TE Technology TC-36-25 RS232 User manual

Instruction Manual

for

Model TC-36-25 RS232

And

Model TC-36-25-RS232-UL

Temperature Controller

For T ermoelectric Coolers

19-SEP-2023

Drawing #4637 Rev. J

1590 Kean e D r ive P one : ( 2 3 1) 9 2 9 -3 966

Tra v e r se Cit y , M I 496 96-8 2 57 Fax: ( 231) 929 -41 6 3

ttp:/ / www .te t e c .c o m e-m a il: c o o l@ tete c .c o m

All Materials Copyright © 2023, TE Technology, Inc.

TE

TECHNOLOGY, INC.

®

2

General Safety Warnings

This manual is availa le in English only. It must e read and followed carefully efore installation and operation.

THE LATEST REVISION OF THIS MANUAL IS AVAILABLE AT www.tetech.com. Verify that you are using the

latest revision availa le.

The temperature controller should not e used as a toy, or serious injury could result. The controller

should only e used for its intended purpose of providing temperature control of TE Technology’s

thermoelectric devices only. The controller is intended for light industrial, la oratory, or similar use. It is

not intended for household use or medical use.

Do not use in an explosive or potentially explosive environment.

Do not use the temperature controller to control capacitive or inductive loads or the controller could e

damaged and/or overheat. Examples of capacitive or inductive loads include ut are not limited to motors,

fans, filters, and solenoids.

Do not allow the electrical connections on the printed circuit oard to touch any electrically conductive

surfaces.

Do not operate in an environment where the controller could come in contact with condensation, water,

metal shavings, dirt or other contaminants, or electrically conductive materials. Ingress of contaminants

shall e addressed when installed in the end product.

Use ESD (Electro Static Discharge) protection when installing and handling the controller.

Do not touch any of the electrical connections or components of the temperature controller while the

controller is energized. Doing so can disrupt the function of the controller.

Do not use if the controller has een damaged in any way.

Only qualified technicians should install and operate this controller with the appropriate personal

protective equipment.

Improper tuning of this temperature controller can lead to excessive thermal cycling and/or overheating

of the thermoelectric device, either of which are known to reduce the lifetime of any thermoelectric

device. Care should e taken to prevent the temperature of the thermoelectric device from going eyond

the range specified y the device manufacturer. Care should also e taken so that any thermal cycling of

the thermoelectric device is a result of changes in the controller’s set-point temperature and not

insta ility at a given set point due to improper selection of the tuning varia les.

The temperature controller ase underneath the transistor-mounting area could exceed 60 °C under

normal operation. Use caution! Protect against accidental contact with hot surfaces.

Use protection devices to prevent hazardous conditions and/or damage to equipment.

Each power input that is used with the controller must e fused separately. Alternatively, a power supply

with integral over-current protection may e used if it is appropriately sized for protecting the

controller/TE device.

The temperature controller is intended to e used with, or incorporated into, other machinery made y TE

Technology, Inc. and must not e put into service until the relevant machinery into which it is to e

incorporated into has een declared in conformity with the essential requirements of the Machinery

Directive 2006/42/EC.

3

For more information regarding protection devices read, TE Technology’s Thermoelectric Cooling Assem ly (TCA)

Instruction manual which is availa le for download from TE Technology's we site at www.tetech.com. The terms

and provisions relating to protection devices as provided in the TCA Instruction manual are here y incorporated y

reference. A copy of the TCA Instruction manual can also e sent via regular mail upon request.

TE Technology, Inc. does not make any warranty, expressed or implied, that the use or operation of the equipment

will e functional or effective if the equipment is not installed and used in accordance with this manual.

TE Technology, Inc. shall not e lia le, and Purchaser shall defend, hold harmless, and indemnify TE Technology,

Inc. from and against, any losses, costs, expenses (including reasona le attorneys’ fees), injuries, lia ilities or

damages of any kind or nature whatsoever, arising out of the use or ina ility to use this TE Technology, Inc.

product, from the omission or failure to use protection devices, or from failure to comply with this manual. This

provision is in addition to any other indemnification provisions which are a part of the Purchase Order or contract

with Purchaser.

Special Notes concerning t e TC-36-25-RS232-UL

The TC-36-25-RS232-UL temperature controller has een tested y MET La oratories, Inc., a licensed nationally

recognized testing la oratory, to UL 60730-1-Part 1-5

th

edition and CAN CSA E60730-1-Part 1-5

th

edition. It has

een evaluated as follows:

Type 1 Action

Electrical Shock Protection Class 0

Class A Controller

(Please note that the TC-36-25-RS232-UL differs slightly in design and manufacture from the standard TC-36-25

RS232. If a controller meeting UL requirements is required, the TC-36-25 RS232 cannot e used a su stitute; only

the TC-36-25-RS232-UL may e used to meet the requirements.)

The TC-36-25-RS232-UL is CE marked. The TC-36-25 RS232 is not CE marked and cannot e used if a CE marked

product is required.

Due to requirements for UL/CSA, the TC-36-25-RS232-UL is sold without a temperature sensor and without any

connecting ca les although UL recognized connectors are provided as a requisite for UL. Temperature sensors

may e ordered separately; however, the temperature sensors that TE Technology offers are not UL recognized.

The controller is intended to e installed for use with an end product. Ingress of contaminants shall e

addressed when installed in the end product.

If the controller is installed in an enclosure, the openings in the enclosure shall e evaluated for access

to hazardous parts.

The controller shall e mounted so that it cannot rotate or e otherwise displaced and cannot e

removed without the aid of a tool.

Mechanical strength of the enclosure shall e evaluated when the controller is installed in an enclosure.

Endurance testing shall e performed as required when the controller is installed in end product.

An adequate protective earthing connection shall e provided to the controller. The protective earthing

connection shall e tested when installed with an end product. See “Safety Ground for TC-36-25-RS232-

UL” diagram on page 35 for further details.

4

Table of Contents

General Safety Warnings .......................................................................................................................................................... 2

License Agreement ................................................................................................................................................................... 5

Features .................................................................................................................................................................................... 8

Setup Instructions................................................................................................................................................................... 13

1.0

Initial Setup ............................................................................................................................................................. 13

2.0

Configuration Setup ................................................................................................................................................ 18

3.0

Tuning Parameter Description ................................................................................................................................ 24

4.0

Cali ration Parameter Description ......................................................................................................................... 26

5.0

Final Setup—Controller Tuning .............................................................................................................................. 27

6.0

Data Acquisition Features ....................................................................................................................................... 31

7.0

Custom Software .................................................................................................................................................... 32

Controller Wiring Diagram: One Power Supply Setup ........................................................................................................... 33

Controller Wiring Diagram: Two Power Supplies Setup ........................................................................................................ 34

Safety Ground for TC-36-25-RS232-UL ................................................................................................................................... 35

Expansion Connector Wiring Diagram .................................................................................................................................... 36

Mechanical Package Drawing ................................................................................................................................................. 37

Block Diagram ......................................................................................................................................................................... 38

RS232 Communications Connections ..................................................................................................................................... 39

Appendix A Trou leshooting Controller ................................................................................................................................. 40

APPENDIX B Trou leshooting Communications Port ............................................................................................................. 42

APPENDIX C Serial Communications....................................................................................................................................... 43

APPENDIX D Thermistors for TC-36-25 RS232 ........................................................................................................................ 56

5

TE TECHNOLOGY, INC. (TE TECH)

License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE OPENING THIS PACKAGE OR SIGNIFYING YOUR ACCEPTANCE BY CLICKING THE APPROPRIATE DIALOG

BOX. OPENING THIS PACKAGE, CLICKING THE APPROPRIATE DIALOG BOX OR USING ANY PART OF THE SOFTWARE SIGNIFIES YOUR ACCEPTANCE OF (1) THESE TERMS AND

CONDITIONS FOR THE LICENSED SOFTWARE, AND (2) THE TERMS OF ACCEPTANCE OF TE TECH FOR ANY PRODUCTS PURCHASED FROM TE TECH. IF YOU DO NOT AGREE WITH

THEM, PROMPTLY RETURN THE PACKAGE UNOPENED AND UNUSED ALONG WITH ANY OTHER ITEM THAT WAS INCLUDED IN THE SAME PRODUCT NUMBER FOR FULL CREDIT.

You, as the Customer, agree as follows:

1. DEFINITIONS

“Application Software” shall mean those portions of the Licensed Software created y TE TECH.

“Designated Hardware” shall mean the one (1) hardware device, purchased from TE TECH, upon which Customer shall run the Licensed Software.

“Licensed Software” shall mean the Application Software plus any other software supplied y TE TECH pursuant to this Agreement.

“Third Party Software” shall mean software owned or licensed y a third party, including ut not limited to operating systems, that is em edded within the Licensed Software

or otherwise included with any product provided to Customer from TE TECH.

2. LICENSE

2.1 Except as provided in section 2.2 elow, you are granted only a personal, non-transfera le, nonexclusive license to use the Licensed Software only on the

Designated Hardware. You may copy the Licensed Software into machine reada le form for ackup purposes or to support your use of the Licensed Software on the

Designated Hardware. No other copies shall e made unless authorized in writing y TE TECH. You may not (i) reverse engineer, decompile, or disassem le the Licensed

Software (except to the extent such foregoing restriction is expressly prohi ited y applica le law); (ii) su -license, lease, or rent the Licensed Software; (iii) distri ute in part,

modify, or create derivatives of the Licensed Software; (iv) amend, modify, or supplement Licensed Software with any additional code except for the purpose of further

configuring the Licensed Software for use with Designated Hardware; or (v) directly or indirectly, export, re-export, download, or ship the Licensed Software in violation of the

laws and regulations of the U.S. The Licensed Software, comprising proprietary trade secret information of TE TECH and/or its Licensor’s, shall e held in confidence y

Customer and protected from disclosure to third parties. No title to the intellectual property is transferred, You must reproduce and include all applica le copyright notices on

any copy. Licensed Software shall not e copied, reproduced, or used for any other purpose outside of operation of the TE TECH hardware, and shall not e used on any other

piece of hardware other than the TE TECH hardware with, or for, which it was provided. Notwithstanding the foregoing, in the event that you download the Licensed Software

from the internet without purchasing Designated Hardware, the Licensed Software may only e used for evaluation purposes and must e deleted (including all copies) within

fifteen (15) days of downloading. You may not use the Licensed Software with any other equipment other than the Designated Hardware without prior written approval from

TE TECH. If no operating system software is included in the software provided under this Agreement, you must make provision for any required operating system software

licenses. At its option, TE TECH may, upon request, provide the source code for the Licensed Software. The limited warranty provided in section 3 elow shall e null and void

immediately upon TE TECH providing the source code, or any portion thereof, to you.

2.2 If you are an authorized TE TECH distri utor or an Original Equipment Manufacturer who incorporates the Licensed Software into your equipment for sale to an

end user, or you use the Licensed Software to create redistri uta les, you may transfer the Licensed Software to an end user provided that the end user agrees to e ound

y the provisions of this Agreement. You shall use your est efforts to enforce your agreement with customers made in accordance with this Section 2.2 and shall promptly

report any violation or suspected violation to TE TECH. In the event that your customer violates any portion of this agreement, you agree to defend, hold harmless and

indemnify TE TECH from any and all such claims. TE TECH may, at its option, ring suit against your customer to enforce the terms of this agreement, TE TECH’s costs and

expenses incurred as a result of such action (including reasona le attorneys’ fees) shall e your responsi ility.

2.3 The Licensed Software may include Third Party Software licensed to TE TECH. Customer here y acknowledges and agrees that any Third Party Software provided

y TE TECH to Customer hereunder (a) shall not e modified and shall e used and/or used and redistri uted or resold (to the extent permitted under Section 2.2) only

em edded within the TE TECH hardware product as provided y TE TECH, ( ) shall always contain and only e redistri uted (to the extent permitted under Section 2.2) with

all proprietary markings present as provided to Customer hereunder and under the same terms and conditions as set forth in this Agreement. All rights and enefits afforded

to TE TECH under this Agreement shall apply equally to the owner of the Third Party Software (the “Third Party”) and its licensors with respect to the Third Party Software. The

Third Party and its licensors are intended third party eneficiaries of this Agreement, and the provisions of this Agreement relating to the Licensed Software, as the same

incorporate the Third Party Software, are made expressly for the enefit of, and are enforcea le y, the Third Party and its licensors. The Third Party and its licensors retain

ownership of all copies of the Third Party Software. Unless a pass-t roug warranty covering t e T ird Party Software is extended directly to you by t e T ird Party, all

T ird Party Software is provided “AS IS” wit out warranty of any kind, and eac T ird Party and its licensors disclaim all warranties, eit er express or implied, including

but not limited to t e implied warranties of merc antability, title, non-infringement or fitness for a particular purpose wit regard to t e T ird Party Software. T e T ird

Party s all not ave any liability for special, indirect, punitive, incidental or consequential damages.

2.4 EXCEPT AS PROVIDED IN SECTION 2.2 ABOVE, IF YOU TRANSFER POSSESSION OF ANY COPY OF THE LICENSED SOFTWARE TO ANOTHER PARTY WITHOUT WRITTEN

CONSENT OF TE TECH, YOUR LICENSE IS AUTOMATICALLY TERMINATED. Any attempt otherwise to su license, assign or transfer any of the right, duties or o ligations

hereunder is void.

2.5 If the Licensed Software or associated documentation is provided to any U.S. Government entity, unit, or agency, the restrictions set forth at section 52.227-19(c)

(“Commercial computer software - restricted rights”) of the Federal Acquisition Regulations (FARs) shall apply. If the Licensed Software or associated documentation is

provided to the U.S. Government, Department of Defense (DOD), or any entity, unit, or agency thereof, the restrictions set forth at section 252.227-7015 (“Technical Data -

Commercial Items”) of the DOD FAR Supplement (DFARS) shall also apply.

2.6 For rights granted in this Agreement, Customer shall pay to TE TECH the then-current product price (license fee) for each copy of the Licensed Software provided

y TE TECH to Customer.

2.7 Customer shall pay all import duties and registration fees and all sales, use and excise taxes (and any other assessments in the nature of taxes however

designated) on the Licensed Software or its license to use the Licensed Software, or resulting from this Agreement, exclusive of taxes ased on TE TECH’s net income.

6

2.8 Customer acknowledges that the Licensed Software, including, without limitation, TE TECH logos, trademarks and all information contained therein, is proprietary

to TE TECH, is valua le, gives a competitive advantage to TE TECH, and could not, without significant expense and difficulty, e o tained or duplicated y others who have not

een a le to acquire the same through means expressly authorized in this agreement. You agree that, unless you first o tain the prior written consent of TE TECH ,or unless

required y law, you shall not communicate or disclose, directly or indirectly, to any person or firm, or use at any time, any of the TE TECH’s proprietary information, except as

provided in this Agreement. The provisions of the section, among certain others, shall survive the termination of this Agreement for whatever reason. The Licensed Software

shall e and remain the exclusive property of TE TECH.

3. WARRANTY

3.1 Only if Customer has purchased Designated Hardware (the purchase price of which automatically includes the license fee), TE TECH warrants that the Application

Software will e in su stantial conformance with the specifications in the manual pertaining thereto as of the date of shipment y TE TECH. If, within ninety (90) days of date

of shipment, it is shown that the Application Software does not meet this warranty, TE TECH will, at its option, either correct the defect or error in the Application Software,

free of charge, or make availa le to Customer satisfactory su stitute software, or, as a last resort, return to Customer all payments made as license fees and terminate the

license with respect to the Application Software affected. TE TECH does not warrant that operation of the Application Software will e uninterrupted or error free or that it

will meet Customer’s needs. All other portions of the Licensed Software are provided “as is” without warranty of any kind.

3.2 TE TECH warrants that the media on which the Application Software is delivered will e free from defects in material or workmanship under normal use and

service for a period of ninety (90) days from the date of delivery. If any defects are discovered in the media is discovered and reported y Customer within ninety (90) days

after delivery TE TECH shall, at no cost to Customer, upon return of same to TE TECH, replace the media and deliver (electronically) to Customer a new and complete copy of

the Licensed Software.

3.3 Any modification to the Licensed Software y the Customer without the express written consent of TE TECH shall void the warranty.

3.4 THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES WITH RESPECT TO THE LICENSED SOFTWARE WHETHER WRITTEN,

ORAL, IMPLIED OR STATUTORY. NO IMPLIED OR STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. NO WARRANTY

ARISING FROM COURSE OF PERFORMANCE, COURSE OF DEALING, OR USAGE OF TRADE SHALL APPLY. NOTWITHSTANDING ANYTHING TO THE CONTRARY HEREIN, UNLESS

CUSTOMER HAS PAID TE TECH A SEPARATE LICENSE FEE THEREFOR, TE TECH MAKES NO WARRANTIES AS TO THE LICENSED SOFTWARE, WHICH IS PROVIDED “AS IS”

WITHOUT WARRANTY OF ANY KIND, WHETHER EXPRESS OR IMPLIED.

4. LIMITATION OF LIABILITY

4.1 IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, BREACH OF WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL TE TECH OR

ITS SUPPLIERS BE LIABLE FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL OR PENAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFIT OR REVENUES, LOSS OF

USE OF THE LICENSED SOFTWARE OR ANY PART THEREOF, OR ANY ASSOCIATED EQUIPMENT, DAMAGE TO ASSOCIATED EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTE

PRODUCTS, FACILITIES, SERVICES OR REPLACEMENT POWER, DOWN TIME COSTS, OR CLAIMS OF CUSTOMER’S CUSTOMERS AND TRANSFEREES FOR SUCH DAMAGES EVEN IF

TE TECH HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

4.2 EXCEPT AS PROVIDED IN SECTION 5, INDEMNITY, IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT OR WARRANTY, TORT (INCLUDING

NEGLIGENCE) OR OTHERWISE, SHALL TE TECH’S LIABILITY TO CUSTOMER FOR ANY LOSS OR DAMAGE ARISING OUT OF, OR RESULTING FROM THIS AGREEMENT, OR FROM ITS

PERFORMANCE OR BREACH, OR FROM THE LICENSED SOFTWARE OR ANY PART THEREOF, OR FROM ANY SERVICE FURNISHED HEREUNDER, EXCEED THE QUOTED CHARGES

FOR THE LICENSED SOFTWARE. ANY SUCH LIABILITY SHALL TERMINATE UPON THE TERMINATION OF THE WARRANTY PERIOD AS SET FORTH IN SECTION 3.

4.3 If TE TECH furnishes Customer with advice or other assistance which concerns Licensed Software or any portion thereof supplied hereunder or any system or

equipment on which any such software may e installed and which is not required pursuant to this Agreement the furnishing of such advice or assistance will not su ject TE

TECH to any lia ility, whether in contract, warranty, tort (including negligence) or otherwise.

4.4 The products (hardware and software) to e licensed or sold hereunder are not intended for use in any application specifically prohi ited in writing y TE TECH,

including, without limitation, in any nuclear, chemical or weapons production facility or activity, or other activity where failure of the products could lead directly to death,

personal injury or severe physical or environmental damage. If so used, TE TECH disclaims all lia ility for any damages arising as a result of the hazardous nature of the

usiness in question, including ut not limited to nuclear, chemical or environmental damage, injury or contamination, and Customer shall indemnify, hold harmless and

defend TE TECH, its officers, directors, employees and agents against all such lia ility, whether ased on contract, warranty, tort (including negligence), or any other legal

theory, regardless of whether TE TECH had knowledge of the possi ility of such damages.

5. INDEMNITY

5.1 Should the Application Software e held y a court to constitute patent or copyright infringement and its use is enjoined, TE TECH shall, at its expense and option,

either procure for Customer the right to continued use, or replace same with a non-infringing product or part, or modify the Application Software so that it ecomes non-

infringing, or remove the software and refund the license charge pertaining thereto (less reasona le depredation for any period of use) and any transportation costs

separately paid y Customer. The foregoing states the entire lia ility of TE TECH for patent and copyright infringement y the Licensed Software or any part thereof.

5.2 The indemnity under the preceding paragraph shall not apply to any use of Application Software in conjunction with any other product in a com ination not

furnished y TE TECH as a part of this transaction. As to any such use in such com ination, or any improper or unauthorized use, installation, or operation of the Application

Software, TE TECH assumes no lia ility whatsoever for patent and copyright infringement and Customer will hold TE TECH harmless against any infringement claims arising

there from (including, ut not limited to, reasona le attorney’s fees).

6. TERM AND TERMINATION

6.1 You may terminate the license granted hereunder at any time y destroying the Licensed Software together with all copies thereof and notifying TE TECH in

writing that all use of the Licensed Software has ceased and that same has een destroyed.

6.2 TE TECH, upon thirty (30) days’ notice, may terminate this Agreement or any license hereunder if Customer fails to perform any o ligation or undertaking to e

performed y it under this Agreement or if Customer attempts to assign this Agreement without the prior written consent of TE TECH. Within twenty (20) days after any such

termination of this Agreement, Customer shall certify in writing to TE TECH that all use of the Licensed Software has ceased, and that same has een returned or destroyed, in

accordance with TE TECH’s instructions.

6.3 Sections 4, 6 and 7 of this Agreement shall survive any expiration or termination and remain in effect. Termination of this Agreement or any license hereunder

shall not relieve Customer of its o ligation to pay any and all outstanding charges hereunder nor entitle Customer to any refund of such charges previously paid.

7

7. IMPORT/EXPORT

7.1 If you intend to import or export (or re-export), directly or indirectly, whether electronically or otherwise, the software products or technical data relating thereto

supplied hereunder or any portion thereof, it is your responsi ility to assure compliance with U.S. and other applica le governmental import and/or export control laws and, if

appropriate, to secure any required licenses or approvals in your own name. You are also responsi le for the accuracy and completeness of any information or certification

you provide for purposes of import or export control compliance.

8. GENERAL

8.1 This Agreement shall e governed y the laws of the State of Michigan, without regard to its conflict of law provisions. You agree that any civil action or claims

which relate to this Agreement or the Licensed Software must e rought and maintained in a court of competent jurisdiction located in Grand Traverse County, Michigan, or,

alternatively, the U.S. District court for the Western District of Michigan. You here y waive venue in any other forum. The provisions of the United Nations Convention on the

International Sale of Goods shall not apply to this Agreement

8.2 Should you have any questions concerning this Agreement, contact TE TECH y writing to: TE TECHNOLOGY, INC., 1590 KEANE DRIVE, TRAVERSE CITY, MI 49686.

8.3 YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT AND AGREE TO BE BOUND BY ITS TERMS AND CONDITIONS. YOU FURTHER

AGREE THAT IT IS THE COMPLETE AND EXCLUSIVE STATEMENT OF THE AGREEMENT BETWEEN US AND SUPERSEDES ANY PROPOSAL OR PRIOR AGREEMENT, ORAL OR

WRITTEN, AND ANY OTHER COMMUNICATIONS BETWEEN US RELATING TO THE SUBJECT MATTER OF THIS AGREEMENT. FURTHER, NO CHANGE OR AMENDMENT TO THIS

AGREEMENT SHALL BE EFFECTIVE UNLESS AGREED TO BY WRITTEN INSTRUMENT SIGNED BY A DULY AUTHORIZED REPRESENTATIVE OF TE TECH.

8

Features

The TC-36-25 RS232 provides i-directional (heating and cooling) temperature control for thermoelectric devices.

Resistive heaters can also e controlled. An H- ridge configuration is used for the power output stage. The output stage

is made from solid-state N-channel MOSFETs (no relays or mechanical components are used). These transistors are

highly efficient and allow for the i-directional flow of current through the thermoelectric coolers. Their high efficiency

reduces the waste heat generated y the controller and allows for a compact design.

This controller is programma le via the RS232 communication port for direct interface with a compati le computer. Field

selecta le parameters or data acquisition in a half duplex mode can e performed. The supplied software is compati le

with Windows 10, Windows 8, Windows 7, and Windows XP. The software provides a graphical user interface for setting

control parameters and receiving feed ack from the temperature sensor. However, the command set is also provided so

that qualified personnel can use the controller as an em edded control, or they can create a custom program interface

using La VIEW, for example. The software can also e used to instruct the TC-36-25 RS232 to save the desired control

parameters to the controller’s non-volatile memory. This allows the controller to e disconnected from the computer and

operated as a stand-alone controller. When operating as a stand-alone controller, the controller can e set to always

control to the stored set point or it can e set up to accept a proportional signal to vary the set point as required.

Mechanically, the controller’s printed circuit oard is mounted to a metal racket that is suita le for either horizontal or

vertical orientation. The controller can operate in am ient temperatures from 0 °C to 60 °C without generally requiring

additional heat sinking. The controller is intended to e used in locations where the controller can e protected y a

secondary enclosure or other means of protection.

9

The MP-2986 Display and Keypad, shown elow, is an optional accessory that can e purchased separately. It provides a

convenient way of showing and adjusting the temperature set point or showing the actual temperature eing sensed

when the TC-36-25 RS232 is operating as a stand-alone controller. See the MP-2986 manual for further information.

10

Main Features

RoHS compliant

Operates as a stand-alone controller or with a computer monitor

Bi-directional, solid-state H- ridge operation for oth heating and cooling

Can e configured to control oth high and low voltage thermoelectric (TE) devices:

Single power supply configuration for TE devices with an input voltage range from (12 to 36) VDC

Dual power supply configuration for TE devices with an input voltage range is less than 12 VDC:

o Controller-circuitry input voltage range from (12 to 36) VDC

o TE device (H-Bridge) input voltage range from (0 to 36) VDC

Maximum 25 A current rating, controls up to 900 W

Soft-start features turns the output on slowly, over a one second period

Over current shutdown that can e set in 2.5 A increments

Open sensor and shorted sensor output shutdown with automatic restart

Low Voltage shutdown protects the H- ridge when the control circuitry voltage is less than 12 VDC

Pulse width modulation of output at 2700 Hz

Computer programma le via RS232 communications port

Control temperature of –20 °C to +100 °C using thermistor supplied with controller

Control temperature of –40 °C to +250 °C using optional thermistors

Proportional (P), Integral (I) and Derivative (D) control that can e selected as P, PI, PD or PID; or Dead and (on/off) with an adjusta le

hysteresis

Temperature resolution of 0.01 °C or 0.01 °F

Control sta ility of ±0.01 °C or ±0.01 °F ( est case, when controlling a cold plate)

Set temperature adjusta le y several options:

Computer set via software/RS-232 communication

Remote potentiometer (customer supplied)

0 mA to 20 mA current loop

0 VDC to 5 VDC adjusta le range

Differential temperature control (allows control to a programma le temperature difference a ove or elow the temperature of the

second thermistor, if used)

MP-2986 Display and Keypad (optional accessory)

No computer programming experience required to use the communications software program

(Supplied software is compati le with Windows 10/8/7/XP)

Command set is provided so programmers can create their own software interface or em edded controller applications

Versatile alarm system:

Computer configura le alarms for 25 mA, with a compliance voltage up to 11 VDC

Alarm cancel: selecta le via computer-software communication or remote contact closure

The second sensor input is configura le as a heat-sink over-temperature shut-down

Non-volatile memory retention of parameters (1,000,000 write cycles maximum; see command #34 in Appendix C for further details.)

Operating temperature range of 0 °C to 60 °C, storage temperature range of -55 °C to +105 °C

11

Pulse-widt modulated power output

The TC-36-25 RS232 requires a constant-voltage power supply to provide power for a thermoelectric (TE) device such as

a TE cooling assem ly or a Peltier (TE) module. The controller regulates the power to the TE device using a method called

pulse-width modulation (PWM). With PWM, the power is rapidly switched “ON” and “OFF” at constant frequency (2700

Hz for this controller). This creates a square-wave “pulse” of power to the thermoelectric device. The “ON” time, or

pulse width, can e varied to create an average output voltage (Vaverage) that is required y the TE device to maintain

the set temperature.

The important advantage to PWM is that it does not cause the extreme temperature excursions that are experienced

with a thermostatic control system. This helps to extend the life and relia ility of the TE devices. Added enefits are

that the controller does not generate a large amount of waste heat and it does not require a large heat sink.

How Pulse

-

w dth Modulat on Works

12

Multiple Control Configurations

Depending on the input voltage required for the TE device, the TC-36-25 RS232 can e used with either one or two

separate power supplies. When using one power supply, an input supply voltage ranging anywhere from (12 to 36) VDC is

required to power oth the controller and the TE device. The output voltage during the “ON” time is approximately equal

to the input voltage.

When using two power supplies, one power supply, ranging anywhere from (12 to 36) VDC, can e used to power the

controller itself; and a second power supply, ranging anywhere from (0 to 36) VDC, can e connected to the H- ridge of

the controller. This second power supply allows the controller to control TE devices that must operate at a voltage less

than 12 V. The self-contained H- ridge output transistors can deliver load currents from (0.1 to 25) A. (NOTE: consult

appropriate installation instructions for power supply and heat sinking requirements for high current operation).

The controller tuning structure allows designation of a variety of control features:

1) The Computer Set Value provides for manual control of the output from 0% to ±100% of load power. This

allows a remote device or computer to designate what output % the controller should deliver.

2) Proportional andwidth (P) in degrees, Integral reset (I) in repeats per minute, and the Derivative rate (D) in

minutes may e configured for P, PI, PD, or PID control.

3) Dead and control (on/off) with an adjusta le hysteresis may also e selected. However, this control mode is

not generally recommended with TE devices.

4) Differential temperature control is provided when two input sensing thermistors are used. The unit will control

the differential etween Input 2 (reference temperature) and Input 1 (actual system temperature).

A control temperature range of –20 °C to +100 °C is standard when using TE Technology’s supplied thermistor sensor

pro e (MP-3193) for the primary sense temperature. Other temperature ranges are availa le with optional thermistors.

The set point of the controller can e changed in a variety of ways y using either a computer, a remote set-temperature

potentiometer, a (0 to 5) VDC signal, a (0 to 20) mA current loop, or the MP-2986 Display and Keypad accessory. A

secondary thermistor can also e used for differential control (or it could e used for alarm condition sensing). All

temperatures may e consistently displayed in °C or °F.

Two types of control output modes may e selected. This determines the direction of the current flow through the

thermoelectric when heating is desired. This current flow may e from Wire Point WP1+ to Wire Point WP2-.

Alternatively, this current flow may e reversed from WP2+ to WP1- as selected in the configuration menu.

Several alarm settings may e selected, some of which provide an output current of 25 mA for alarm signaling. The

settings can e selected for no alarm function, tracking alarm, and fixed-value alarm. Alarm temperature values can e

entered in the setup menu using the supplied software. The computer-controlled selection is availa le for additional

em edded controller input/output options. The alarm setup menu also provides for selection of an alarm latching

condition. The alarm sensor may e either the control temperature sensor or a secondary thermistor sensor.

The various alarms have the a ility to determine the status of the output power to the thermoelectric cooler or auxiliary

heater. The main output power may e maintained during an alarm condition or shut down, depending on the user’s

setting.

13

Setup Instructions

1.0 Initial Setup

Portions of the temperature controller (the aluminum frame near the output transistors, for example) can

exceed 60 °C during normal operating conditions. Temperatures greater than 60 °C can result in a hazard

to the user. Use caution! Protect against accidental contact with hot surfaces.

If the temperature controller is to e used under conditions such that its surface temperatures could

possi ly exceed 60 °C, test the surface temperatures under the worst-case operating conditions of

maximum am ient temperature and highest output current and voltage. If any portion of the

temperature controller exceeds 60 °C place adequate guards around the temperature controller to

prevent contact with any hot surfaces.

NOTE: the maximum allowable ambient temperature for the controller is 60 °C. Furthermore, the

maximum allowable temperature of the controller base underneath the transistor-mounting area) is 90

°C.

1.1 The TC-36-25 RS232 can run as a stand-alone controller, meaning that it can operate without the use of a

computer. However, a computer is required initially to set up various operating parameters.

Make sure the computer is OFF and the controller is UN-POWERED. Connect the RS232 Communications Port

from the controller (JP4) to the RS232 input (Serial Communications Port) on the computer. Pin 1 of JP4 is the

controller’s RX, Pin 2 of JP4 is the controller’s TX, and Pin 3 of JP4 is the controller’s shield.

When using the supplied RS-232 ca le, connect the wires to JP4 as follows (see “RS232 Communications

Connections” for further information):

JP4-1: clear wire

JP4-2: red wire

JP4-3: lack wire

1.2 Attach the thermistor to the temperature-control location.

Generally, attaching the thermistor to the cold side of the TE device provides etter control sta ility than locating

it at the o ject, liquid, or air that is to e cooled/heated. However, in doing so, there will e a temperature

difference etween the TE device and the o ject, liquid, or air that is to e cooled/heated. The temperature set

point can e adjusted to compensate for this temperature difference if necessary.

14

NOTE: When possi le, it is recommended that at least 50 mm of the thermistor’s wire e thermally connected to

the cold side of the TE device. This can e accomplished y placing aluminum tape over the thermistor wires and

adhering the wires and tape to the cold side of the cooler. If this is not done, the thermistor wires will e at a

different temperature than the cold side and they will add or remove heat in the region of the thermistor, making

the temperature reading significantly less accurate and thermal response time slower.

The standard thermistor supplied with the TC-36-25 RS232 is the MP-3193. Appendix D “Thermistor Styles for TC-

36-25 RS232” shows dimensional data on the MP-3193 and other thermistor styles readily availa le as well as the

corresponding temperature-resistance data. If you are using the MP-3193, it is recommended that you use

thermal grease (such as TE Technology TP-1) etween the thermistor and the surface to which it is mounted.

See also section 2.8 for further details on using thermistors with different resistance-temperature curves than the

standard thermistor.

1.3 Connect the thermistor wire leads to terminals JP2-5 and JP2-6. The thermistor is non-polarized, so it does not

matter which particular lead goes to which terminal. (See “Controller Wiring Diagram” for reference. The

thermistor is indicated in the diagram as the ‘primary thermistor’.) You can lengthen the wire leads if necessary.

The gauge of the wire is generally not important since the resistance of the wire is insignificant to the resistance of

the thermistor.

1.4.0 The TC-36-25-RS232 can e used with either one or two separate power supplies, depending primarily on the

nominal operating voltage of the TE device. If the maximum TE device input voltage is less than 12 V, then two

power supplies must e used with the controller. In this case, one power supply is for the TE device, and the other

power supply is for the controller itself (the microprocessor and associated electronics). Of course, just one power

supply can e used for powering oth the controller and the TE device provided that the TE device’s nominal

operating voltage is within (12 to 36) V.

When using one power supply for powering the controller and the TE device together, the power supply

input voltage is passed directly through the controller to the TE device during the "ON" pulse. The user

should choose an input voltage that is required for the TE device and yet is also is also ≥12 V ut ≤ 36 V.

The controller could e damaged if it is operated outside this range.

When using two power supplies, the controller input power supply voltage must e ≥12 V ut ≤36 V and

provide a minimum of 200 mA current. The TE device power supply input voltage can e ≥0 V ut ≤36 V,

ut it should e no greater than the rated input voltage for the TE device.

The TE device current rating should e no more than 25 A at the supplied input voltage regardless of

whether you are using one power supply or using two independent power supplies. NOTE: the

maximum allowable ambient temperature for the controller is 60 °C. The maximum allowable

temperature of the controller base underneath the transistor-mounting area) is 90 °C. The controller

might need additional heat sinking, depending on ambient conditions and how much current is being

drawn by the TE device.

15

The controller does have an internal 25 A fuse to limit current (Littelfuse PN: 0997025.WXN for controllers

made after 1-JAN-2021 or Littelfuse PN 142.6185.5256 for controllers made prior to 1-JAN-2021). This fuse

provides a degree of protection to the controller. If the fuse needs replacing, e sure to compress the fuse

holder tines to ensure the new fuse will have good electrical contact to the fuse holder. In any case, an

external fuse, appropriately sized for protecting the TE device, should e connected etween the

controller and the TE device to prevent damage and to prevent injury to the user should an over-current

condition occur with a TE device rated for less than 25 A. Alternately, a power supply with integral over

current protection can e used if it is appropriately sized for protecting the controller/TE device.

When making a TE device from a single TE module, the maximum operating voltage is usually no more

than 75% of the rated Vmax of the TE module for cooling applications. The 75% rule is ased on the TE

module eing thermally connected to a “good” heat sink; system modeling should e done to verify this

rule is applica le though. If multiple TE modules are used in an electrical series or series-parallel

com ination, the Vmax of the system will e approximately 75% of the rated Vmax of each TE module

multiplied y the num er of modules in series. Applying an input voltage to the controller that is greater

than the Vmax of the system will not necessarily damage the controller (unless voltage and/or current

limits are exceeded), ut the TE module(s) could e damaged y overheating as a result.

Power supply and TE Device wire leads should e kept as short as possi le to minimize electrical losses

and reduce the likelihood of generating unwanted electromagnetic interference. Use wires of a sufficient

gage appropriate to the amount of electrical energy each wire is to carry. Wire insulation and size must

also e appropriate to the am ient temperature and/or temperature of o jects in contact with the wire.

Wire leads supplied y TE Technology are for prototyping purposes and should e reviewed for

appropriateness in the final application.

Use protection devices to prevent hazardous conditions and/or damage to the load (e.g. cooling assem ly,

heater, etcetera) and other related equipment. Protection devices must operate independently of the

temperature controller circuitry. Protection devices should e placed at all points on the load and related

equipment where a hazardous condition can e detected. These protection devices should de-energize

the TC-36-25 RS232, the load, and, as necessary, other related secondary equipment. It is further

recommended that such devices require the user to remove and correct the root cause of a fault efore

allowing the TC-36-25 RS232, the load, and related equipment to e re-energized. Protection devices

should include, ut are not limited to:

Fuses to prevent against electrical overloads,

Over/under temperature thermostats to prevent against hazardous and/or damaging temperatures,

Liquid flow meters to prevent against damage due to loss of coolant flow

The TC-36-25 RS232 controller (in conjunction with the standard and optional sensors) can detect under-

temperature and over-temperature conditions as well as over-current conditions, and it can e configured

to de-energize the load when such conditions are detected. However, hazards and/or risk of loss or

damage to the load (e.g. cooling assem ly, heater, etcetera), and/or secondary equipment could still occur

if the temperature controller and/or sensors were to malfunction. Therefore, independent, redundant

protection devices are recommended in addition to the safeguards provided y the temperature

controller. For the purposes of this manual the temperature controller and sensors are not considered

protection devices.

16

1.4.1 One Power Supply Operation:

Make sure the power supply is NOT energized while making electrical connections to the controller.

Power supply should e of voltage needed for TE device.

If voltage is not etween 12 V to 36 V then a two power supply configuration is necessary.

a) Install jumper across JP6-1 and JP6-2 (default setup)

) Connect the constant DC voltage power supply (12 to 36) V to the controller:

Positive power supply terminal to WP3

Negative power supply terminal to WP4

c) Do NOT connect the TE device to the controller at this time.

d) See the “Controller Wiring Diagram Single Power Supply Setup)” for further details.

1.4.2 Two Power Supplies Operation:

Make sure the power supplies are NOT energized while making electrical connections to the controller.

a) Remove jumper across JP6-1 and JP6-2

) Connect the constant DC voltage controller power supply (12 to 36) VDC, 150 mA minimum to the controller:

Positive power supply terminal to JP6-2

Negative power supply terminal to JP6-3

Note: JP6 is a Molex connector, part num er 22-23-2031

c) Connect the constant DC voltage TE device power supply (0 to 36) VDC to the controller:

Positive power supply terminal to WP3

Negative power supply terminal to WP4

Install a 1.5 k, 1 W (customer-supplied) resistor across the positive and negative power-supply

terminals.

d) Do NOT connect the TE device to the controller at this time.

e) See the “Controller Wiring Diagram Two Power Supplies Setup)” for further details.

1.5 Turn power on to oth the computer and the power supply(s) (which in turn powers up the controller). The on-

oard green LED will flash at a steady rate to indicate that the controller is energized correctly.

Do not mount the controller to a surface which is exposed to a source of heat, such as from electronics,

machinery, or solar radiation.

Do not cover the controller with any o ject or otherwise restrict natural convection airflow around the

controller. Doing so could cause the controller to overheat.

Do not mount the controller to an insulating surface. Doing so could cause the controller to overheat.

Do not operate the controller in such a manner as to cause the surface temperature of the circuit oard or

its frame to reach 70 °C. Otherwise the controller might e damaged and there might e a risk of fire as a

result.

Do not allow the controller to e exposed to water (such as from dripping or leaking water lines or from

water-vapor condensation if the surface temperature of the controller is elow the dew point

temperature).

17

Do not allow metallic dust/shavings to contact the controller electronics.

1.6 Insert the TC-36-25 RS232 software CD into the computer CD drive or download the software from the TE

Technology we site at http://tetech.com. To run the software from the CD, select START, RUN from your Windows

Desktop and then enter D:\TC-36-25 RS232.exe (CD drive letter may vary). This will load the software into your

computer's RAM. Alternatively, (and prefera ly) copy the TC-36-25 RS232.exe file to your hard-disk drive and run

the program from there.

1.7 The Main Menu screen will appear on your computer monitor. All selections are made from this menu screen.

18

1.8 In the PC COMMUNICATIONS section, select the RS232 communications port (COM1 through COM255) to which

the controller is connected y using the SELECT COMM PORT menu key. After making this selection, click on the

INITIALIZE utton.

If you only have USB ports availa le on your computer, you can use our optional RS232 Adapter to provide USB to

RS232 conversion. If you use your own USB to RS232 converter, e aware that some converters might inject noise

on the transmit line from the computer and disrupt communications. The noise pro lem might e alleviated y

installing a 0.001 microfarad, 50 V ceramic capacitor etween JP4-1 and JP4-3.

NOTE: If you receive an error message, please refer to Appendix A “Troubleshooting Communications Port.”

2.0 Configuration Setup

2.1 In the CONFIGURE section of the software, the various selections elow are used to esta lish the custom operating

criteria for the controller.

2.2 SET TEMP TYPE menu key:

a) COMPUTER SET VALUE: temperature set point is determined from software input

) POTENTIOMETER SET, 0 TO 5vdc SET, or 0 TO 20 mA SET: temperature set point is determined y remote input.

Refer to the “Controller Wiring Diagram” and the “Block Diagram” for additional information. If you intend to

use one of these options, you will need to enter the SET TEMP HIGH RANGE and SET TEMP LOW RANGE values.

These values are used to linearly scale the temperature range (or fixed percentage output power) that you are

controlling within to the full range of the external input. The set limit values must e within the temperature

range that the TC-36-25 RS232 is capa le of controlling. For example, suppose you are using a (0 to 5) VDC

external input to control the set point. If you then enter -20 for the SET TEMP LOW RANGE and +100 for the SET

TEMP HIGH RANGE, this will create a linear scale of 5 V per 120 degrees or 0.0417 V/degree. So, to control to

10 °C, for example, you would set the external input voltage to 1.25 V.

19

c) DIFF.SET=INP2+FIXED SET: actual set temperature is the sum of the temperature sensed y the optional,

secondary thermistor input sensor and the temperature entered as the FIXED SET TEMP value. This allows the

controller to maintain a constant temperature difference etween the primary thermistor temperature and the

secondary thermistor.

d) JP3 DISPLAY SET VALUE: the temperature set point is determined y the set point entered with the MP-2986

Display and Keypad accessory. The DISPLAY FUNCTION ENABLE check ox must e checked as well to ena le the

MP-2986. The allowa le set temperature range for the MP-2986 can e set to the limits indicted y the values

entered in the SET TEMP HIGH RANGE and the SET TEMP LOW RANGE oxes. However, to send these values to

the display, the SEND SET RANGE TO DISPLAY utton must e clicked. This utton is located in the lower right-

hand corner of the software. See the MP-2986 manual for further details.

2.3 CONTROL TYPE menu key:

a) DEADBAND CONTROL: selects on/off control mode. However, DEADBAND CONTROL should not e used unless

care is taken to prevent the TE device from eing damaged y excessive thermal cycling.

) PID CONTROL: selects proportional/integral/derivative control mode. When this mode is selected, the

temperature controller compares the actual temperature to the set temperature and automatically adjusts the

output power accordingly.

c) COMPUTER CONTROL: ena les the user to select a constant, fixed-duty-cycle output (a fixed percentage output,

see section 3.2 for further details.) The duty cycle is set y the value entered into the FIXED SET TEMP ox. This

ena les the use of the externally connected computer to adjust the power output manually. There are 511 discrete

output levels in the cooling mode and 511 discrete output levels in the heating mode. These are selected y

entering values from -5.11 to +5.11 in the FIXED SET TEMP ox. Also, see Appendix C, #14, FIXED DESIRED

CONTROL SETTING.

20

2.4 CONTROL MODE menu key:

HEAT WP1+ AND WP2- or HEAT WP2+ AND WP1-. This selection esta lishes the polarity for the heating mode of

the thermoelectric cooler. It allows you to reverse the current flow in the TE device without having to change the

wiring.

NOTE: For TE Technology’s standard products, the TE+ red) wire should be attached to WP2 and the TE- black)

wire should be attached to WP1 as shown in the “Controller Wiring Diagram.” The CONTROL MODE should then be

set to HEAT WP1+ and WP2-. Again though, do NOT connect the TE device at this time.

2.5 ALARM TYPE menu key:

a) NO ALARMS PICKED: no alarm condition will e monitored.

) SET TRACKING ALARMS: allows an alarm to e set with respect to the set temperature. It will move accordingly

with a change of the temperature setting. This option can e used for a high alarm, low alarm, or oth settings.

c) FIXED VALUE ALARMS: permits the setting of a fixed, a solute temperature either a ove or elow the set point

temperature or oth.

d) COMPUTER CONTROLLED ALARM: provides for user activation of the alarm relay via the computer software.

The “Expansion Connector Wiring Diagram” shows how customer-supplied LED’s can e installed to signal

various alarm conditions.

Associated with the ALARM TYPE configuration are the HIGH ALARM SETTING ox, LOW ALARM SETTING ox, and

the ALARM DEADBAND ox. If an alarm type has een selected, enter the desired high and low temperature

values that will trigger an alarm condition. The ALARM DEADBAND option sets the hysteresis of the alarm values

from 0.1 degrees to 100 degrees.

2.6 POWER OUT SHUT DOWN IF ALARM menu key:

a) NO SHUT DOWN IF ALARM: controller will continue to supply power to the TE device regardless of alarm

condition.

) MAIN OUT SHUTDOWN IF ALARM: shuts off power output to the TE device when an alarm condition exists.

This manual suits for next models

1

Table of contents

Other TE Technology Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Sorel

Sorel MTDC Installation and operating instructions

TestEquity

TestEquity F4 user manual

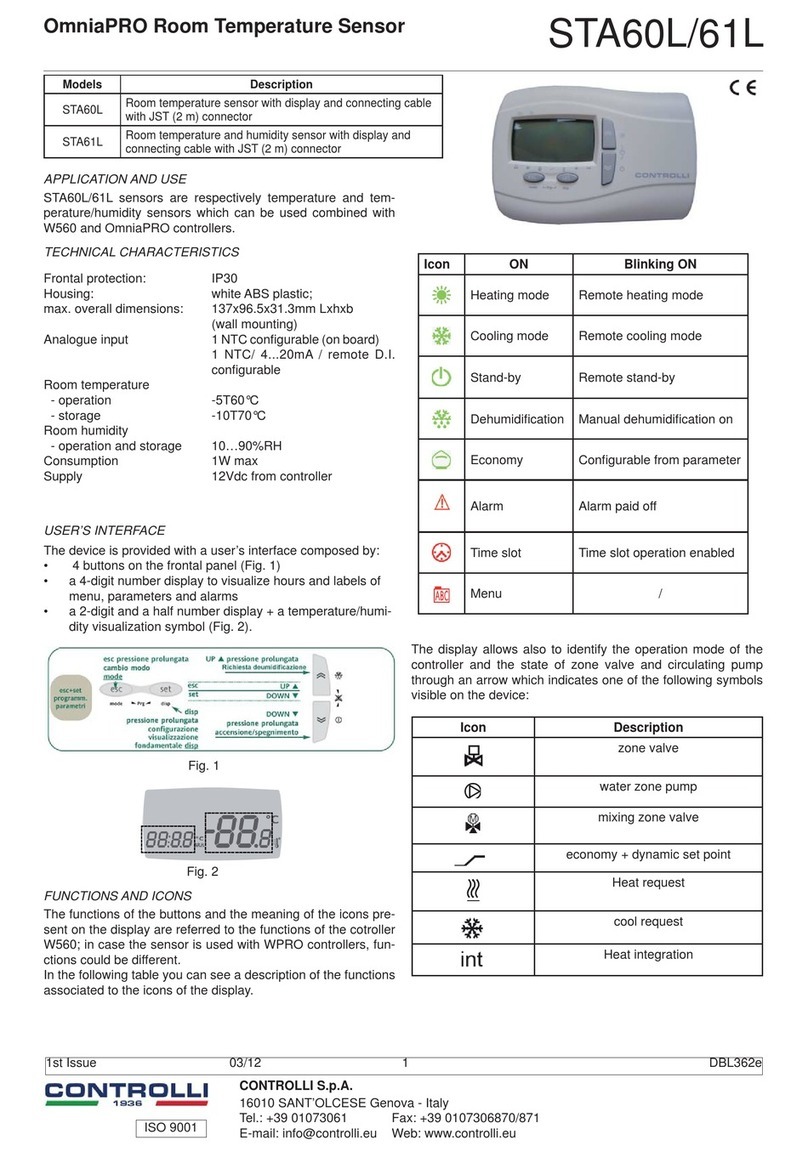

Controlli

Controlli OmniaPRO STA60L quick start guide

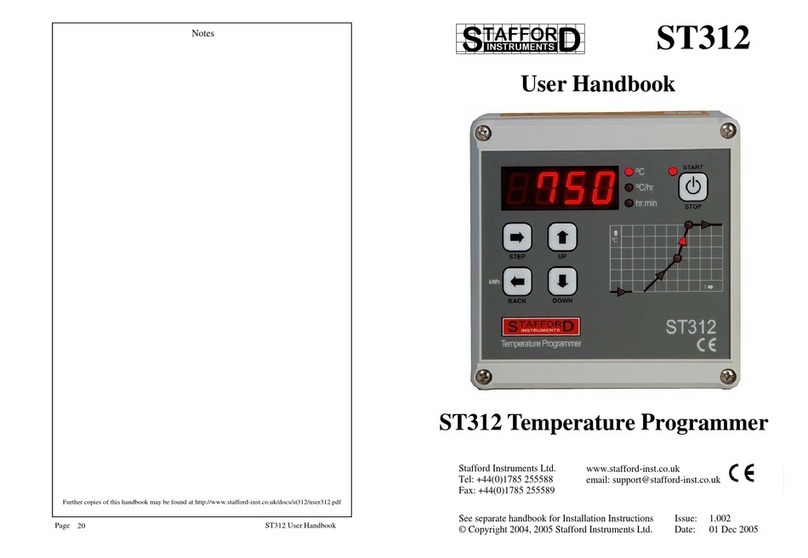

Stafford Instruments

Stafford Instruments ST312 User handbook

Viessmann

Viessmann VITOTROL 100 Operating Instructions for the System User

clare

clare ClareOne quick guide