Technologies Paving Innovation TC101 User manual

TC101 TEMPERATURE

CONTROLLER

User Manual

Kratbjerg 214 - DK 3480 Fredensborg - Denmark - Phone: +45 48 48 26 33 - Email: sales@tf-technologies.com

www.tf-technologies.com

3

User Manual

TC101 TEMPERAURE

CONTROLLER

www.tf-technologies.com

4

Content and structure

This User Manual for TC101 Temper-

ature Controller covers specic part

numbers

S-50153

and

S-50168

has

been developed to the operator to pro-

vide necessary information to operate

the TC101 Temperature Controller.

The User Manual is a practical guide for

the operation of TC101 Temperature

Controller. This manual has been dived-

ed into colour-coded sections, enabling

the user easily look up the potential

subject of interest.

TC100 Temperature Controller

S-50153 & S-50168

About TC101 Temperature Controller User Manual

Copyright

All information, text and pictures are the

intellectual property of, and copyrighted

material of TF-Technologies A/S. All rights

are reserved. The User Manual may not

be copied, displayed, quoted, published,

sold, modied, or distributed without the

written consent of TF-Technologies A/S.

Disclaimer

TF-Technologies A/S and its distributors

may not be held liable for potential edi-

torial errors, omissions or failure eects.

Suggestions regarding updates or correc-

tion of potential errors are appreciated.

Contact information

TF-Technologies A/S

Kratbjerg 214

3480 Fredensborg

Denmark

T: +45 4848 2633

E: sales@tf-technologies.com

User manual information

Document name: TC101

Temperature

Controller

User Manual

Document number: G702303

Publication date: 29 January 2022

Check for User Manual updates:

www.tf-technologies.com/paving-academy

About this manual

5

TC101 Temperature Controller

The TC101 is a Temperature Controller,

which monitors and maintains a user de-

ned temperature of material contained

in hot-boxes and similar containers. This

feature prevents overheating of the ma-

terial and maintains the optimal tempera-

ture for the contained material.

These part numbers have a built-in ”Re-

start” feature, should the burner ame

be extinguished or not light on with the

initial system start up. Ignition will re-

start on a continuous 3 minute time cycle,

until the burner in question re-lights or

the ”OFF” button is operated.

These part numbers are former versions

of the TC101 Temperature Controller

and do not comply with the 2006/42/EC

Machinery Directive (MD). Please refer to

part numbers S-50121 and S-50122 with

additional safety features and without

automatic re-ignition for MD compliance.

Symbol overview

This user manual uses a range of symbols

and warning notications throughout the

manual to make the operator aware of im-

portant safety measures or information re-

garding operation. The following symbols

are used in this manual:

About this manual

1.

2.

3.

Step-by-step instructions

Indicates a step-by-step instruc-

tion, where a particular order

of actions is required or recom-

mended

6

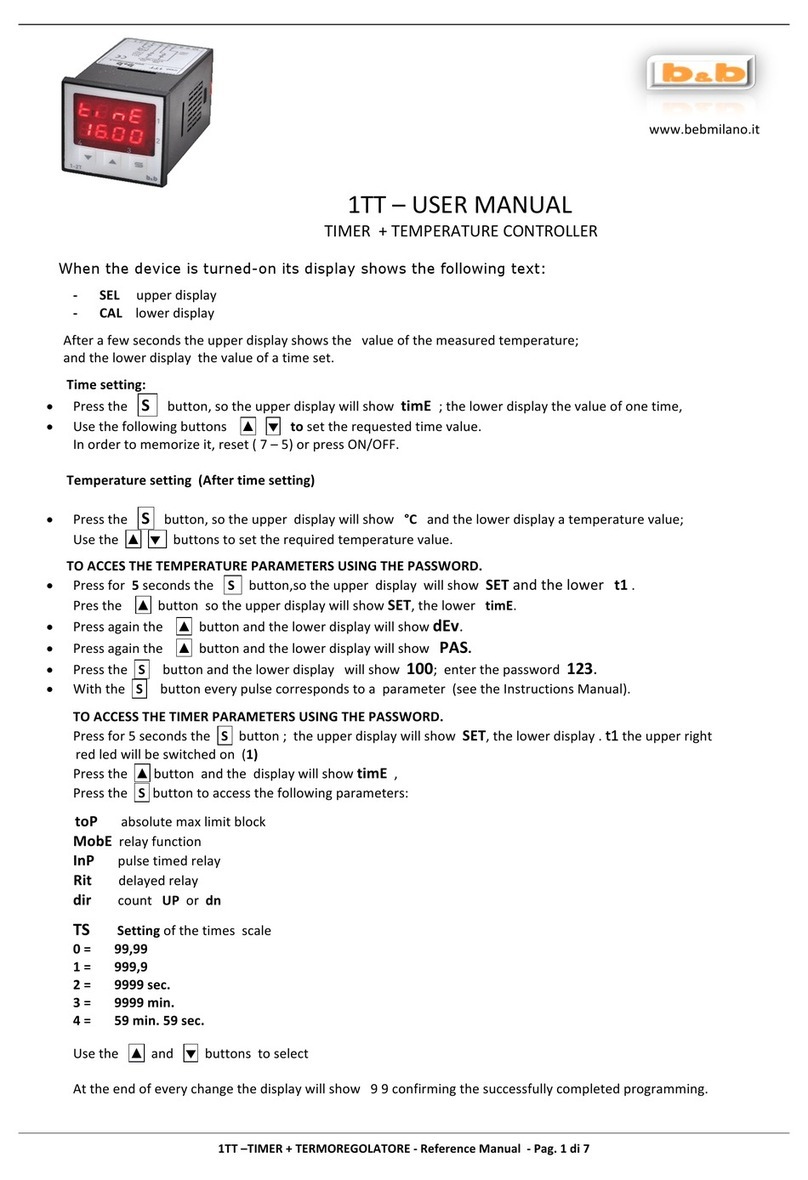

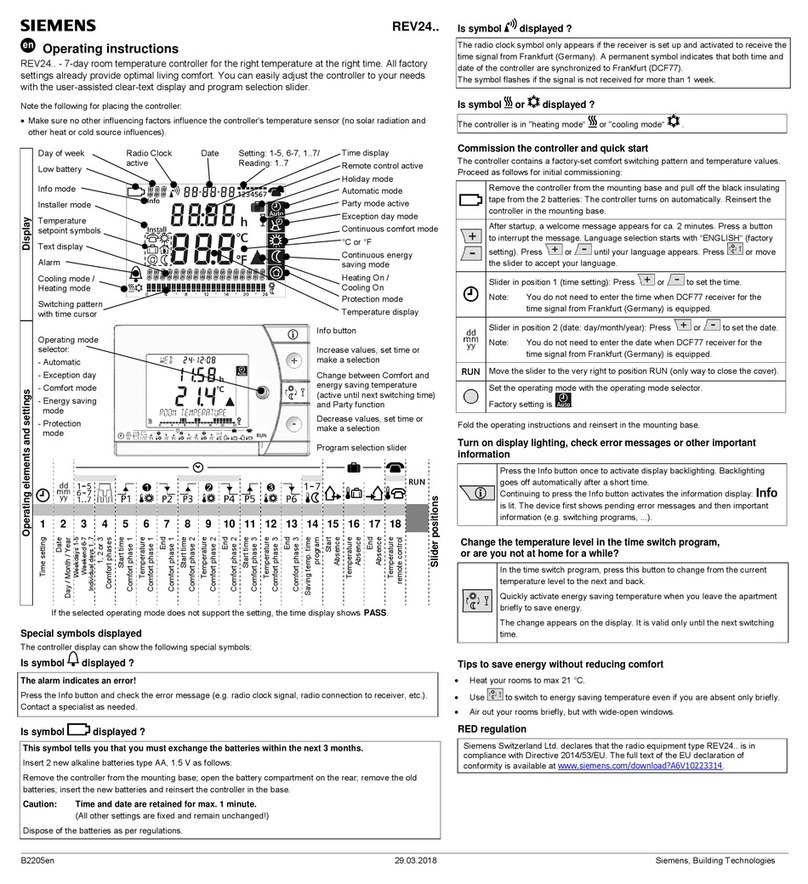

Operation

Operation

• Burner LED

This LED indicates that the “BURNER”

output is driven to ground(/turned on)

• Power switch

The power switch has two positions.

In the middle position (OFF), power is

turned o, and no outputs are active.

In the lower position (ON), power is

on, and outputs are controlled by the

electronics

• TEMP. SET

This switch determines what information

is displayed. When held upwards (TEMP.

SET position), the selected temperature

is displayed and during this mode it is

also possible to select/reselect a material

temperature by turning the TEMP.ADJ.

turning knob

In the middle position, the current mate-

rial temperature is displayed

• Display

This is a 3 digit LED display, which

shows temperature and various error

codes

• Error chart

This is just a printed error chart,

which shows possible error-codes. All

error codes will ash in the display to

attract attention. (See troubleshoot-

ing section for full explanation)

• TEMP.ADJ.

This knob adjusts the selected tem-

perature within a range of either 20°

C - 90° C (S-50153) or 50° C - 175°

C (S-50168). As mentioned it is used

in conjunction with the TEMP. SET

switch (3)

Burner LED

Power Switch

TEMP. SET

Display

Error Chart

TEMP.ADJ

7

Operation

• Mounting screws

All mounting screws are 3 x 8 mm

• Connector

This is the Temperature Controller’s only

international connector. The pin assign-

ment is as follows:

0. Flame error input.

1. Sensor input.

2. Sensor input.

3. Burner output.

4. Not connected

5. + 12 Volts DC.

6. 0 Volts (Ground)

• Metal Shield

This reduces electrical interference.

Display

Error Chart

TEMP.ADJ

Mounting srew hole

Connector

Metal shield

8

1

2

3

1.

2.

3.

Description of operation

When powered up and the control switch

is in the “ON” position, the display will read

8.8.8. for approximately one second, then

1.01 followed by 0.02 (or similar digits).

The current screed temperature will then

be displayed.

The state of the burner output is indicated

by the burner LEDs (1) in the display. When

the preset temperature is reached, the

module (Micro Processor) will deactivate

burner output.

It is possible to view the preset

temperature setting, at any time by

switching the TEMP. SET switch (3)

Temperature adjustment

The system is designed for simple

operation, and only one adjustment is

required, the temperature setpoint setting.

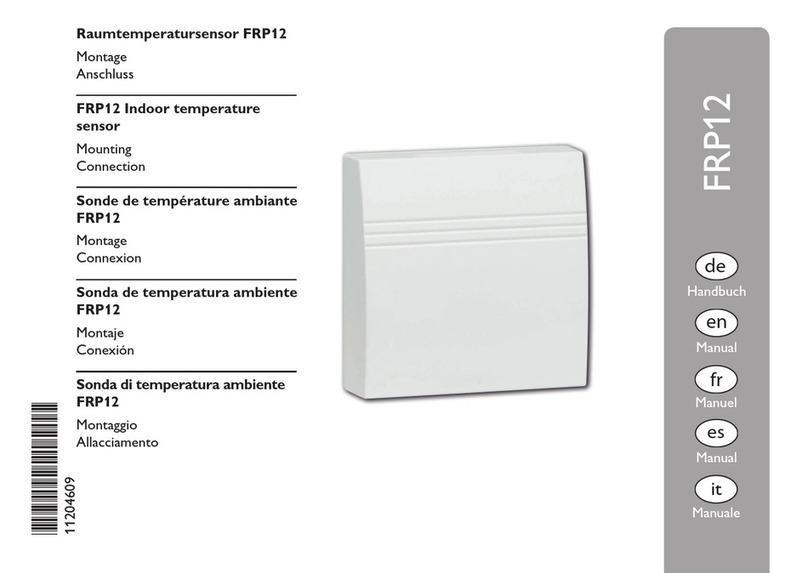

Fig. 3 - TC101 Temperature Controller in a box

The temperature adjust-

ment range is from either

20° C - 90° C (S-50153) or

50° C - 175° C (S-50168).

To adjust the temperature,

ensure power supply is “on”

and operate module control

switch (2) to “ON” position

Hold the TEMP. SET switch

(3) upwards and turn

“TEMP.ADJ.” turning knob to

desired “Cut out” temper-

ature, then release TEMP.

SET switch.

The system will now operate

automatically and burners

will deactivate at the new

preset temperature. Burners

will reactivate when the

temperature has dropped 2°

C below the setpoint.r with

4mm or 5/32 inch screws

Step-by-step instruction for

Temperature preset

(cut out temperature)

Operation

9

Fails startup Damaged

Failes in operation Connection

Erratic display Sensor type

Unstable temperature Sensor connection

Display shows error-code “---“ Low voltage

Display shows error-code “OL“ Sensor

Display shows error-code “SE“ Sensor/cable

Display shows error-code “FE“ Ignition system

Display shows error-code “F99“ Overload

•

Check connector for sucient coltage at the con-

nector. If this is OK, then the module is probably

damaged.

•

Check system wiring and all connectors for correct

connections.

•

Incorrect sensor type used. Replace sensor with

proper PT-100 type.

•

If displayed temperature is higher than actual

temperature, some unwanted resistance is connected

in series with the sensor. This could be the use of

very thin cables or bad connections on the sensor

cable. Recommended cables should be no less than

0.75 mm2

•

Check sensor connectors, if all connections found OK,

replace sensor.

•

This indicates low supply voltage. Check the battery

voltage. This should be above 11 Volts.

•

Low voltage can also be caused by two loads sharing

the same small cable. (High resistance). Generally this

instrument should be directly connected to the battery

to avoid electrical interference and voltage drop.

•

This indicates that the actual temperature is higher

than the adjustment range. That might happen if the

sensor is defective

•

Sensor is defective, short-circuit

•

Sensor is defective, open

•

Sensor cable failure

•

This flame-error code indicates that the Temperature

Controller has received error-input on connector-pin 0.

(Probably because one of the connected ignition-box-

es cannot detect any flame).

•

Check the ignition system

•

This indicates overload of the Temperature Controller’s

burner output.

Trouble-Shooting

Symptom Probable Cause Appropriate Action

Appendix

10

Display is disutbed TC101

Instrument resest, shows “8.8.8“ Electrical interference

Shuts down after 7 sec. Condensation

•

This is probably because the TC101 and one or more

of the gas-valves that it controls share a common

power supply cable. As mentioned earlier the TC101

should have its own large cables directly connected

to the battery

•

This indicates some sort of electrical interference, or

incorrect wiring

•

This is the most common problem experienced with

the system, and in general is caused by condensation

built up on the ”HT” leads, after an overnight machine

shut down. The problem can be rectified by wiping

the ”HT” leads.

If the fault persists check the following:

•

One person needs to turn on the TC101 system, while

another person observes the yellow led indicators on

the FCB24/FCE24 (or similar TF-Technologies) ignition

boxes.

•

The indicators should be on and ”STEADY”, if one or

more of the yellow indicators are flickering it indicates

a possible problem in the area of that specific burner,

check the following:

1.Gas pressure (As per machine manufacturers specifi-

cations)

2. Spark plug gap (Approx. 3-4mm)

3. Spark plug electrode position (Earth electrode must

face flame direction

4. Air to gas ratio

NOTE: Ignition boxes (FCB24/FCE24 or similar) must

be fitted away from heat source.

Symptom Probable Cause Appropriate Action

Appendix

11

Fig. 2 - Overview of MatManagerTM paving quality system mounted on asphalt paver

Appendix

Technical Specication (data sheets)

12

Appendix

13

Table of contents