Tecnocontrol CE100 User manual

EN

IST-1100.CE01.02/B

File: IST-1100 CE01 02-B_CE100-EN.DOC

CENTRAL SYSTEM

CE100

USER INSTRUCTIONS

TECNOCONTROL S.r.l.

Via Miglioli, 47 20090 SEGRATE (MI) - Tel. (+39) 02 26922890 - Fax (+39)02 2133734

http: www.tecnocontrol.it e-mail: [email protected]

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 2/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

IMPORTANT NOTE

The control panel CE100 has three selectable laguages:

Italian, English and French.

If the control panel CE100 is not already set your language, please

see on page 18 “Code Setup (Password)” and on page 20 “Setting

the language”.

Documento / Document name: IST-1100 CE01 02-B_CE100-EN.DOC

Oggetto / Subject : CE100

Rev. Data / Date Da / By Note

1 14/02/2008 UT/BD Revised Text

A 27/07/2009 UT/FG Revised Text and Diagrams

B 28/05/2012 UT/FG Revised Text

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 3/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

CONTENTS

DESCRIPTION............................................................................................................4

CENTRAL SYSTEM MONITORING ...........................................................................5

Alarms Reset.......................................................................................................................................6

Sensor Details Viewing ......................................................................................................................6

Enabling – Disabling Sensors ...........................................................................................................7

CE100 INSTALLATION ..............................................................................................8

ELECTRICAL CONNECTIONS ...........................................................................................................9

CONNECTING THE DETECTORS....................................................................................................10

GAS DETECTORS USE.....................................................................................................................11

COLLEGAMENTO DELLA ELETTROVALVOLA GAS....................................................................12

CENTRAL SYSTEM SETUP.....................................................................................13

Keyboard use and general information’s.......................................................................................13

SENSORS SETUP .............................................................................................................................13

Table 2 - Pre-configured parameters for the Relays.....................................................................15

SENSORS COPY...............................................................................................................................16

SENSORS DELETE...........................................................................................................................16

MODIFYING SENSORS SETUP........................................................................................................16

Sensor modification .........................................................................................................................16

CODE SETUP (PASSWORD)............................................................................................................18

LEVELS OF CODES AND DEFAULT CODES .................................................................................18

CODE EDIT (PASSWORD)................................................................................................................18

Backlight............................................................................................................................................19

ELECTRICAL OPERATIONS “TEST”......................................................................19

Input Test (Detectors).......................................................................................................................19

Output Test (Relays and Led)..........................................................................................................19

SETTING THE LANGUAGE ..............................................................................................................20

APPENDIX................................................................................................................20

LIST OF ANOMALY MESSAGES AND ALARMS............................................................................20

LIST OF ACOUSTIC AND OPTICAL SIGNALS ...............................................................................20

TECHNICAL CHARACTERISTICS...........................................................................21

Technical Characteristics central system Mod. CE100 ................................................................21

Technical Characteristics Expansion CE101 (*).............................................................................21

Technical Characteristics Supply Module AL100..........................................................................21

Technical Characteristics of Lead Battery charger AL101...........................................................21

Technical Characteristics of Lithium Battery charger AL102......................................................21

Technical Characteristics of Lithium Battery BA100....................................................................21

CONFIGURABLE 4÷20 mA DETECTORS TABLES................................................22

Connecting Detectors 4-20mA two-wire products up to December2008....................................22

NOTES:...............................................................................................................................................23

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 4/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

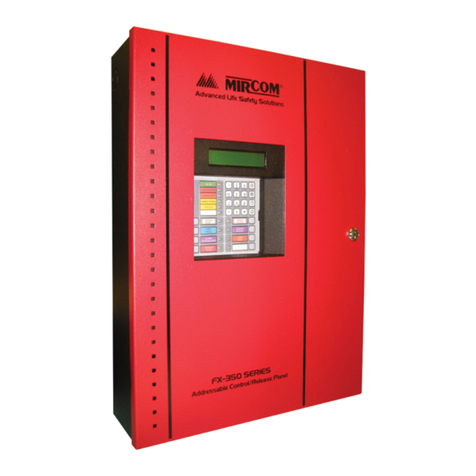

DESCRIPTION

The CE100 gas Central System is realized for DIN rail mounting and it can be connected up to six

4÷20mA remote sensors. It represents a useful instrument for monitoring and controlling areas where

there might be the presence of flammable, toxic gases or oxygen.

CE100 Central Unit: data processing module, with keyboard, backlighted graphic display

122x32 pixel, no.2 4÷20mA sensors inputs and relays outputs.

CE101 Sensors Unit: module with no.2 4÷20mA sensors inputs.(Max n. 2 modules for each

CE100)

AL100 230V/24 Power supply: module (230Vac-50Hz) with 24Vcc/15W output to powered the

CE100 and no.2 CE101.

AL101 Pb Battery Power supply:12Vcc 3Ah or 7Ah Pb Battery power supply module.

AL102 Li-Ion Battery Power supply module to be use with BA100.

BA100 Battery Li-Ion module with lithium battery 10.8Vcc 1,7Ah to maintain the system

powered on in absence of main power supply, to be use with AL102.

1 2 3 4 5 6 7 8 9 10 1112 13

1415 1617 1819 20 21 22 23 24 25

!

Tecnocontro lS rl CE100

ESC

12345678

1011 1213 1415 16 17

9123456

14 15 16 17 18

AL 100

AL101

AL102

BA 100

CE 101

12345678

1011 1213 1415 16 17

9

AL 100

AL101

AL102

BA 100

123456

14 15 16 1718

CE 101

CE100

–

Central

Unit

CE101

n.2Sensors

Imputs

AL100

230V to 24V

Power Supply

AL101

Pb Battery

Power Supply

CE101

n.2 Sensors

Imputs

Possible combinations:

CE100 The Central Unit: can autonomously works if it has an external power supply

12÷24Vdc (at least 15W). It has no.2 4÷20mA sensor inputs (S1-S2) and no.

4 outputs relays, of which no.3 alarm relays (U1-U2-U3) and no.1 Fault relay

(U4).

AL100 + CE100 Central unit powered at 230V: to the central unit add the AL100 power

supply, that connected to the 230Vca, powers the central at 24Vdc.

AL100 + CE100

+ n. 1 CE101 Combination for 4 sensors: to the central unit (that has 2 inputs) add no.1

CE101 module to have other 2 inputs for 4÷20mA sensors (S3 e S4).

AL100 power supply powers both the centrals CE100 and CE101.

AL100 + CE100

+ n. 2 CE101 Combination for 6 sensors: to the central unit (that has 2 inputs) add no.2

CE101 modules to have other 4 inputs for 4-20mA sensors (S3, S4, S5 e S6).

AL100 power supply powers both the centrals CE100 and CE101.

AL100 + CE100 +

one or two CE101

+ AL101

Combination with Lead Battery: to the previous combinations, it is possible

to add the AL101 module to power a lead battery from 12Vdc 3Ah or 7Ah. (Not

included in the supply).

AL100 + CE100 +

one or two CE101

+ AL102 + BA100

Combination with Lithium battery: in alternative to the previous one, it is

possible to use the AL102 power supply and BA100 battery to Lithium-Ion

10.8/1.7Ah (the battery module has to be installed on the left part of the AL102

module).

CE100 central unit can be connected to:

- 4÷20mA transmitters, 3 wires with “Replaceable cartridge sensor”for:

Flammable gases with catalytic sensor: type TS292K (IP65) or TS293K (explosion proof Ex-d) with

range 0÷20%LEL

Flammable gases with Pellistor sensor: type TS292P (IP65) or TS293P (Ex-d) with range

0÷100%LEL.

Toxic gases with electrochemical cell: type TS220E (IP65) or TS293E (Ex-d)

Oxygen with electrochemical cell: type TS220EO and TS293EO (Ex-d) with range 0÷25%O2.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 5/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

-1-

1: 0000 LEL 4: 0004 ppm

2: 0006 ppm 5: 0001 LEL

3: 0000 LEL 6: - - - - - - - -

- NOTE: Obviously also our previous transmitter’s models made from December 2008 until today

can be connected to this equipment, which are 4÷20mA transmitters, 3 wires for flammable gases

type TS292K (IP65) or TS293K (Ex-d) with range 0÷20%LEL, or type TS293P (Ex-d) with range

0÷100%LEL and 4÷20mA transmitters 2 wires with electrochemical sensor for toxic gases and

Oxygen, type TS220E (IP65).(See note and diagram at Page.22)

- WARNING: inputs can be taken on also with other sensors with range in % LEL or ppm that have

a 4÷20mA signal referred to ground and working technical specifications(Range, minimum

operating voltage, current absorbed, etc….) the same of our products.

We disclaim no liability for malfunctions or failures caused by not compatible products.

The CE100 central unit has 3 Alarm relays:

Each sensor has 3 alarm levels associated to the Alarm Relays (PRE1, PRE2 and ALL). Consider that

the three relays are in common with all sensors, but it can be set different alarm values for each

single sensor.

The CE100 central unit has a Fault relay (FAULT)

- In case of Fault the sensors activate the common Fault Relay. (FAULT).

Every output relay can be configurated as follow:

- Delay ON from 0 to 4 minutes at exceeding of the alarm threshold set.

- Delay OFF from 0 to 30 minutes to the return under the threshold level set.

- Time ON from 0 to 30 minutes, this function only works, if you want to stop the alarm output after

a defined time, even if the sensor remains above the alarm threshold set. (The program does not

allow setting it, if it’s already used the “Delay OFF”). For example it can be used to activate devices

that cannot be powered for a long time or to send an impulse to a telephone dialer or any other

device.

- MEMORY The relay stays in “Alarm” even if the sensor returns under its threshold level. (The

program does not allow to set it, if it’s already used the “Time ON”). Make the RESET to reset it to

the normal conditions.

-LOGIC the relay can be set in POSitive logic with normally closed contact (NC) or in NEGative

logic with normally opened contact (NO).

CE100 central unit has an internal BUZZER:

-It emits a “Beep”, when the keys are pressed, moreover, from the Menu “Divers” (Miscellaneous), it

can be chosen to let it active in case of Alarm (ALL)

CE100 central unit has got a function that allow to disabilities sensors:

-Each sensor can be “disabled“without remove or cancel it from the program.

In this case, the sensor value will be visualized with *symbol before the sensor number, but it

cannot activate any relay. This function is useful in case of Faults, anomalies or maintenance and

sensor calibration.

Ce100 central unit is protected from “PASSWORD”

-The menu access is protected through “Code” (4 numbers Passwords). To enter to this function

it’s necessary to digit the Password.

CENTRAL SYSTEM MONITORING

When switching on the CE100, after the message shown

by side, the display will show a 60 seconds count down.

This is for stabilize the sensors and to avoid false alarms.

Then, the CE100 will show the situation of the connected

detectors. The Display shows all detectors (max 6).

(Detectors not programmed are indicated with a

dashed line). Upper on the right is indicated the

enabled code level. (See at page18 chapter

Password).

For each sensor, the display shows the measured value and also its status: FAULT< (<1mA)

PRE1, PRE2, ALL, FAULT> (over 24 mA). (See explaination in the chapter “Sensor details”).

TECNOCONTROL

CE100 SW Rev x.xx

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 6/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

MENU PRINCIPALE

Service9Menus Protected

8

Configuration6Code

(

Password

)

7

Details

2

Divers (Miscellaneus)5Disablin

g

4Enabling9

Reset1

MAIN MENU

Details2 Enablin

g

3

Reset1

Important Note:all detectors inputs are protected against wire breakings (connection between

detectors and Central System) and against short circuits. If a short circuit occurs, to avoid damages to

the central system or to the sensor, the power supply to that input, is automatically stopped (all others

continue to work properly). Simultaneously the yellow LED “FAULT” lights up and the correspondant

relay is activated (if programmed). Only after having solved the short circuit problem (to test if the

channel is no more in short circuit protection you need to mesure if there is voltage between the

terminals “+” and “-“ with a multimeter) it will be possible to restore normal operational conditions.

Alarms Reset

This procedure should be performed to reset the relay

outputs, programmed latched in normal conditions, only

when the alarm situation is finished.

From the normal screen, press key

ESC

to access to

MAIN MENU.Select “1-Reset” then press to

confirm.

(The menu selected is indicated by an arrow and by the

dark background. Keys are used for navigate

into the menus, those indicated semi-hidden can only be

activated with the code).

After the message RESET DONE, display return to the

MAIN MENU. Press

ESC

to view the normal screen.

Sensor Details Viewing

This function allows you to view all parameters of each

sensor.

From the MAIN MENU press to select 2-Details then

press to confirm. All settings details about Sensor

no. 1 will appear.

Using keys and all Details can be seen:

1st line: type of sensor, 2nd line: the name of sensor, 3rd

line: scale settled, 4th line: the sensor status, 5th line:

input current in mA. Then, you can see the values of the

alarm levels (PRE1, PRE2, ALL).

Pressing key you can see details of the other

sensors. (If a sensor is not used, it will appear a dashed line) Press

ESC

to go back to the

MAIN MENU.

NOTE: In the 4th line, after the value, shows the status of the sensor, with this significance:

FAULT < (<1 mA) ................ Sensor fault, disconnected or not powered

NORmal (up to PRE1) ......... Sensor is in its normal operating conditions.

PRE1, PRE2, ALL ............... the sensor has exceeded the set alarm levels, is always

shown the highest alarm.

FAULT> (above 24 mA)....... The sensor is measuring a gas concentration beyond all limits,

or is broken or disconnected.

Reset

Done

Details

Sensor n° 1

TS292KM

0020 LEL

0000 LEL: Normal

I = 04.0 mA

0010 LEL : PRE 1

0015 LEL : PRE 2

0020 LEL : ALL

Sensor n. 1

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 7/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

MAIN MENU

Disabling4Miscellaneus5

Enablin

g

3

MENU PRINCIPALE

Ena

b

lin

g

3

Disablin

g

4

Details

2

Disabling

Sensor n° 1

TS292KM

Disabling

Sensor n° 1

TS292KM

SENSOR DISABLED

WARNING: From the main menu to access the menu 3-Enable, Disable 4-and 5-

Miscellaneous, you must enter the CODE LEVEL 2 (See chapter "Code" on p. 18).

Enabling – Disabling Sensors

Each single sensor can be "Disabled" and then "Enabled"

without having to delete it from the program. The CE100

will continue to display it, with the symbol next the

sensor number, but it will not activate any alarm. This

function is useful in case of faults, malfunctions or

maintenance and calibration of the sensors.

From the normal screen, press

ESC

to access to MAIN

MENU.After having inserted the code level 2, with

select “3-Enbling” or “4-Disablling” then press to

confirm. Then with the same key select the number of

sensor to be Enabling or Disabling.

Pressing the key the following message will appear

Sensor enabled or Sensor disabled.

Press

ESC

to return to MAIN MENU.

SETTING FUNCTION "MISCELLANEOUS"

This function allows you to set some options.

From the MAIN MENU press select “5-Miscellaneus”

press to confirm and then with o select

the desiderate choice (highlighted line). Press to go

to the next line and in the same way you can set the

required value. Press

ESC

to return to MAIN MENU.

BUZZER:If you select YES means that in case of alarm, as

well as the red Led also the internal buzzer will activated.

If you select NO, the buzzer will never switched on.

BATTERY: Select ABSENT if you have not installed any

supply module for the backup battery.

Select AL101 if the CE100 is installed with the Module

AL101 to charge a lead acid battery (12V 7Ah max).

Select AL102, if is installed the AL102 battery charger

module and BA100 Lithium Battery Module (10.8V 1.7Ah).

NOTE: If in the row BATTERY, it was selected the AL101 or

AL102, the CE100 activates automatically, a test of one

minute every 24 hours. If the battery is low voltage or

exhaust, the yellow LED will flash to indicate the fault.

EV STATUS (electro valve) select YES if you installed a

solenoid Tecnocontrol (models from VR480 to VR400)

with the position sensor connected to the "CONTACT

SOLENOID VALVE".

Press

ESC

to return to MAIN MENU.

In case of alarm the CE100 will check if the valve has effectively closed, otherwise the yellow

LED will light on and the fault relay will activate (FAULT). The display will show the symbol

for the failure to close.

NOTE: This control acts only on the 3th alarm level, and then the valve must be

connected to relay ALL.

Miscellaneous

BUZZER : OFF

BATTERY :ABSENT

EV STATUS :NO

Miscellaneous

BUZZER :OFF

BATTERY :AL101

EV STATUS :NO

Miscellaneous

BUZZER :OFF

BATTERY :AL 102

EV STATUS :NO

Miscellaneous

BUZZER :OFF

BATTERY :AL 101

EV STATUS :YES

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 8/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

IMPORTANT REMARK INSTRUCTIONS INCLUDED INTO THE MANUAL BELOW

INCLUDE INSTALLATION AND SYSTEM SETUP PROCEDURES TO BE EXECUTED

ONLY BY QUALIFIED AND AUTHORIZED PEOPLE.

CE100 INSTALLATION

The control panel should be mounted in a suitable enclosure or cabinet to accommodate

modules on a DIN rail. For your convenience, we recommend to install the modules in the

order shown, with the power supplies on the left of CE100 and the expansions on the right.

The space occupied, depends on the configuration of CE100 (see fig. 1).

The full configuration with lithium-ion battery is 17 modules. For example, can be used an 18

modules enclosure, available from most suppliers of electrical equipment (e.g. in Fig. 2).

12345678910111213

!

Tecnocontrol Srl CE100

ESC

1234567

8910

12345

6789 10

AL100

AL101

AL102

BA100

CE101

1234567

AL100

AL101

AL102

BA100

12345

14 15 16 17 18

CE101

141516171819

20 21 2324 2526 2728

8910 11 18

225 mm

120 mm

Fig. 1

22 23 25 26 27 2820 21

4U

2U

2U

3U

3U

3

1

2

Fig.3 - polarized plug-

in terminals

Fi

g

.2

WARNINGS:

A. Do not install the modules CE100 near heat sources such as contactors, power

supplies or other.

B. Terminals (Fig. 3) are polarized plug-in (1); we recommend using appropriate

cable lugs to the conductors (2) and anchor the cables to the structure to avoid

excessive stress to the circuit and the terminals themselves. Use a screwdriver

(3) with a suitable size.

C. The wiring diagrams on the following pages, for simplicity are always shown

with all the sensors.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 9/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

ELECTRICAL CONNECTIONS

MODULE AL100 (AC 230Vca/24Vdc-15W)

230Vac Power supply mains must be connected to terminals “L e N”. (See figure 4).

MODULE AL101 (AC 230Vca charger for Lead 12V Battery)

230Vac Power supply mains must be connected to terminals “L e N”. (See figure 4).

Battery can be used a 12V Lead battery with a capacity for the request autonomy and the

connected total load. With one 3Ah, battery life is about 2 hours (with n. 2 Sensors and Gas

Valve 12V-12W max); while with a 7Ah you have more than 3 hours life (with n. 4 or n. 6

Sensors and a Gas Valve 12V-12W max). The battery must be connected to AL101

terminals "B +" (red) and "B-" (Black) (see figure 4).

Example for calculating the hours of autonomy of an installation with 4 sensors (typically

absorb 2W each) and a 12V solenoid valve that absorbs 12W:

hours4

12W2W)x(4 7Ahx12

veelectrovaltheofWno.2Wxdetectorsgasconnectedofno. BatterytheofAhno.x12

Connecting to the CE100 the power supply should be connected to the CE100 with 3-wire

on terminals "INT, + and -" as shown in figure 4.

+ -

A

L100

12/24V

V+

V-

INT

+ - S1

+ - S2

-+ S3

+ -S5

S6

S4

A

L101

AL102 SENSOR

1 SENSOR

2 CE101 n.1

SENSOR 3-4 CE101n.2

SENSOR 5-6

Fig 4– Connection Diagram with Power Supply Module AL101

GND IN

T

GND

CENTRAL UNIT

CE100

C N

A

PRE1 C N

A

PRE2 C N

A

A

LL C N

A

FAULT

RE

L

A

YSOUTPUTS

MODULE

AL101

Pb12VBattery

Charger

L

230V

B+B- INT +

-

+

-

BATT CE100

V

ALV.

N

MODULE

AL100

230VPower

suppy

+ -

CE100

L

230V

N

+ -

CE100

B+

B-

INT

V-

BATT E+

E-

CE100

V+

VALV

24Vdc

12Vdc

If you haveinstalled the

A

L101, connect it to a

Pb

battery

12Vd

c

/

7Ah

max

230Vac

230Vac

CNA

PRE1 C N

A

PRE2 C NA

ALL C N

A

FAULT

REL

A

YSOUTPUTS

Relay PRE1

–

1st

A

larm level

Relay PRE2

–

2nd

A

larm Level

Rela

y

ALL

–

3rd

A

larm Level

Rela

y

FAULT -Fault

CENTRAL UNIT CE100

Inputs: Please see the chapter on the next page “Connecting the detectors“.

Outputs: all 4 relays have only one voltage-free changeover contact. The contact rate

(resistive) is 3A at 250Vac. All output relays contacts are indicated with "C" (common), "NO"

(normally open). This designation refers to the relay in position without power, or programmed

in negative logic. During the programming can be chosen if every single alarm relay must be

in "Negative logic" (the contact will be NO) or "Positive logic" (the contact will be NC). (See

fig. 5, fig. 7 and the NOTE on page 12).

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 10/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

MODULE AL102 (AC 230Vca charger for Li-Ion BA100 Battery)

230Vac Power supply mains must be connected to terminals “L e N”. (See figure 5).

Battery the BA100 module, which contains the lithium battery, has a cable that should be

connected to the corresponding socket.

Connecting to the CE100 the power supply should be connected to the CE100 with 3-wire

on terminals "INT, + and -" as shown in Figure 5.

+ -

A

L100

12/24V

V+

V-

INT

+ - S1

+ - S2

-+S3

+ - S5

S6

S4

A

L101

AL102 SENSOR

1 SENSOR

2 CE101 n.1

SENSOR 3-4 CE101n.2

SENSOR5-6

Fig 5– Connection diagram as in Fig.4, but with Modules AL102 and BA100

GND INT

GND

CENTRAL UNIT

CE100

C N

A

PRE1 C N

A

PRE2 C N

A

A

LL C N

A

FAULT

REL

A

YSOUTPUTS

MODULE

AL100

230Vac Power

Supply

+ -

CE100

L

230V

N

+ -

CE100

24Vdc

12Vdc

MODULE

BA100

LithiumBattery

Connect the polarizedconnector, of the BA100 module,to the

A

L102 socket.

230V

a

c230Vac

C N

A

PRE1 C N

A

PRE2 CNA

A

LL C N

A

FAULT

REL

A

YSOUTPUTS

Rela

y

PRE1

–

1

s

t

A

larm level

Rela

y

PRE2

–

2nd

A

larm level

Relay ALL

–

3rd

A

larm level

RelayFAULT -Fault

MODULE

AL102

BatteryCharger

forBA100

L

230 V

N

INT + - E

+

E-

BATT CE100

V

ALV .

B-

B+

INT V-

BATT E+

E-

CE100

V+

VALV

B-

B+

CONNECTING THE DETECTORS

CENTRAL UNIT CE100 can be connected up two detectors with 4 to 20mA output (S1 and

S2). To have other four (from S3 to S6), you need to install the Expansion Modules CE101.

CE101 MODULE (Expansion of two inputs for detectors 4 to 20mA)

Inputs by installing a CE101 module can be connected two sensors (S3 and S4). Installing

a second CE101 module can be connected other two sensors (S5 and S6).

Connecting with CE100 the first module CE101 should be connected with 4 wires, to

CE100 terminals “+, –, S3 e S4“, as shown in figure 6. If you installed the second module

CE101, is should be connected to the CE100 terminals "+, -, S5 and S6".

Connection with 3-wires 4÷20mA gas detectors

- Detectors for flammable gases with “Replaceable Cartridge Sensor”: with Catalytic sensor:

TS292K (IP65) or TS293K (Explosion-proof Ex-d) series with 0÷20%LEL range and with

Pellistor sensor: TS292P (IP65) or TS293P (Ex-d) series with 0÷100%LEL range.

- Detectors with “Replaceable Cartridge Sensor” using electrochemical cells: for toxic gases

TS220E (IP65) or TS293E (Ex-d) series and for oxygen TS220EO e TS293EO (Ex-d)

series with 0÷25%O2range.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 11/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

The connection with 4 to 20mA three wires detectors should be performed (fig. 6) between

detector’s terminals "+", "-" and "S" and the corresponding input terminals of the CE100 and

CE101 modules.

The section of the connecting cables

between the panel and the sensors

must be adequate to the distance and

the type of sensor used, as shown in

Table.

We recommend the use of shielded cables, the screen (shield) must be connected only by

the central side and a single point of "GROUND".

+ - S +

SENSOR

A (S5)

-S

SENSOR

B (S6)

S5

+

- S

S6

+

-

S

S3

+

- S

S4

+

- S

+ - S +

SENSOR

A(S3)

- S

SENSOR

B (S4)

+ -

AL100

12/24V V+ V- INT

+ - S1

+- S2

-+ S3

+ - S5

S6

S4

AL101

AL102 SENSOR

1 SENSOR

2 CE101n.1

SENSOR 3-4 CE101 n.2

SENSOR 5-6 CE100 SENSOR

+ - SA

SB

Fig 6 – Connetction diagram with

three wires 4÷20mA detectors

S

3

+ - SA

SB

CE100 SENSOR

+

- S

S1 +

- S

S2

+

GND

S4

S5

+

GND

S6

CE100

CENTRAL UNIT

C NA

PRE1 CNA

PRE2 CNA

A

LL CNA

FAULT

USCITE RELÉ

1st

CE101

INPUTS

DETECTORS

from S3to S4

2nd

CE101

INPUTS

DETECTORS

from S5 to S6

4÷20m

A

INPUTS

+ - S

+

SE N S OR

-S

SENSOR

+ - S

+

SENSOR

-S

SE N SOR

+

-S

A

SB + - S

A

SB

GAS DETECTORS USE

WARNING Always refer to specific instructions attached to them. Please note that all

documentation attached to the products "Central Unit and Gas Detectors" must be

read and kept.

Distance Cable

from 0 up to 300 meters 3x1.5 mm2 shielded

From 300 up to 600 meters 3X2.5 mm2shielded

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 12/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

COLLEGAMENTO DELLA ELETTROVALVOLA GAS

The Manual Resetting NO or NC Solenoid Gas Valve or if required, the Automatic too with

230Vac supply, must be connected as shown in fig.7. If the valve has a 12V coil, please use

the note at the bottom of this page and the figure 8, without consider the “Solenoid Valve with

Position Sensor" not present in the "Normal" Solenoid valve.

Relé PRE2 - 2°Livellod’Allarme

Rela

y

FAULT - Fault

Relay

A

LL

–

3

rd

A

larm Level

MODULE

AL101

Pb Battery

Charger

L

230V

B+

B- INT

V

+

V-E+ E-

BATT CE 100

V

ALV

.

N

MODULE

AL100

230Vca Power

Supply

+ -

CE100

L

230VN

230Vac

CENTRAL UNIT

CE100

C N

A

PRE1 C N

A

PRE2 C N

A

A

LL C N

A

FAULT

RELAYS OUTPUTS

RelayPRE1

–

1st

A

larmLevel

230VcaSiren

(SE301A)

Fig 7– Wiring diagram with gas valve and Siren

NO or NC Manual

Resetting Valve

(

VR600÷VR65

0

)

CONNECTION OF THE SOLENOID GAS VALVE WITH POSITION SENSOR

If you have installed a Tecnocontrol solenoid valve with the position sensor (VR400 to VR480

models) connected to the "VALVE CONTACT", in the menu "MISCELLANEOUS" you must

configure YES the STATE EV (Electro Valve).

WARNING: This control works only on 3rd alarm level, so the valve must be connected to

relay ALL.

If an alarm occurs, the CE100 will check if the valve has been effectively closed, otherwise

the yellow LED will light and the FAULT relays activates. The display will show the symbol

for the failure to close.

Rela

y

FAULT -Fault

RelayPRE1

–

1

s

t

A

larm Level

Relay PRE2

–

2nd

A

larm Level

Fig 8– Wiring diagram with gas valve with position sensor and Siren

CENTRAL UNIT

CE10 0

CNA

PRE1 CNA

PRE2 C N

A

A

LL CNA

FAULT

MODULe

AL101

Pb Battery

Charger

L

230V

B+B- INT V+ V-E+ E-

BA TT CE 100

V

ALV

.

N

MODULE

AL100

230Vac Power

supply

+ -

CE1 0

0

L

230V

N

230Va

c

230Va

c

ManualResettingValve

(VR400÷VR480)

With“POSITION

SENSOR” and with

12Vdccoil.

Rela

y

A

LL

–

3rd

A

larm Level

REL

A

YSOUTPUTS

GND

12Vdc

“

V

ALVE

CONTACT”

Terminals

Terminal “

E

-

“

Te

r

minal“

E

-

“

NOTES: The AL101 and AL102 modules have an auxiliary output “VALVE“ at 12VDC/12W

max (terminals E+ and E-). You can power a gas solenoid valve or other device, operating at

12VDC (10.8÷13.8VDC), whose absorption maximum does not exceed 12W (1A). This

output is protected from "Short Circuit", but should not be connected loads that exceed the

indicated current capacity, or which may generate noise on power supply.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 13/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

MAIN MANU

Confi

g

uration6

M Exclusio

n

4Miscellaneu

s

5

Sensor choice

Sensor n. 1

Sensor Choice

Sensor n. 1

Model : TS293Px

Sensor Choice

Sensor n. 1

Model : TS293Px

Valve : NO

CONFIRM ? NO

CENTRAL SYSTEM SETUP

Keyboard use and general information’s

The numbers to be changed or entered appear on the display highlighted by the Cursor

(flashing black rectangle). To change or enter a number you can use:

The key to move up or increase a value.

Key to move down or decries a value.

Key to confirm or to enter in the Reset Menu.

Key

ESC

to enter and exit menus.

After having entered the first sensor setup, the software propose this setup as the standard

for all others sensors, in this case, if you are entring more sensors with the same setup, all

operations will be much more easy and quick.

SENSORS SETUP

If any sensors have been already configured, the

following message will be displaied:

IMPORTANT NOTES

A - To set up the Central or make changes later, from the normal screen, press

ESC

to

enter the MAIN MENU. Select 8-Protected Menu and then enter the "Code Level 3".

(Please see on page 18 chapter CODES).

B - At the first set up, the sensor no. 1 must be programmed first. Why choosing the

type of "valve", if installed, is binding, you cannot change this set up in the other

sensors, because the choice only affects the 3rd Alarm Relay "ALL", it follows that

the gas shutoff valve should only be connected to these relays.

Pressing the

ESC

key, you enter in the MAIN MENU.

After entering the code (CODE ACCEPTED), press

ESC

to

return to MAIN MENU, then press key select “Set

up” and press to confirm. Now, press to select

the sensor number to be configured and press to

confirm.

Example:

“1-Sensor Choice”Select “1” press to confirm and

advance to the next line.

“Model”, with key selects the installed gas detector

type (e.g. TS293Px) then press . (See the following

pages to Tables 1 and 2).

"Valve" presses key to select the desired valve type,

if installed. After selecting one of the three options below,

then press to confirm.

NO = Normally Open

NC = Normally Closed

NOT = No Valve installed

"CONFIRM" will be asked to confirm the inserted set up, with the arrow select YES and

then to confirm. If you leave NO the operation will be cancel (please see chapter

"DELETION SENSORS").

1:--------- 4:----------

2:--------- 5:----------

3:--------- 6:----------

-3-

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 14/24

Table 1 - Pre-configured parameters of the detectors (sensors)

To simplify setup, the models indicated in the table are pre-configured with default settings; you can use in common situations. The detectors

into brackets has operational characteristics identical to the first highlighted in bold, the only difference is the type of protection custody. If

necessary you can also configure other detectors, selecting the "Generic" ones. In addition, you can change all parameters of each sensor

according individual requirements.

NOTE - (1): The alarms can be set for the oxygen detectors are: PRE1 and PRE2 to lack, and ALL for excess oxygen. Furthermore, the alarm

threshold PRE2 activates the 1st relay (PRE1), while the threshold PRE1 activates the 2nd relay (PRE2).

NOTE - (2): The twin TS250CB detectors must be programmed on two distinct inputs. The CO as TS220EC and gasoline vapours as TS292Kx.

MODEL GAS RANGE UNITS PRE1 (Level 1) PRE2 ( Level 2) ALL ( Level 3)

TS220EA (TS293EA) NH30-300 ppm 10 20 50

TS220EC (TS293EC) ((2

)

TS250CB) CO 0-300 ppm 50 100 200

TS220EH (TS293EH) H2S 0-100 ppm 10 20 50

TS220EN (TS293EN) NO 0-100 ppm 10 20 50

TS220ES (TS293ES) SO20-20 ppm 10 20 50

TS292KG LPG 0-20 %LEL 10 15 20

TS292KM METHANE 0-20 %LEL 10 15 20

TS292Kx (TS292KB, TS292KI)((2

)

TS250CB)INFLAMMABLE 0-20 %LEL 10 15 20

TS293KG LPG 0-20 %LEL 10 15 20

TS293KM METHANE 0-20 %LEL 10 15 20

TS293Kx (TS293KB, TS293KI) INFLAMMABLE 0-20 %LEL 10 15 20

TS292Px (TS292PM, TS292PG, TS292PI,

TS292PB) INFLAMMABLE 0-100 %LEL 10 15 20

TS293Px (TS293PX-S, TS29PX-H,

TS293PE, TS293PS) INFLAMMABLE 0-100 %LEL 10 15 20

IR101 CO2 0-2.00 % vol. 0.20 0.50 1

IR102 CO20-2.00 % vol. 0.20 0.50 1

Generic

(1

)

TS220EO (TS293EO) Oxygen (O2) 0-25.0 % vol. 18.5 19.5 22.5

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 15/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

Table 2 - Pre-configured parameters for the Relays

MODEL

Relay PRE 1

Delay ON (sec)

Delay OFF (sec)

Positive Logic

MEMORISED

Relay PRE 2

Delay ON (sec)

Delay OFF

Positive Logic

MEMORISED

Relay ALL.

Delay ON (sec)

Delay OFF (sec)

Delay OFF (sec)

Positive Logic

MEMORISED

Relay FAULT

Delay ON (sec)

MEMORISED

TS220EA

K1

1 1 NO NO

K2

1 1 NO NO

K3

30 1 1 SI YES

K4

30 YES

TS220EC 1 1 NO NO 1 1 NO NO 30 1 1 SI YES 30

YES

TS220EH 1 1 NO NO 1 1 NO NO 30 1 1 SI YES 30

YES

TS220EN 1 1 NO NO 1 1 NO NO 30 1 1 SI YES 30

YES

TS220EO 1 1 NO NO 1 1 NO NO 30 1 1 SI YES 30 YES

TS220ES 1 1 NO NO 1 1 NO NO 30 1 1 SI YES 30 YES

TS292KG 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS292KM 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS292Kx 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS293KG 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS293KM 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS293Kx 1 1 NO NO 1 1 NO

NO 30 1 1 NOTA 1 YES 30 YES

TS292Px 1 1 NO NO 1 1

NO NO 30 1 1

NOTA 1 YES 30 YES

TS293Px 1 1 NO NO 1 1

NO NO 30 1 1

NOTA 1 YES 30 YES

IR101 1 1 NO NO 1 1

NO NO 30 1 1

NOTA 1 YES 30 YES

IR102 1 1 NO NO 1 1

NO NO 30 1 1

NOTA 1 YES 30 YES

Generic 1 1 NO NO 1 1

NO NO 30 1 1

NOTA 1 YES 30 YES

NOTE 1 “YES” if we choose NC VALVE (normally closed valve) or “NO” for NO Valve (normally open valve)or NOT VALVE.

TIME ON (in seconds) for all relays K1, K2, K3 and K4 is= 0. This parameter should only be used and as indicated in "Change

Sensor" on page 17.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 16/24

Sensor copy

Sensor n. 1 2

TS292KM

Setup

Senso

r

delete3

S

ensor choice1Sensor Cop

y

2

Sensor copy

Sensor n. 1

TS292KM

Sensor copy

Sensor n. 1 2

TS292KM

CONFIRM ? NO

SENSORS COPY

From the MAIN MENU, with key select the sub-

menu “Setup”. Press , select with “2-Sensor copy”

then press to confirm.

Sensor choice Select with the desired sensor you

wish to copy and then press to confirm.

Sensor copy to an arrow with a number reference on its

right will appear. With insert the desired sensors to

be copy and then press .to confirm.

“CONFIRM”will be asked to confirm the configuration

inserted. With select YES and press .

If you leave NO the operation will be cancel

SENSORS DELETE

From the MAIN MENU, with key select the sub-menu “Setup”. Press , select with

“3-Sensor delete” then press to confirm.

Sensor Selection: with , choose the number of sensor to be deleted, and then press

to confirm.

Confirm: will be asked to confirm the cancellation with , select YES and press to

confirm. If you leave NO, the operation will be cancelled.

NOTE: You cannot delete the sensor No.1.

MODIFYING SENSORS SETUP

It is possible to modify a sensor already configured in two ways:

1 - If you want to change the threshold values or alarm output is sufficient to operate as

described below in section Sensor Setup.

2 - If you need to change sensor model, (except No. 1 which can be reconfigured only) is

recommended before, delete it, then configure it as if new, see the previous paragraph

Sensors delete.

Sensor modification

From the MAIN MENU, with key select the sub-

menu “Setup”. Press , select with “4-Sensor

modification” then press to confirm.

Sensor Selection: with , choose the number of

sensor to be deleted, (The sensors are not configured,

are indicated with a dot line) then press to confirm.

NOTE: If you do not want to continue, press twice

ESC

to

return to the MAIN MENU.

Setup

Sensore delete

3Sensor modification4

Sensor co

py

2

Sensor modification

Sensor n. 3

Model : TS292KM

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 17/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

"PARAMETERS" parameters are proposed in succession,

to move to the next without changing it, simply press

.

“Endo of scale” (Full Scale 9999 max) you can change this

value with the keys then press to confirm.

“Unit” (LEL, %, ppm, °C) to change this value, using the

keys then press to confirm.

“Level PRE1” modify with then press .

“Level PRE2” modify with then press .

“Level ALL” modify with then press .

NOTE: The three thresholds value must have an

increasing progressive value or equal, with the

exception of the Model TS220EO or TS293EO Oxygen

(See NOTE 1 at the bottom of Table 1).

“Output PRE1” first alarm threshold.

“Delay ON”: is the delay of the relay output, in minutes and seconds (max 4’10’’), since the

alarm threshold is exceeded.

“Delay OFF”: is the time, in minutes and seconds (max 30’), during which the output (relay)

remains active, even after the end of the alarm condition.

“Time ON”: is the interval of time, in minutes and seconds (max 30'), during which the output

remains activated, from when it is exceeded the alarm threshold. At the end of this time, the

output (relay) returns to normal operation even if the value and above the alarm threshold

WARNING: "Time ON" can be set, only if the “Delay OFF” is set to "ZERO" and is not

selected "Latched output” YES.

"Positive logic" Indicates if the relay works with Normally

Closed contact (Positive), normally open or normally

(Negative). Modify this with key , to "NO" (Negative) or

"YES" (Positive), then press to confirm.

"Latched output" if you want the output remains activated,

even when the alarm returns under its threshold. Modify

this with key , to "NO" or "YES" and then press

to confirm.

WARNING: "Latched output” YES, can only be set if the Delay OFF and Delay ON time, are

set to "ZERO". Normally the "Latched output” YES" is used on the 3rd alarm

level, to prevent resetting of the solenoid gas valve (either manual or

automatic resetting) without first verifying that the Central Unit is in alarm.

Then, continue as above, also for the other items "Output PRE2" (2nd alarm threshold - Relay

PRE2), "Output ALL" (3rd alarm threshold - Relay ALL) and "Output FAULT" (indicating a failure - FAULT

relay).

CONFIRM: will be asked to confirm the changes inserted

(if you leave NO, the whole operation will be cancelled).

By key selecting YES and then press to

confirm, and then press

ESC

to return to the MAIN

MENU.

Sensor modification

Sensor n° 1

Model : TS292KM

CONFIRM ? NO

Sensore modification

Parameters

End of scale : 0020

Sensore modification

Parameters

Level PRE 1 : 0010

Sensore modification

Output PRE1

Dalay ON : 00’01’’

Sensore modification

Output PRE1

Delay OFF : 00’01’’

Sensor modification

Output PRE1

Positive Logic : NO

Sensor modification

Output PRE1

Latched Output: NO

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 18/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

CODE SETUP (PASSWORD)

The code consists of an access key that, when inserted, is to protect all the system settings

from unauthorized changes. If you want to change the Setup of inputs, outputs and the Code,

you must first enter the correct code.

From the MAIN MENU, with key select the sub-

menu “8-Protected menu”. Press to confirm.

When the message "CODE LEVEL 1" (which in this

version is not active) with the keys you can

move to the "CODE LEVEL 2" or "CODE LEVEL 3", then made

the choice you want, press to confirm.

To select the code, with the keys moves the

cursor to the request number, and with confirms the

choice. After entering the 4 digit, display will show "CODE

ACCEPTED", press

ESC

, to return to the MAIN MENU and

now you can change the settings enabled.

LEVELS OF CODES AND DEFAULT CODES

The CE100 has three levels of code, with different access so as to allow people with different

responsibilities and expertise to operate on the central unit. The three "Code Levels" are

factory preset, it is recommended to change them anyway, and keep them carefully.

Code 1 in this version, has no effect on the menu, under normal use you can go

directly to the menu 1-RESET, 2-DETAILS, 7- CODES, and 8- PROTECTED MENU.

Code 2 2222 for use by the plant manager, also gives access to the menu 3-ENABLE, 4-

DISABLE, and 5-MISCELLANEOUS

Code 3 for maintenance or installation, gives access to all menus.

CODE EDIT (PASSWORD)

From the MAIN MENU, with key select the sub-

menu “7-Code” and press to confirm.

Appear, CODE LEVEL 1 (which in this version is not

active) then the keys you can move to the

"CODE LEVEL 2" or "CODE LEVEL 3".

After you make your selection, press to confirm.

After selecting the code level to edit, enter the 4 digit

original code, with keys scroll numbers and

confirm with . (For each number entered will appear

a star for confirmation).

Then enter the New Code, scroll the numbers with keys

and confirm with .

MAIN MENU

Setu

p

7Protected menu8

Divers (Miscellaneus)6

Protected Menui

CODE LEVEL 2

Protected Menu

INSERTCODE 2

0123456789#$%&-

Code

INSERtCODE2

0123456789#$%&-

MAIN MENU

Code7Protected Menu

8

Setu

p

6

Code

CODE LEVEL 2

Code

NEW CODE 2

0123456789#$%&-

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 19/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

Code

CODE STORED

Code

CONFIRM CODE 2

0123456789#$%&-

Test output

LGreen

MENU PRINCIPALE

Protected Menu8Service9

Code

7

Service

Test Outputs2Test In

p

uts1

Lan

g

ua

g

e

3

Test Inputs

1=04.0mA 2=04.0mA

3=04.0mA 4=04.0mA

5=04.0mA 6=04.0mA

Then to confirm renter the New Code, scroll the

numbers with keys and confirm with .

Now will show STORED CODE, with

ESC

you will return to

the MAIN MENU.

From this moment, the new inserted code becomes

active.

PAY ATTENTION: we suggest writing and keeping the Password in a safety place. In

case you lose the Password get in contact with our technical support.

Backlight

The display backlight will automatically switch off, when not used, after 60 seconds; pressing

any key it light back again.

ELECTRICAL OPERATIONS “TEST”

WARNING: This procedure must be performed with extreme care by trained

and authorized personnel, because both are activated relay outputs that

activate the connected devices, both internal functions the control panel.

The CE100 is equipped with a test program that allows

verifying the electrical operation

From the MAIN MENU, after inserting the Code Level 3,

with select the submenu "9-Service" and then press

to confirm.

Input Test (Detectors)

With key select “1-Test Inputs” and then press .

Now, you will see the sensor’s values, expressed in mA,

even those not configured. Obviously does not consider

the value of those not installed, which can be "0mA" to

"50 mA". At the centre of the display there will be the

symbol of the solenoid valve with Position Sensor.

Output Test (Relays and Led)

Press key

ESC

to go back to menu “Service”, with key

select “2-Test Outputs”, then press to confirm.

From here starts the sequence of tests listed below.

Repeatedly pressing the key activates ON and OFF one after another all Led: LGreen,

LYellow, LRed, the Buzzer and the outputs relay: the PRE1, PRE2, ALL and FAULT.

Finally, will be displayed the Battery voltage, with activation of the internal test "load".

Module AL101 (lead battery) - this value should be about 12VDC

Module AL102 + BA100 (Lithium battery) this value should be about 10.5 Vdc

WARNING: Test Battery, must obviously be only used when the modules are installed

AL101 or AL102. Do not leave this test active for more than a minute. During the test is

activated, the "load" to the internal CE100, consisting of power resistors which

obviously will become hot.

IST-1100.CE01.02/B CE100 “TOWN” / User Instructions PAG. 20/24

TECNOCONTROL S.r.l. - Via Miglioli, 47 20090 SEGRATE (MI) - Tel. 02.26 92 28 90 - Fax 02.21 33 734

Language

FRENCH

Language

ENGLISH

Language

ITALIANO

SETTING THE LANGUAGE

With key select "3-Language" and press to

confirm

With keys you can change the language and

pressing confirms the choice.

APPENDIX

LIST OF ANOMALY MESSAGES AND ALARMS

NO SENSORS CONFIGURED The central system is not configured.

FAULT- The input signal is less than 1 mA. The sensor could be

faulty, not connected or not powered.

UNDERFLOW The input signal is between 1 and 3,5mA. The detector could

be out of calibration on the beginning of the scale.

PRE1 The 1st alarm threshold has been exceeded and the related

output relay is active (if configured).

PRE2 The 2nd alarm threshold has been exceeded and the related

output relay is active (if configured).

AL The 3rd alarm threshold has been exceeded and the related

output relay is active (if configured).

OVERFLOW The input signal is between 21 and 24 mA. The sensor is

detecting gas, but the full scale has been exceeded.

FAULT+ The input signal is greater than 24 mA. The sensor could be

faulty, or it’s detecting gas but it has exceeded its full scale.

Mains 230Vac power supply is missing.

Battery empty.

The valve with Position sensor is not close.

Display switched off if the greed Led is ON, the Display could be damaged or the

contrast is too low, tries to regulate it with the trimmer on the

Board: (“Contrast ADJ” bottom right corner) placed in the CE100

housing, on the PCB placed into the front cover.

LIST OF ACOUSTIC AND OPTICAL SIGNALS

Intermittent Buzzer One of the detectors has exceeded the 3rd Alarm Level (ALL)

or the AUX input is active.

Green Led on Mains power supply ON (normally working condition).

Green Led Blinking The CE100 is powered by the Battery; the Mains is OFF.

Red Led on One of the sensors has exceeded the 3rd Alarm level (AL3).

Red Led Blinking One of the Detectors has exceeded the 1st Alarm and/or 2nd

Alarm levels (AL1 and/or AL2) or one of the Latched Output

relay has been activated.

Yellow Led Blinking Battery voltage is less than 10.8Vdc.

Yellow Led on One of the sensors is FAULT+ (>24mA)or FAULT- (0 mA).

Green Led and Display OFF Mains power supply OFF, and battery has powered the

central system till it got down. If the battery voltage gets

down under 10VDC, it is automatically disconnected to avoid

damages.

Table of contents

Other Tecnocontrol Control Panel manuals