Nic RA-7000A+SANPRA 5 User manual

FULLY-AUTOMATIC REDUCING VAPORIZATION

MERCURY ANALYZER

RA-7000A+SANPRATM5

Quick Start Guide

COMTEMTS

SAFETY PRECAUTIONS··················· 1

PRINCIPLE OF MEASUREMENT ········ 3

BEFORE MEASUREMENT ················· 4

Articles Required for Measurement

·4

Procedure for Preparation of

Standard Mercury Solution

············4

Preparations of Reagents

··············6

MEASUREMENT ····························· 8

Flow of Measurement

····················8

Startup of System

························9

Self Check

·································· 10

Reagent Filling

··························· 13

Procedure for Setting Method

······ 14

Setting Procedure for Measurement

Condition

··································· 15

Setting of Table Condition

············ 16

Registration & Setting of Standard

Mercury Solution

························ 17

Registration & Setting of Unknown

Sample(ENVIRONMENTAL

WATER)

··································· 19

Start of Measurement

················· 20

Checking of Measurement Result

·21

Printing of Measurement Result

··· 23

Reagent Discharge

······················ 24

Shutdown of System

··················· 25

Cleaning of Apparatus················· 26

Introduction

The “Quick Start Guide” is aim at help to understand the basic measurement

procedures.

Read the separate “instruction Manual” for detailed measurement methods and

equipment handling.

Please read this manual in conjunction with the "Instruction Manual" to ensure correct and safe use.

Be sure to read the "Safety Precautions" section of the instruction manual for precautions regarding

installation, preparation, and maintenance.

After read it, please keep it in a safe place so that you can view it at any time.

1

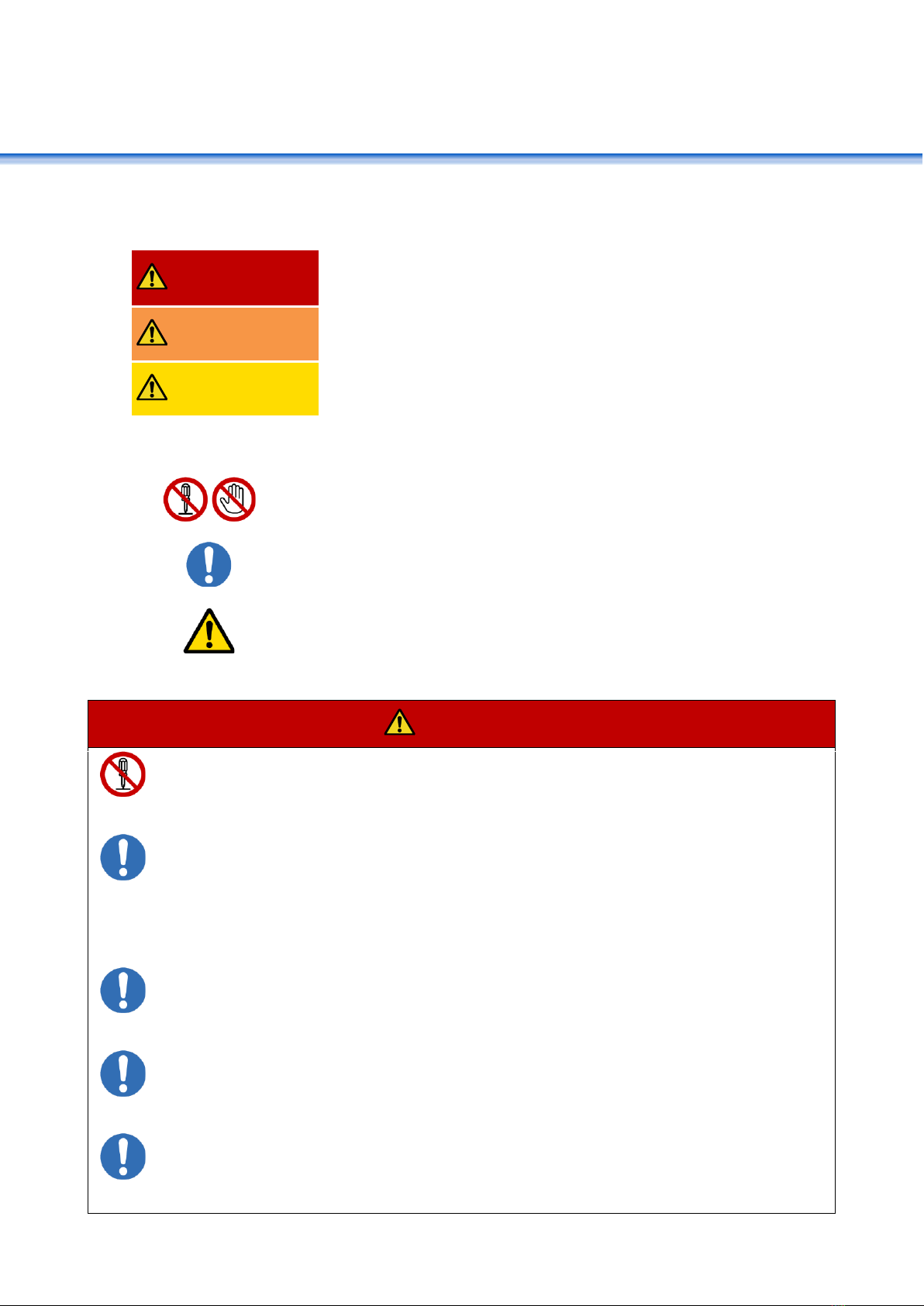

SAFETY PRECAUTIONS

To use this product safely, be sure to observe the following precautions:

Classification

Danger

In the case of mishandling, a death or a serious injury may

result immediately.

Warning

In the case of mishandling, a death or a serious injury may

result.

Caution

In the case of mishandling, a slight injury or property

damage may result.

Graphic Symbols

Indicate the contents that must not be carried out.

Indicate the contents that must be carried out.

Indicates the contents that require care.

Danger

Do not carry out disassembling or remodeling that is not

described in this document.

Otherwise, a serious accident may occur.

Be sure to carry out ventilation.

There is a risk of volatilization from hazardous samples or generation of toxic gases

when heated.

Do not use SANPRATM in an enclosed space.

Install the equipment so that the air inside SANPRATM5 is locally exhausted.

Wear protective equipment.

Reagents to be used contain acute toxic and corrosive substances. Before using the

instrument, wear protective equipment.

Use the instrument according to this document.

If the instrument is operated or handled erroneously, a serious accident or failure

may occur.

When using the instrument, observe the specification range.

If the instrument is used out of the specification range, a serious accident or failure

may occur.

2

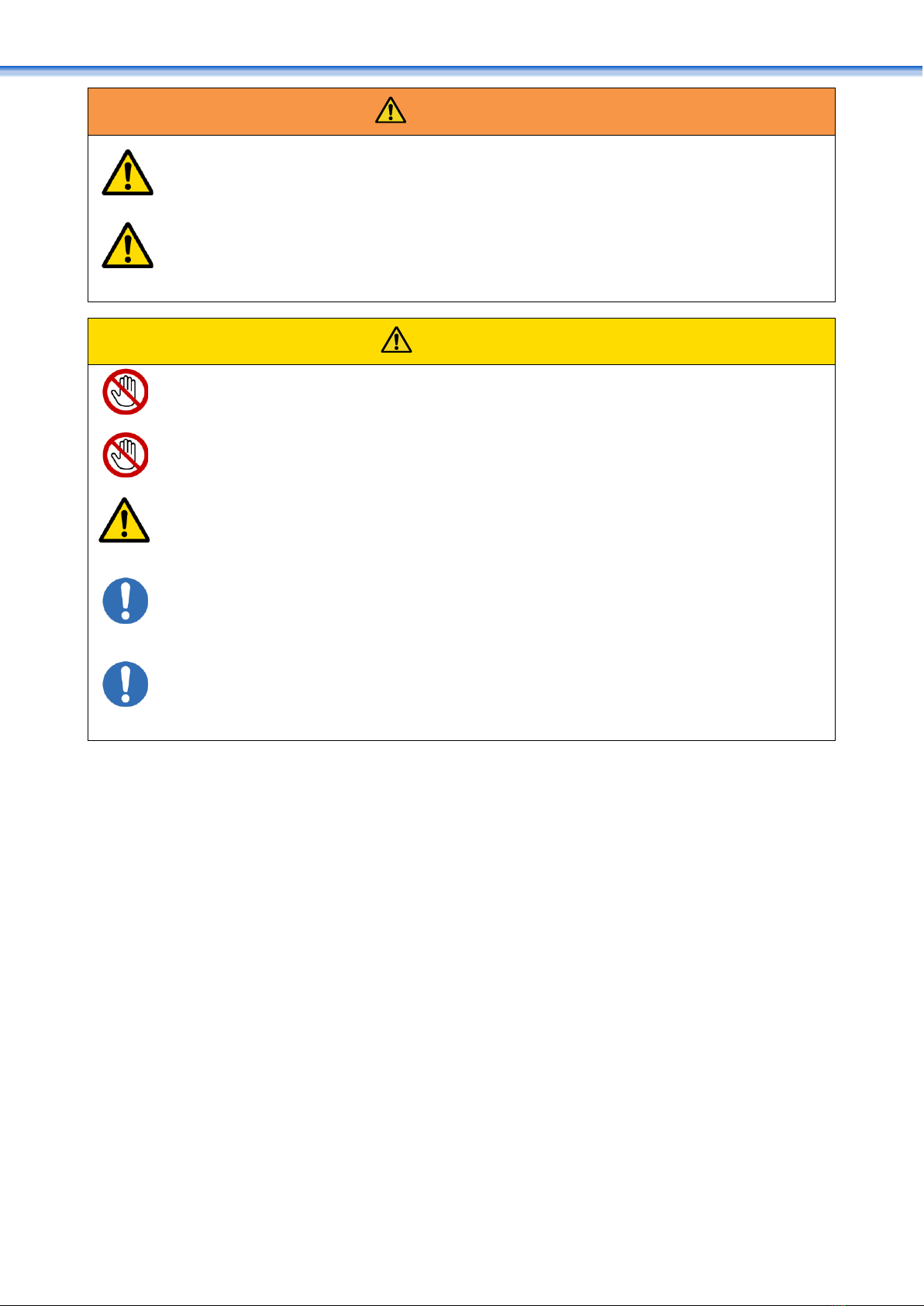

Warning

Take care when handling a reagent.

Acquire, supervise and read carefully the SDS (safety data sheet) of a reagent, and

take care when handling it.

Care about the contents of the caution labels of the instrument.

Read carefully the contents of the caution labels, and take care when using the

instrument.

Caution

Do not operate the instrument with a wet hand.

An accident or failure may occur.

Do not use the sample tube that has been cracked or chipped.

An injury may result. Also, Measurement cannot be performed properly.

Take care when handling a glass component.

If a glass component is broken by mistake, an injury may result.

Take care not to drop or hit any glass component.

Keep reagents and standard mercury solutions appropriately.

If any reagent or standard mercury solution is not kept appropriately, it will be

impossible to guarantee the performance of the instrument.

Process effluents appropriately.

When discarding effluents, do so appropriately according to the regulations of each

local government.

3

PRINCIPLE OF MEASUREMENT

Sulfuric acid, nitric acid and potassium permanganate solution are added to a sample, a vermilion

residue of permanganic acid ion is checked, and then potassium peroxodisulfate is added. When

this solution is heated, the oxidative decomposition of a mercury compound in the solution occurs

and bivalent mercury ions (Hg2+) are produced.

After cooling, hydroxylammonium chloride solution is added to reduce excessive potassium

permanganate. When stannous chloride solution is added to the sample after this wet

pretreatment, bivalent mercury ions (Hg2+) are reduced to zero valent metal mercury (Hg0) and

changed to mercury gas by bubbling.

Hg2+ + Sn2+ → Hg0↑ + Sn4+

After acid mist and steam generated by the bubbling are removed by the dehumidifier and the

membrane filter, the absorbance is measured at 253.7 nm, which is the first absorption

wavelength band of mercury.

Using the absorbance, the quantity of mercury is calculated from a calibration curve prepared by

measuring known quantities of mercury.

V2

Flow

Adjustment

Valve

Air Pump

V1

Flow Sensor

Membrane Filter

Dehumidifier

Inlet Activated

Carbon Filter

Outlet Activated

Carbon Filter

Bubbler

Sample

Cap

Light

Absorption

Cell

Detector

(REF)

Detector

(SIG)

Drain

Pump

Mercury

Lamp

Effluent

Tank

Rinse

Tank

Sample

Tank

Rinse

Bottle

P8

P7

P1

P2

P3

P4

P5

P6

HONH3Cl

KMnO4

H2SO4

HNO3

K2S2O8

SnCl2

Dispensing

Cap

4

BEFORE MEASUREMENT

Articles Required for Measurement

Pure Water

Pour water of A3 or A4 defined

by JIS K0557 into a washing

bottle.

Standard Mercury Solution

Examples: 1 ppm, 0.1 ppm,

0.01 ppm

Measurement Reagent

Prepare sulfuric acid and

stannous chloride solution.

Cleaned Sample tube*

Cleaned Stirrer*

Micropipette (up to 200 μL)

Used for the measurement of liquid sample

such as standard solution.

Micropipette (up to 1000 μL)

Used to add a sample or pure water.

Micropipette (up to 5000 μL)

Used to add a sample or pure water.

Procedure for Preparation of

Standard Mercury Solution

The concentration of standard mercury solution changes greatly after preparation, and calibration

curves may disperse and reproducibility may lower.

Therefore, we add L-cysteine to diluted standard mercury solution to suppress the change of the

concentration.

Caution

Before using the reagents, wear protective equipment.

1Preparation of L-Cysteine Solution (10 mg/L)

Pour 10 mg of L-Cysteine

(HSCH2CH(NH2)COOH) in a 1000 mL

measuring flask.

Caution

Use L-cysteine.

Note that this is not cystine or L-cysteine

hydrochloride.

After adding approximately 600 mL of pure

water, add 2 mL of nitric acid and shake the

flask.

Caution

Always add concentrated nitric acid after adding

a large amount of pure water.

If nitric acid is added directly to L-cysteine or

there is not enough water, decomposition will

occur and the effect will be lost.

L-Cysteine

10 mg

Pure Water

Approx. 600 mL

Nitric Acid

2 mL

1)

2)

5

Add pure water to make the whole volume

1000 mL.

2Preparation of Standard Mercury Solution (10 mg/L)

Take 1 mL of standard mercury solution (1000

ppm) for the atomic absorption, and add L-cysteine

solution (10 mg/L) to make the whole volume 100

mL.

Reference

No problem will arise even if pure water is used

for strict measuring near the marked line.

3Preparation of Standard Mercury Solution (0.1 mg/L)

Take 1 mL of standard mercury solution (10 mg/L),

and add L-cysteine solution (10 mg/L) to make the

whole volume 100 mL.

Reference

No problem will arise even if pure water is used

for strict measuring near the marked line.

*When you want to prepare standard mercury solution of less than 0.1 mg/L, carry out dilution in the

same way.

Caution

When repreparing standard mercury solution, use the same measuring flask if possible.

Before using a new measuring flask, wash it sufficiently using 1:10 nitric acid.

Especially before preparing standard solution of 1 ppm or less, carry out acid cleaning

carefully and also wash the plug part sufficiently to prevent contamination from the

measuring flask.

Custody

It is possible to use L-cysteine solution and prepared standard mercury solution for six months

when they are stored in a cool, dark place.

Since stability worsens when standard mercury liquid has become old or has been left in a warm

place, we recommend storing it in a cool, dark place and managing the date of preparation.

Pure

water

Whole

Volume

1000 mL

3)

Standard

Mercury

Solution for

Atomic

Absorption

1mL

L-Cysteine

Solution

Whole

Volume

100 mL

Standard

Mercury

Solution

1mL

L-Cysteine

Solution

Whole

Volume

100 mL

6

Preparations of Reagents

Referring to the following, prepare reagents and pour them into supplied reagent containers.

Items in [] are reagents used by us.

Caution

Before using the reagents, wear protective equipment.

Use reagents that contain little mercury, such as ones for mercury analyses, for precise

analyses or for toxic metal measurements.

The amount of reagents should be around 30 mL more than the [Amount of reagents

specified in the Measurement Condition] x [Number of measurements].

Note that an additional amount of reagents may be used for potassium permanganate

solution, by the number of times the color check is carried out.

Reagent

Bottle

Reagent

Preparation Procedure

P1

Potassium Permanganate Solution

(5% w/v)

KMnO4

Dissolve 50 grams of potassium permanganate

in pure water. Then filter the solution with the

glass filter and adjust it to 1 liter.

【Potassium permanganate solution (50 g/L)

for mercury analyses manufactured by Kanto

Chemical 500 mL: 31540-08】

P2

Sulfuric Acid (1+1) or 50% v/v

Sulfuric Acid

H2SO4

Pour 50 mL of distilled water into a beaker and

add 50 mL of sulfuric acid slowly while cooling

and stirring the solution.

Caution

Be sure to add sulfuric acid to water little by

little. Pouring water into sulfuric acid is very

dangerous because bumping occurs.

When adding sulfuric acid, be sure to pour

little by little while cooling the solution.

Otherwise, you may get burned.

(

The sulfuric acid is diluted two-fold for

protection of the tube pump.)

【

[Sulfuric acid 1:1 for mercury analyses

manufactured by Kanto Chemical 500 mL:

37928-08]

[64% sulfuric acid manufactured by FUJIFILM

Wako Pure Chemical 500mL: 198-11565]

P3

Nitric Acid (1+3) or 25% v/v HNO3

HNO3

Take 3 parts pure water in a beaker, and add 1

part nitric acid (1.38) while stirring.

Caution

Be sure to add nitric acid to water little by

little. Pouring water into nitric acid is

dangerous because heating occurs.

(

The nitric acid is diluted four-fold for

protection of the tube pump.

)

【Nitric acid (1.38) for toxic metal

measurements manufactured by FUJIFILM

Wako Pure Chemical 500 mL: 140-04016】

7

P4

Potassium Peroxodisulfate Solution

(3% w/v, 4 % w/v, 5 % w/v)

K2S2O8

Dissolve 30, 40 or 50 grams of potassium

peroxodisulfate in distilled water, and adjust it

to 1 liter.

(3% w/v, 4 % w/v; The concentration is

reduced to prevent crystallization)

【Potassium peroxodisulfate solution for toxic

metal measurements manufactured by

FUJIFILM Wako Pure Chemical 500 g: 164-

09175】

P5

10% Stannous Chloride Solution

SnCl2

Add 60 mL of sulfuric acid (1:20) to 10 g of

stannous chloride dihydrate, melt it while

heating and stirring, leave the solution until it

is cooled and add water to make the volume

100 mL. (Preparation before use)

or

[Stannous chloride solution for mercury

analyses manufactured by Kanto Chemical 500

mL: 36522-08]

P6

Hydroxylammonium Chloride Solution

(0.8% w/v, 1.0% w/v, 1.2% w/v, 1.5% w/v)

HONH3Cl

Dissolve 8, 10, 12 or 15 grams of

hydroxylammonium chloride in distilled water,

and adjust it to 1 liter.

(The concentration is adjusted so that the

amount to be added becomes 2.5 to 3 mL.)

【Hydroxylammonium chloride for toxic metal

measurements manufactured by FUJIFILM

Wako Pure Chemical 100 g: 085-03451】

Sodium chloride (1.2% w/v, 1.4 %

w/v) – hydroxylamine hydrochloride

(1.2% w/v)

NaCl - HONH3Cl

Dissolve 12 or 14 grams of sodium chloride

and 12 grams of hydroxylammonium chloride

in distilled water, and adjust it to 1 liter.

P7

Pure Water for rinsing

1L

8

MEASUREMENT

To help you understand the basic measurement method of this instrument, the following

explanation uses the measurement of Method3 as an example.

For details on setting conditions for actual measurement, please refer to the instruction manual.

Flow of Measurement

Measurement Operation Start

Start up the system.(p. 9)

Reagent filling(p. 13)

Reagent discharge(p. 24)

Putting away the samples

Shut down the system.(p. 25)

Is the check result OK?

Register a sample.(p. 17 and p. 19)

Make a measurement.(p. 20)

Measurement Operation End

All OK

NG

Issued

9

Startup of System

1Turning On of Instrument

Turn on the personal computer to start

Windows.

Turn on the power switches on the RA-7000A

and the SANPRATM5.

The status display lamps blinks.

2Startup of Control and Analysis Software

Start the control and analysis software

RA7000AWin.

When the system has started up normally, the

status display lamp lights light blue and

[Ready] is displayed on the status bar.

The SANPRATM5 initialization screen will appear.

Click "OK" to initialize the instrument.

The setup screen appears.

Click “Yes” to perform the self check.(P. 10)

2)

10

Self Check

1Startup of Self Check

Click [Run] on the “Self Check” tab.

Reference

When the "STANDBY" message is displayed in

the upper right corner of the screen, the optical

system is being stabilized, so it is recommended

to execute the check after the display disappears.

If an equipment check is executed while the

"STANDBY" message is displayed, accurate

voltages will not be recorded.

A self check message appears.

Click [Run].

2Checking of GLP Counter

The checking results of the GLP counter appear on

the self check screen.

Make sure whether all checking results are “PASS”

or not.

If any item in the GLP counter exceeds the

threshold, “FAIL” will be displayed. Replace the

component.

Reference

Refer to the instruction manual for the measures

to be replace the parts.

GLP Counter

Threshold Value

Lamp

5000 hours

Membrane Filter

2000 hours or 1 year after replacement

Air Pump Usage

2000 hours or 2 years after replacement

Drain Pump Tube

700 hours or 1 year after replacement

Activated Carbon Filter

1000 mg

P1 pump tube

700 hours or 1 year after replacement

P2 pump tube

700 hours or 1 year after replacement

P3 pump tube

700 hours or 1 year after replacement

P4 pump tube

700 hours or 1 year after replacement

P5 pump tube

700 hours or 1 year after replacement

P6 pump tube

700 hours or 1 year after replacement

P7 pump tube

700 hours or 1 year after replacement

P8 pump tube

700 hours or 1 year after replacement

Heater

2000 hours

1)

11

3Checking of Cooling Fan Operation

A confirmation message for the cooling fan

operation appears.

Make sure that the cooling fan in the back of

the sample table blows air.

After the checking, click [OK].

4Checking of Operation of Duct Fan

A confirmation message for the operation of

the duct fan appears.

Make sure that the operation sound of the duct

fan is heard.

After the checking, click [OK].

5Setting of Sample tube

A message appears to prompt you to set a

sample tube for the flow rate adjustment.

Set an empty sample tube at No. 81 on the

sample table.

After the completion of the setting, close the

front door of the SANPRATM5 with both hands

and click [Next].

Caution

If [Next] is clicked without closing the door, a

confirmation message will appear.

After closing the door, click [Next].

1)

1)

1)

12

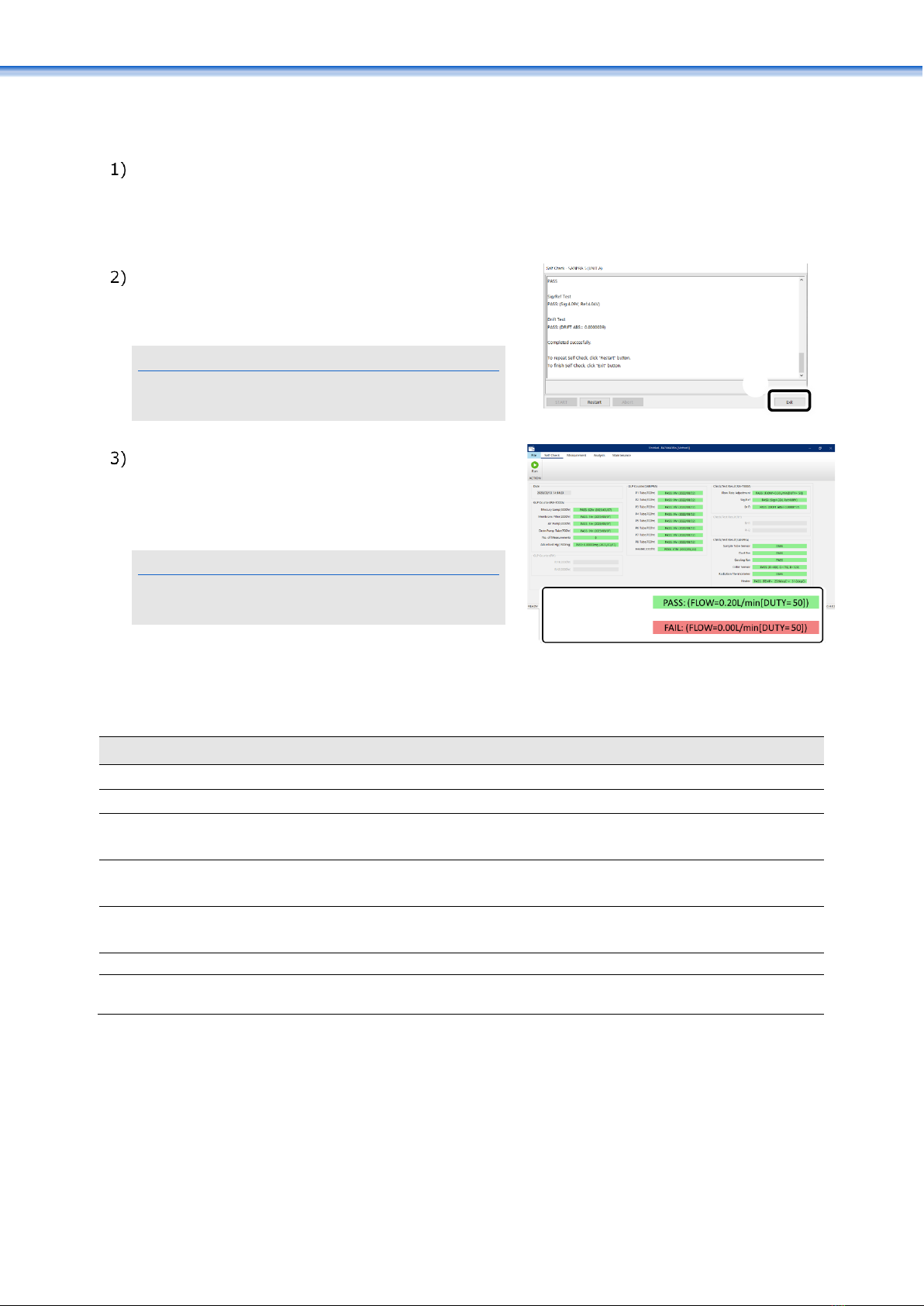

6Checking of Self Check Result

After the setting of a sample tube, the self check automatically proceeds and the checking

results appear on the self check screen.

If any checking result is “FAIL”, a message will appear.

Take measures for that checking item.

When all checking results are “PASS”, a normal

completion message appears.

Click [Exit].

Reference

When you want to carry out the self check again,

click [Restart].

A message appears to register the self check

results.

When [Yes] is clicked, the self check results

appear on the self check screen.

Reference

A result with “PASS” is displayed in green, and

one with “FAIL” in red.

Judgment Criterion for Self Check and Measures

Checking Item

Judgment Criterion

Flow Rate Adjustment

A flow rate of 0.20 L/min. is kept for five seconds.

Radiation Thermometer Test

A positive value is output from the thermometer.

Heating Test

The heater temperature rises by 4℃ within five minutes

after the heating check starts.

Color Sensor Test

Of the signals (R, G, B) from the color sensor, at least

one nonzero number is output.

Container Sensor Test

No. 81 on the table is detected and the presence or

absence of a sample tube is judged correctly.

SIG/REF Test

The voltages of SIG and REF are 3.5-4.5 V.

Drift Test

The quantity of the drift is 0.0005 ABS or less in 30

seconds.

2)

Normal

Abnormal

13

Reagent Filling

The reagent tubes must be filled with reagent before starting measurement.

Caution

Before using the reagents, wear protective equipment.

Working while the arms or sample table is in operation may cause an entrapment accident

and risk of equipment failure.

Do not work inside the device while it is in operation.

Click [Filling] on the “Measurement” tab.

From this point on, follow the message.

Click [START].

Insert the rinse tube (P8) into the rinse tank.

Insert the rinse tube into the effluent tank.

Insert the luer fittings at the ends of the

reagent bottle tubes into the tubes of the

reagent bottles and twist clockwise to connect

them to the reagent bottles.

Caution

Before the connection, check carefully the labels

of each bottle and each tube.

Click [Next], and the reagents will be supplied.

Caution

Make sure that the reagents are instilled from the

end of the tube into the rinse bottle.

A completion message appears.

Click [Exit] to terminate the reagent filling.

3)

5)

1)

7)

14

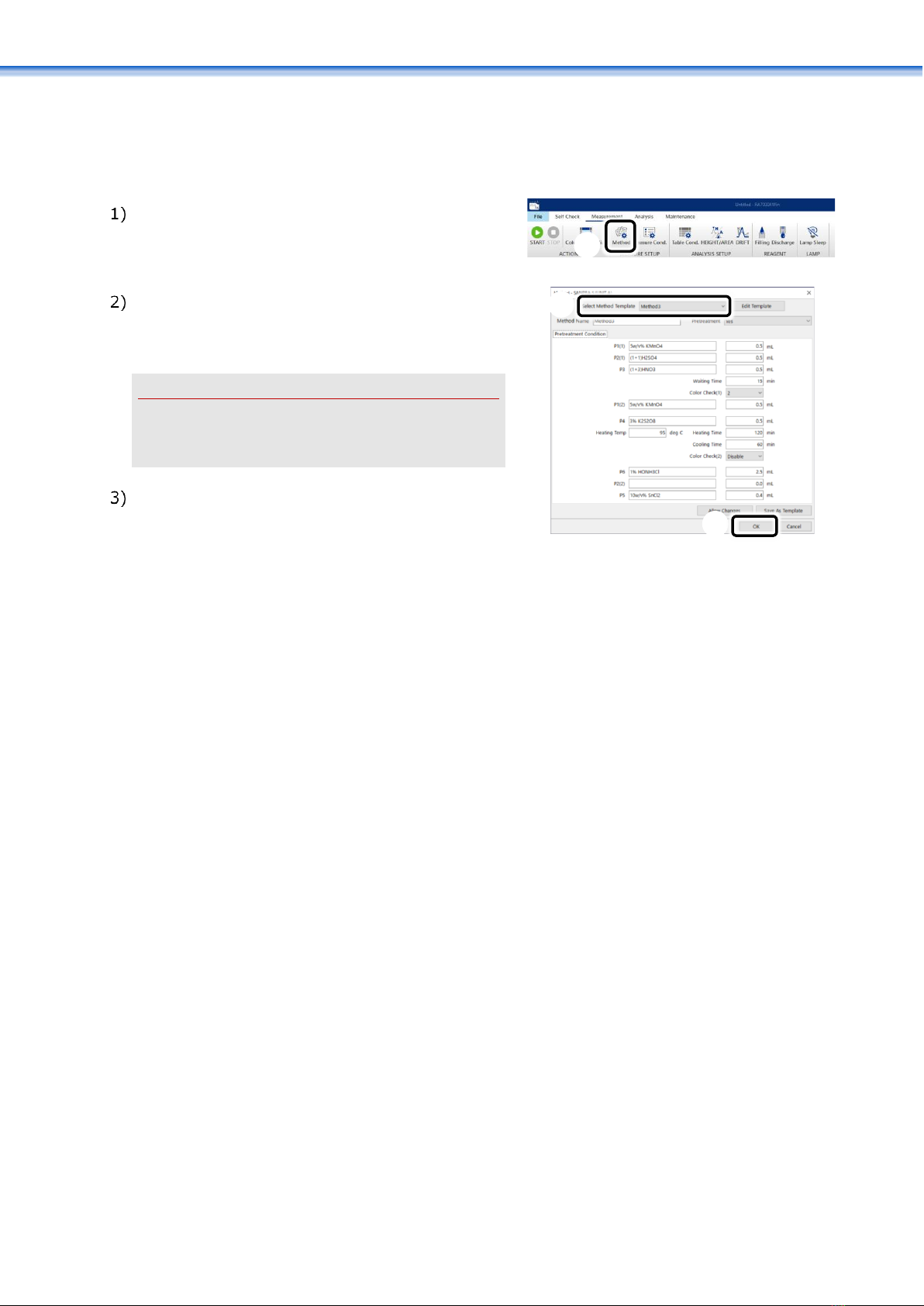

Procedure for Setting Method

Default methods have been registered as methods to measure samples.

Click [Method] on the “Measurement” tab.

Set a method.

Select a method name to be used for a

measurement at “Select Method Template”.

Caution

It is impossible to change a method after the

start of a measurement. When you want to

change a method, make a measurement newly.

After the selection, click [OK].

Default Measurement Methods

EPA M245.1, 7470a_ASTM D3223(5mL)

EPA M245.1, 7470a_ASTM D3223(4mL)

APHA 3112B

Method1 – 5 ; for Japanese

Method TEST

1)

2)

3)

15

Setting Procedure for

Measurement Condition

A measurement condition is set.

Caution

It is impossible to change a measurement condition after the start of a measurement.

When you want to change a measurement condition, make a measurement newly.

Click [Measure Cond.] on the “Measurement”

tab.

The “Measurement Condition” screen appears.

Set an instrument control condition.

Set each item for control.

Caution

The item for the liquid level auto adjustment is

displayed only when the dilution rate has been

selected using [SMP]-[Unit] in the table

condition.

Reference

Usually, use a default value for a measurement

time.

When a special measurement method is used, it

is possible to change a measurement time.

When automatic liquid level adjustment is

enabled, a sample of 5 mL or more can be placed

in the sample tube and set in the instrument.

The excess volume is automatically drained out

to adjust the sample volume to 5 mL before

measurement is performed.

Click the tab for checking and set the threshold

value of each checking item and operation after

the checking.

After the setup, click [OK].

2)

3)

4)

1)

16

Setting of Table Condition

Click [Table Cond.] on the “Measurement” tab.

Or click [Table Cond.] on the “Analysis” tab.

The “Table Condition” screen appears.

Set a common table condition.

Click the “Common” tab and set information for

the analysis mode and drift correction.

Reference

Usually, set the analysis mode to “AREA”.

Usually, set the drift correction to “ON”.

Click the “STD” tab and set the type of a

calibration curve and the unit of standard

samples.

Reference

Usually select “y = ax + Blank”. Change the

calibration curve according to the official

methods.

In the case of the measurement of 0.05 ppb or

less, select the HIGHT analysis.

When mercury is measured beyond 40 ppb (200

ng/5 mL), select the cubic formula.

Click the “SMP” tab and set a type, unit and

other items for unknown samples.

After the setup, click [OK].

1)

2)

3)

4)

5)

17

Registration & Setting of Standard

Mercury Solution

Measurements for Calibration Curve of 0.05 ppb, 0.10 ppb and 0.15 ppb.

1Registration Procedure for Calibration Curve

Click [STD] on the “Measurement” tab.

Enter information on standard mercury

solution.

STD

[ppb]

SVOL

[mL]

CVOL

[mL]

DVOL

[mL]

0.000

5.000

5.000

5.000

0.050

5.000

5.000

5.000

0.100

5.000

5.000

5.000

0.150

5.000

5.000

5.000

Reference

A STD [ng] value is automatically calculated

Blanks should be set an arbitrary number of

times to confirm the measurement results.

Click check boxes for samples to be measured.

Reference

When you want to place two or more check

marks simultaneously, put the cursor in a

position other than a check box and drag the

mouse.

Input Item

Input Contents

STD

Enter the concentration of standard mercury solution to be used.

SVOL

Enter the sample volume of the standard mercury solution

extracted to the pretreatment container.

CVOL

Enter the volume measured after pretreatment.

DVOL

Enter the volume dispensed from the pretreated sample to the

sample tube.

1)

2)

3)

18

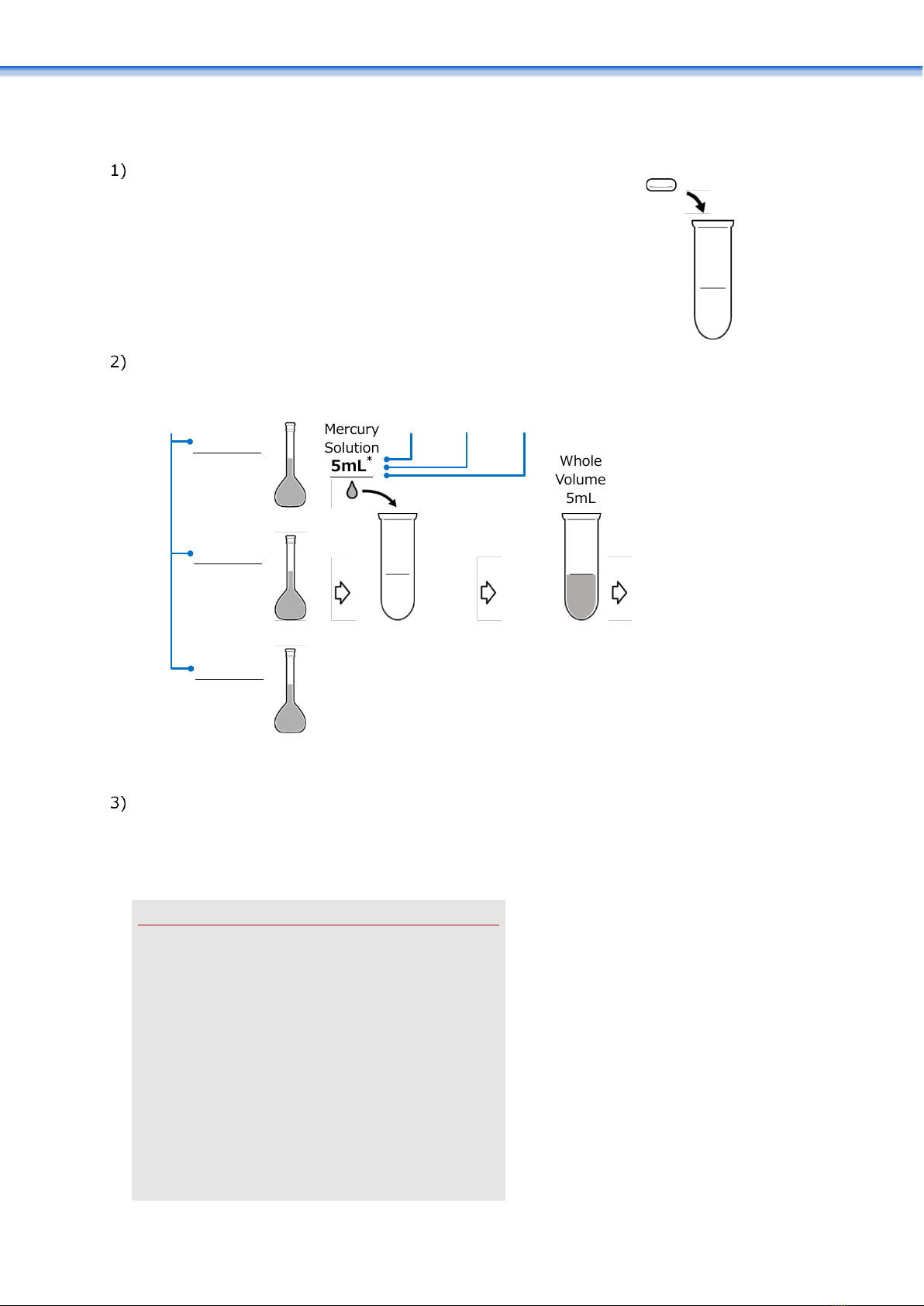

2Setting of Standard Mercury Solution

Put a stirrer beforehand into a sample tube.

Pour 5 mL the mercury standard solution into a sample tube.

*For the blank measurement, take a 5 mL pure water.

*When you want to carry out the liquid level auto adjustment, dispense an arbitrary volume of 5 mL

or more of standard mercury solution in a sample tube.

Open the front door of the instrument.

Set sample tubes at the numbers on the

sample table that have been registered on the

table screen.

Caution

No. 81 is for the self check. It cannot be used for

measurements.

Set samples sequentially without skipping any

number.

Otherwise, the heating temperature may vary.

Take care not to drop a sample tube when

setting it on the table.

Otherwise, the liquid sample in the sample tube

may splash.

Do not touch the arm.

Otherwise, the arm may get out of adjustment.

Do not remove the sample table to set sample

tubes. Otherwise, you may drop the table and

get injured.

Stirrer

0.05ppb

Standard

Mercury

Solution

0.10ppb

Standard

Mercury

Solution

0.15ppb

Standard

Mercury

Solution

Standard

Mercury

Solution

5mL*

Whole

Volume

5mL

Set in the instrument

STD

DVOL

CVOL

SVOL

Table of contents

Other Nic Measuring Instrument manuals