Introduction

This product range includes a wide range of functions,

including AC Ammeters and maximum demand meters; AC

Voltmeters; DC Ammeters and milliammeters; DC

Voltmeters and millivoltmeters; Elapsed time meters;

Frequency meters; AC wattmeters and var meters and

Power factor meters.

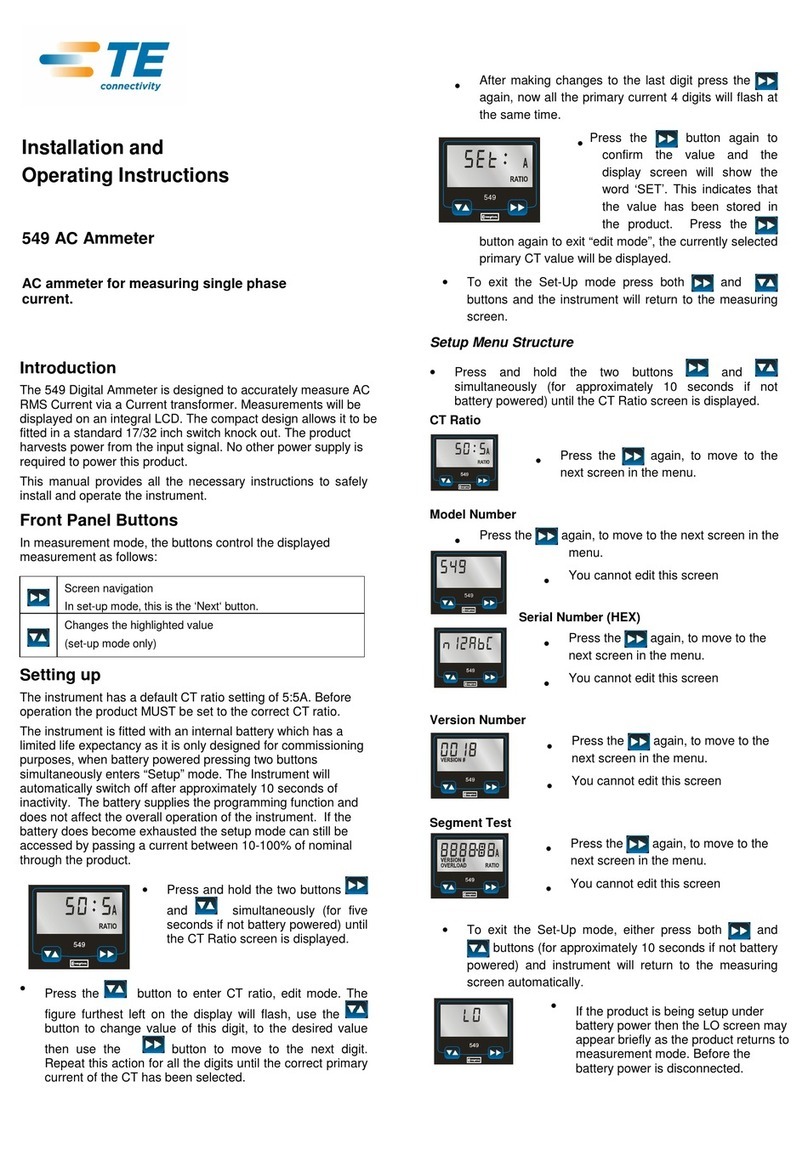

Marking and ratings

Body side labels show function, electrical rating, and

connection diagram, where there are more than two

terminals on the unit. For two terminal units, the terminals

are connected directly across the input to be measured.

Terminal numbers are moulded into the base adjacent to

each terminal stud and corresponding numbers appear on

the connection diagram. Note that the electrical rating may

differ from the dial scale marking, and the unit side label is

definitive.

These meters are intended for a rated temperature range, is

-20/+60 deg C and up to 80% relative humidity, and only for

indoor use at an altitude of less than 2000m. Shock

maximum level is 30g.

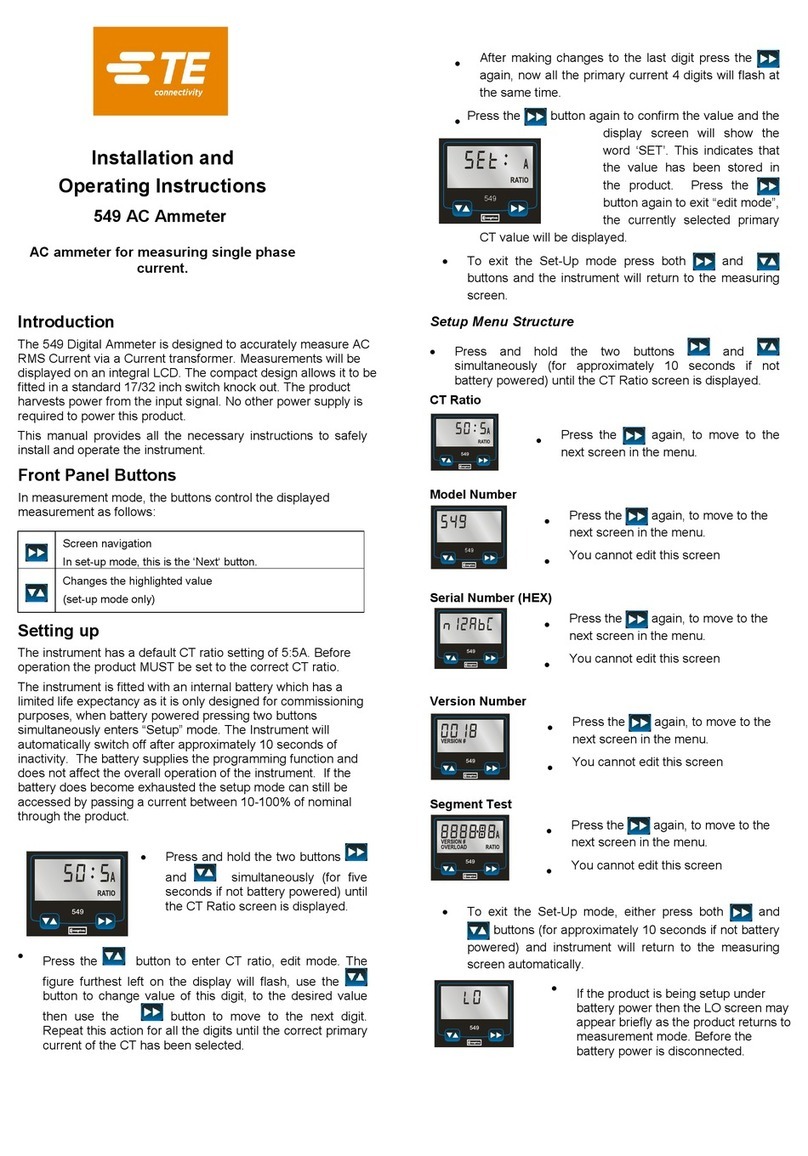

Installation

The meter should be installed in line with the requirements

of the local electrical code. It should be installed in a dry

position, not in direct sunlight and where the ambient

temperature is reasonably stable and within ratings above.

These units are only for built in use and with terminals

inaccessible to users after installation and should be

mounted to a DIN panel cut-out up to a maximum thickness

of 5 mm. Mounting is by 2 opposed corner clamps. It may

be convenient to use a 7mm screwdriver style nut driver to

engage the barrel nuts on those models with plastic nuts,

particularly when starting the thread, but great care must be

taken not to over tighten. It is very easy to cause damage

with excessive torque when using a nut driver, so final

tightening should be performed with finger pressure only.

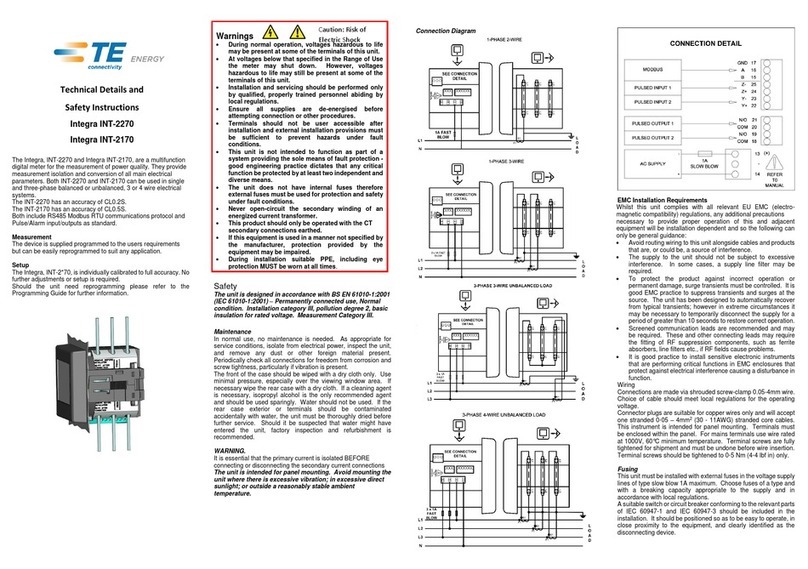

Fusing and connections

External voltage transformers and current transformers may

be used where appropriate to extend the range, provided

that the ratings marked on the side label are not exceeded

at point of connection to meter. These products are

designed for permanently connected use, normal condition

measurement category III, pollution degree 2 (e.g. non

ventilated panels or ventilated panels with filters, without

condensation occurring), basic insulation, for rated voltage.

Connection diagrams shown on the unit side label should

be carefully followed to ensure correct polarity and phase

rotation where applicable. Terminals are intended for use

with insulated ring lugs. Ensure a minimum spacing of

5.5mm (0.21”) between uninsulated parts of adjacent ring

lugs. Tighten terminal screws to 2Nm (1.5 ft/Lb) only.

These products do not have internal fuses therefore

external fuses must be used for safety protection under

fault conditions. Voltage input lines where required must be

fused with a quick blow fuse 1A maximum. Auxiliary supply

lines, where required must be fused with a slow blow fuse

rated 1A maximum. Current metering circuits directly

connected in line with the load must be fused at the rated

current for the meter. Where fitted, current transformer (CT)

secondaries must be connected to protective earth in

accordance with local regulations. Do not fuse CT circuits.

The equipment into which this meter is installed must have

a clearly marked adjacent means of isolating the supply

voltage to permit safe access for subsequent maintenance.

Ensure supply circuits are rated for meter VA: >4.5VA

Choice of associated components

Choose fuses of a voltage rating equal to or exceeding the

rated voltage of the circuit into which the meter is connected

and of a type and with a breaking capacity appropriate to

the supply to which the fuse is connected. Connection

wires and ring lugs should be rated for at least 1A for

voltage and auxiliary lines and to at least the rated current

for current measuring circuits. Additionally, wires for DC

current meters rated over 50mA must be rated at 75 deg C

or greater. Ensure cables and ring lugs have a voltage

insulation rating equal to or greater than the rated voltage of

the circuit to which they are connected.

CT cable impedance should ensure that CT VA rating is not

exceeded and it’s accuracy impaired.

Cleaning and maintenance

As required, wipe the front face with a damp cloth, ensuring

that no moisture enters the unit or penetrates behind the

mounting panel. No maintenance is required beyond

periodically checking the mechanical zero of the meter as

described overleaf in “commissioning”, if necessary

removing any accumulations of dust or other foreign matter

from the terminal area and ensuring that connections

remain tight.