GB

7

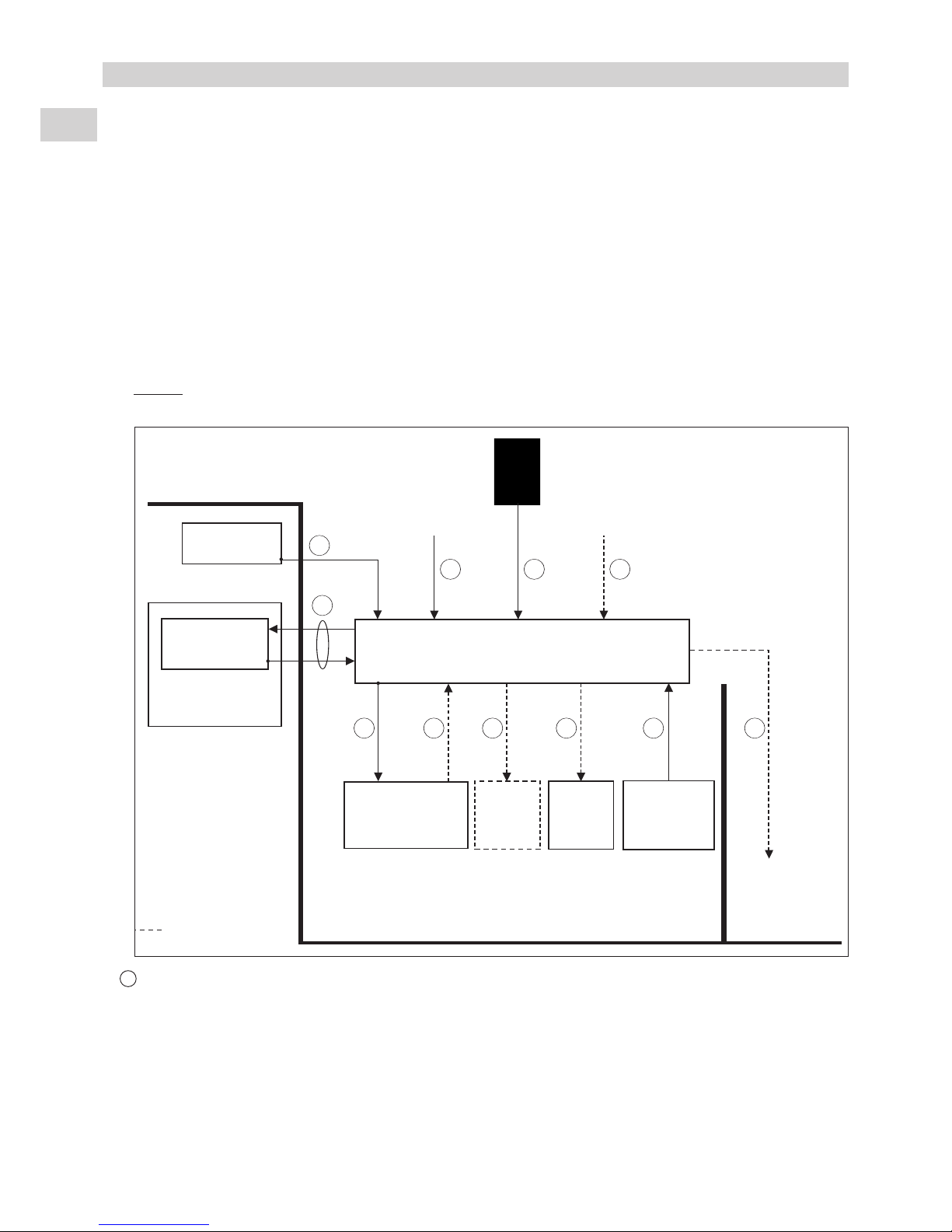

B BUS

-2-conductor cable, min. size 1 mm2.

-Total length of the BUS connection: 40 meters (heating board A1 / control box connection).

-To be connected to the heating board A1.

CControl box power supply

- 230 V, single-phase, 50 Hz + ground (Class I).

-It must be supplied from a protection and disconnect device in compliance with current regulations.

- Cable 3G 1.5 mm2.

- To be connected directly on circuit breaker Q1 of the box (Terminals Uand N).

Note: The control box is supplied by the BUS.

D Outside temperature sensor

-2-conductor cable, min. size 0.5 mm2.

- Maximum length 25 meters.

- To be connected to the heating board A1.

E Generator control

- Shielded cable with 2 twisted pairs (shielding on generator side).

• 1 pair for generator on.

• 1 pair for the generator alarm signal.

- Min. cable size: 0.5 mm2.

- Maximum length 25 meters.

- To be connected to the heating board A1.

F Supplementary boiler authorisation

- Potential-free changeover contact, available on the box's terminal strip (terminals A, B, C).

- 2 A resitive at 230 Vac maximum.

- Actuated contact = boiler authorised.

- This signal is not mandatory if the supplementary valve is connected.

G Boiler alarm unavailable (as required)

- A contact from the boiler can possibly be connected on the heating board A1 for signalling on the control box and closure

of the supplementary valve.

-This contact must be potential-free and of good quality.

-Contact open = alarm.

- A maximum connection length of 25 meters and size 0.5 mm2.

H Boiler supplementary valve control (if any)

- "On/Off" control signal, 230 V / 50 Hz (30 VA maximum) available on the box's terminal strip:

-terminal 2 = common (connected to the Neutral)

-terminal 1 = valve opening control

- terminal 3 = valve closing control

-It is possible to connect either a 3-point valve (3 wires) (available as an accessory), or a spring type return valve (2

wires).

-Minimum cable size 0.75 mm2.

JCirculator (if any)

-It is possible to supply a circulator with 230 V / 1 / 50 Hz directly via the box's terminal strip (Terminals 4 - Neutral / 5 -

Phase / Ground).

-Maximum current 1.6 A(for a superior current strength, the signal must be relayed).

-Cable 3G 1.5 mm2.

- The circulator must have its own thermal protection (not supplied).

L Water temperature sensor (installation return)

- Sensor delivered with a cable measuring 3.5m long.

- This connection may be extended with a 2-conductor cable (minimum 0.5 mm2cross-section) and with a maximum

length of 25 meters.

- To be connected to the heating board A1.

X Pilot wire for electric convectors (if any)

-To send shut-down, "Anti-freeze" (prolonged absence) or "Eco" orders to electric convectors in zone 2. Convector

control (not supplied) must be adapted to receive this type of signal (standard GIFAM 4). Consult the manual of the

electric convectors.

-230 VAC signal from the heating board A1.

- 1.5 mm2single-pole cable adapted for the operating voltage.

-Max. number of convectors controlled by the pilot wire: 20.

-Note: The electrical power supplied to the convectors must be the same as that of the control.

Note: ensure that the ground connections of the various system components are interconnected.