Operating Instructions—P6047

SECTION 2

OPERATING INSTRUCTIONS

General Information

The P6047 Probe enables you to connect an

oscilloscope into acircuit with minimum loading

and without impedance matching. Due to slight

variations in input capacitance between instru-

ments, even of the some type, it is necessary

to compensate the probe whenever changing

from one instrument to another. Recheck com-

pensation before making critical measurements.

Lack of compensation can cause measurement

error since both waveshape and amplitude of

the display are affected. The probe is provided

with an adiustment to match the probe time con-

stant to the time constant of the instrument. The

following procedure should be used to compen-

sate the probe.

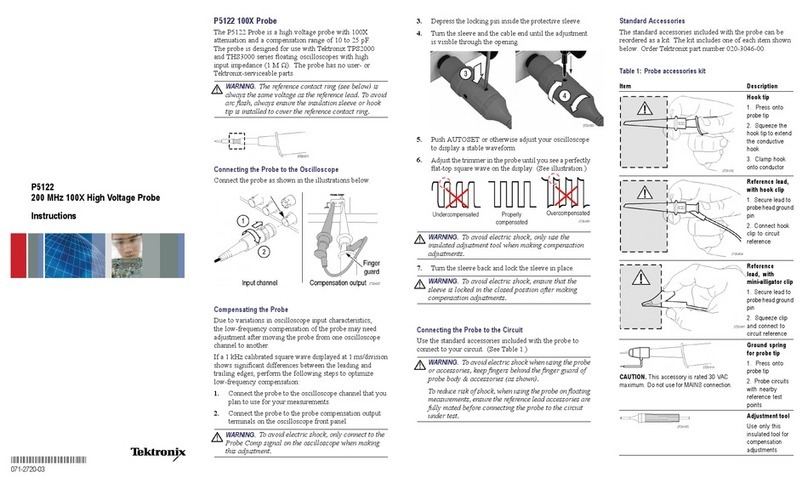

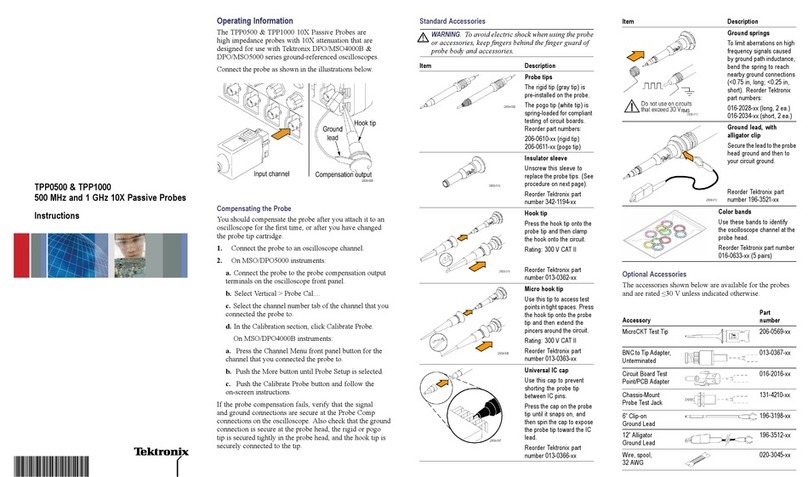

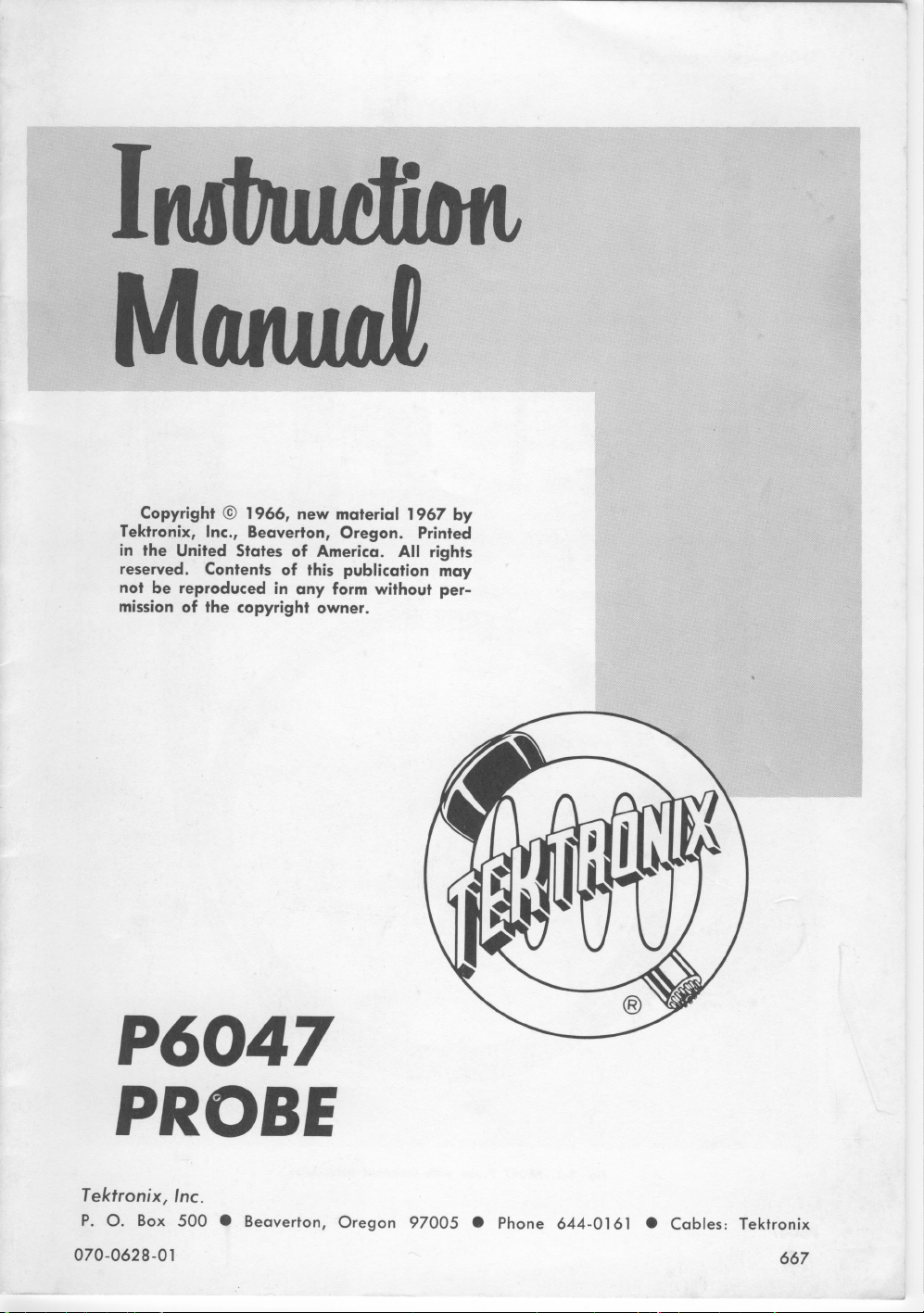

Compensation

1. Set the oscilloscope calibrator for an output

of suitable amplitude.

2. Touch the probe tip to the calibrator output

connector.

3. Set the sweep rate to display several cycles

of the calibrator signal.

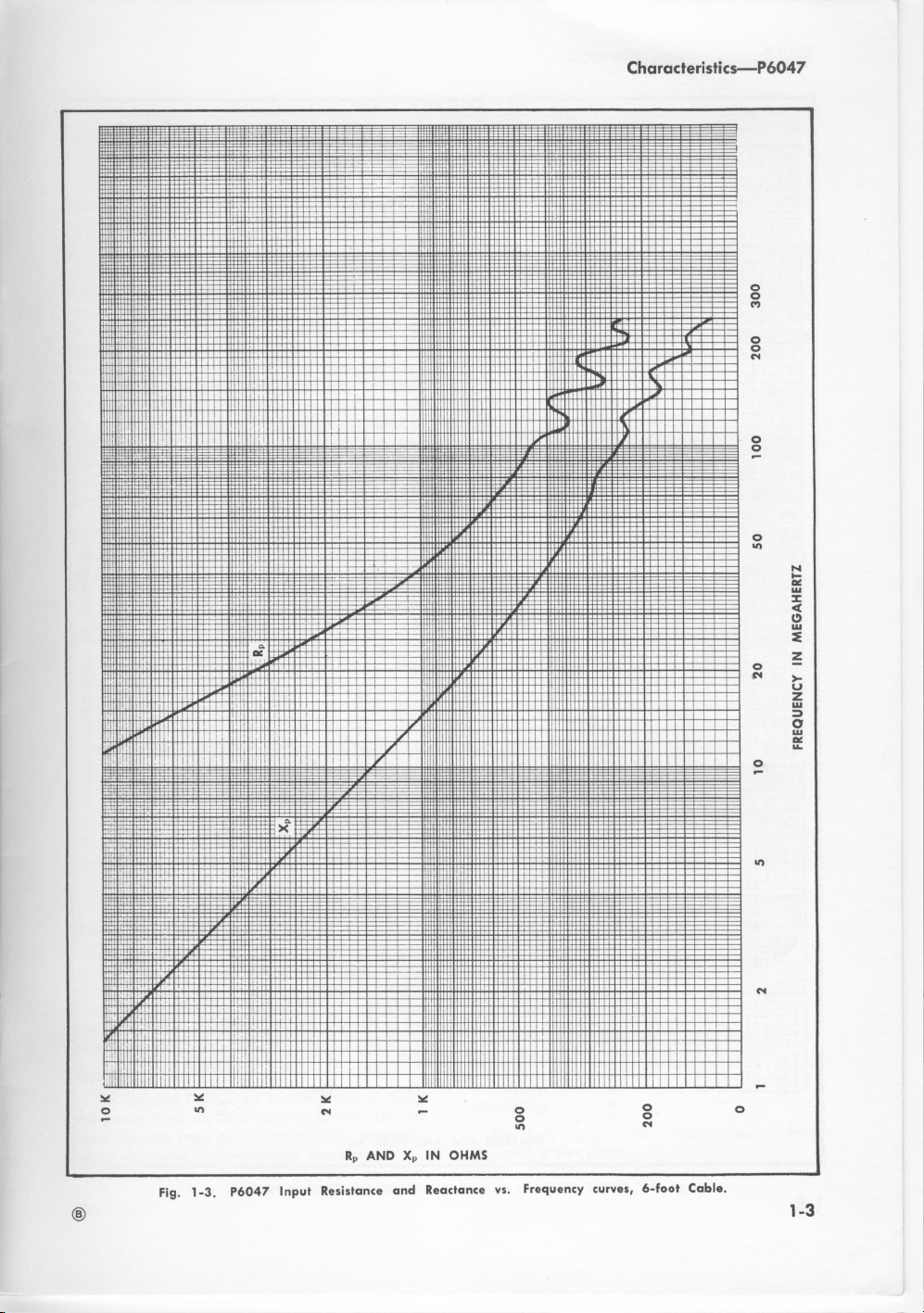

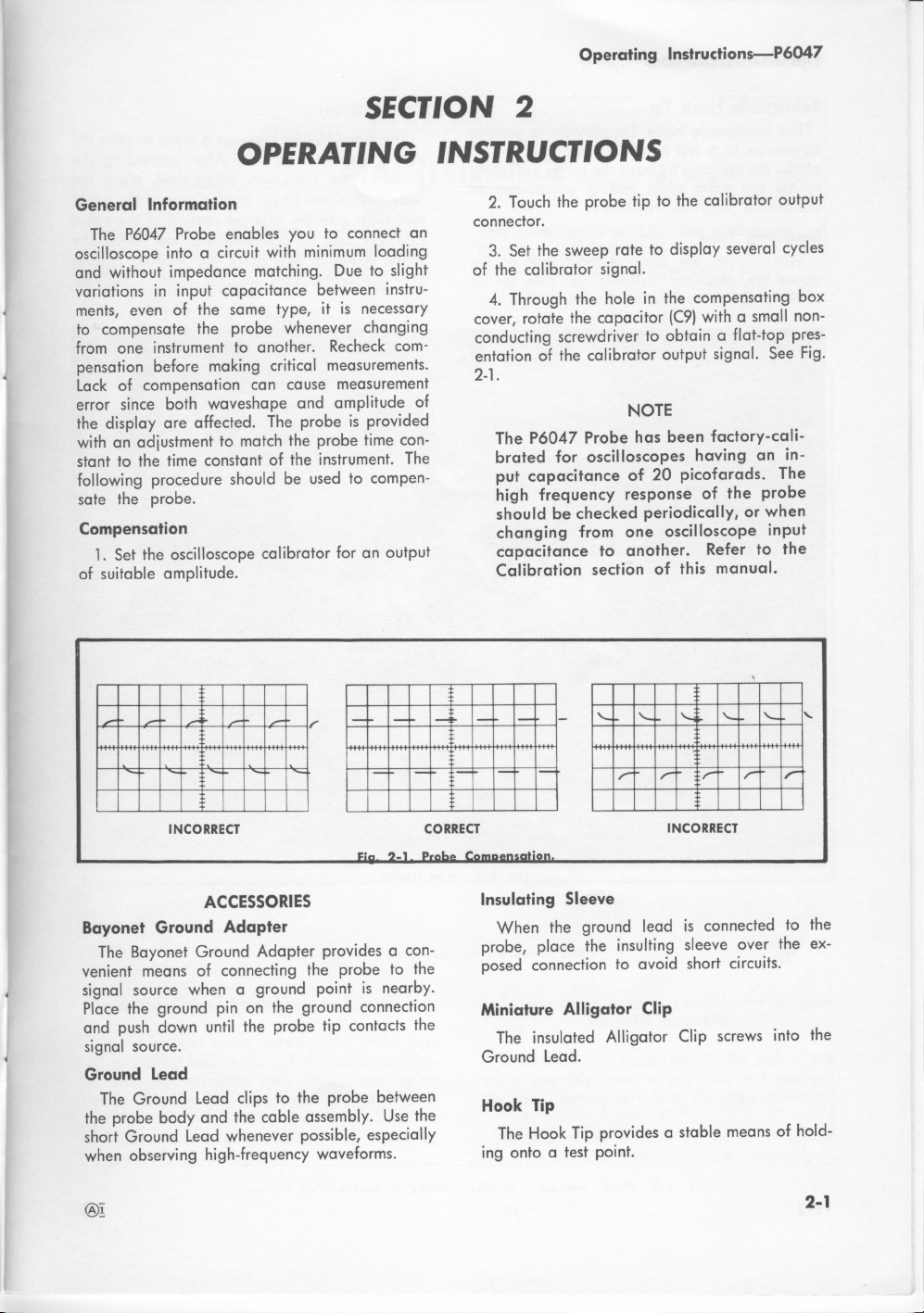

4. Through the hole in the compensating box

cover, rotate the capacitor (C9) with asmall non-

conducting screwdriver to obtain aflat-top pres-

entation of the calibrator output signal. See Fig.

2-1.

NOTE

The P6047 Probe has been factory-cali-

brated for oscilloscopes having an in-

put capacitance of 20 picofarads. The

high frequency response of the probe

should be checked periodically, or when

changing from one oscilloscope input

capacitance to another. Refer to the

Calibration section of this manual.

INCORRECT

ACCESSORIES

Bayonet Ground Adapter

The Bayonet Ground Adapter provides acon-

venient means of connecting the probe to the

signal source when aground point is nearby.

Place the ground pin on the ground connection

and push down until the probe tip contacts the

signal source.

Ground Lead

The Ground Lead clips to the probe between

the probe body and the cable assembly. Use the

short Ground Lead whenever possible, especially

when observing high-frequency waveforms.

@i

CORRECT

Fin 2-1 Fromm

INCORRECT

Insulating Sleeve

When the ground lead is connected to the

probe, place the insulting sleeve over the ex-

posed connection to avoid short circuits.

Miniature Alligator Clip

The insulated Alligator Clip screws into the

Ground Lead.

Hook Tip

The Hook Tip provides astable means of hold-

ing onto atest point.

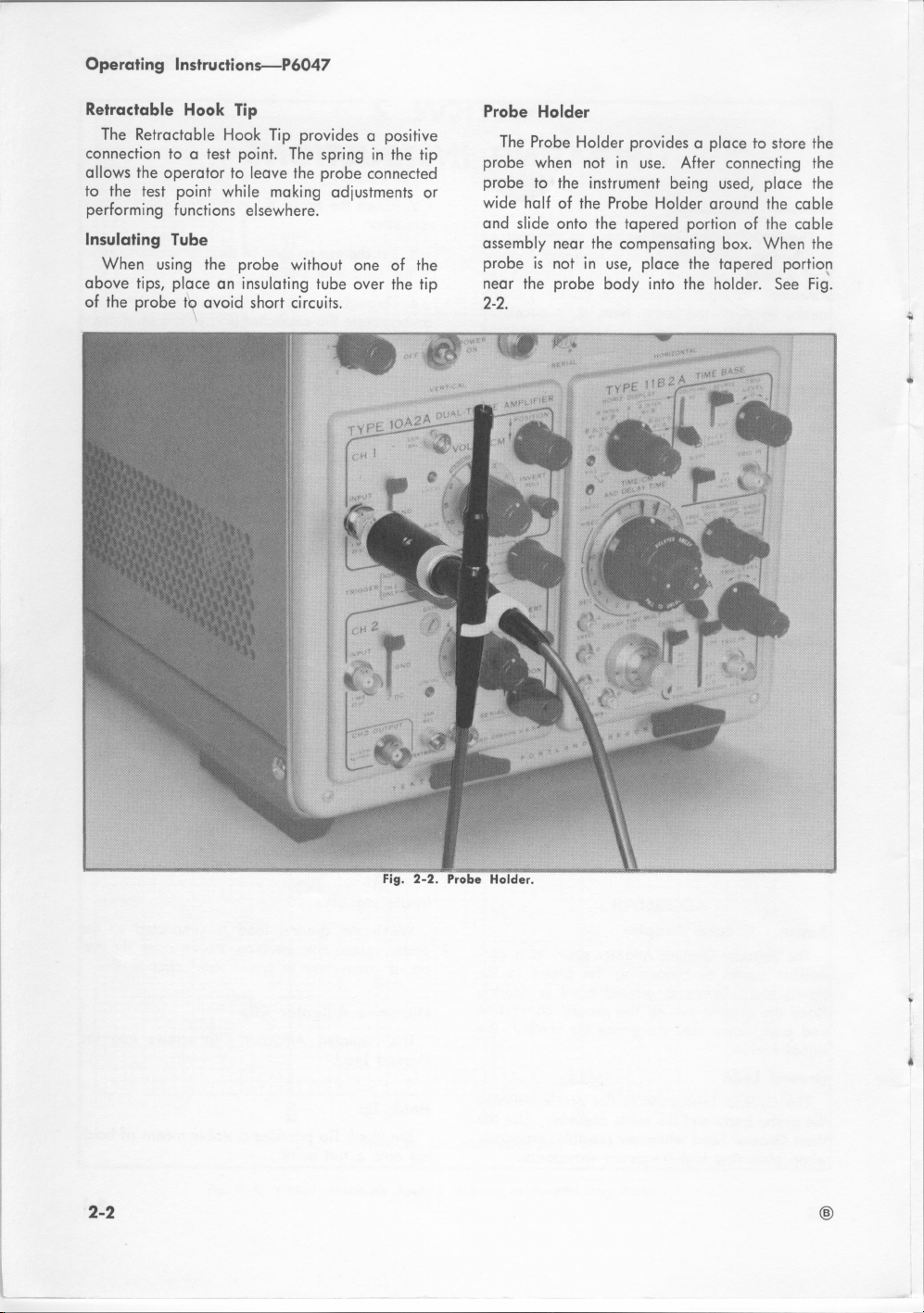

2-1