2Expert-32P rev.11

TABLE OF CONTENTS

Page

PRECAUTIONS ........................................................................... 3

FEATURES ................................................................................. 4

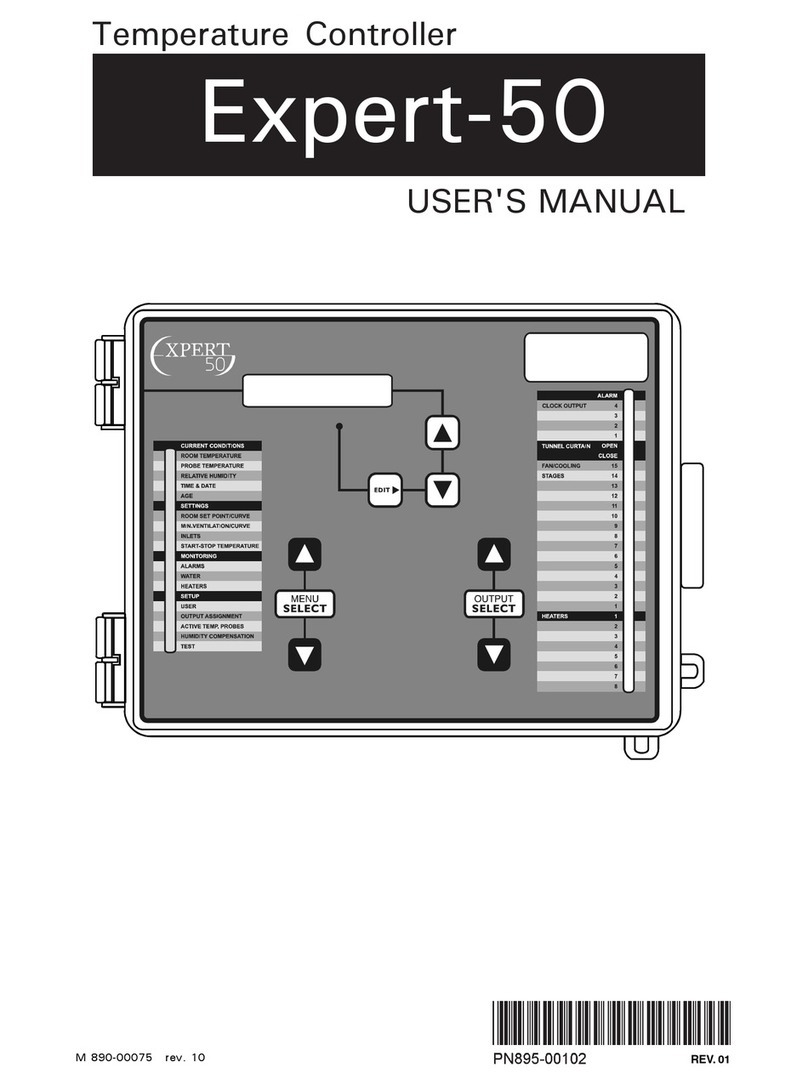

LOCATION OF THE CONTROLS ................................................... 7

INSTALLATION .......................................................................... 9

Mounting Instructions ................................................................ 9

Connections ............................................................................. 9

CONTROLLER SETUP ................................................................ 12

Brooding / Grow Out / Clean Mode Setup .................................... 12

User Setup ............................................................................ 12

Relay Assignments .................................................................. 17

Probe Assignments ................................................................. 20

TEMPERATURE SETTINGS ......................................................... 21

Viewing Temperatures ............................................................. 21

Temperature Set Points ........................................................... 24

Temperature Curve ................................................................. 26

TIME AND DATE ...................................................................... 28

MINIMUM VENTILATION ........................................................... 29

Principle of Operation .............................................................. 29

Minimum Ventilation Curve ....................................................... 31

HUMIDITY CONTROL ................................................................ 33

HEATER SETTINGS ................................................................... 36

FAN SETTINGS ........................................................................ 38

COOLING ................................................................................ 41

TUNNEL VENTILATION .............................................................. 43

Curtain: moving times based on the stages' activation ................... 43

Curtain: based on the static pressure .......................................... 44

VENT DOORS ........................................................................... 51

AIR INLET CONTROL ................................................................. 56

CLOCK OUTPUTS ..................................................................... 57

ALARM SETTINGS.................................................................... 59

MONITORING FUNCTIONS ......................................................... 64

CLEAN MODE .......................................................................... 66

TEST MODE ............................................................................. 68

TECHNICAL SPECIFICATIONS .................................................... 69

FACTORY SETTINGS ................................................................ 70