Technics RS-630USD User manual

Other Technics Tape Deck manuals

Technics

Technics SV-DA10 User manual

Technics

Technics RS-1500 User manual

Technics

Technics RS-631 User manual

Technics

Technics RS-MB5MK2 User manual

Technics

Technics RS-1700 User manual

Technics

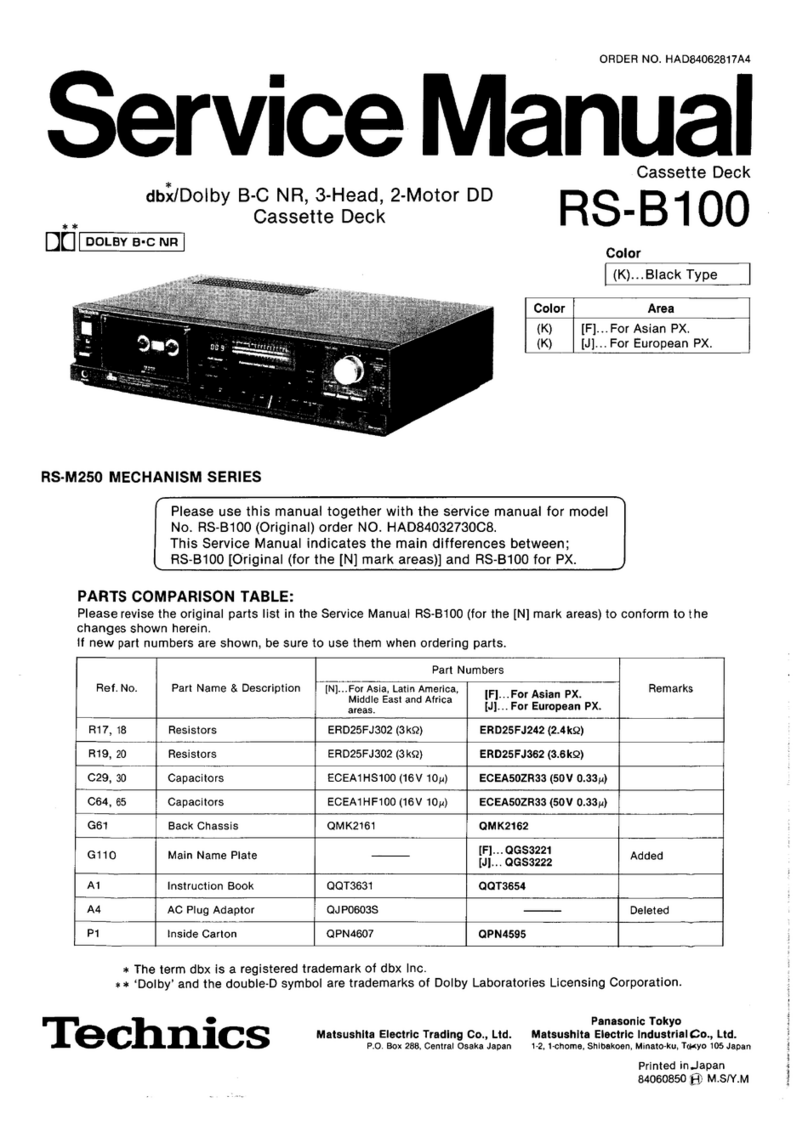

Technics RS-B100 User manual

Technics

Technics RS-M95 User manual

Technics

Technics RS-B11W User manual

Technics

Technics RS-1500US User manual

Technics

Technics RSTR155 - DUAL CASS RECORDER User manual