SAFETY

DANGER: THIS CHUCK IS CAPABLE OF CONTRIBUTING TO SERIOUS INJURY, AS WITH ANY

OTHER POWERTOOL ACCESSORY, IF USED IMPROPERLY ON THE LATHE.

Before using the SuperNova Chuck, read and understand this instruction manual. Read and

understand also the lathe owner's manual. If you do not have a manual, contact the supplier of

your lathe to obtain one before using the lathe and Chuck.

User must be professionally trained to use this chuck. Vocational school courses recommended.

As with other chucking methods, an extremely cautious and sensible approach is necessary. With the

SuperNova Chuck it is not possible to give exact directions as to the amount of tightening pressure

required for workholding. Follow closely strict guidelines in this manual for different jaw types on wood

blank diameters and length, plus turning speed.

BEFORE USING SUPERNOVA CHUCK MAKE SURE THAT -

• ALWAYS WEAR EYE PROTECTION WHICH COMPLIES WITH CURRENT ANSI STANDARD Z87.1

(USA). WE RECOMMEND THAT A FULL FACE SHIELD BE USED AT ALL TIMES.

• Chuck is properly secured on lathe spindle. Follow mounting instructions for your lathe for faceplates

and other spindle fixtures.

• For safety, DO NOT ROTATE CHUCK UNDER POWER WITHOUT WOOD BEING GRIPPED.

•WARNING: EXCESSIVE SPEED IS A SERIOUS LATHE HAZARD. ALWAYS TURN AT THE SLOWEST

SPEED POSSIBLE.

• Speed will vary with wood blank size. The larger the blank the slower the speed. Consult your lathe

manual or lathe information plate for speed guidelines.

• DO NOT ATTEMPT TO USE THE CHUCK UNLESS THE LATHE SPEEDS ARE KNOWN, YOU MUST

STRICTLY FOLLOW THE MAXIMUM SPEED LIMITS SET OUT IN THE OPERATING SECTION OF

THIS MANUAL. DO NOT EXCEED THEM UNDER ANY CIRCUMSTANCES.

• EXAMINE WOOD CAREFULLY. ONLY MOUNT WOOD THAT IS SOUND, If any cracks, splits, or

weakness is found in wood - DO NOT MOUNT ON CHUCK. DO NOT MOUNT ANY WOOD THAT IS

LIKELY TO BREAK UP DURING TURNING (E.G. ROTTEN OR SPONGY WOOD). DO NOT USE

POORLY JOINTED/LAMINATED WOOD.

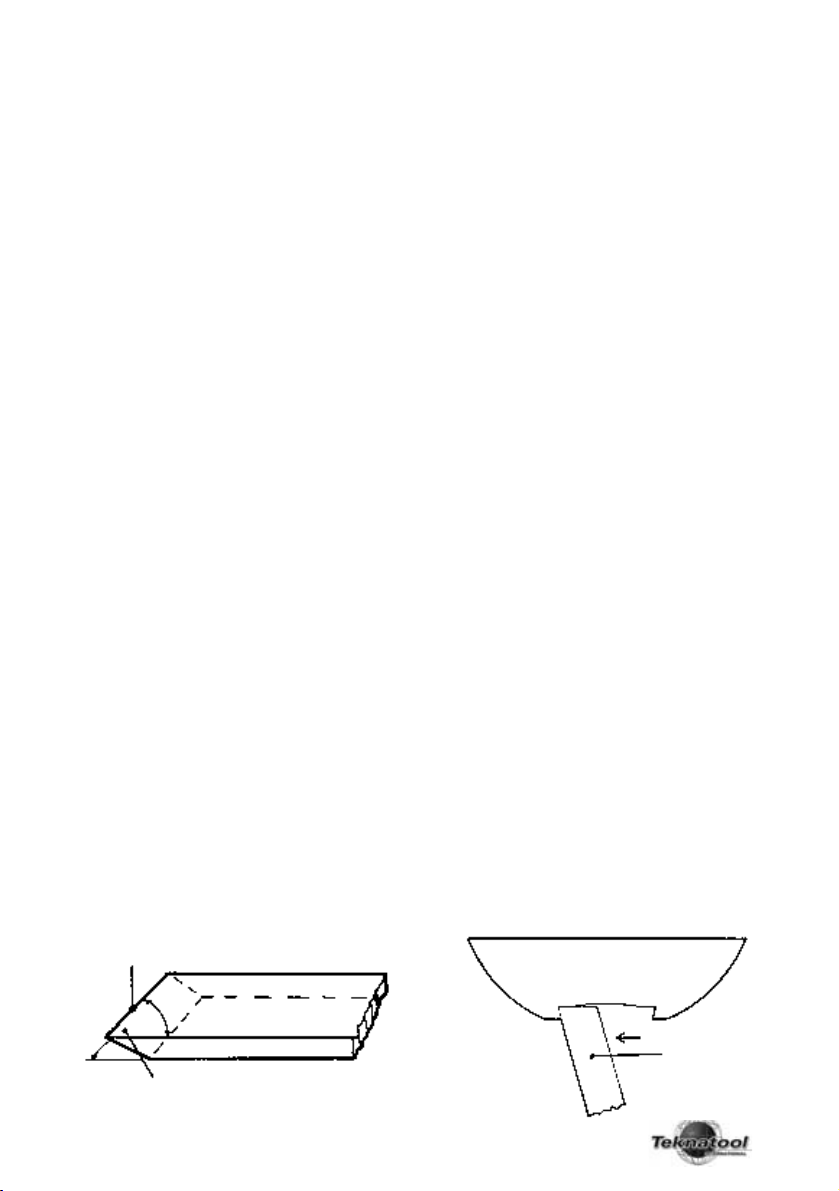

• Make sure wood is clamped firmly. Follow mounting instructions for different gripping modes and jaw

types. In the expansion mode do not use undue force or jaws may split the wood.

• Do not exceed maximum guidelines in this manual for wood blank diameters/length set out in this

manual for different modes and jaw types. DO NOT USE WITH ANY COPYTURNER OPERATIONS

• Check wood is securely held in chuck, before operation. Check grip by vigorously wrenching wood

blank back and forth. If any loosening occurs, re-examine holding area for adequate grip (Following

mounting guidelines) and any damage to holding area. Rotate manually to make sure of clearance

before switching power on.

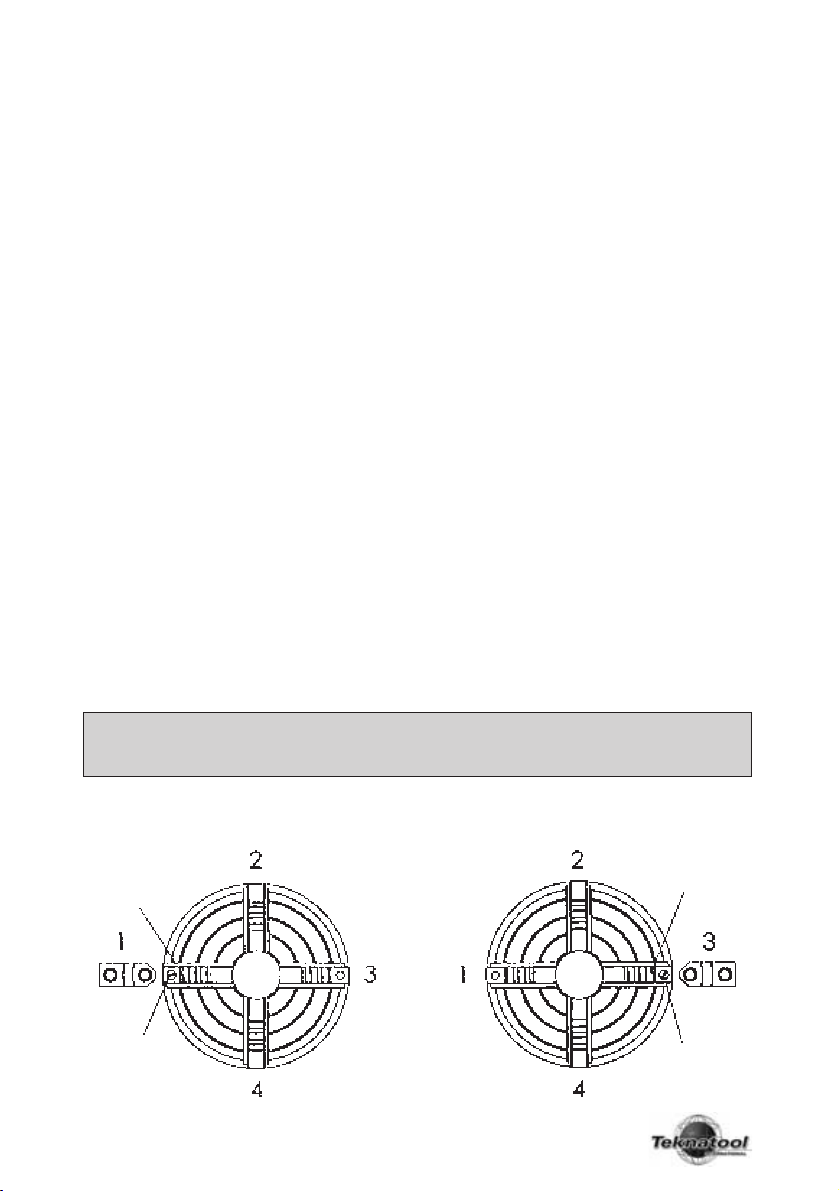

• WARNING FOR SAFE OPERATION. DO NOT EXTEND JAW SLIDES BEYOND CHUCK BODY UNDER

ANY CIRCUMSTANCES. ONLY OPERATE CHUCK WITH JAW SLIDE STOP SCREW IN PLACE AND

TEST TO MAKE SURE IT IS ADJUSTED OUT TO STOP JAW SLIDE.

• This prevents jaw slides from dislodging from chuck.

• Irregular or out of balance stock needs to be turned at the slowest possible speed until it is in

balance. For use on outboard/left-hand rotation -

• MAKE SURE INSERT IS SECURELY LOCKED WITH GRUBSCREW BEFORE USE. Use only hand

held woodturning chisels to shape wood being held in chuck.

• USE THE RIGHT CHISEL FOR THE JOB AND DO NOT FORCE TOOLS. Use safe and commonly

approved chisel techniques. Wherever possible stand to one side of the revolving wood.

• WEAR PROPER CLOTHING. Do not wear any loose clothing, neck ties, gloves, bracelets, rings or other

jewellery that could get caught in moving parts. Wear protective hair covering to contain long hair.

• DRUGS, ALCOHOL, MEDICATION. Do not operate chuck or lathe while under the influence of drugs,

alcohol or any medication.

• KEEP CHILDREN AND VISITORS AWAY. All children and visitors should be kept safe distance from

the work area.

Make workshop childproof with padlocks, master switches, or by removing starter keys.

3