ZONEBB3Z(AC/HP)01: Quick Reference Guide

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

2

Component Location and Wiring

Considerations

Locating Bryant 3-Zone System

All wiring is connected back to the Bryant 3-Zone System. Select a

location near the furnace or fan coil where wiring from each thermostat,

each damper actuator, and the equipment itself can come together easily.

The Bryant 3-Zone System is approved for indoor use only and should

never be installed with any of its components exposed to the elements. It

may be installed in any area where the temperature remains between 32°

and 158°F, and there is no condensation. The cover must be installed to

prevent damage from other sources. Do not locate where it will be

accessible to children. Remember that wiring access is likely the most

important consideration.

Wiring Considerations

• All wiring in the Bryant 3-Zone system may be unshielded

• Ordinary thermostat wire is ideal

• Use 22 gage or larger for normal wiring

• Lengths over 100 ft should use 20 gage or larger wire

• Each damper actuator required 3 conductors

• The connection to thermostat and equipment (furnace or fan coil)

could require as many as 8 conductors for a multi-state installation

• The Leaving Air Temperature (LAT) and Heat Pump Temperature

(HPT)-(used with heat pumps only) sensors require 2 conductors each

• Cables with excess conductors are acceptable

Step 1 – Mounting the Bryant 3-Zone System

The Bryant 3-Zone System can be mounted in either vertical or

horizontal position near the HVAC system inside the home. It is

designed so that wires can enter it from behind, above, or below. Plan

wire routing before mounting.

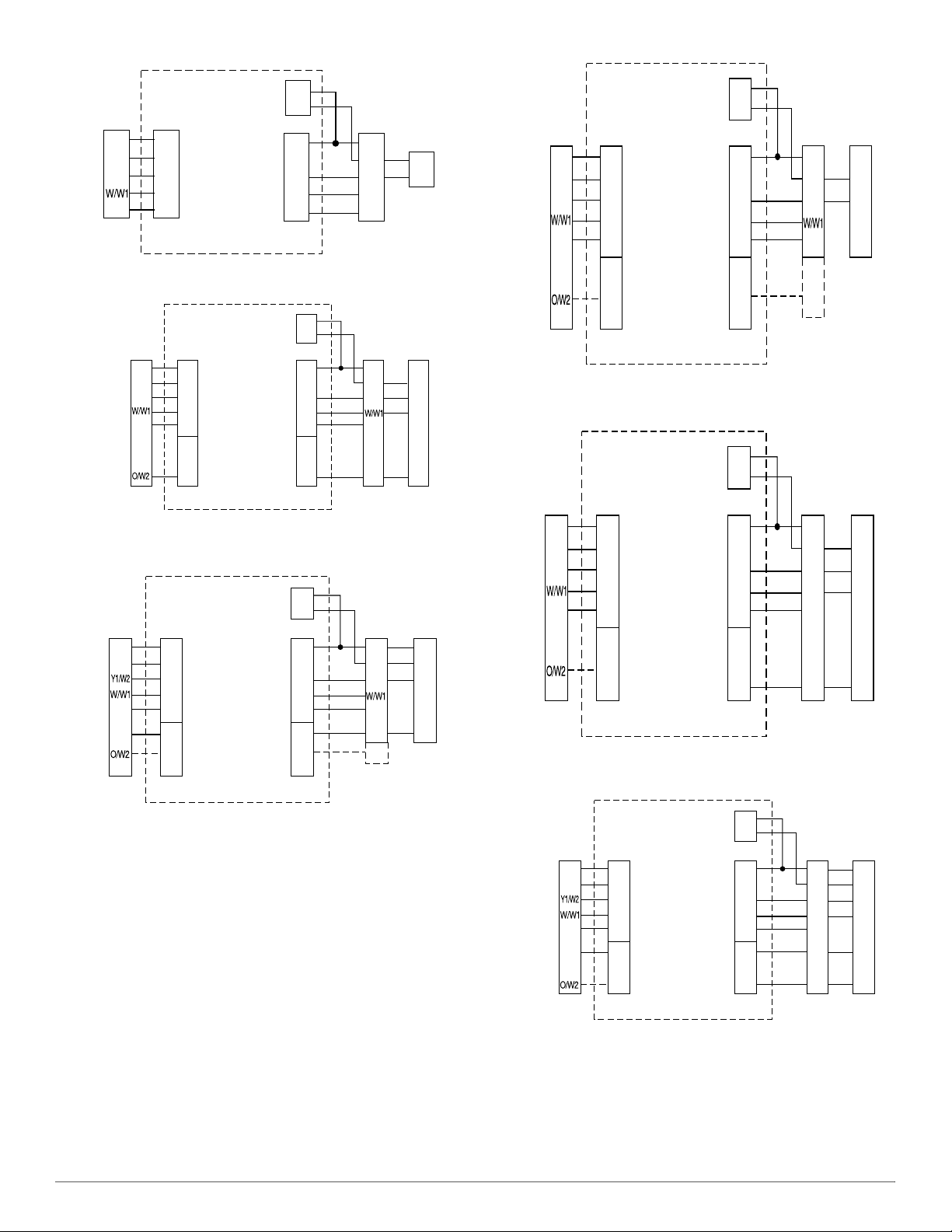

Fig. 2 – Mounting the System

1. Remove the front cover from the base and use the base as a

template to mark drilling locations on the wall, stud , or roof truss.

2. Mount using 4 screws (and wall anchors) provided. (See Fig. 2.)

3. Level for appearance and tighten screws.

Step 2 – Install Thermostats in each desired Zone

Location

1. Install each thermostat according to the manufacturer’s instructions

in their designated Zone location.

2. Connect the thermostats wires to their respective Zone designation

on the right side of the the 3-Zone Panels. (See Fig. 3).

Step 3 – Install Zone Dampers

Each damper has 3 connections: Close (CLS), Open (OPN), and

Common (COM). Find the connection points along the lower left side

of the 3-Zone Control. Suggested colors are CLS = RED; OPN =

GREEN, COM = WHITE. Field label and make the connections at the

dampers and at the 3-Zone Control. Be careful not to cross zone

numbers.

If duct work required multiple dampers for a single zone, up to 5

dampers may be wired in parallel and may be installed in any position.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Turn off unit before routing control wiring or any service operation.

Remember, there may be more than one power supply to unit.

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

To prevent possible damage to Bryant 3-Zone System, do not mount

control on plenum, duct work, or flush against furnace.