Norac UC5 MAX User manual

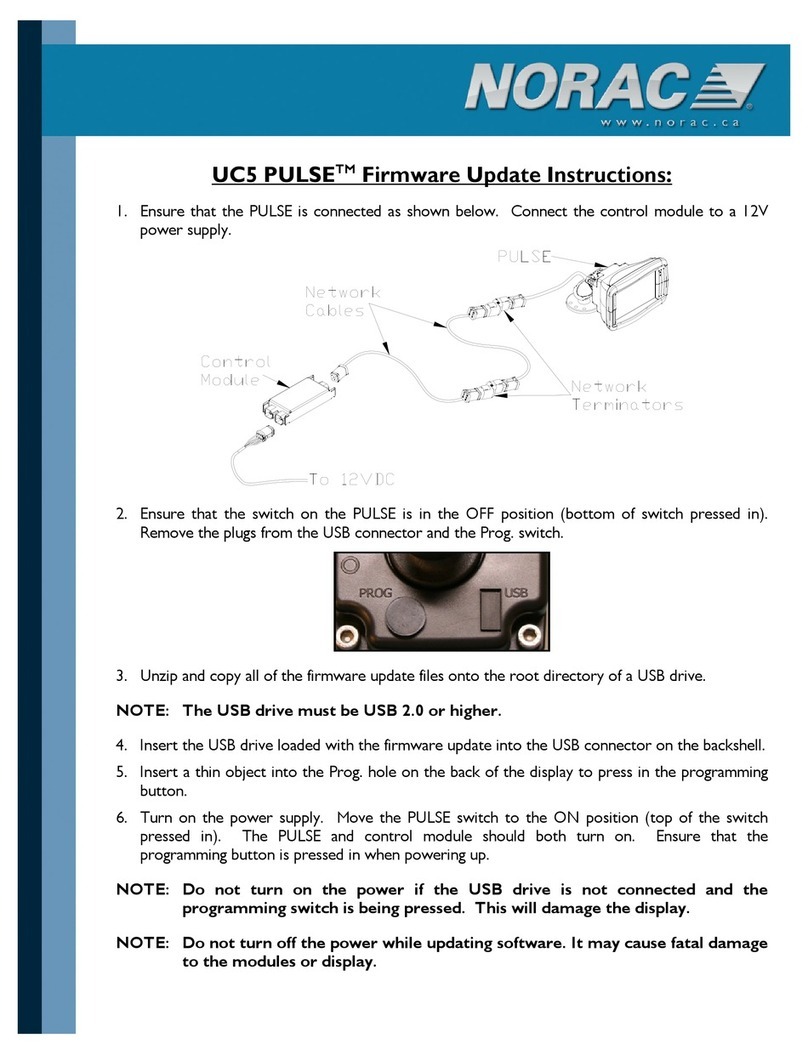

UC5 MAX Ultrasonic Sensor Upgrade

Installation Manual

5468BC-MAX

Printed in Canada

Copyright 2015 by NORAC Systems International Inc.

Reorder P/N: 5468BC-MAX-INST Rev A (UC5 MAX Ultrasonic Sensor Upgrade)

NOTICE: NORAC Systems International Inc. reserves the right to improve products and their specifications without notice and

without the requirement to update products sold previously. Every effort has been made to ensure the accuracy of the information

contained in this manual. The technical information in this manual was reviewed at the time of approval for publication.

Contents

1Introduction................................................................................................................ 1

2Kit Parts ...................................................................................................................... 2

3MAX Ultrasonic Sensor Installation ........................................................................ 3

4Roll Sensor Removal.................................................................................................. 6

5Software Setup........................................................................................................... 7

6Appendix A: Sensor Bracket Installation ................................................................ 8

7Appendix B: Cable Drawings.................................................................................. 12

1

1Introduction

Congratulations on your purchase of the NORAC Spray Height Control System. This system is

manufactured with top quality components and is engineered using the latest technology to

provide operating reliability unmatched for years to come.

When properly used the system can provide protection from sprayer boom damage, improve

sprayer efficiency, and ensure chemicals are applied correctly.

Please take the time to read this manual completely before attempting to install the system. A

thorough understanding of this manual will ensure that you receive the maximum benefit from

the system.

Your input can help make us better! If you find issues or have suggestions regarding the parts

list or the installation procedure, please don’t hesitate to contact us.

Do not use high speed power tools/drills when installing hardware.

The use of dielectric grease is not recommended on any NORAC electrical

connections.

To ensure all stainless steel hardware does not gall or seize apply a light coating of

the supplied Permatex Anti-seize grease to all threaded parts upon installation.

Permatex Anti-seize lubricant is preferred, but other similar anti-seize products

may be used.

Every effort has been made to ensure the accuracy of the information contained in

this manual. All parts supplied are selected to specially fit the sprayer to facilitate

a complete installation. However, NORAC cannot guarantee all parts fit as

intended due to the variations of the sprayer by the manufacturer.

Please read this manual in its entirety before attempting installation.

2

2Kit Parts

2.1 List of Parts

Item Part Number Name Quantity

E07 50100 ULTRASONIC MAX SENSOR 2

M02 5468BC-MAX-INST MANUAL INSTALLATION UC5 MAX ULTRASONIC SENSOR UPGRADE 1

P03 105882 UC5 NETWORK 6 PIN PLUG 2

2.2 Severe Terrain Bracket and Hardware Kits

If the sprayer already has two sets of brackets installed on each boom, one near the end and

one approximately halfway between the outer bracket and the chassis, the severe terrain

option has already been installed. Follow the installation instructions in Section 3.1.

If the sprayer only has one set of brackets near the end of the booms, a bracket kit is needed

to complete the installation. Depending on the type of brackets needed, the following kits are

available from NORAC. Follow the installation instructions in Section 3.2.

Part Number Name Quantity

5464BC-LP UC5 LOW PROFILE BRACKETS AND HARDWARE 1

5464BC-BA UC5 BREAK-AWAY BRACKETS AND HARDWARE 1

5464BC-NT UC5 NITRO BRACKETS AND HARDWARE 1

Figure 1: Low Profile Bracket

Figure 2: Break-Away Bracket Figure 3: Nitro Bracket

3

3MAX Ultrasonic Sensor Installation

3.1 Sensor Installation with an Existing Severe Terrain Option

1. Remove the inner height sensors from the brackets. Keep these sensors as spares.

2. Install the sensors (E07) into the brackets with the lower serial number on the left (Figure

4 and Figure 5). Connect the sensors where the original sensors were disconnected.

Figure 4: Sensor Serial Number Arrangement (Rear Mount Boom)

The E07 sensors will be mounted in the positions shown in black.

Figure 5: Sensor Serial Number Arrangement (Front Mount Boom)

4

3.2 Sensor Installation without an Existing Severe Terrain Option

1. Install the brackets as shown in Section 6.

2. Install the sensors (E07) into the brackets with the lower serial number on the left (Figure

4 and Figure 5).

3. The outer wing sensors will have been installed with either a 2-way coupler with terminator

(NORAC part number 43764T [E20]) or a 3-way coupler and a terminator plug (NORAC

part numbers 43760 and 43764 [E10 & E20]). Determine which type is installed and follow

the appropriate set of instructions.

3.2.1 Installation with 2-Way Coupler with Terminator

1. Remove the 2-way coupler with terminator (E20) from the outer sensor and install it at the

inner sensor.

2. Install the 3-way coupler (E10) at the outer sensor. Plug the existing CANbus cable (C05)

and the sensor cable into the 3-way coupler.

3. Connect the CANbus cable (C06) between the 2-way coupler with terminator (E20) and

the 3-way coupler (E10).

Components shown in black are included in this kit.

Components shown in green are included in the bracket and hardware kit.

Components shown in blue are existing components.

Figure 6: Electrical Installation: 2-Way Coupler with Terminator

5

3.2.2 Installation with 3-Way Coupler and Terminator Plug

1. Remove the terminator plug (E20) from the existing 3-way coupler installed at the outer

sensor.

2. Install the 3-way coupler (E10) at the inner sensor. Plug the terminator plug (E20) and the

sensor cable into the 3-way coupler.

3. Connect the CANbus cable (C06) between the 3-way couplers.

Components shown in black are included in this kit.

Components shown in green are included in the bracket and hardware kit.

Components shown in blue are existing components.

Figure 7: Electrical Installation: 3-Way Coupler and Terminator Plug

6

4Roll Sensor Removal

1. Locate the two NORAC roll sensors (small rectangular box with a cable running from it).

There will be one mounted on the boom frame and one mounted on the intermediate

frame of the sprayer. Some machines will have a third roll sensor mounted on the chassis.

2. Disconnect and remove all roll sensors. Refer to the installation manual for the specific

make/model of sprayer for roll sensor mounting locations. Installation manuals are available

at www.norac.ca.

3. Insert the 6-pin plugs (P03) into the 8-way coupler where the roll sensors were connected.

Figure 8: NORAC Roll Sensor

Figure 9: NORAC 8-Way Coupler

7

5Software Setup

1. Start up your sprayer and test the sprayer’s functionality. The display terminal does not

need to be powered on for the original boom function switches to operate. Unfold the

booms and raise/lower each boom and the main section.

Confirm that the cabling and hoses are agreeable to the entire range of motion.

2. If any functions do not work, review the hydraulic and electrical portions of this manual to

check for proper installation.

3. Turn on the power for the display terminal using the switch on the side.

4. The procedure for the installation of the Spray Height Control system is now complete.

Begin the AUTOMATIC SYSTEM SETUP procedure as described in the UC5 Spray Height

Control Operator’s Manual.

8

6Appendix A: Sensor Bracket Installation

6.1 Ultrasonic Sensor Mounting Guidelines

The following guidelines will ensure optimal sensor performance and prevent sensor

measurement error. These rules should be followed for both the wing sensors and the main

lift (middle) sensor.

1. In its lowest position, the sensor must be 9 inches (23 cm) or more from the ground (A).

2. Ensure that there are no obstructions within a 12-inch diameter circle projected directly

below the center of the sensor (B).

3. The sensor should be approximately vertical at normal operating heights.

4. The bottom of the sensor must be at least 9 inches above the spray nozzles (C).

5. The bottom of the sensor must be at least 9 inches in front of the spray nozzles and boom

structure (D).

Figure 10: Sensor Mounting Guidelines (Left – Low Profile; Right – Break-Away and Nitro)

A problem can arise if a sensor is not mounted correctly. It is possible for the

sensor to read off of the boom instead of the ground. This may only become

apparent once the control system is switched from soil to crop mode.

Also be careful that the sensor bracket does not collide with any other part of the

boom when the boom is folded to transport position. If possible, mount the sensor

brackets while the booms are folded to ensure they will not cause interference.

9

6.2 Wing Sensor Installation

1. The sensor bracket should be oriented forward (ahead of the boom).

2. Mount the sensor brackets onto the boom half way between the tip and center of the

sprayer.

3. Mount the NORAC ultrasonic sensor into the sensor bracket and run the sensor cable

either through hole in the back or through the sensor tube depending on the style of

bracket. Ensure the cable is clear of moving parts and will not be damaged during folding.

6.3 Low Profile Bracket Mounting

1. Minimize the distance between the bolts to prevent bending the bracket and prevent the

bracket from loosening over time.

2. Ensure the bracket is mounted tight against the bottom of the boom, minimizing the

distance between the boom structure and the angled flange.

Figure 11: Low Profile Bracket Mounting Guidelines

Figure 12: Low Profile Bracket Mounting

Front

10

6.4 Break-Away Bracket Assembly and Mounting

1. Assemble the breakaway sensor bracket as illustrated in Figure 13.

Figure 13: Breakaway Bracket Assembly

2. Compress the spring and insert it together with the collar into the base.

3. Slide the tube through the assembled part.

4. Using the bolt and nut, tighten the collar to the tube with the sensor tube centered.

5. Apply a small amount of grease to the rotating surfaces of the bracket.

Figure 14: Breakaway Bracket Mounting

FRONT

11

6.5 Nitro Bracket Assembly and Mounting

1. Assemble the breakaway sensor bracket as illustrated in Figure 15.

Figure 15: Nitro Bracket Assembly

2. Apply a small amount of grease to the rotating surfaces of the bracket.

Figure 16: Nitro Bracket Mounting

FRONT

12

7Appendix B: Cable Drawings

7.1 ITEM C06: 43210-10 - CABLE UC5 NETWORK 18 AWG - 10M

TOPCON Agriculture Canada

3702 Kinnear Place

Saskatoon, SK S7P 0A6

TOPCON Agriculture Americas

W5527 Hwy 106

Fort Atkinson, WI 53538

TOPCON Precision Agriculture Europe

Avenida de la industria,

35, Tres Cantos, España

Spain

Support

Phone: 888 979 9509

Web: www.norac.ca

Table of contents

Other Norac Control System manuals

Norac

Norac UC4 Total Control User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac Case AFS Pro 300 User manual

Norac

Norac UC5 ECHO Display Kit User manual

Norac

Norac UC4 Plus Rogator 64 Series User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual