Adtech ADT-RC400 User manual

ADTECH Robotic Drive System

ADT-RC400

User Manual

(Electrical Wiring)

Information of manual

I

Information of manual

This manual is edited By ADTECH (SHENZHEN) TECHNOLOGY CO., LTD.

The editors of this manual:

The version of this manual:V2.0

Copy Right

All parts of this manual, property right owned by Adtech (Shenzhen) Technology

Co.,LTD (hereinafter referred to as) to all, without permission, no unit or individual is not any

imitation, copying, copying or translation. Position this guide without warranty of any kind,

expressed or implied. As mentioned by this manual or its product information, arising out of,

directly or indirectly, information flow, loss of interest or career ending, and its employees

will not take any responsibility. In addition, the products and information mentioned in this

manual are for reference only, subject to updates without notice.

All rights reserved, do not reproducing.

ADTECH (SHENZHEN) TECHNOLOGY CO., LT

II

Range of manual

This is the first manual of QC400 drive robotic control system including full description,

drive control for the initial users, to help users select reasonable motor type; followed this

specification for drive control electrical wiring between the machine and the robot in detail.

Precautions

※Transport and storage

Product package iteration of no more than six;

It is not available in the product box on the climb, stand or place heavy objects;

Cannot use drag the cables attached to the product or handling products;

No collision, scratching the Panel and display screen;

Product box should avoid wet, dry and the rain.

※Opening inspection

After opening the packaging please confirm whether you purchased the product;

Check whether the products in transit damage;

Control list identifies whether the part is complete, there is no damage;

Product model, lack accessory or transport damage, please contact with me.

※Wiring

To participate in connections and inspection personnel must have the appropriate

skills for professionals;

Products must be reliable earthling, grounding resistance should be less than 4

ohms; you cannot use the neutral (zero line) instead of ground;

Wiring must be properly and firmly, so as not to lead to product failure or

unexpected consequences;

And surge absorption diode must be connected in accordance with the

regulations are connected with, otherwise you will damage;

Plug or open the front of the chassis, you must cut off the power supply.

※Maintenance

Must cut off the power before repair or replacement of components

Should check the fault when a short circuit or overload occurs, troubleshooting

before they can restart

Cannot pass off frequently, if required to re-apply after a power failure,

separated by at least 1 minute

※Others

III

Do not open the Cabinet without permission,

Long when not in use, please cut off the power.

To pay special attention not to let dust, iron powder into the controllers.

Output relay if the use of solid state relays shall be freewheeling diode in

parallel in the relay coil. Check if the power supply meets the requirements, put

an end to the controller is burnt out.

Life of the controller temperature has much to do with the environment, if the

processing temperature is too high, please install the cooling fan. Controller

working ambient temperature range between 0 ℃-60 ℃.

To avoid high temperatures, humidity, dust or corrosive gas environments.

Shake strongly to add buffer rubber rails.

※Maintenance

Under normal conditions of use (environment conditions: average 30 ℃, load

80%, running 12 hours a day), please press the following items for routine

checks and regular checks.

Daily Check

Daily

Recognition of environmental temperature,

humidity, dust and foreign bodies

●There are no abnormal vibrations,

sound

●Ventilation holes without being

clogged with yarn and other

Period Check

1 year

●Substantial part is loose or not

●Terminal block damage

IV

Since the robot system is more complex, dangerous. The manual records and

security-related precautions, please strictly observe transactions as recorded.

Safety Precautions and mark

Mark

Mark meaning

Danger

Use wrongly, it will lead to a dangerous situation,

causing serious injury or death

note

Use wrongly,It will lead to a dangerous situation that

may cause personal injury or damage to equipment

which caused material damage.

Ban

Absolutely unenforceable

!

Forcibly

Must be implemented

Danger

Please do not use this system in the flammable and explosive environment.

Likely to cause injuries or fire.

Please follow the instructions drawings or wiring.

Prone to electrical shock and damage the

motor.

In an energized state, do not arbitrarily pull the plug, in the operating state, do not touch

the robot operation site.

Easy electric shock, causing personal injury.

Energized state, not for wiring, maintenance and other operations, be sure to power at

least 5 minutes before proceeding.

V

Easy electric shock.

Please be sure to take a reliable grounding between the drive and the robot body.

When the fault occurs easily lead to electric

shock, fire incident, easy to trigger errors.

Non professional personnel, please do not open the drive and control one machine shell,

please do not use hand to touch the drive and control of internal components

Easy electric shock

In the case of power, do not touch the power plug of the integrated machine.

Easy electric shock.

Please do not damage, the weight of cable or cable suspended load

Easy electric shock

The energized state, do not plug the drive terminal machine control on

Easy electric shock and short circuit

Running state, do not pull out the terminal on the one machine

Easy electric shock and short circuit

VI

Attention

Please pay attention to the drive and control of the motor and the heat of the peripheral

equipment.

Easy to burn.

When a fault occurs, the power supply is cut off, the cause is identified and removed, and

the low speed running equipment should be removed.

If there are adverse factors, easy to cause

false action.

When using the controller and the robot body, it cannot exceed the scope of its

specification.

Easily cause damage to the product.

When the robot is moved, it needs to be fixed with the attached fixed tool.

To prevent the lifting arm, due to accidents.

The installation, operation, maintenance and inspection before, be sure to read the

instructions carefully, according to the operating instructions in step.

Easy electric shock, fire

Power supply voltage, power capacity must be specified by the company's specifications.

Improper use of equipment failure, easy to

cause a fire.

Please correct use of the correct control of each other to drive one machine and robot.

Prone to failure

VII

Should be regularly on the implementation of the robotics drive system maintenance and

inspection operations.

Neglect of maintenance and inspection is an

important cause of equipment failure and

accidents.

Please do not put heavy objects on the product.

Easily cause damage

Please correct the wiring in the instruction manual.

The wrong wiring way is easy to cause the

robot or the drive control one machine

damage or cause a fire.

When an exception occurs, please stop.

Easy electric shock, personal injury, fire

Need to repair, please contact our company, please do not disassemble.

Easy cause trouble.

Do not impact

Easy cause trouble

VIII

Ban

In the course of the robot's movement, no person is allowed to stand in the robot action

area.

There will be a major injury accident.

Equipment to prevent the movement of the robot in the workplace.

When the device is abnormal, it is easy to

cause damage.

The emergency stop switch on the handheld display device is prohibited.

Robots in an accident or is not running

properly, you need an emergency stop

switch, stop operation of the equipment.

There is no correct operation of the prohibition on the instruction manual.

Incorrect operation will bring about the

incorrect operation of the equipment.

Other personnel outside the operating personnel to close to the equipment

Touching the dangerous area can cause the

injury or the major accident.

When an accident, to cut off the power supply, clear reasons.

When there are bad reasons, the robot may

have a wrong action, causing adverse

consequences.

Users are prohibited to carry out parts of the exchange and transformation.

IX

Will reduce the system performance and

may malfunction

Please do not remove the cleaning.

Easy to cause fire, easy to get electric shock.

Please don't make the product stored in the leaks, water, and other harmful gases in the

environment.

Prone to failure

Forced

!

Please keep the sun out of the sun.

!

Easy cause trouble

Please use the specified range.

!

Easily cause burn, failure

Equipment protection cover must be shut off during operation.

!

Open the protective cover will have electric

shock, the disabled.

Operator to go through the full training.

!

Incorrect operation will cause the device to

malfunction, resulting in disability or major

disaster.

If the robot is not in accordance with the specified direction of action, press the emergency

stop, stop the equipment operation.

!

Accidents and failures.

X

Power cord must be used with the specified wire.

!

Prone to fire and failure.

XI

Safety regulations

Before starting the run, we need to know all the tasks of robot in accordance with the

program to be executed;

Robots run in automatic mode, personnel are not allowed to enter any of its movement

reach areas;

When the need for programming, testing and maintenance work, the robot shall be placed

under manual mode;

When debugging personnel enter the robot work area, he shall carry a teach pendant, to

prevent others from malfunction;

When the robot does not work for a long time, the fixture should not place items; it shall

be empty machine;

After a power outage, the main power on the robot should shut down timely, and remove

the clamp on the work piece.

XII

Catalogue

1. System Introduction and Overview of Functions ................................................................14

1.1 System Components...................................................................................................14

1.2 Robotics Drive System Instructions...........................................................................14

1.3 FlexPendant Introduction...........................................................................................15

1.4 Feature Overview.......................................................................................................16

1.4.1 Technical Parameters .......................................................................................16

1.4.2 Product Configuration......................................................................................18

1.4.3 Basic Specifications.........................................................................................18

2. External Wiring....................................................................................................................18

2.1 System Configuration ................................................................................................18

2.2 Product Description of Each Part...............................................................................21

External Profile of 72Pins Robot Controller.......................................................21

External Profile of 48Pins Robot Controller.......................................................22

3. Power Cord Connect............................................................................................................23

Main Power Supply.............................................................................................23

IO Power Supply.................................................................................................24

4. Motor Wiring Terminals.......................................................................................................25

4.1 Diagrams for Two Kinds of Motor’s Terminal <72Pin>/<48Pin>.............................25

72Pin Heavy Load Connector ................................................................................25

48Pin Heavy Load Connector ................................................................................25

4.2 MOTOR Terminal<72Pin> Signal Description.........................................................26

26-Pins Encoder Definition.................................................................................28

20-Pins Power Definition....................................................................................29

16-Pins IO Line Definition .................................................................................30

IO Wiring Diagram for 72Pin Robot ..................................................................31

4.3 Connection Instances of Motors for 72Pin ................................................................32

4.3.1 Panasonic Motor Wiring Instance....................................................................32

4.3.2 Tamagawa Motor Wiring Instance...................................................................36

XIII

4.3.3 Sanyo Electric Wiring Instance........................................................................39

4.3.4 SANKYO Electric Wiring Instance.................................................................43

4.4 Signals’ Definition for <48Pin> Motor Terminal ......................................................47

Definition of 16Pin Encoder...............................................................................49

Definition of two-channels External Encoders...................................................51

Definition of 19Pin Power..................................................................................52

Definition of 16Pin or 20Pin IO..........................................................................53

IO Wiring Diagram for 48Pin Robot ..................................................................55

4.5 Connection Instances of Motors for 48Pin ................................................................56

5. Digital Input and Output Interfaces .....................................................................................72

5.1 Digital Inputs .............................................................................................................72

5.1.1 Input Interface Definition and Pin Functions...................................................72

5.1.2 Digital Input Schematic Diagram ....................................................................74

5.2 Digital Output Interface.............................................................................................76

5.2.1 Output Interface Definition and Pin Functions................................................76

5.2.2 Schematic Diagram of a Digital Output...........................................................78

6. Communication Port............................................................................................................81

6.1 COM1 Port Wire Drawing.........................................................................................81

6.2 COM2 Port Connection .............................................................................................83

6.3 LAN Port....................................................................................................................84

6.4 USB Interface.............................................................................................................85

6.5 Product Installation Size Chart ..................................................................................85

14

1. System Introduction and Overview of Functions

1.1 System Components

Drive machine control system mainly consists of the following three parts:

1)QC400 drive control system

2)Handheld FlexPendant

3)Connecting Cables

1.2 Robotics Drive System Instructions

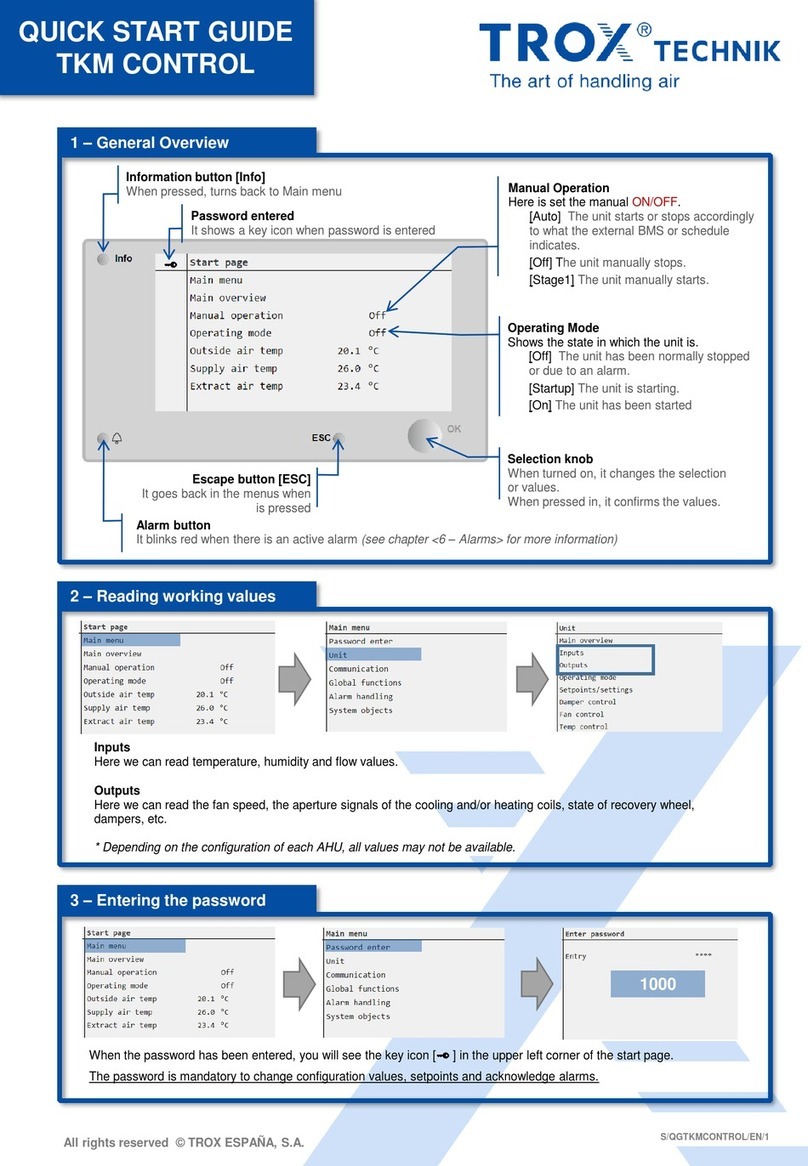

Figure 1-1 shows the schematic side of robotic drive controller(QC400);

The system machine integrated several CPUs (ARM9 + DSP + FPGA), which are

control module, high-performance servo drive module, I/O module, display module,

communication module as a whole;

Interfaces include motor power cable, encoder cable, IO cable, and power cable and

so on.

1. Interface of power , encoder and IO cables;

2. Handheld Flex Pendant connector;

3. External IO board interface;

4. 190~240V Power interface

Figure 1-1 QC400 schematic side

15

1.3 FlexPendant Introduction

Front view of Flexpedant is shown in Figure 1-2:

Figure 1-2 Front view of FlexPendant

Back view of Flexpedant is shown in Figure 1-3:

Three Position

Switch

Figure 1-3 Back view of FlexPendant

16

1.4 Feature Overview

1.4.1 Technical Parameters

Table 1-1 Drive control integrated machine technical parameters

model

ADT-QC400

Handheld

FlexPendant

screen

color display with a resolution of 800 * 600

programming language

G-code

Teach mode

Manual Teach

Size/weight

355mm*248mm*70mm/2KG

Drive

Control

System

QC400

Drive

control

function

control axes

4 axis

support motor

type

supports all-digital AC servo motors (for

example: Sanyo, Panasonic, Tamagawa,

Adtech and other brands)

position

detection

method

detection encoder (incremental / absolute)

power

single-axis power below 1.2KW, four-axis

total power below 3KW

External

input

Standard IO

34 road (with opto-coupler isolation)

External

output

Standard IO

27 Road (6 relays, 21 Road NPN open

collector)

Motion control function

circular interpolation, continuous path, the

trajectory to follow, all kinds of acceleration

and deceleration, etc.

Coordinate system

joint coordinate system, world coordinate

17

system, the tool coordinate system, User

Coordinate System

Cartesian coordinate

display mode

Cartesian coordinate display mode, the joint

coordinate

External communication

RS-232:2CH(9 pin)、 Ethernet:1CH

(100Mbps/10Mbps)USB2.0:2CH

Dimensions / Weight

length (including aviation head) 517mm *

Width 160mm * high 273mm / 20KG

Power

Single-phase within AC200V~230V,50Hz

18

1.4.2 Product Configuration

Table 1-2 Product configurations

Name

Descriptions

Qty

QC400

host controller

1 set

Plug

the host power supply plug

1 pcs

USB

USB download cable

1 pcs(optional)

serial line

9 female-female serial line

1 pcs(optional)

Connecting cable

Cable host and motor, encoder cable

1 pcs

Input connecting cable

Input Wiring 37-pin host input port junction

1 pcs

Input board

I/O input board

1 piece

Output connecting cable

Output Wiring 25pin output port junction a host

1 pcs

output board

I/O output board

1 piece

RPB06

handheld FlexPendant

1 set(optional)

1.4.3 Basic Specifications

Table 1-3 Basic specifications

Climatic conditions

Temperature

Working

-5℃~50℃

Storage and transportation

-30℃~70℃

Relative humidity

Working

20%~90%(℃)

Storage and transportation

10%~95%(℃)

Atmospheric pressure

86Kpa~106Kpa

2. External Wiring

2.1 System Configuration

Before using the drive control integrated machine, you need to complete the system

wiring, wiring distributed as follows:

19

Peripheral Devices

SCARA Robot

FlexPendant

IO Board

QC400 Controller

Figure 2-1 System Configuration

Other manuals for ADT-RC400

1

Table of contents

Other Adtech Control System manuals

Adtech

Adtech 4 Series User manual

Adtech

Adtech ADT-DK300A User manual

Adtech

Adtech CNC9 Series User manual

Adtech

Adtech ZM430A-A01 User manual

Adtech

Adtech 4 Series Mounting instructions

Adtech

Adtech ADT-CNC4220 User manual

Adtech

Adtech Q2BYG806DK User manual

Adtech

Adtech ADT-09 Series User manual

Adtech

Adtech NCT-04 User manual

Adtech

Adtech ADTECH4 CNC Series User manual