TEDA XQ114/6B User manual

MODEL XQ114/6BHYDRAULIC POWER TONG PARTS

OPERATION MANUAL

2014-10

YANCHENG TEDA DRILLING AND PRODUCTION EQUIPMENT CO., LTD

Safety Instruction and Legend Description

Safety Instruction

●Operators must read and know this manual well.

●Operators must wear work uniform, safety shoes, safety helmet, safety gloves, etc.

●Tie the back guy according to the instruction. Don’t tie it in the wrong direction.

●Operation at the side of tong body opening.

●Don’t touch the running parts with hands when the tong is running.

●Don’t touch the running parts with hands when the tong is running.

●Keep sundries out of the working area.

●The pump should be off or the hydraulic tong power shut down as maintaining or hanging the jaw

plates, die seats or tong dies.

●Over-pressure and over-torque are forbidden.

●Don’t add or dismount any parts to the tong.

●Original parts made by should be used.

Legend Description

Serious Warning

Warning

Recommendation or Suggestion

Safety first, standard operation problems may occur if bugs are not rid of.

CONTENTS

1.Summary.................................................................................................................................................................1

2.Specification............................................................................................................................................................1

3.Installation................................................................................................................................................................1

4.Operation..................................................................................................................................................................2

5.Maintenance & Lubrication......................................................................................................................................3

6.Ordinary problems and troubleshooting guide.......................................................................................................4

7.Table of jaw and dies................................................................................................................................................4

7.1The table of jaw specification................................................................................................................................4

7.2The table of dies specification..............................................................................................................................4

8.Connection between pressure and torque.................................................................................................................5

9.Figures and parts list.................................................................................................................................................5

9.1Assembly and parts list.........................................................................................................................................6

9.2Master tong and parts list.......................................................................................................................................7

9.3shell and accessory and parts list............................................................................................................................8

9.4Tong head assembly and parts list........................................................................................................................10

9.5Braking and centralizing mechanism and parts list..............................................................................................12

9.6Centralizing mechanism and parts list..................................................................................................................13

9.7Transmission mechanism and parts list................................................................................................................14

9.8gear assembly and parts list.................................................................................................................................16

9.9Hand control valve and parts list.........................................................................................................................17

9.10Safety door assembly and parts list..................................................................................................................19

9.11Backup tong and parts list................................................................................................................................20

9.12Backup tong head assembly and parts list..........................................................................................................21

9.13Backup tong head assembly and parts list..........................................................................................................23

9.14Hanger assembly and parts list...........................................................................................................................25

9.15Front guide pole assembly and parts list...........................................................................................................26

9.16Rear guide pole assembly and parts list............................................................................................................27

10.Trucking, storage and after service..................................................................................................................28

Model XQ114/6B HYDRAULIC SUCKER ROD TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

1

1. Summary

Model XQ114/6B(4 1/2") hydraulic power tong is an open type power tong for the making up and breaking out of

tubing in well services. This product has the following features:

1.1 The tong is made up of master tong and backup tong, the master tong has a high and low gear train, the tong

is compact, light and efficient.

1.2 The master tong and backup hydraulics operate on valve banks independent of each other.

1.3 There is an evident speed :high speed at top grade and large torque at low grade.

1.4 The tong has incorporated a new system of disc brake to hold the jaws to connection more effectively.

1.5 Makeup and breakout are made easy with a simple turn to the reset knob on the tong and backup.

1.6 The backup has been supplied with quick coupling hoses and connections for quick and easy installation for

jobs where you need a backup and the backup can be removed in seconds for jobs that a backup is not

required.

2. SEPCIFICATION

2.1 Application tubing range: 73mm -114mm (2 7/8"-4 1/2")

2.2 High gear rated torque: 1.5 kN·m (1100 ft·lbs)

2.3 Low gear rated torque: 6 kN·m (4400 ft·lbs)

2.4 High gear max rotation speed: 85rpm

2.5 Low gear max rotation speed: 20 rpm

2.6 Opening of tong head: 118mm (4.6")

2.7 Overall dimension (L×W×H): 750×500×600mm (29.5"×19.7"×23.6")

2.8 Weight: 220kg ( 485 lbs)

2.9 Rated system pressure: 11MPa (1600 PSI)

2.10 Max oil supply: 100L/min (26GPM)

3. INSTALLATION

3.1 Examination before installation

●Examine the power tong, if damage by transportation should be maintain.

●Examine the fastener, if loose tightened.

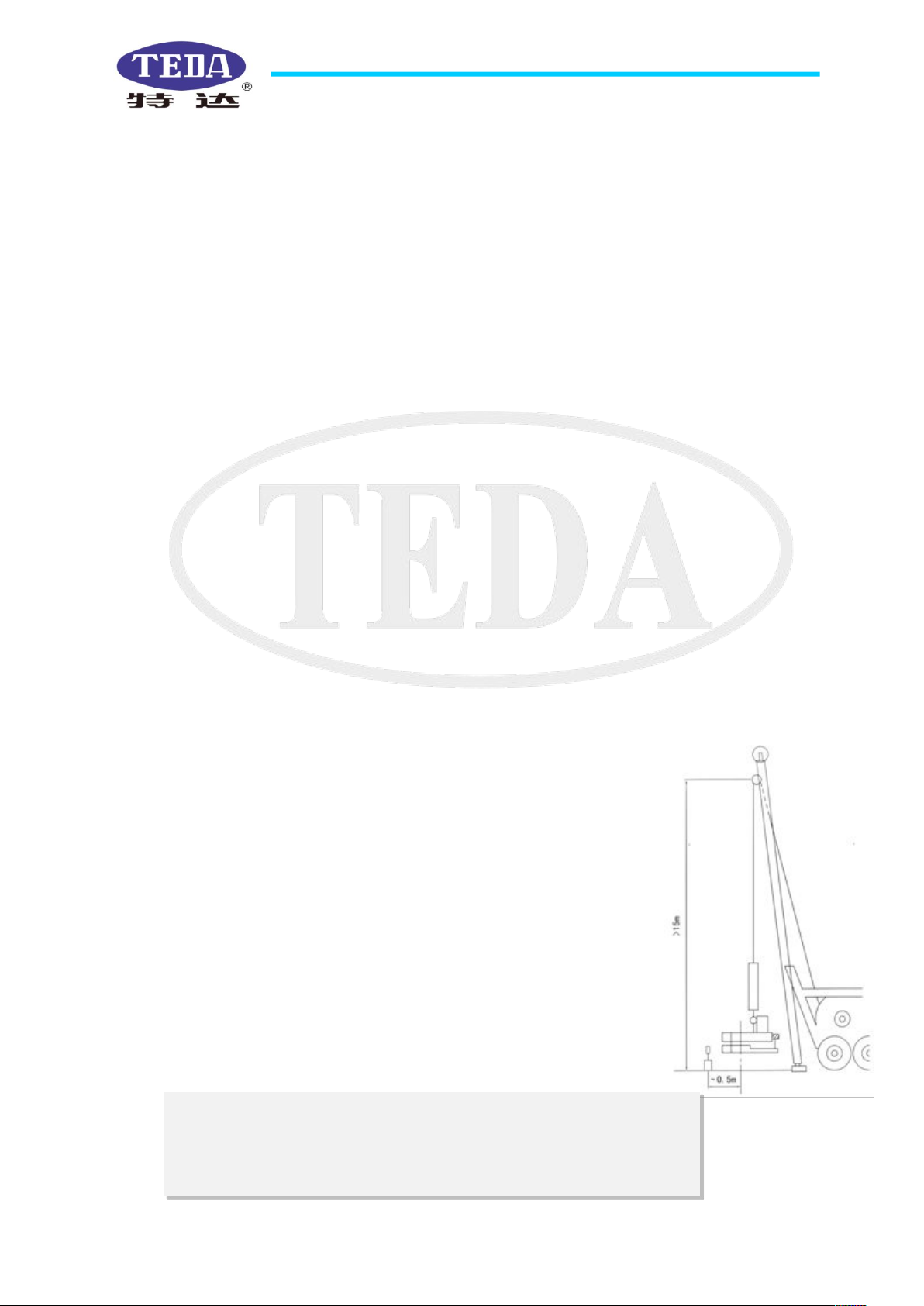

3.2 Hanging

Connect lift with tong hanging rod(Z6-42) and hang the tong on the derrick of

workover rig. The hanging height is proper when the backup tong could rightly

grip the tubing collar(see Fig.1).

●The hanging point is 15 m above ground.

●Under free hanging, power tong head’s center is about 0.5m above the well

center.

●Adjust the extend end of suspender face down, when installing the casket.

Fig.1

Model XQ114/6B HYDRAULIC SUCKER ROD TONG OPERATION MANUAL

YANCHENG TEDA DRILLING & PRODUCTION EQUIPMENT CO.,LTD

2

3.3 Level

Adjust the screw (Z6-58)on the tong hanger to level the tong and

backup, this should be done to ensure proper gripping of the

jaws(see Fig.5).

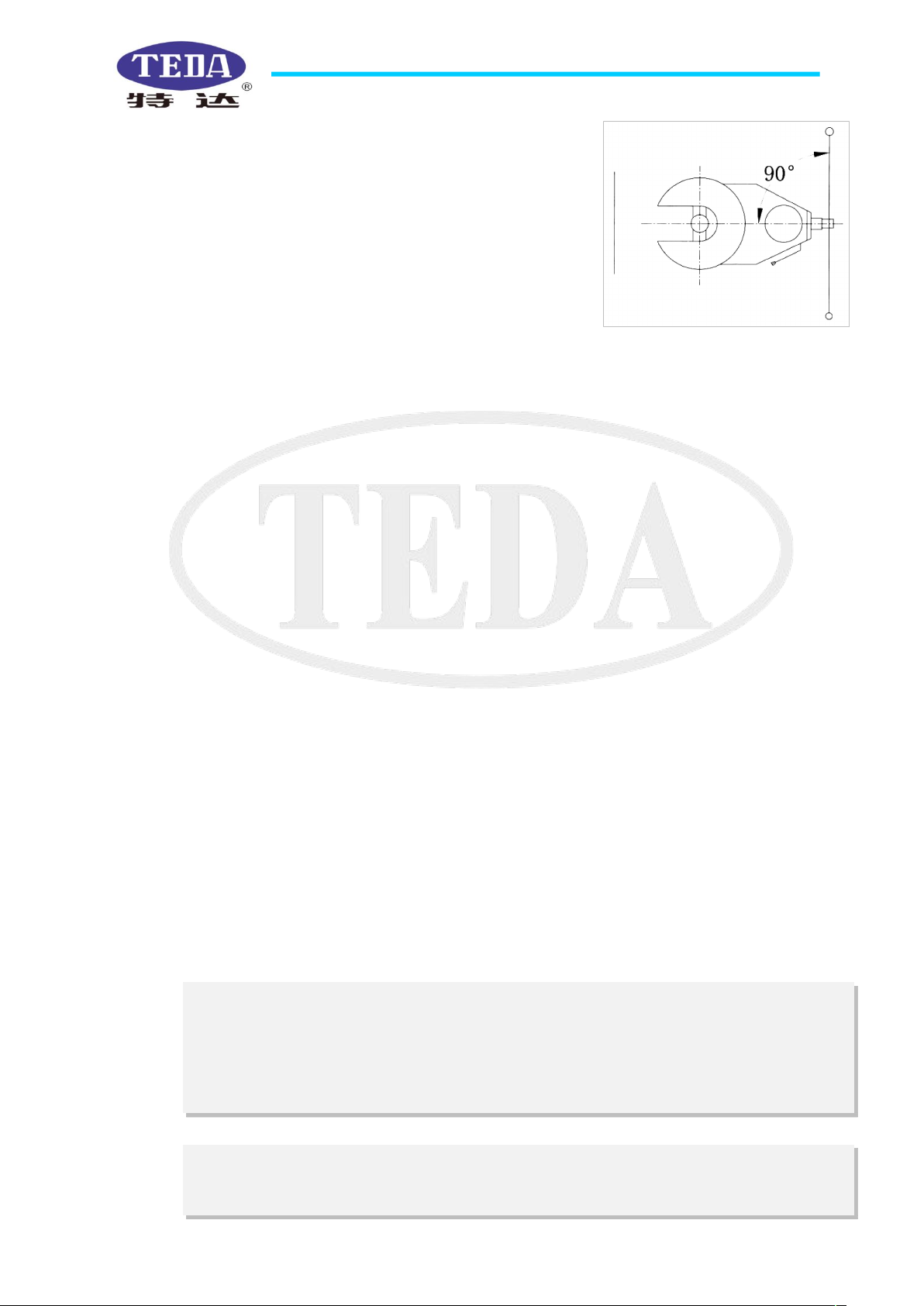

3.4 Back guy

Tie one end of back guy on derrick and the other end on back guide

seat (Z6-32)of power tong, back guy should be capable of bearing a

load of 20 kN, when power tong is in make up position, the back

guy should be at right angle to the tong and on the opposite side of operator who operates the control

handles(see Fig.2), this insures a safe operation.

3.5 Pressure hoses

Connect hoses from the hydraulic power source to the control valve bank of the power tong. The inlet and the

outlet hoses can’t be misconnected.

4. OPERATION

4.1 Make up

After aligning the opening tong head with the backup, turn the reset knobs of each (Z6-49) and (B6-3) switch

the arrow to point the direction of make-up. Locate the tong and backup on to the tubing. The backup should

be engaged to lock onto the tubing first.

Once the backup jaws have been locked on, commence make up with the tong. After the tubing is made up,

reserve rotation of the tong to align the opening of the tong with the tubing. Once this is accomplished,

reverse the backup to align the opening of the backup to the tubing. The tong can be moved off the tubing.

Confirm proper make up torques required from your tubing supplier.

4.2 Break out

Aligning the opening tong head with the backup, turn the reset knobs of each(Z6-49) and (B6-3) and switch

them to point the direction of break out, then push it towards the tubing. Making the jaws of the tong and the

backup line up squarely on tubing. Engage the backup first locking onto the tubing. Commence break out

with the tong. Initial break out should always be done in low gear range. Once break out is accomplished.

The joint may be spun off in high gear. To come off the couplings reverse the rotation of the tong and backup

slowly to align the opening of the tong and backup to the tubing. The tong can now be removed off the

tubing.

●Don’t disassemble hydraulic pipe at a high pressure, otherwise, accidents may occur and the

equipment may be damaged.

●Don’t approach the running part of hydraulic power tong by your body or clothes.

●Only operators are allowed to approach hydraulic tong to avoid trouble caused by turning the

operating lever.

●The temperature of the hydraulic oil should not be over 65℃.Over heating can make hydraulic

system seal fail to worj and slow down the running speed of tong.

Left

right

Break out direction

Make up direction

Fig.2

Table of contents

Other TEDA Industrial Equipment manuals