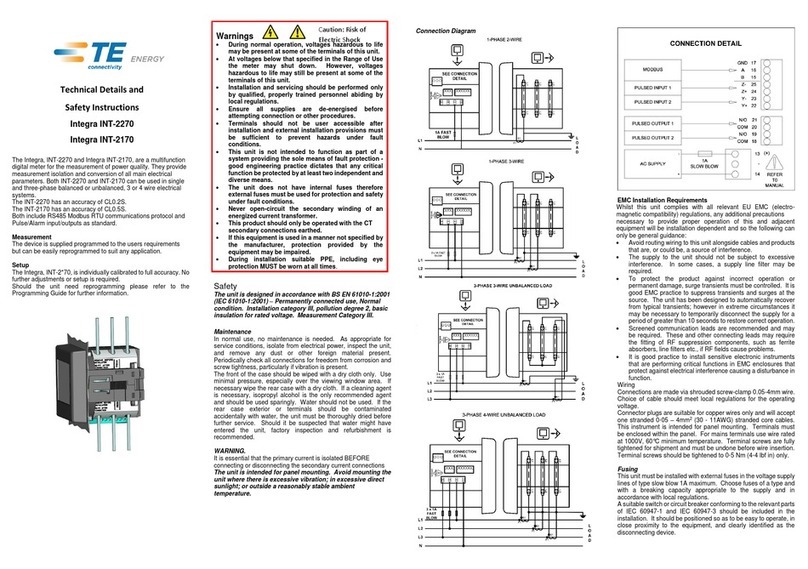

Installation

The unit may be mounted in a panel of any thickness up to a

maximum of 6mm (0·25in). Leave enough space behind the

instrument to allow for bends in the connection cables. As the

front of panel enclosure conforms to IP52, it is protected from

dripping water. The unit is intended for use in a reasonably

stable ambient temperature within the range -10 to +55°C. Do

not mount the unit where there is excessive vibration or in

excessive direct sunlight.

Safety

The unit is designed in accordance with BS EN 61010-1:2001

(IEC 61010-1:2001) – Permanently connected use, Normal

condition. Installation category III, pollution degree 2, basic

insulation for rated voltage. Measurement Category III.

EMC Installation Requirements

Whilst this unit complies with all relevant US EMC (electro-

magnetic compatibility) regulations, any additional precautions

necessary to provide proper operation of this and adjacent

equipment will be installation dependent and so the following can

only be general guidance:

•Avoid routing wiring to this unit alongside cables and

products that are, or could be, a source of interference.

•The signal to the unit should not be subject to excessive

interference. In some cases, a supply line filter may be

required.

•To protect the product against incorrect operation or

permanent damage, surge transients must be controlled. It

is good EMC practice to suppress transients and surges at

the source. The unit has been designed to automatically

recover from typical transients; however in extreme

circumstances it may be necessary to temporarily reduce the

magnitude of the measured signal to the point where the

instrument turns off for a period of greater than 10 seconds

to restore correct operation.

•It is good practice to install sensitive electronic instruments

that are performing critical functions in EMC enclosures that

protect against electrical interference causing a disturbance

in function.

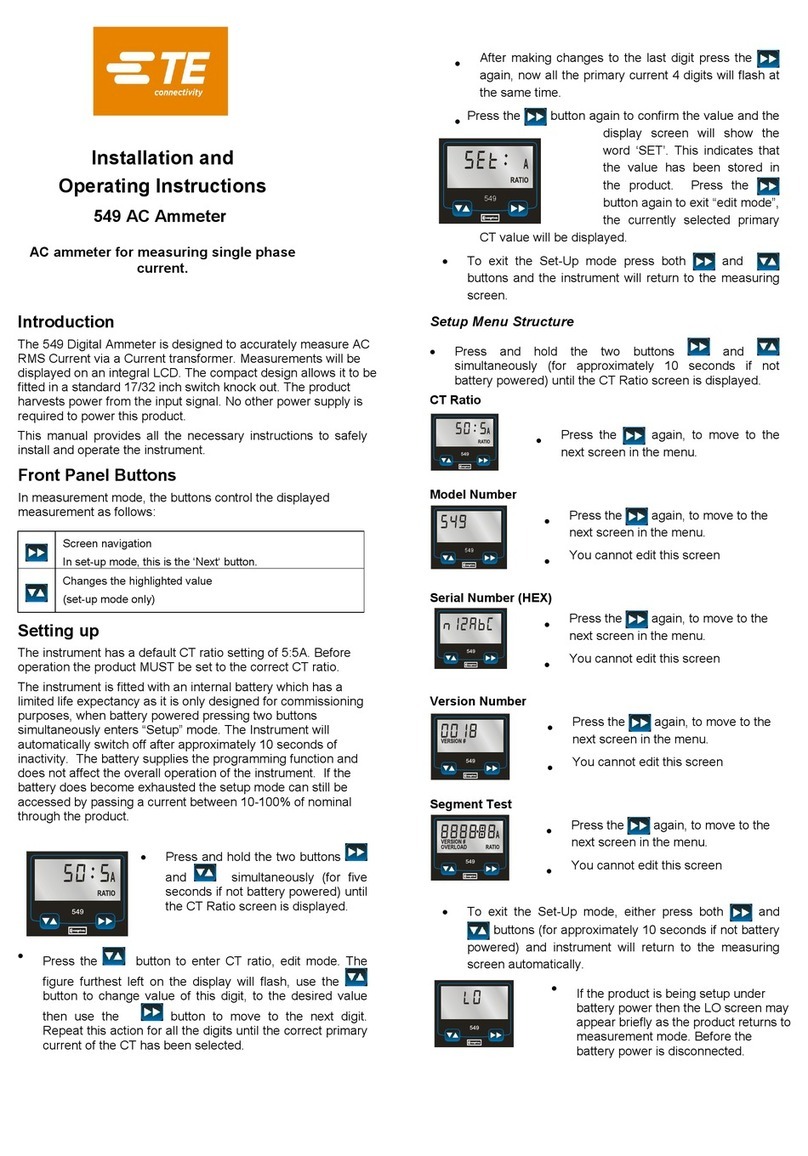

Wiring

Input connections are made to terminals posts. Use cable lugs

suitable for 6-32 UNC screw. Wiring should conform to national

Electrical Code Class 1 and sized appropriate to CT secondary

current ratings.

The current inputs of this product are designed for

connection into systems via current transformers only.

Instrument transformers used for connection to the meter must

be of approved type and compliant with ANSI/IEEE C57.13 or

IEC 60044-1, selected and sized appropriate to the supply

network being monitored. CT secondaries must be grounded in

accordance with local regulations. It is desirable to make

provision for shorting links to be made across CT secondary’s to

permit easy replacement of a unit should this ever be necessary.

This instrument is intended for panel mounting. Terminals must

be enclosed within the panel. Terminal nuts should be tightened

to 8.0 lbs in (1.0Nm) only.

Earth/Ground Connections

For safety reasons, current transformer secondary connections

should be grounded in accordance with local regulations. Under

no circumstances should the product be operated without this

Earth connection.

Maintenance

In normal use, little maintenance is needed. As appropriate for

service conditions, isolate from electrical power, inspect the unit,

and remove any dust or other foreign material present.

Periodically check all connections for freedom from corrosion and

screw tightness, particularly if vibration is present.

The front of the case should be wiped with a dry cloth only. Use

minimal pressure, especially over the viewing window area. If

necessary wipe the rear case with a dry cloth. If a cleaning agent

is necessary, isopropyl alcohol is the only recommended agent

and should be used sparingly. Water should not be used. If the

rear case exterior or terminals should be contaminated

accidentally with water, the unit must be thoroughly dried before

further service. Should it be suspected that water might have

entered the unit, factory inspection and refurbishment is

recommended.

Contains no serviceable parts:

In the unlikely event of a repair being necessary, it is

recommended that the unit be returned to the factory or nearest

Crompton Instruments / TE Connectivity service centre.

This product contains a Lithium cell, and should be recycled or

disposed of in accordance with local environmental regulations.

Specification

Measurement Inputs

Nominal Input Current 5A AC RMS

Max. Continuous input Overload 6A AC RMS

Max. Short duration input Current 50A for 1 second.

Maximum VA Burden 3 VA

Frequency 60Hz +/- 2%

Maximum Total Harmonic Distortion 30%

Maximum Crest Factor 1.68

Range of Use

Values of measured quantities, components of measured

quantities, and quantities which affect measurement errors to

some degree, for which the product gives meaningful readings:

Ratio 5 … 2000A

Accuracy

Current (A) ± 1% of range

Warnings

•During normal operation, voltages hazardous to life

may be present at some of the terminals of this unit.

•Installation and servicing should be performed only

by qualified, properly trained personnel abiding by

local regulations.

•Ensure all supplies are de-energised before

attempting connection or other procedures.

•Terminals should not be user accessible after

installation and external installation provisions must

be sufficient to prevent hazards under fault

conditions.

•Never open-circuit the secondary winding of an

energized current transformer.

•This product should only be operated with CT

secondary connections Earthed.

•If this equipment is used in a manner not specified

by the manufacturer, protection provided by the

equipment may be impaired.

•If sufficient torque setting of 8.0Ibs in (1.0Nm) cannot

be applied to the rear fixing, the product should not

be installed.

Caution: Risk of