CHECKING

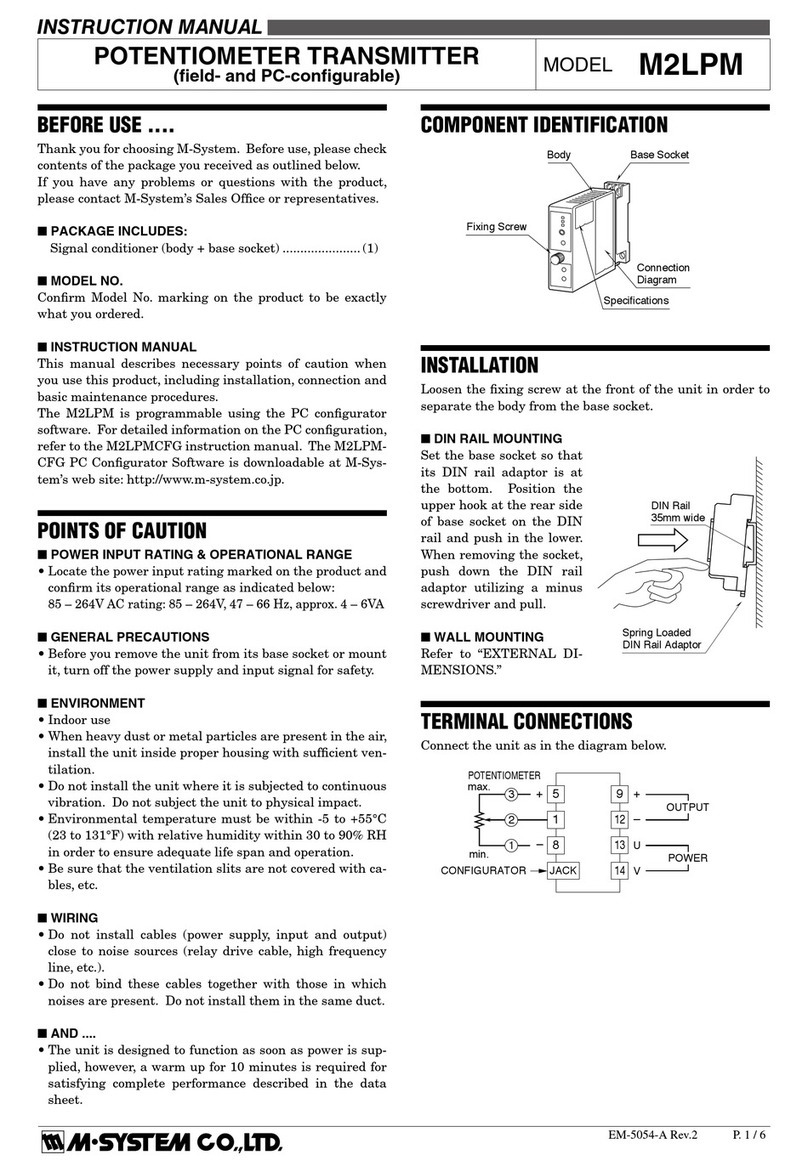

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration, unless you need to match the signal to a receiving

instrument or conduct regular calibration.

Zero and span are adjusted with using the Programming

Unit (model: PU-2x). Also, fine adjustments can be done

with the potentiometers behind the front cover.

Refer to the Operation Manual for Model PU-2x for expla-

nations how to use the programmer.

■WARNING ON USE OF THE PROGRAMMING UNIT

• Be sure to disconnect the Programming Unit before you

turn on/off power supply to the unit.

• The output signal is held when the Programming Unit is

connected. You need to disconnect when confirming cur-

rent output values.

■HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

• Fine Output Calibration

Using the Programming Unit (ITEM 19, 20)

ITEM 19 is for Zero, and ITEM 20 is for Span.

1) Turn the unit into Program mode (ITEM 01).

2) Apply simulated 0% input. Increase/decrease values

(default: 0%) at ITEM 19 until the output signal is cali-

brated to actual 0%.

3) Apply simulated 100% input. Increase/decrease value

(default: 100%) at ITEM 20 until the output signal is cali-

brated to actual 100%.

4) Apply simulated 0% input again and check 0% output.

5) When 0% value is changed, repeat the above procedure

2) – 4).

The 0% value may be shifted when the output span is

greater than the input span (gain >1).

• Fine Output Calibration via the Front Potentiometers

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

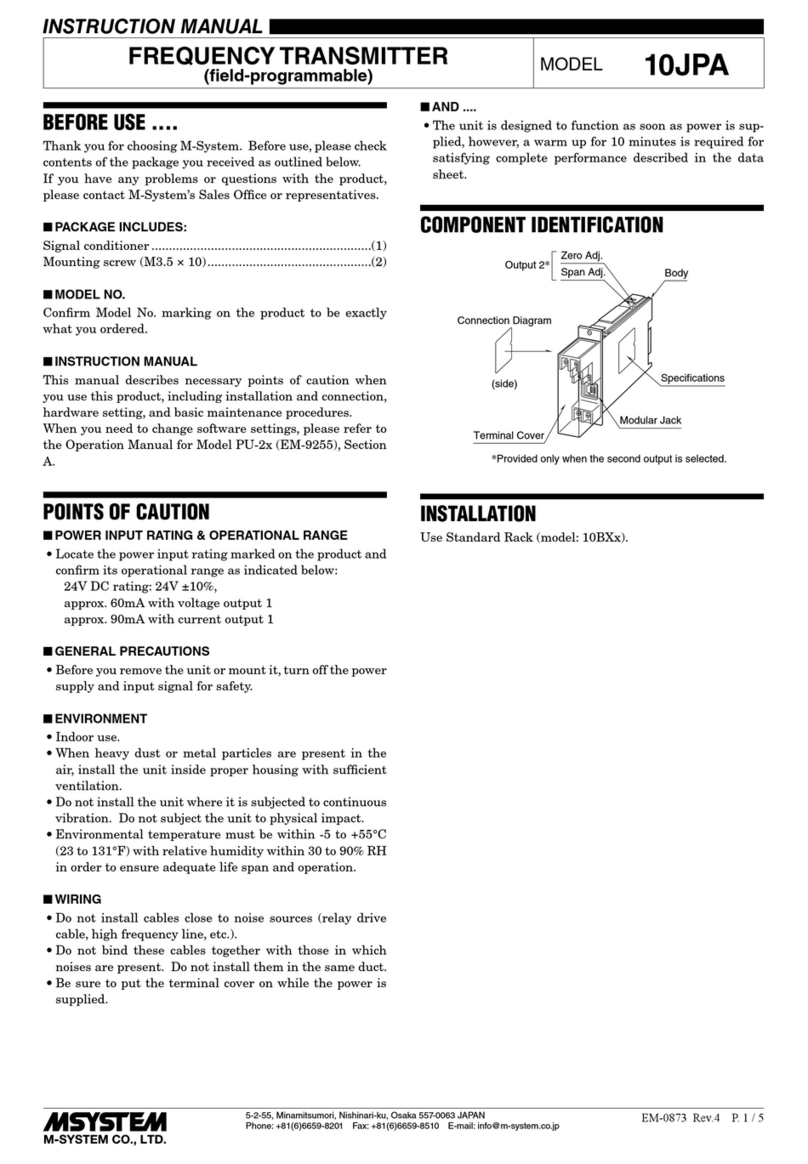

• Using Linearization Table

Please have the PU-2x Operation Manual ready at hand.

Max. 16 calibration points defined by sets of input and out-

put values can be programmed. Use only necessary number

of points, arranged in order from the smallest input value.

X (nn) : Input Signal in %

Y (nn) : Output Signal in %

X or Y : -15.00 to +115.00%

-15% 0

X01

X02 X03 X04 X05 +115%

Y01

Y02

Y03

Y04

+100% Y05

INPUT

OUTPUT

-5%

Figure 1. Linearization Table

[GROUP 01]

ITEM MDFY. DATA EXAMPLE

60

61

P

P

X (01) : XXX.XX

Y (01) : XXX.XX

62

63

P

P

X (02) : XXX.XX

Y (02) : XXX.XX

64

65

P

P

X (03) : XXX.XX

Y (03) : XXX.XX

66

67

P

P

X (04) : XXX.XX

Y (04) : XXX.XX

68

69

P

P

X (05) : XXX.XX

Y (05) : XXX.XX

70

71

P

P

X (06) : XXX.XX

Y (06) : XXX.XX

72

73

P

P

X (07) : XXX.XX

Y (07) : XXX.XX

74

75

P

P

X (08) : XXX.XX

Y (08) : XXX.XX

76

77

P

P

X (09) : XXX.XX

Y (09) : XXX.XX

78

79

P

P

X (10) : XXX.XX

Y (10) : XXX.XX

80

81

P

P

X (11) : XXX.XX

Y (11) : XXX.XX

82

83

P

P

X (12) : XXX.XX

Y (12) : XXX.XX

84

85

P

P

X (13) : XXX.XX

Y (13) : XXX.XX

86

87

P

P

X (14) : XXX.XX

Y (14) : XXX.XX

88

89

P

P

X (15) : XXX.XX

Y (15) : XXX.XX

90

91

P

P

X (16) : XXX.XX

Y (16) : XXX.XX

Modication Code

S: Modifiable at any time.

P: Modifiable only when the MAINTENANCE SWITCH is

in the “PRG” mode.

JFX

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1669 Rev.9 P. 3 / 5