BA_Caremaster-SF1-SF2_BGIA_110901_GB.doc - 5 - 01.09.2011

2 Preface

One sector of extraction equipment has become very significant in recent years. The filtering of

extracted pollutants and the recycling of filtered air to the working area.

This is a surely a sign that the environmental consciousness of every one of us has altered very

strongly in favour of our environment. For a long time now, no one has denied that pollution occurs

during production. However, the pollutants depend on the process that is used. One can basically

distinguish between gases and fumes (smoke). Fumes could also really be described as dust. If

you examine this dust under a microscope, you will find that they consist of very fine particles, often

with a size of 1 µm or smaller, that can enter the lungs.

The classical method of trying to improve the working conditions of polluted workplaces is general

ventilation. In this case, the general rule is a multiple change of air in the workshop, i.e. the

complete volume of air in the workshop is replaced. However, this method only achieves a small

reduction in the level of pollution within the breathing space of the user.

The same applies to “overhead” extraction, i.e. the installation of large extractor hoods above the

workplaces. This is the worst airflow imaginable, since the pollutants first pass through the

breathing space of the user, and only afterwards are they contained and extracted. This is surely

not the point of the exercise. A much more effective method than overhead/wide-area extraction is

the removal of pollutants directly at their source, with localised extraction. Both the investment and

the operating costs are much, much lower if localised extraction is used.

The environmental and workplace-safety measures are especially important requirements for

succesSF-BIAul application of a technology, in addition to the technological optimisation of the

processing method. In a time of increasing sensitivity and tougher legislation, the task therefore lies

in making an early assessment of the potential hazards for the workplace and the environment, and

reducing them as appropriate.

3 Function of the TEKA-CAREMASTER-BGIA

The TEKA–CAREMASTER-BGIA filter unit is primarily used for localised extraction of dust and

smoke particles. For this purpose, the unit can be equipped with one arm.

Limits of application:

welding fumes with oil mist, aluminium dust, gases, water etc.

(If you are uncertain, please contact the manufacturer!)

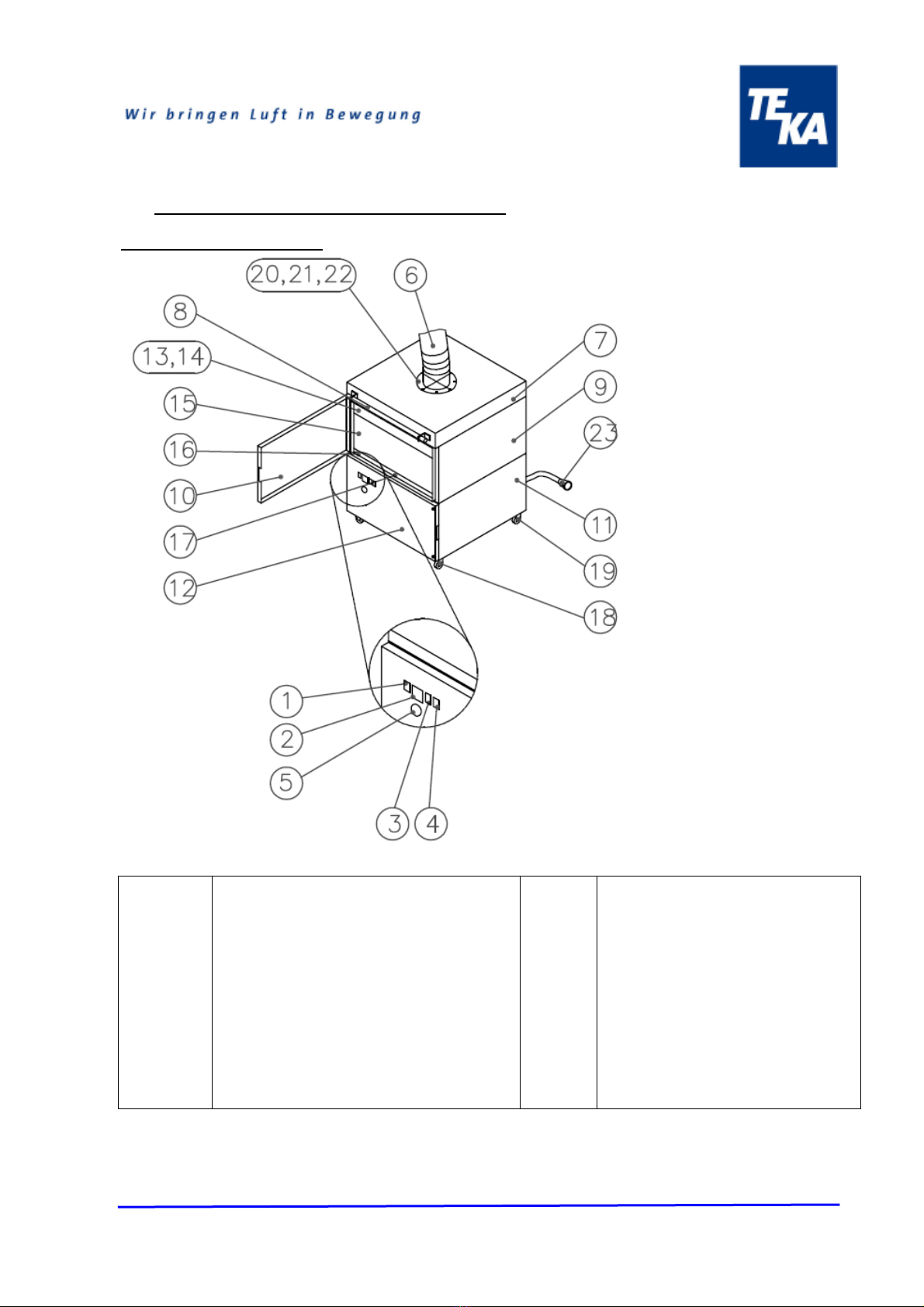

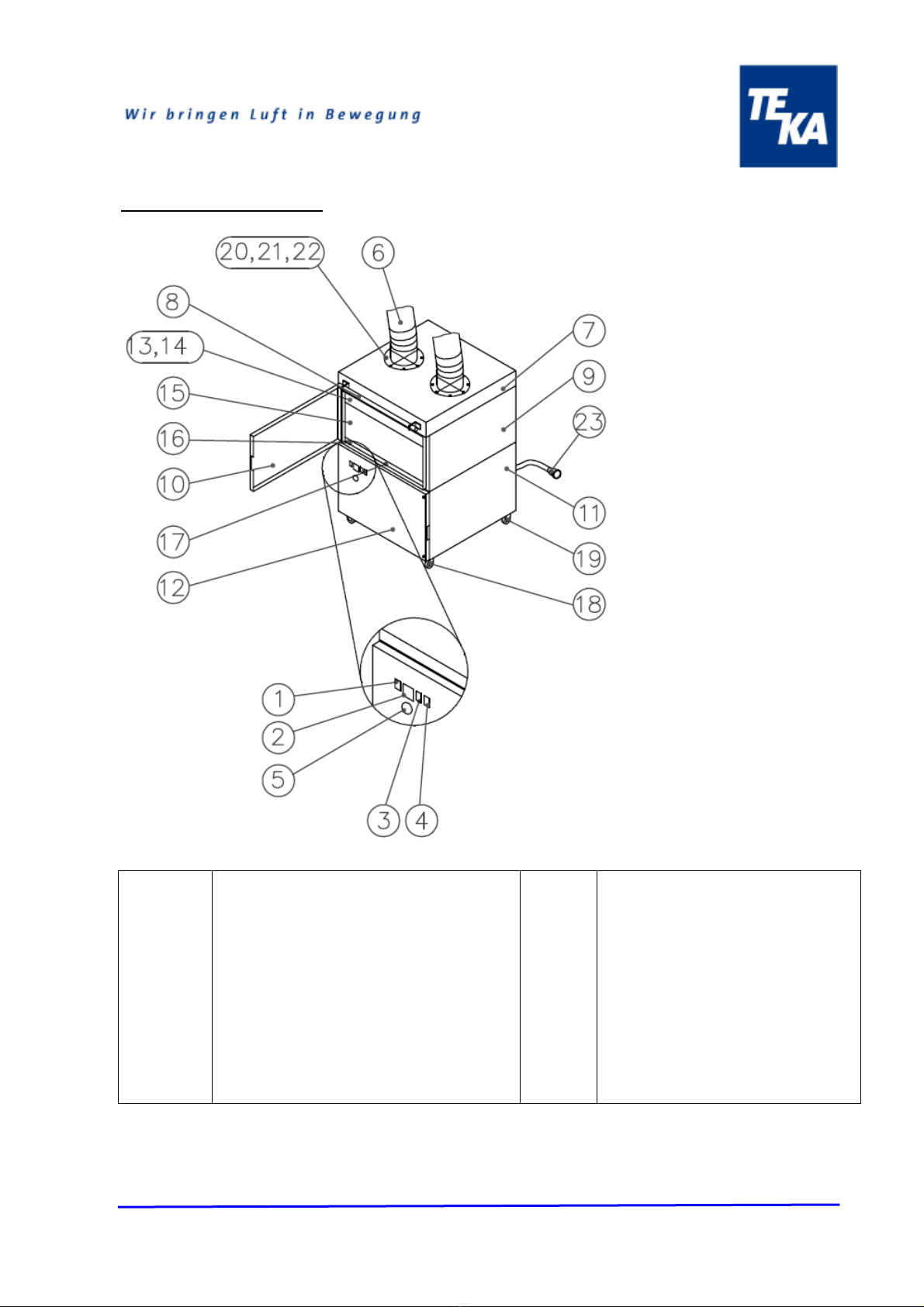

The polluted air is sucked into the extractor hood (or application-specific fitting) and transported

through the extractor arm (or extractor hose) to the filter unit. Here, the coarse dust particles are

collected in the pre-filter mat (Pos.14). The subsequent particle filter (Pos.15) traps extremely fine

dust particles with an efficiency of better than 99%. The clean air passes the fan and the noise

attenuation module and returns upward into the room via the exhaust grid. The filtered air is then

sucked in by the ventilator and recycled to the air in the workshop through the exhaust grille at the

back of the unit.

Caution:

As soon as the resistance to the air flow from the accumulated dust particles on the filter cartridge

markedly effects the suction performance, the filter elements shall be exchanged.

(refer to chapter 7.1: “Changing of pre-filter mat“ , chapter 7.2: “Change of particle filter“ )