Table of Contents

23A7031A

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

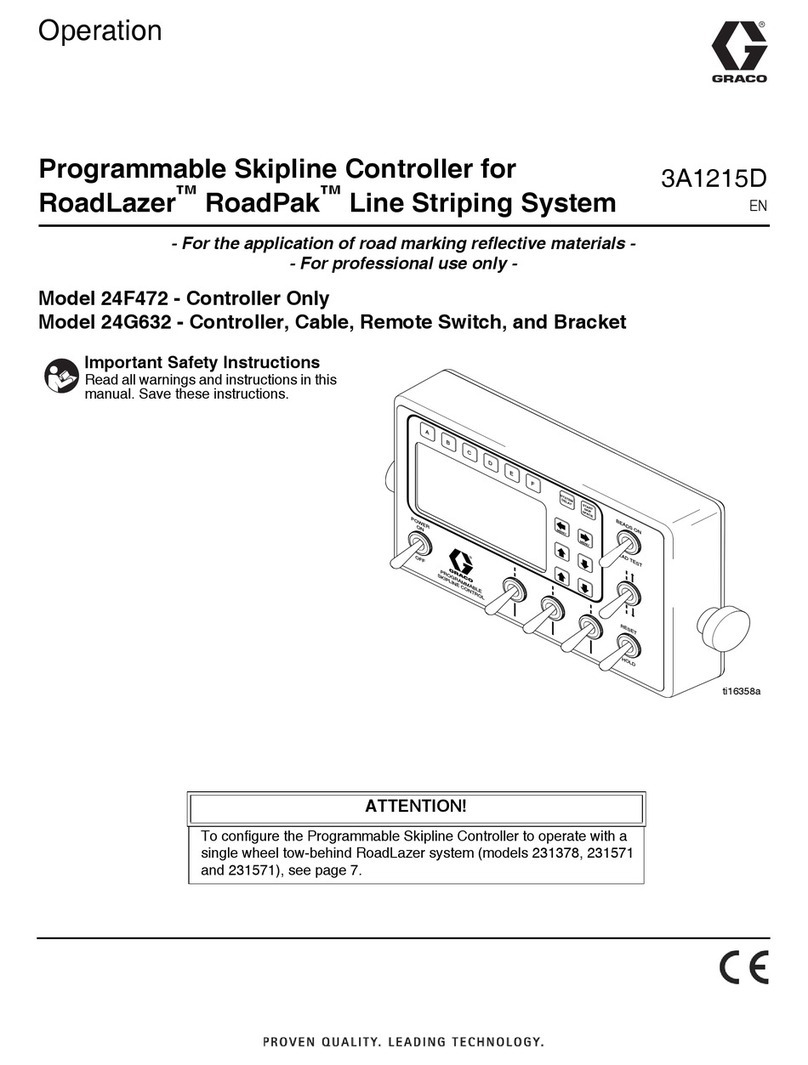

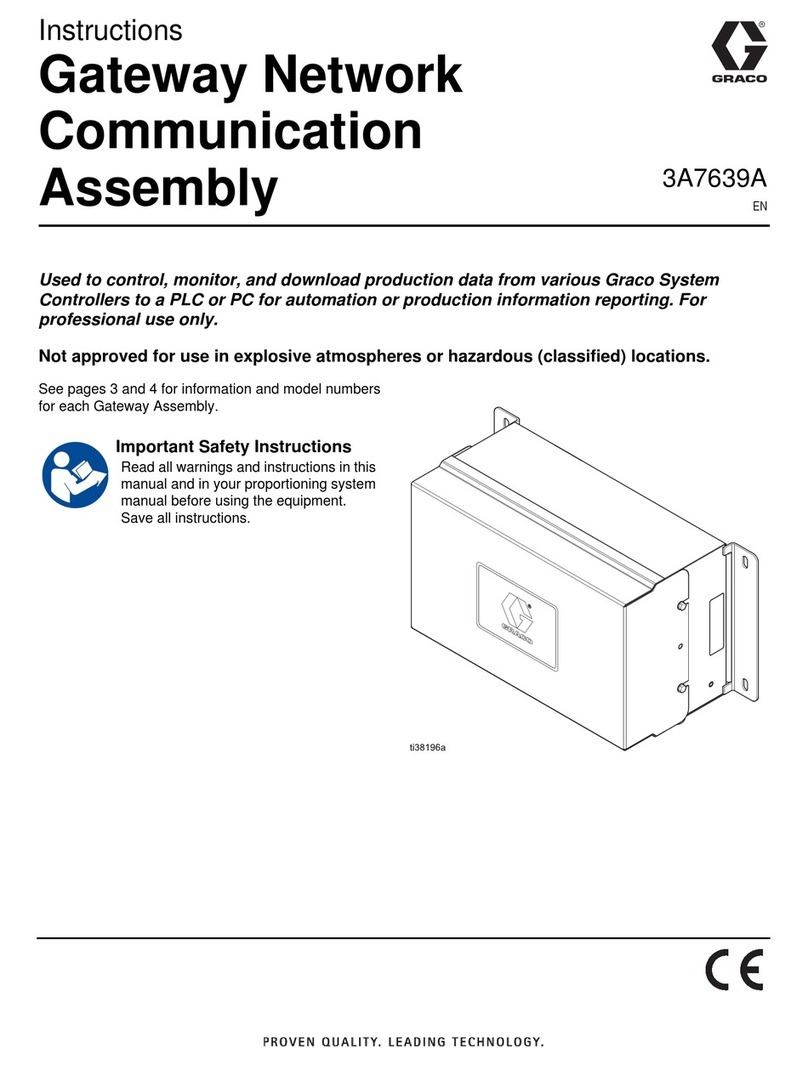

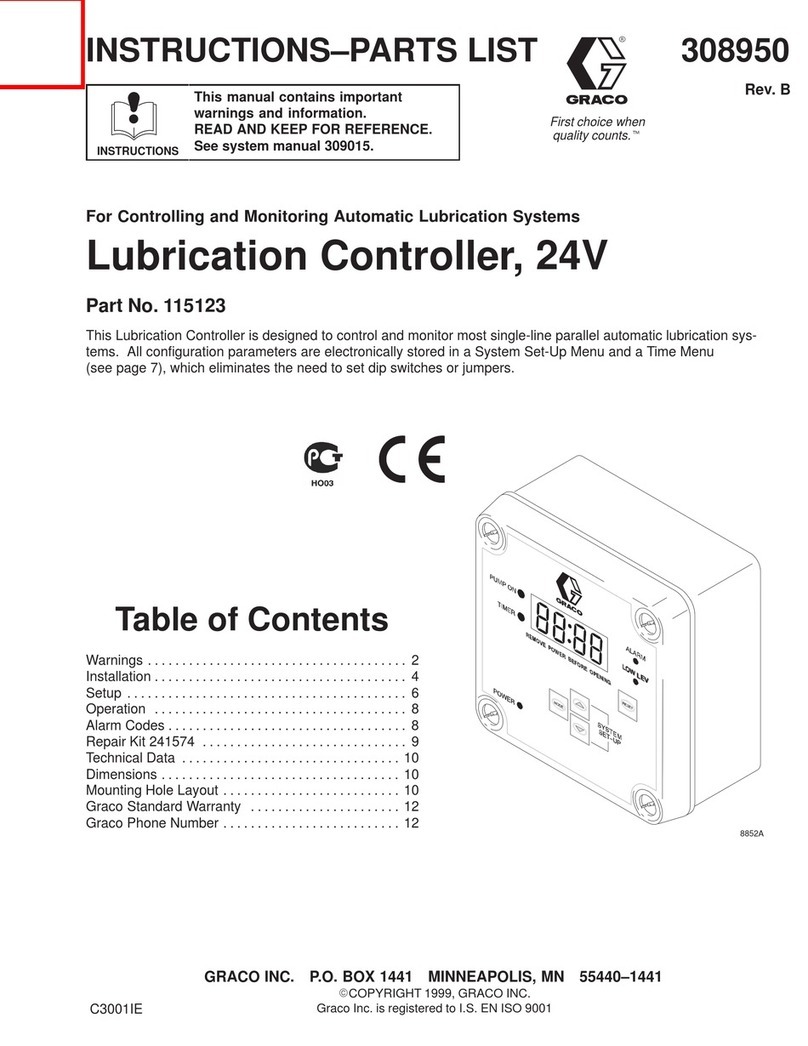

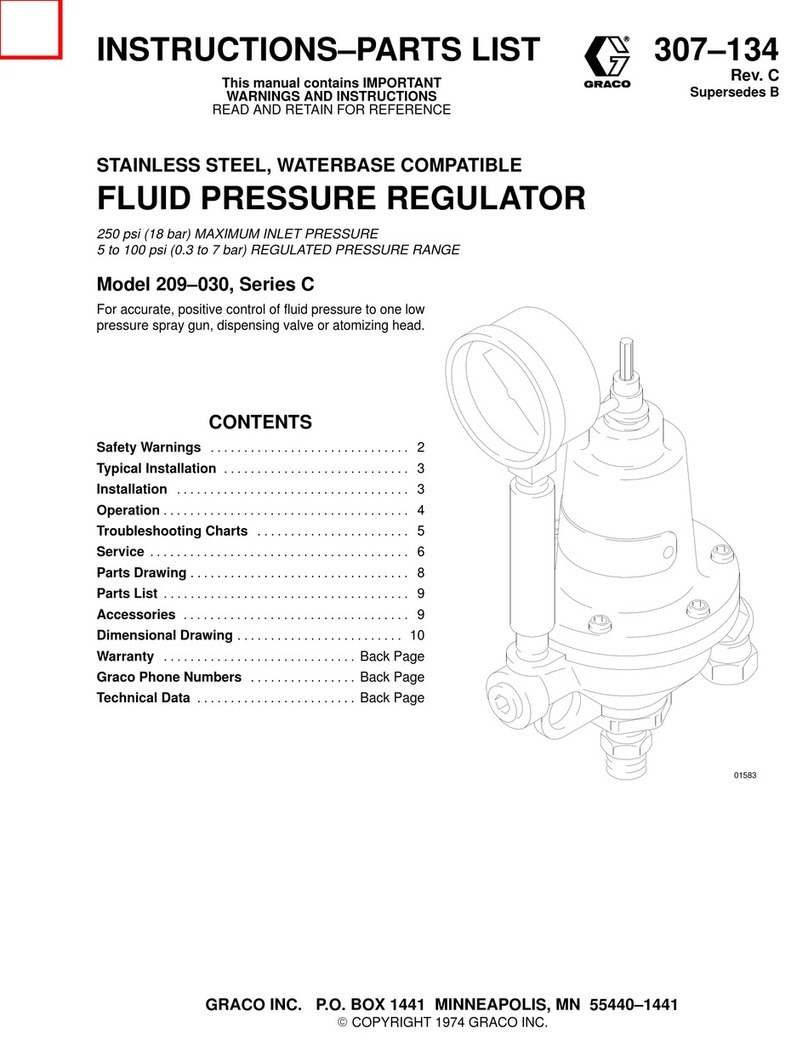

Component Identification . . . . . . . . . . . . . . . . . . . . 4

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

System Configuration . . . . . . . . . . . . . . . . . . . . . . . 8

Injector System . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Divider Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sensor Wiring Configurations. . . . . . . . . . . . . . . . 11

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Navigating Setup and Data Entry. . . . . . . . . . . . 12

Change Settings . . . . . . . . . . . . . . . . . . . . . . . . 12

Low Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Additional Advanced Features . . . . . . . . . . . . . . 14

Program Settings . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Recycling and Disposal at End of Life . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

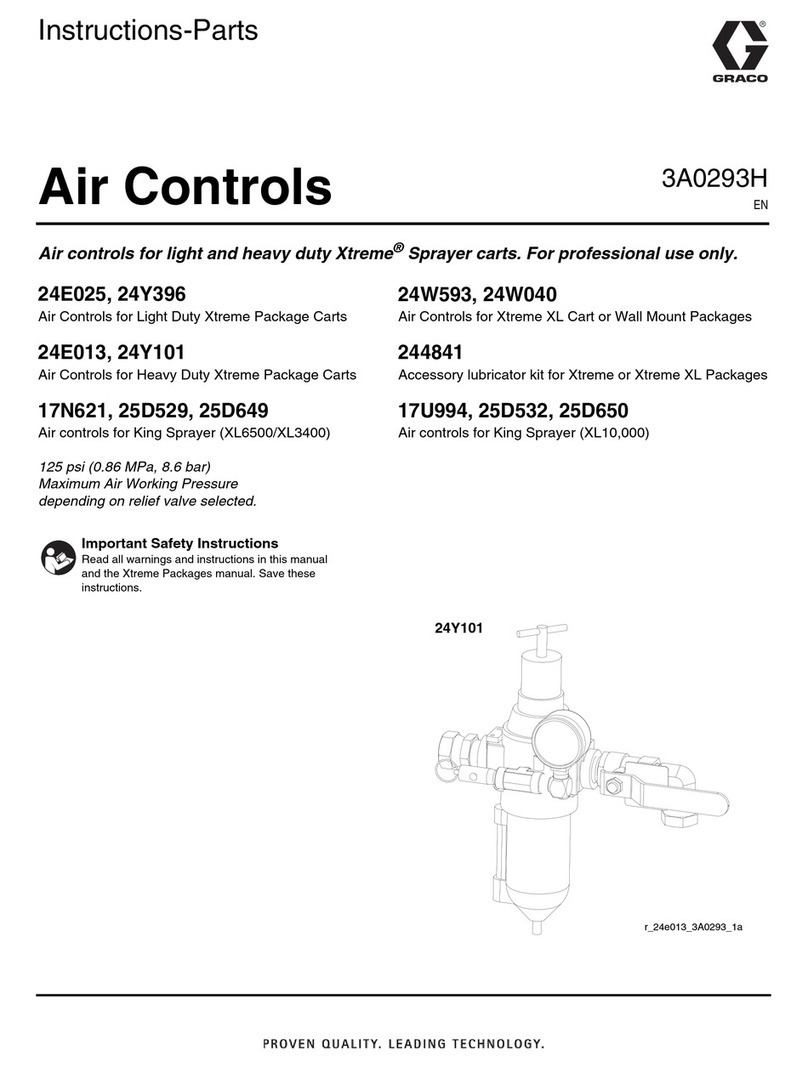

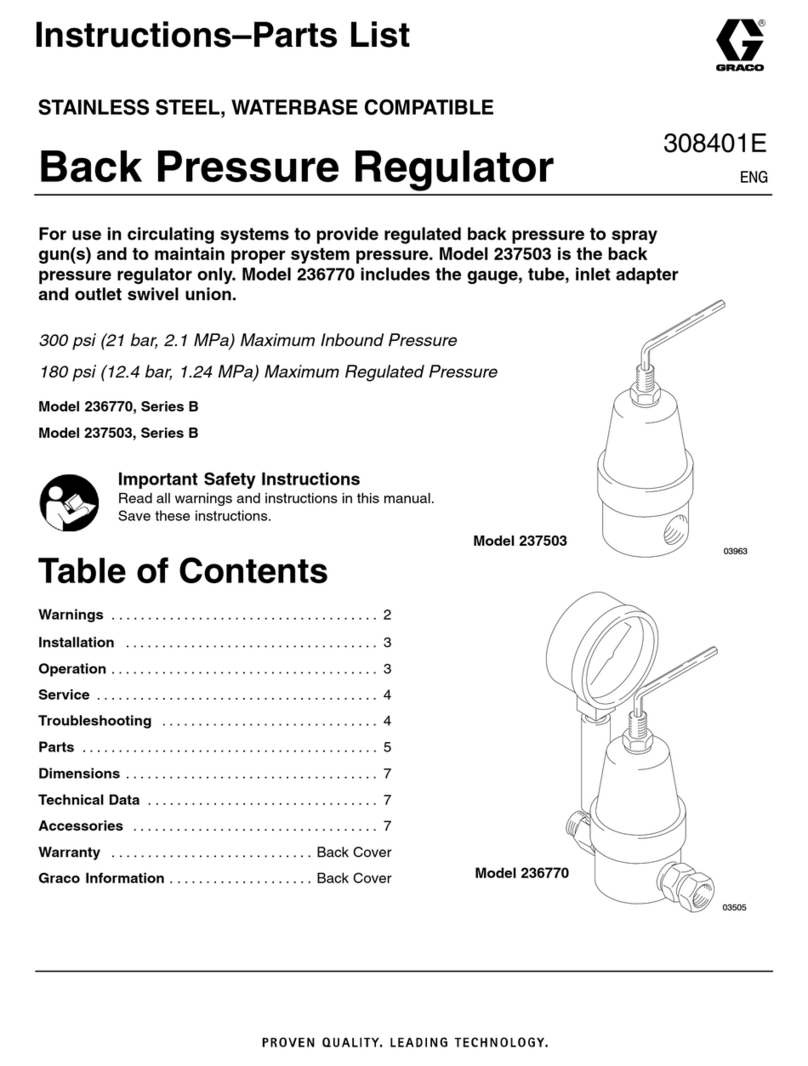

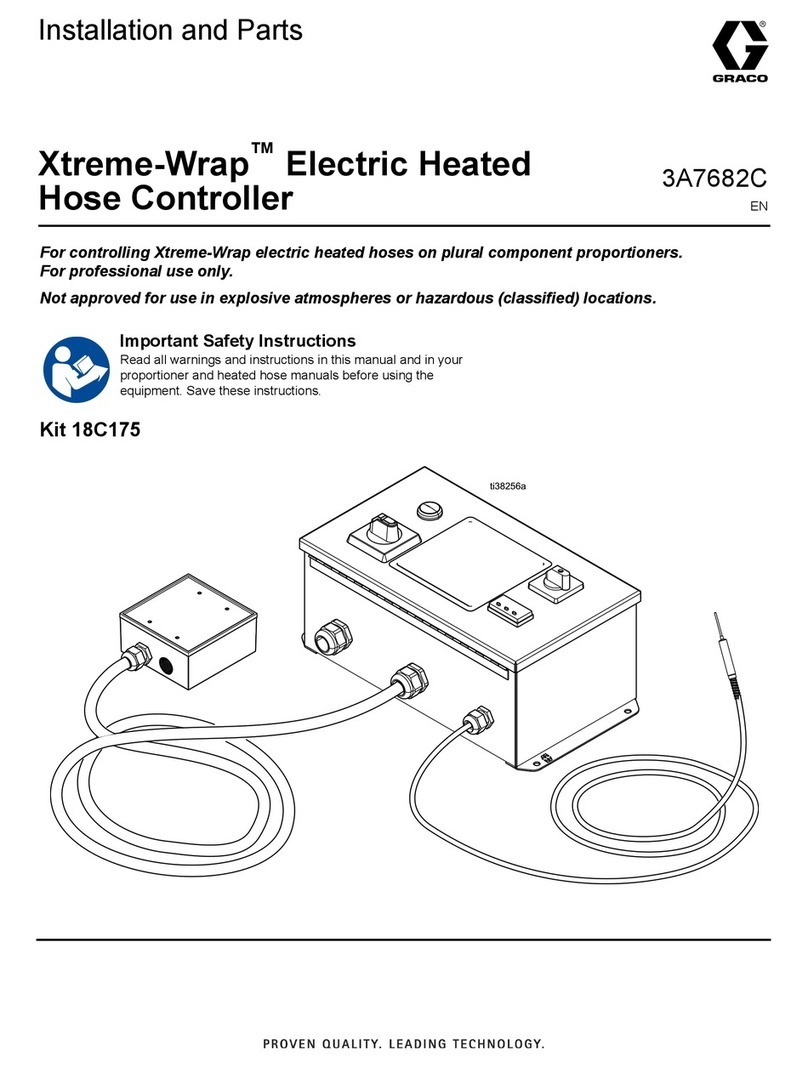

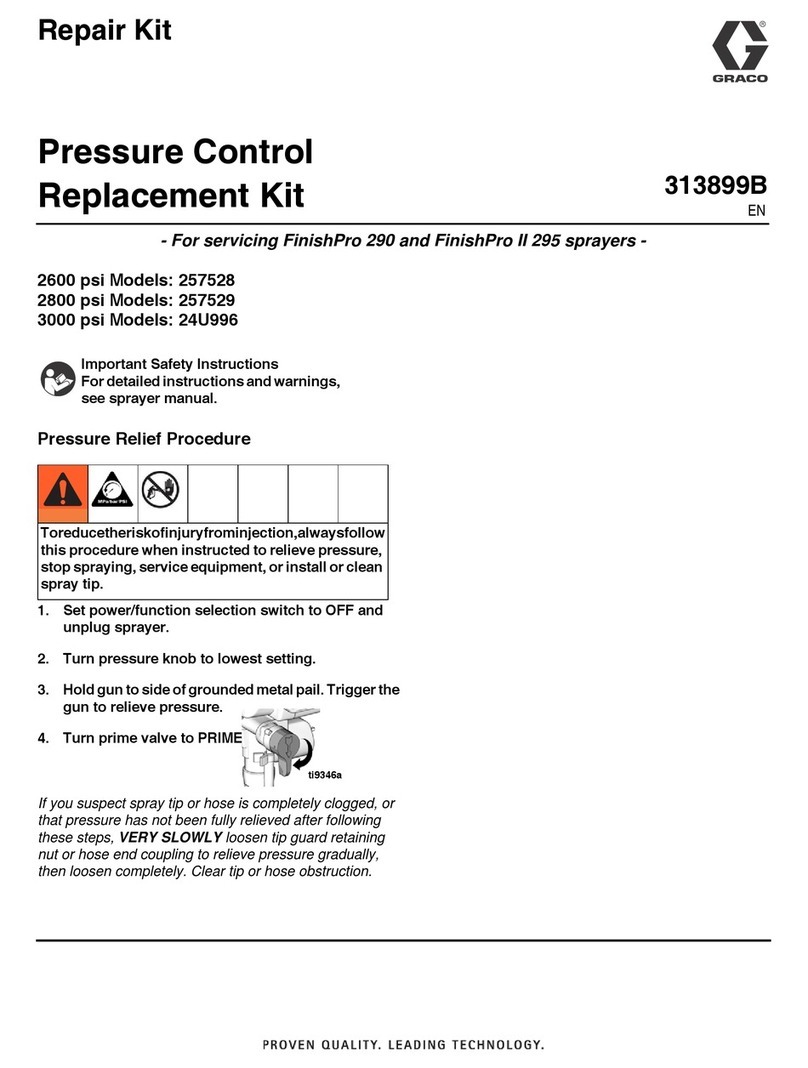

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting Hole Layout . . . . . . . . . . . . . . . . . . . . . . 23

Technical Specifications . . . . . . . . . . . . . . . . . . . . 24

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Radio Frequency Approvals. . . . . . . . . . . . . . . . 25

California Proposition 65 . . . . . . . . . . . . . . . . . . 25

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 26