Table of contents

1 General 4

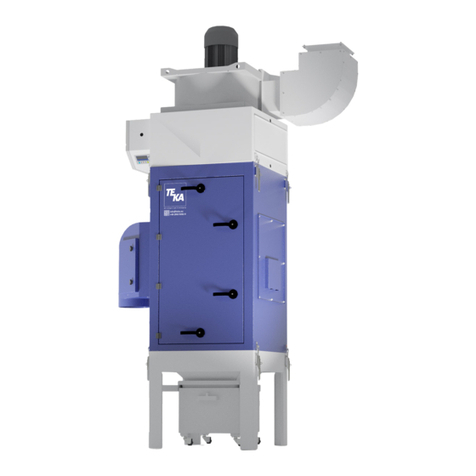

2 Description of the system elements 5

2.1 Illustration of the system elements 5

2.2 Functionality of the system 6

2.3 Intended use 6

3 Safety instructions 6

3.1 Definition of the hazard symbols 6

3.2 General safety instructions 7

4 Storage, transport and installation of the device 8

5 Commissioning 9

5.1 Connecting the suction line and exhaust air line 9

5.1.1 Assembly of the silencing housing 10

5.2 Electrical connection 11

5.3 Precoating of the filter cartridges 12

5.4 Connecting the compressed air supply 12

5.4.1 Compressed air supply for the cleaning of the filter cartridges 12

6 Operating the system 13

6.1 Explanation of the operating elements 13

7 Maintenance 14

7.1 Reset to maintenance state 15

7.2 Cleaning the filter cartridges 16

7.3 Replacing the filter cartridges 17

7.4 Emptying the dust collecting tank 19

7.5 Draining the condensate 20

7.6 Precoating of new filter cartridges 21

7.6.1 Feeding the precoat via a FVS (TEKA spark pre-separator) 22

7.7 Cleaning the copper baffle plate 23

8 Dismantling / Disposal 24