VG412

3

TOOL SET-UP

1. Ground the Power Drive. Be sure the power drive is connected to an internally grounded electrical

system.

2. Avoid dangerous environments. Don’t use the machine in damp or wet locations. Don’t use the tool

on sloped or uneven ground or floor. Keep work area well illuminated. Allow sufficient space to

operate tool and accessories properly and for others to pass safely.

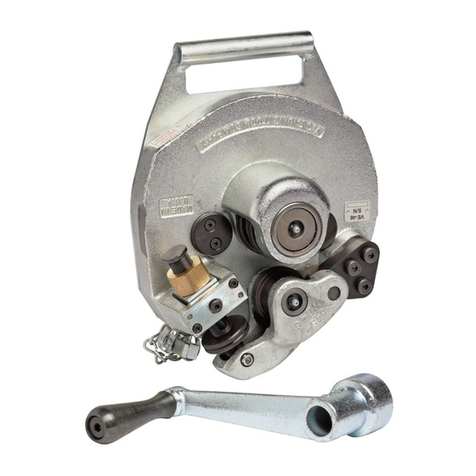

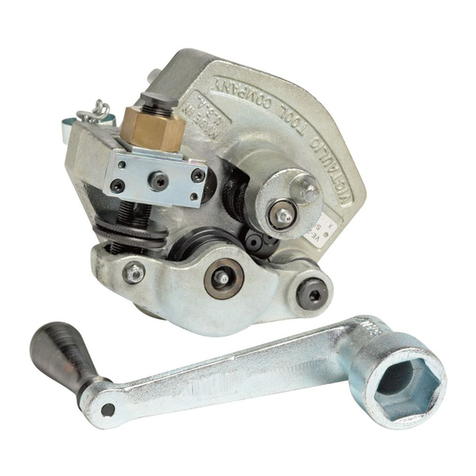

3. Prevent back injury. During tool set-up, one person cannot safely handle the tool assembly because

it weighs 145 lbs ( 66kg). Two people are needed to safely handle the assembly. If a hoist is available

use it to lift the tool assembly into position.

4. Only use power drive supplied with tool. Use of a different power drive may result in personal

injury, poorly cut pipe ends or grooves and damage to the tool.

5. Pipe must be properly prepared in accordance with Victaulic pipe preparation specifications.

OPERATING TOOL

1. Inspect the equipment. Prior to starting the tool, check the movable parts for any obstructions. Be

sure that guards and tool parts are properly installed and adjusted.

2. Prevent accidental startings.Un-plug the tool when making adjustments and performing

maintenance.

3. Operate with foot switch only. The power drive must be operated with a safety foot switch as the

operator will require it to operate the tool safety.

4. Keep hands away from tool holders and gears during operation. Tool holders and gear can crush

or cut fingers and hands.

5 Never reach inside pipe ends during operation.

6. Do not over reach. Keep your proper footing and balance at all times. Be sure you can reach foot

switch safely at all times. Do not reach across tool or pipe. Keep hands and loose tools away from

moving parts.

7. Wear safety glasses and footwear.

8. Keep work area clean. Cluttered areas, benches and slippery floors invite accidents.

9. Wear ear protection if exposed to long periods of very noisy shop operations.