection cables

8

Tamper Switch with Spring

9

Memory Battery Link

10

Cable Screen Braid Earthing Clamps

11

Reset Link

EXcel4 Controller Page 3

1.2 System capabilities –EXcel4

EXcel4is a four-door access control unit (ACU) that is administered by a computer (PC)

running TDSi’s EXgarde software. More than one controller can be administered

simultaneously from one or more computers, and TDSi manufacture several controller

types besides EXcel4that can co-exist in a single system.

The software is used to monitor events and to program ACUs with card numbers, access

rules and other parameters such as input and relay functions. The software does not

need to be running continuously, as ACUs hold all the information they need to provide

the security features that have been set up.

When EXcel 4 is used as a two-door controller, four inputs and two relays become

“spare” and may be used for monitoring and control of other equipment.

Feature

Example: Four-door

configuration

Example: Two-door

configuration

Maximum number of

readers per door (readers

may have associated

keypads)

1

2

Egress inputs

4

2

Door sensor inputs

4

2

Spare Inputs

0

4

Spare Relays

0

2

Readers and Doors

Maximum is 4 readers with 1,2,3 or 4 Doors

Card capacity

(with EXgarde express or

lite)

5 000

Card capacity

(with EXgarde Pro)

18 000

Anti-pass-back

(with EXgarde Pro)

Timed or True

Mantrap

Yes

Time groups

64

Card expiry by date

Yes

Communications

RS232, RS485, Ethernet (TCP/IP)

Firmware

Can be Flash Upgraded

Visual Indications

Green LED

Mains present

Red LED

Fault present: output fuse fail

Amber LED

Battery Standby operation

EXcel4 Controller Page 4

1.3 Technical specification EXcel4

Input Voltage

100 - 240 VAC nominal ±10 %

Input Frequency

50/60 Hz

Mains Input Fuse

T3.15A 20 mm 230 v HRC

Output Voltage

13.4 to 14.2 VDC (13.8 VDC nom) on mains power

10.0 to 12.3 VDC on battery standby

Output Load Current

4A maximum

Output Ripple

150 mVpk-pk max

Load Output Fuse

F4.0 A 20 mm

Overload Protection

Electronic shutdown until overload/short circuit removed

Standby Battery

Capacity/Recharge Time

1 x 7 Ah Sealed Lead Acid/13 hours (to 80% capacity)

Standby Battery Charge

Current

0.5 A

Standby Battery Fuse

Protection

F1.0 A 20 mm

Storage Temperature

Range

-20 °C to +80 °C

Operating Temperature

Range

-5 °C to + 45 °C

Operating Humidity

<95 %RH, non-condensing

Case Dimensions

390 x 410 x 90 mm

Weight

5.7 kg (unpacked)

Door/Control Relay

Changeover volt-free contact 30 V, 2 A rating

TCP/IP Communications1

Ethernet 10Base-T or 100Base-Tx (Auto-Switching), RJ45,

with indication LEDs for 10Base-T connection,

T-Base-TX connection, link and activity

EXcel4 Controller Page 5

1.4Cable specifications

Always use suitable cable. Access control systems differ from intruder alarm systems in

that reader and communications cables carry high-speed data signals that can

become distorted or corrupted if inadequate cable is used.

The following tables show the recommended cable types that should be used when

making connections to our EXcel 4 access control systems.

Part №

Cable Type

Cores

Maximum

Distance

Magnetic

Stripe

Reader

5002-0360

Belden 9730

6

60m

Belden 9503

6

25m

OS6C24/Alpha 5096/BICC H8124

6

20m

Screened Alarm Cable

8

Up to 30m

EXprox /

EXprox2

5002-0354

5002-0355

Belden 9730v

6

150m

Belden 9503

6

150m

OS6C24/Alpha 5096/BICC H8124

6

150m

Screened Alarm Cable

8

150m

Optica

5002-0390

5002-0391

Belden 9730

6

150m

Belden 9503

6

150m

OS6C24/Alpha 5096/BICC H8124

6

150m

Screened Alarm Cable

8

150m

Digital IR

5002-1781

5002-1791

Belden 9730

6

150m

Belden 9503

6

150m

OS6C24/Alpha 5096/BICC H8124

6

150m

Screened Alarm Cable

8

150m

MIFARE /

EXsmart2

5002-0433

5002-0434

5002-0435

5002-0436

5002-0440

5002-0441

5002-0442

Belden 9730

6

150m

Belden 9503

6

150m

OS6C24/Alpha 5096/BICC H8124

6

150m

Screened Alarm Cable

8

150m

EXcel4 Controller Page 6

Part №

Cable Type

Cores

Maximum

Distance

DIGIgarde

/

DIGIgarde

Smart /

PALMgard

e

5002-0450

5002-0451

5002-0460

Belden 9730

6

150m

Belden 9503

6

150m

OS6C24/Alpha 5096/BICC H8124

6

150m

Screened Alarm Cable

8

150m

Indala

Proximity

Reader

5002-0133

5002-0137

5002-0217

5002-0218

Belden 9730

6

150 m

Belden 9503

6

60 m

OS6C24/Alpha 5096/BICC H8124

6

60 m

Screened Alarm Cable

8

Up to 30m

Dataline

Keypad

5002-0286

5002-0315

5002-0316

Belden 9729

4

140m

FBOS2P24

4

100m

OS2P22/Alpha 5902/Belden 9502

4

60m

OS4C24/Alpha 5094/BICC H8123

4

40m

RS-232

Communi

cations

7/0.2 mm 3–core screened cable

3

15m

RS-485*

Communi

cations

Belden 9729

4

FBOS2P24

4

OS2P22/Alpha 5902/Belden 9502

4

OS4C24/Alpha 5094/BICC H8123

4

Screened Alarm Cable

8

CAT V (screened)

Min. 2

Inputs

7/0.2mm (screened)

2

300m

Relays

7/0.2mm or 16/0.2mm (screened)

2

Depende

nt on load

and

cable

choice

* Dependent on the converter and cable type used.

When using an EX9520R converter or USB to serial converter configured to 2-wire mode, a

maximum cable length of 500m is possible. Use of an MA45 converter or USB to serial

converter configured for 4-wire mode will allow distances of up to a maximum of 1200 m

to be achieved.

EXcel4 Controller Page 7

2Installation

2.1 Mains Installation

This product must be fed from a mains power source having a separate (approved)

disconnect device and fitted with a fuse or other over-current protection device rated

at 3 A maximum. Ensure that the disconnect device used has appropriate earth fault

protection to the applicable standard.

Fix the PSU to the wall or other support structure in the correct orientation i.e. with the

transformer and space for the standby battery at the bottom of the unit using the

screws supplied. Allow clearance to for the lid of the product to be fitted and

removed.

NOTE. The product is to be installed in an area with free air movement and with a

minimum of 100 mm clearance between the sides and lid of the power supply case and

any adjacent surface (wall, ceiling or other partition).If you wish to run EXvisitors on a

separate PC, you will also need to obtain additional workstation licenses, available from

TDSi

This equipment MUST be earthed.

Knock-outs are provided in the case for mating with external trunking or conduit.

The mains input cable must be to the applicable standard with a 3 Amp or greater

current capacity, i.e. 0.5 mm2 nominal conductor area, having an operating voltage

of 300/500 Vac.

The mains cable should be routed to use different entry/exit holes (4) in the case to

those used for other connected equipment (e.g. readers, locks, network cables,

inputs, outputs etc.)

Grommets should be used to protect cable sheaths from chaffing. These should meet

a minimum flammability specification of UL94 HB and should be correctly sized i.e.

close fitting with respect to the cable sizing.

The mains input cable should be securely fastened to the case saddle (1) in position

using a cable tie.

2.1.1 Power Supply

Power supply unit providing a regulated 13.8 VDC output supplying continuous full rated

current to the access control unit and locks and an additional 0.5 A for trickle charging a

standby battery. The load output features full electronic short circuit protection under

mains operation. LED’s are provided to indicate mains present and fault conditions.

A single 12 v lead acid battery is required –Yuasa, 12v, 7Ah type, or similar.

EXcel4 Controller Page 8

2.2Installation do’s and don’ts

It is vital to observe anti–static precautions when working inside the ACU cabinet.

Suppressors MUST be fitted across all inductive loads as close as possible to the device itself.

These devices include (but not limited to) motors, locks, auxiliary relays and sounders. Suitable

suppressors are included in the installation kit supplied with this controller.

Solder and tape all connections. DO NOT use crimps or B–connectors or wire nuts or punch–

down blocks.

Each ACU must be grounded to a good mains ground. This can be achieved via the ground

wire (cable shield) from the power supply or by a separate wire to mains ground.

All cable runs must be in shielded cable. The shield of each cable must be grounded at one

end, and at one end only. This will usually be at the ACU chassis plate. However, if the

peripheral equipment (lock releases, card reader’s etc.) is grounded then the shield of the

cable must be grounded at the peripheral end and not at the ACU end.

Cable runs must be at least 2 meters long. This allows induced static to dissipate before it

reaches the electronics.

The braid of the cables (or the drain wire or ground wire) must be terminated to the earthing

clamps which are mounted to the chassis plate (unless the peripheral is connected to ground -

see below). The "pig tails" of the screened cable should be kept as short as possible to reduce

the radiating length.

The lengths of un-shielded wire should be kept to an absolute minimum. This will reduce the

chances of noise pick up. They must not be allowed to protrude into the area of the

electronics.

Where metal-cased peripheral equipment (lock release, card reader etc.) is to be mounted on

a metal surface (e.g. a metal doorframe) ensure that the metal surface is grounded and that

the cable ground wire is connected at the peripheral end and in this instance the cable

ground wire must not be connected at the ACU end, because the metal surface where the

peripheral equipment is connected should be providing a good ground.

Where peripheral equipment (lock releases, card reader’s etc.) is to be mounted on a non-

metal surface, the peripheral must not be grounded independently and the ground wire must

not be taken to a local ground but connect back at the ACU chassis which should be connect

to a good ground (earthed). If the peripheral is metal-cased then the ground wire can be

connected to the metal case, but this still needs grounding via the wire screen back at the

ACU chassis.

When using RS485 communications, attention must be paid to the special earthing

requirements detailed in the section titled "Communications".

In addition to these general principles, it is vital to follow the specific requirements for installing

peripheral equipment (readers, lock releases etc.) These requirements are explained in the

relevant places of this manual

Please note that in all recommendations for wire, minimum gauge requirements are listed. It is

the responsibility of the installing company to follow all local and national electrical codes as

they apply.

Never install any access control system until approval has been obtained from local fire

authority. In particular note that the use of an exit (egress) button may not be legal. Single–

action exit may be required.

The use of shielded cable, and adherence to correct grounding procedures, is necessary for every

connection to the controller.

EXcel4 Controller Page 9

2.3 Terminating screened cable at the ACU

It may or may not be necessary to terminate cable screens at the ACU end. The

following diagrams show when it is necessary, and how to do it to maximise the

effectiveness of the screening.

2.3.1 When to terminate

The following two diagrams show correct methods of grounding cable shields, where the

peripheral equipment may or may not be connected to ground already.

Figure 2 - Peripheral mounted in Non-Metal surface

Figure 3 - Peripheral mounted on Metal surface

EXcel4 Controller Page 10

2.3.2 How to terminate

The following pictures show how the cable screen should be terminated to the ACU

chassis. This also holds the cable firmly in place while terminating the cable cores. If you

are not terminating the cable screen to the chassis, use a cable tie through the holes in

the chassis to hold the cable in place.

Figure 4 - Incorrect Screening Method (Tails Left Long)

Figure 5 - Correct Screening Method (Tails Kept Short)

EXcel4 Controller Page 11

2.3.3 Readers

The screen braid of the cables must be terminated to the earthing clamps on the side of

the chassis plate unless the reader is connected to ground. Any portion of the

unscreened cable should be kept as short as possible and not be allowed to protrude

into the area of the electronics.

The following section covers the most popular readers currently supplied by TDSi. For any

other reader, please refer to the documentation that came with the reader.

EXprox Proximity readers (5002-0354 and 5002-0355)

Digital IR reader (5002-1781)

(The analogue IR reader 5002-0035 cannot be used with the EXcel4)

EXprox2 and EXprox2K Proximity readers (5002-0395 and 5002-0396)

Mifare EXsmart readers (5002-0440 and 5002-0441, mullion styles)

Mifare EXsmart2 readers (5002-0435, 5002-0433, 5002-0436, 5002-0434)

EXcel4

terminal pins

Reader connection

Colour

Terminal Pin connection

EXprox Proximity

readers (5002-0354 and

5002-0355)

Mifare EXsmart (5002-

0440 and 5002-0441)

Digital IR reader (5002-

1781)

EXprox2 and EXprox 2K

proximity reader (5002-0395

and 5002-0396)

EXsmart2 Mifare and

EXsmart2K Mifare(5002-

0435,5002-0433,5002-0436,

5002-0434)

These readers have

additional switch connections

put SW1 and SW2 to OFF

14

Reader 1 MAG-DATA

Yellow

3 (Mag Data)

15

Reader 1 MAG-CLK

White

4 (Mag Clock)

16

Reader 1 LED

Blue

7 (Red LED)

18

Reader 1 0V

Black

2 (0V)

17

Reader 1 +12V

Red

1 (9 to 16V DC 75mA Max)

28

Reader 2 +12V

Red

1 (9 to 16V DC 75mA Max)

25

Reader 2 MAG-DATA

Yellow

3 (Mag Data)

26

Reader 2 MAG-CLK

White

4 (Mag Clock)

27

Reader 2 LED

Blue

7 (Red LED)

29

Reader 2 0V

Black

2 (0V)

28

Reader 3 +12V

Red

1 (9 to 16V DC 75mA Max)

30

Reader 3 MAG-DATA

Yellow

3 (Mag Data)

31

Reader 3 MAG-CLK

White

4 (Mag Clock)

32

Reader 3 LED

Blue

7 (Red LED)

29

Reader 3 0V

Black

2 (0V)

44

Reader 4 +12V

Red

1 (9 to 16V DC 75mA Max)

41

Reader 4 MAG-DATA

Yellow

3 (Mag Data)

42

Reader 4 MAG-CLK

White

4 (Mag Clock)

43

Reader 4 LED

Blue

7 (Red LED)

45

Reader 4 0V

Black

2 (0V)

EXcel4 Controller Page 12

Optica Proximity Reader with Keypad (5002-0390 and 5002-0391)

EXcel

terminal

Reader connection

Terminal Pin connection

14

Reader 1 MAG-DATA

4 (Mag Data)

15

Reader 1 MAG-CLK

3 (Mag Clock)

16

Reader 1 LED

5 (Red LED)

18

Reader 1 0V

1 (0V)

17

Reader 1 12V

2 (10 - 14V)

28

Reader 2 12V

2 (10 - 14V)

25

Reader 2 MAG-DATA

4 (Mag Data)

26

Reader 2 MAG-CLK

3 (Mag Clock)

27

Reader 2 LED

5 (Red LED)

29

Reader 2 0V

1 (0V)

28

Reader 3 12V

2 (10 - 14V)

30

Reader 3 MAG-DATA

4 (Mag Data)

31

Reader 3 MAG-CLK

3 (Mag Clock)

32

Reader 3 LED

5 (Red LED)

29

Reader 3 0V

1 (0V)

44

Reader 4 12V

2 (10 - 14V)

41

Reader 4 MAG-DATA

4 (Mag Data)

42

Reader 4 MAG-CLK

3 (Mag Clock)

43

Reader 4 LED

5 (Red LED)

45

Reader 4 0V

1 (0V)

Reader LED control in EX series bicolour

The Reader LED default is set to bi-colour. (This can be reprogrammed to Red Only.)

The LED line is held at approximately 5V, and in normal mode will pulse to 0 Volts every 2

seconds (red LED). Upon access granted this will activate to 12 Volts for 5seconds

(Green).

EXcel4 Controller Page 13

2.4 Power supply for locks

The built-in power supply has four outputs each with a 1A quick blow fuse. Overall supply

is 4 A across these 4 terminals. 1 A is required for the ACU which leaves 3 A for locks.

These connections can be found on the small PCB (Output Distribution Board) top left of

the Unit.

Controller

Terminal

Equipment Connection

1+

Connected to +12 V IN, Terminal 10 on ACU

PCB

Maximum 4 Amps

available across all 4

pairs of Terminals (1 A

required for ACU)

1-

Connected to 0 V, Terminal 11 on ACU PCB

2+

Door lock Supply (up to 1 A max.)

2-

Door lock 0 V

3+

Door lock Supply (up to 1 A max.)

3-

Door lock 0 V

4+

Door lock Supply (up to 1 A max.)

4-

Door lock 0 V

2.5 Locks

If the lock(s) are to be powered from the built-in power supply - this is subject to a

maximum peak current of 2A lock (Relays are rated at 2A 30 V) Note: the built in PSU

supplies 4A maximum, 1A generally is required for the ACU and readers etc., which

leaves 3A for Locks overall.

For more than 3A required for locks, then a separate power supply is required, modify the

wiring accordingly.

It is advisable to provide a rating of at least 50% more than the current rating of the Lock.

For example a 600mA lock should be allocated at least 900mA overall –thus 3 of these

rated locks could have power supplied by the built in PSU.

2.6 Suppression of Electrical Noise

CAUTION! : A suppressor MUST be fitted at the lock.

DC lock strikes must be fitted with suppression components i.e. diode plus capacitor or

MOV device (Metal Oxide Varistor). AC lock strikes must be fitted with a suitable

specialised suppressor, the TDSi suppressor provided is specialized and supports both AC

and DC locks - part number 4262-0095.

TDSI provide 2 suppressors each with the EXpert2, EXpert2Slave EXpander and 4 with an

EXpert4: Suppressors can be fitted are not polarity governed.

EXcel4 Controller Page 14

Figure 6 - Suppressor

Table of contents

Other TDSi Controllers manuals