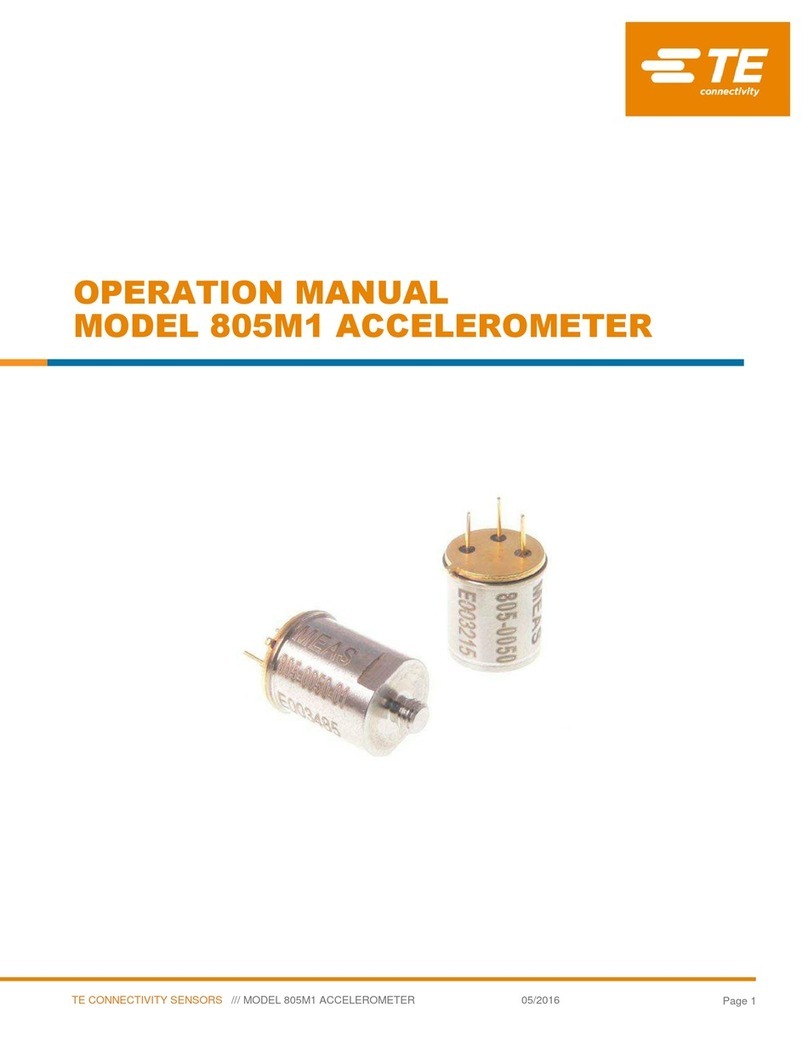

Operating Manual

Operating Manual 832 & 832M1, Rev B www.te.com October 20, 2015

2 of 8

Warranty

TE Connectivity accelerometers are warranted

during a period of one year from date of

shipment to original purchaser to be free from

defects in material and workmanship. The

liability of Seller under this warranty is limited to

replacing or repairing any instrument or

component thereof which is returned by Buyer,

at his expense, during such period and which

has not been subjected to misuse, neglect,

improper installation, repair, alteration, or

accident. Seller shall have the right to final

determination as to the existence and cause of a

defect. In no event shall Seller be liable for

collateral or consequential damages. This

warrant is in lieu of any other warranty,

expressed, implied, or statutory; and no

agreement extending or modifying it will be

binding upon Seller unless in writing and signed

by a duly authorized officer.

Receiving Inspection

Every TE Connectivity accelerometer is carefully

inspected and is in perfect working condition at

the time of shipment. Each accelerometer

should be checked as soon as it is received. If

the unit is damaged in any way, or fails to

operate, a claim should immediately be filed with

the transportation company.

Service Concerns

If a TE Connectivity instrument requires service,

first contact the nearest TE Connectivity

representative. They may be able to solve the

problem without returning the unit to the factory.

If it is determined that factory service is required,

call Customer Service at the regional

headquarters for an RMA number before return.

Returns

All units being returned to the factory require an

RMA (Return Material Authorization) number

before they will be accepted. This number may

be obtained by calling Customer Service at the

regional headquarters with the following

information; model number(s), quantity, serial

number(s), and symptoms of the problem, if

being returned for service. You must include the

original purchase order number if under

warranty.

Recalibration Services

The Vibration Sensors Design Center and its

two manufacturing facilities in China and France

offer factory re-calibration services for

Piezoresistive, Piezoelectric and Integrated

Electronics Piezoelectric (IEPE, ISOTRON, ICP,

etc.) accelerometers. NIST (US), DKD

(Germany), COFRAC (France) traceable

calibration services on sensitivity at 100 Hz (102

or 120 Hz in Europe) and full frequency sweeps

are offered. Contact the regional headquarters

for pricing information.

Inquiries

Address all inquiries on operation or applications

to your nearest Sales Representative, or to the

Vibration Applications Support as follows:

Global Headquarters

1000 Lucas Way

Hampton, VA 23666, USA

Tel: +1 757 766 1500

Vibration Sensors Design Center

32 Journey, Suite 150

Aliso Viejo, CA 92656, USA

Tel: +1 949 716 7324

European Headquarters

105 av. du Général Eisenhower

BP 1036, 31023 Toulouse Cedex, France

Tel: +33 (0) 561 194 543

Asian Headquarters

Measurement Specialties (China), Ltd.

F1.6-4D, Tian An Development Compound

Shenzhen, China 518057

Tel: +86 755 8330 1004