TECO-Westinghouse FLUXMASTER 100 Series User manual

This manual suits for next models

19

Other TECO-Westinghouse Inverter manuals

TECO-Westinghouse

TECO-Westinghouse F510 Series User manual

TECO-Westinghouse

TECO-Westinghouse PA7300 Series User manual

TECO-Westinghouse

TECO-Westinghouse MA7200 PLUS User manual

TECO-Westinghouse

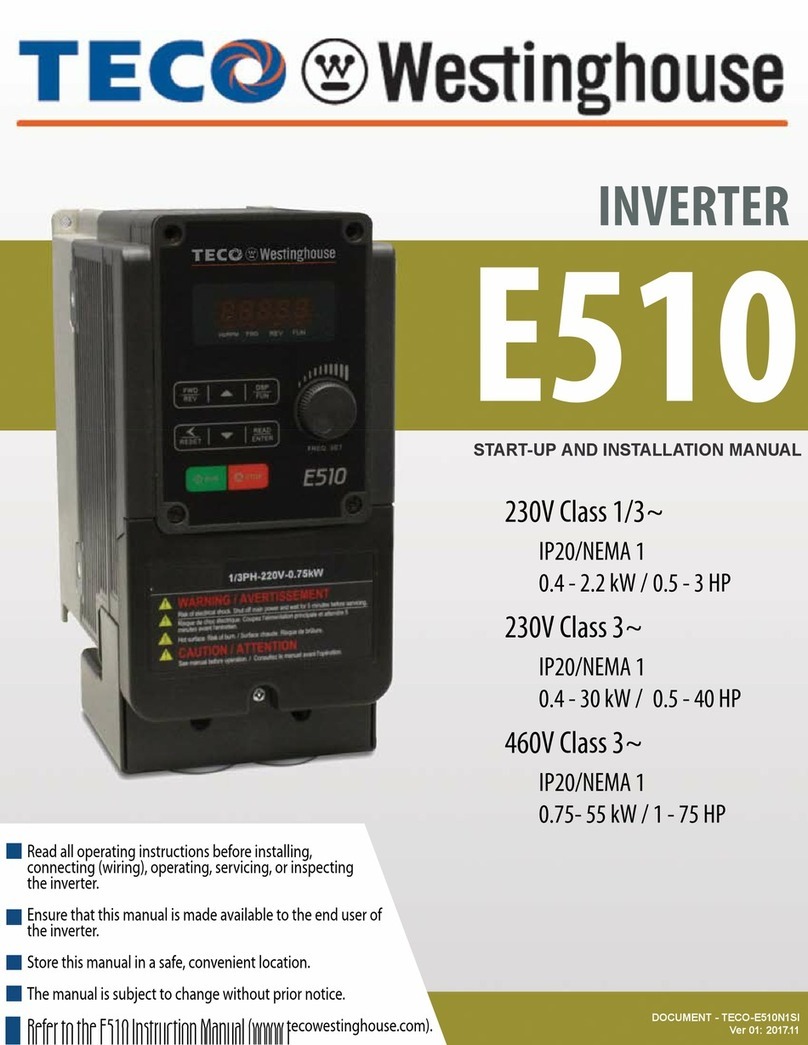

TECO-Westinghouse E510 User manual

TECO-Westinghouse

TECO-Westinghouse E510-201-H-U Installation and operation manual

TECO-Westinghouse

TECO-Westinghouse PA7300 Series Instruction manual

TECO-Westinghouse

TECO-Westinghouse L510-1P2-H1-U Installation and operation manual

TECO-Westinghouse

TECO-Westinghouse E510 Installation and operating manual

TECO-Westinghouse

TECO-Westinghouse F510 Series User manual

TECO-Westinghouse

TECO-Westinghouse A510 User manual

Popular Inverter manuals by other brands

Black & Decker

Black & Decker bdv066 instruction manual

Omron

Omron KP100L-OD - QUICK LINE Quick installation guide

Victron energy

Victron energy Phoenix MultiPlus 12/3000/120 manual

Growatt

Growatt MOD 3-15KTL3-X quick guide

AIMS Power

AIMS Power PWRIC150012W instruction manual

SMA

SMA SUNNY TRIPOWER 60 installation manual

Goodwe

Goodwe ET Series Quick installation guide

Ingecon

Ingecon SUN 125 U 208 Outdoor installation manual

EKO

EKO PV Blocks MP-1000S instruction manual

Powermate

Powermate PM0645500 owner's manual

Westinghouse

Westinghouse iGen4500DF quick start guide

MPP Solar

MPP Solar Grid PV-Inverter 10Kw Installation and operation manual