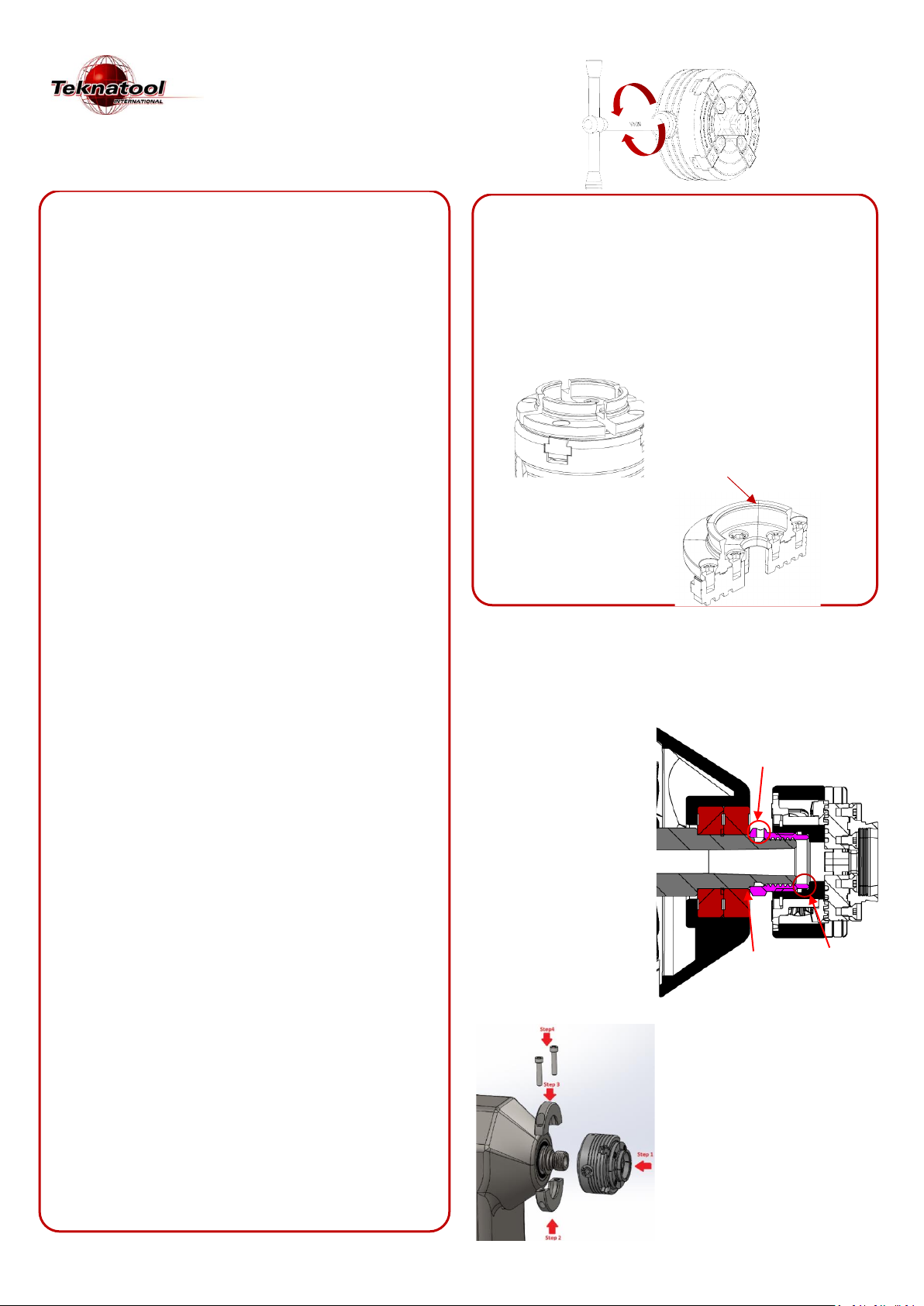

1. If the chuck is an insert model,

ensure the insert is fully seated in

the chuck body before mounting

on the lathe.

2. For both Insert & Direct Thread

model: Thread the chuck on the

lathe spindle until the chuck comes

firmly in contact with the

bearing/spindle shoulder with no

gaps between.

3. Place the red thread protecting

fibre washer into the M6 threaded

hole. Then screw the 6mm grub

screw in position and tighten with

the provided 3mm Allen Key to

prevent the chuck from loosening

on lathe spindle.

YOUR SAFETY

Keep these instructions in a safe place for future reference.

WARNING: This chuck is capable of contributing to serious injury (as with any other

power tool accessory) if this manual guidance is not followed or if it is used improperly

on the lathe. Read and understand the lathe owner's manual. If you do not have a

manual, contact the supplier of your lathe to obtain one before using the lathe and

chuck. User must be professionally trained to use this chuck. Vocational school courses

or other expert tuition is recommended.

As with other work holding methods, an extremely cautious and sensible approach is

necessary. With the LITE G3 Chuck it is not possible to give exact directions as to the

amount of tightening pressure required for adequate work holding or approved chisel

cutting techniques. Follow closely strict guidelines in this manual for different jaw

types on wood blank diameters and length, plus strictly follow recommended lathe

speeds.

Safe Operation:

Eye Protection: Woodturning operations can result in objects being thrown into your

eyes which can result in severe eye damage. Protective eye wear must be used at all

times. Everyday vision wear is not protective eye wear. We recommend a full-face shield.

Always wear eye protection which complies with current ANSI Standard Z87 (USA).

Noise Protection: Use ear plugs or ear defenders. Particularly if the noise exceeds 85dB.

Exposure to high levels of noise can lead to hearing problems.

Dust Protection: Use respiratory protective equipment (dust mask, portable respirator

device). Exposure to high levels of irritating dust when turning or sanding hardwoods,

soft woods and manufactured composite boards (MDF) can result in serious health

problems. In addition, adequate workshop dust extraction must be used.

Chuck is properly secured on lathe spindle: Follow mounting instructions for your lathe

for faceplates and other spindle fixtures. Do not rotate chuck under power unless

workpiece is firmly clamped.

WARNING: LATHE SPEED: Excessive speed is a serious lathe hazard. Always turn at the

slowest speed possible. Ideal speed will vary with wood blank size. The larger the blank

the slower the speed. Consult your lathe manual or lathe information plate for speed

guidelines. Do not attempt to use the chuck unless the recommended lathe speeds to

size of wood blank are known. In addition, you must strictly follow the maximum speed

limits set out in the operating section of this manual. Do not exceed them under any

circumstances.

CHECK WORKPIECE: Examine wood blank carefully before mounting on chuck/lathe.

Only Mount Wood that has no cracks, splits, holes, or any other weaknesses (e.g. rotten

or spongy sections). Do not use poorly jointed or laminated wood. Irregular or out of

balance stock needs to be turned at the slowest possible speed until it is in balance.

Make sure wood is clamped firmly. Follow mounting instructions for different gripping

modes and jaw types. In the expansion mode do not use undue force or jaws may split

the wood.

Do not exceed maximum guidelines in this manual for wood blank diameters/length set

out in this manual for different modes and jaw types.

Check that the wood is securely held in chuck before operation. Check grip by vigorously

wrenching wood blank back and forth. If any loosening occurs, re-examine holding area

for adequate grip (Following mounting guidelines) and any damage to holding area.

Rotate manually to make sure of clearance before switching power on.

DUPLICATOR OR JIGS: Do not use chuck for work holding with a duplicator or jigs.

Safe Practice:

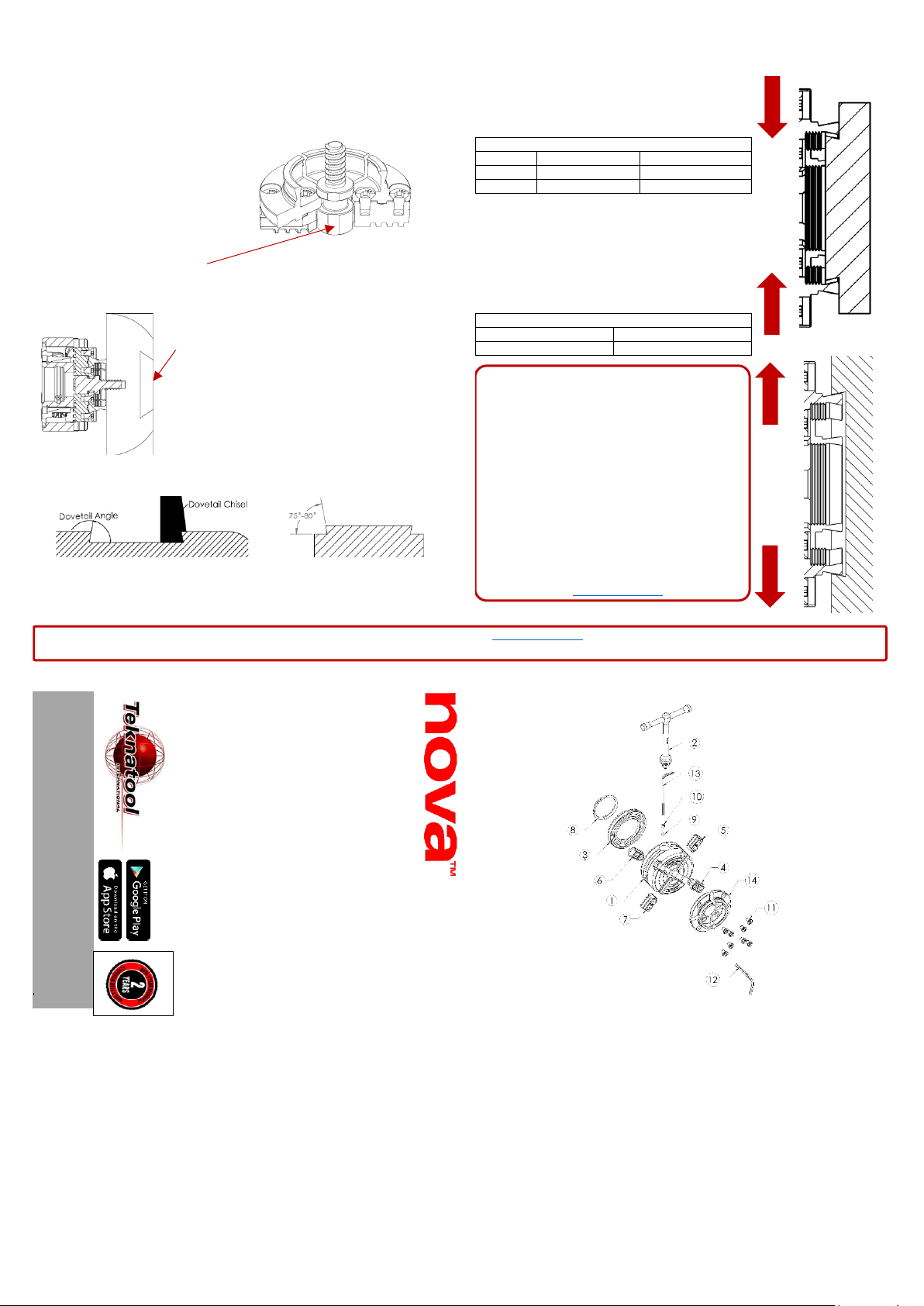

CHISEL USE: Use only handheld woodturning chisels to shape wood being held in chuck.

Use the recommended chisel for the job. Use safe and commonly approved techniques.

WARNING: Never attempt to place hands on a moving chuck on a lathe. Wait for the

chuck to come to a complete stop before hands are anywhere near the chuck. Trying to

grab at a moving chuck could result in SERIOUS INJURY. Jawslides: For safe operation do

not extend the jawslides beyond the chuck body under any circumstances.

Wherever possible stand to one side of the revolving wood.

WEAR SUITABLE CLOTHING: Do not wear any loose clothing, neck ties, gloves, bracelets,

rings, or other jewellery that could get caught in moving parts. Wear protective hair

covering to contain long hair.

DRUGS, ALCOHOL, MEDICATION: Do not operate chuck or lathe while under the

influence of drugs, alcohol, or any medication.

KEEP CHILDREN AND VISITORS AWAY: All children and visitors should be kept safe

distance from the work area.

Make workshop childproof with padlocks, master switches, or by removing starter

keys.