Table of contents

1. General 3

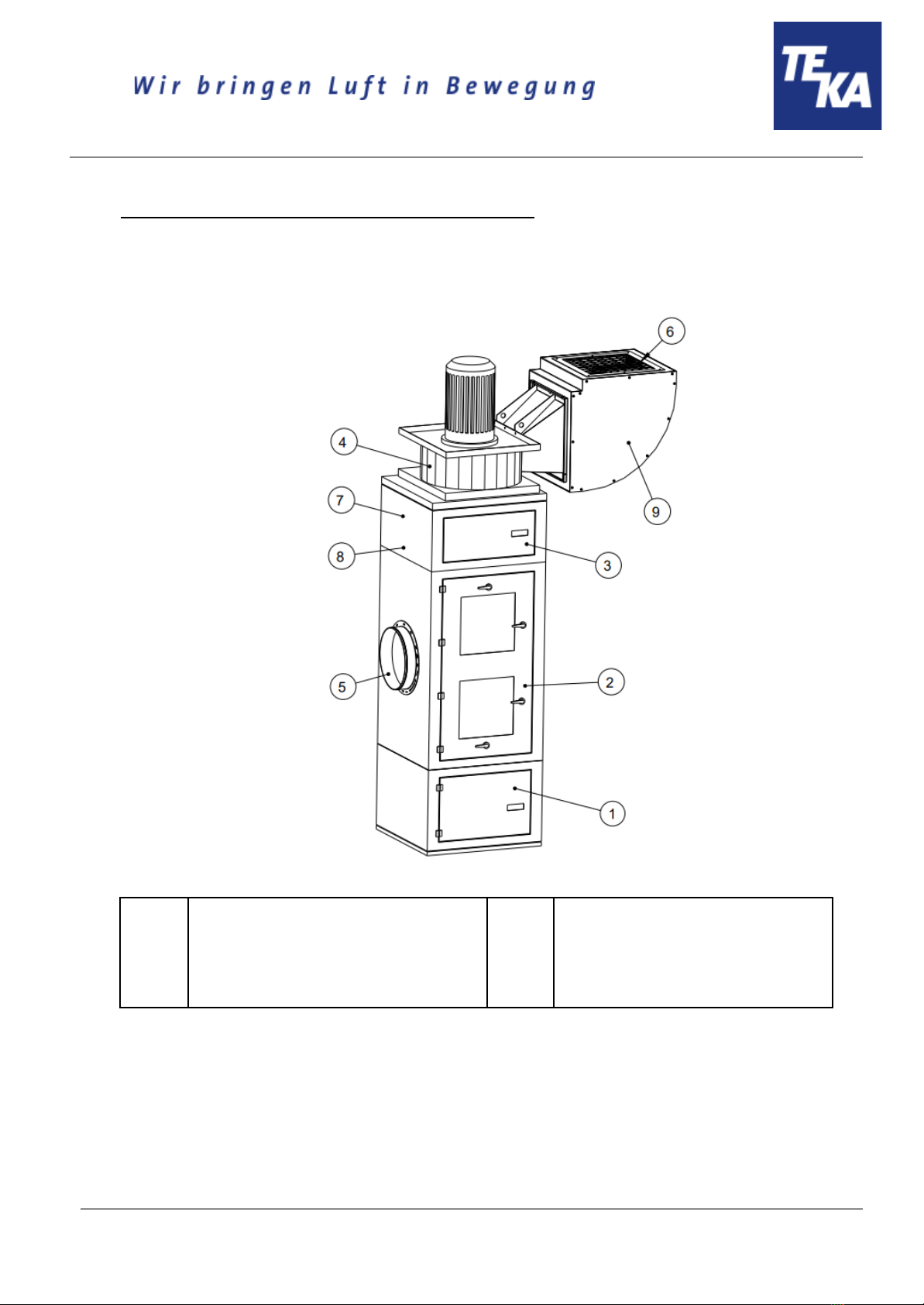

2. Description of the system elements 4

2.1. Illustration of the system elements 4

2.2. Functionality of the system 4

2.3. Intended use 5

2.4. Residual risk 5

3. Safety instructions 5

3.1. Definition of the hazard symbols 5

3.2. General safety instructions 6

4. Storage, transport and installation of the device 7

5. Commissioning 8

5.1. Connecting the suction line and exhaust air line 9

5.2. Electrical connection 10

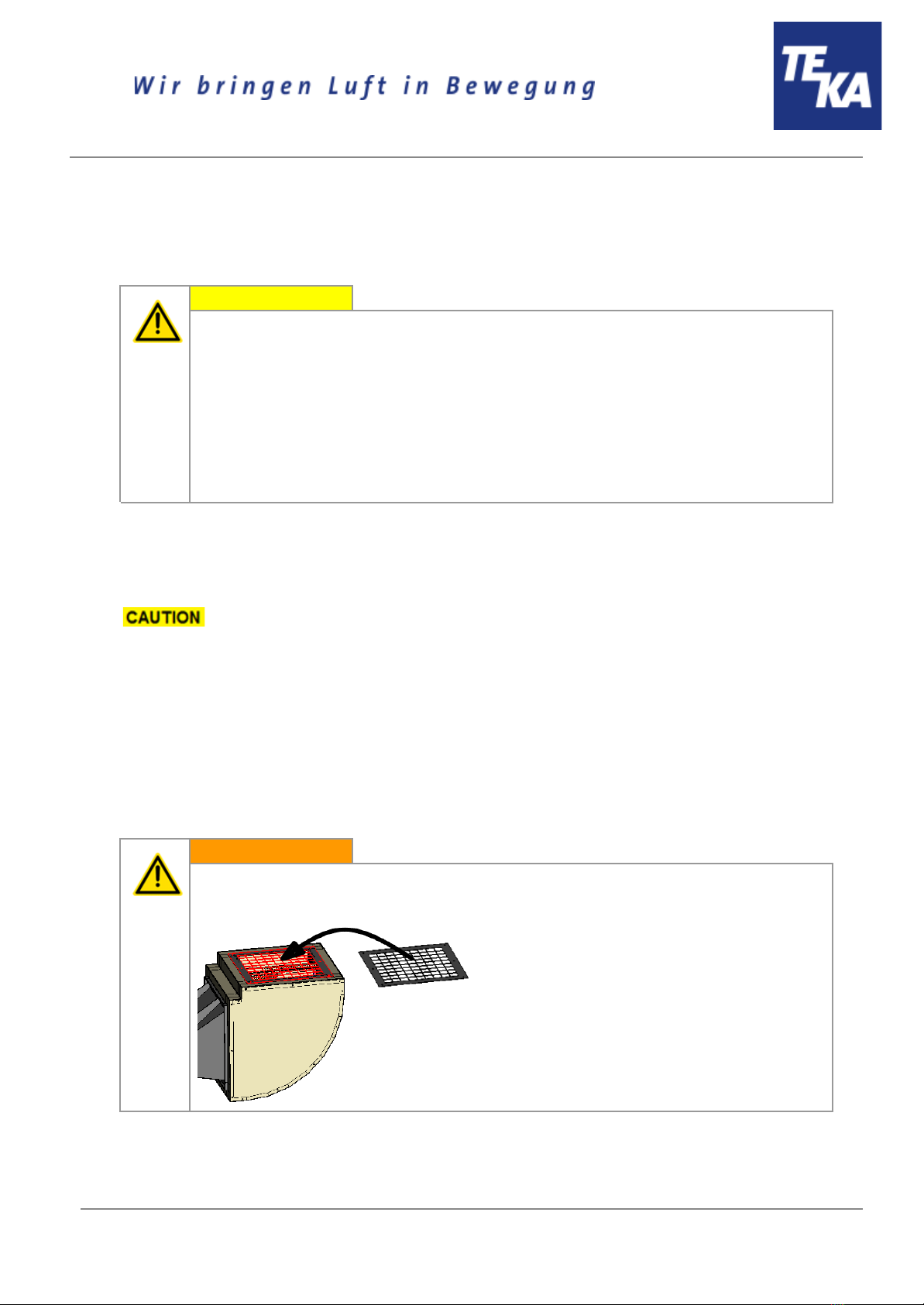

5.3. Precoating of the filter cartridges 11

5.4. Connecting the compressed air supply 11

5.4.1. Compressed air supply for the cleaning of the filter cartridges 11

6. Operating the system 12

6.1. Explanation of the operating elements 12

7. Maintenance 13

7.1 Reset to maintenance state 14

7.2. Cleaning the filter cartridges 15

7.3. Replacing the filter cartridges 16

7.4. Emptying the dust collecting tank 22

7.5. Draining the condensate 23

7.6. Precoating of new filter cartridges 24

7.6.1. Feeding the precoat via a FVS (TEKA spark pre-separator) 25

7.7. Cleaning/replacing the particle sensor 26

7.8. Replacing the filter mats at the control cabinet 27

8. Dismantling / Disposal 28

9. Diagnostics and troubleshooting 28

10. List of spare parts 30

11. Technical data 31

12. EC declaration of conformity 32

13. Training protocol 33

14. Maintenance intervals 34

14.1. Usage-related maintenance 34

14.2. General maintenance 35

14.2.1. Visual inspection of the device 35

14.2.2. Visual inspection of the pipelines for dust deposits 36

14.2.3. Visual inspection of the pneumatic pipes 36

BA_FilterCube_4_IFA_20230808_EN